Ice rinks are marvels of modern engineering, with skaters gliding effortlessly across the smooth surface. But, have you ever wondered how the ice manages to remain so smooth and flawless, even after several hours of heavy use? Here comes the Zamboni, an iconic piece of equipment almost synonymous with resurfacing the ice. This blog post delves into the mechanics of the Zamboni to discover how it works in resurfacing the ice for the optimal skating experience. We shall also examine its five-step processes, from scraping off all blemishes to laying down thin water films that keep the rink in perfect order. Whether you are a curious skater, a hockey enthusiast, or simply someone who appreciates excellent engineering, this article will highlight the intricate processes involved in the development of this remarkable machine. Let’s hit the ice and explore Zamboni’s secrets!

Introduction to Zamboni Machines

The Zamboni is a special purpose vehicle designed for the maintenance and resurfacing of ice rinks. It involves scraping off the very top layer of ice to rid it of scratches and imperfections, collecting the shavings, and shedding a thin layer of clean water that freezes quickly to form a smooth, clean, and even surface. Invented sometime in 1949 by the American inventor Frank Zamboni, the machine has since become a crucial factor in the proper maintenance of ice for skating, hockey, and other ice sports. With a design so efficient, Zamboni gives you the best quality ice in the shortest time with the least effort.

What is a Zamboni?

An ice-resurfacing machine was created by Frank Zamboni in 1949 and was designed to efficiently smooth and maintain the quality of ice rink surfaces for sporting and leisure activities.

Purpose of the Zamboni in Ice Rinks

The Zamboni maintains a skating surface in the best possible condition by shaving, collecting, and resurfacing ice on rinks. In operation, the machine works by scraping a thin layer of dulled ice with a sharp blade; this scraped ice is then collected into a hopper, whereas fresh hot water is scattered onto the newly cleaned surface. Hot water fills in any scratches or cracks; as soon as the water freezes, a smooth and sparkling sheet of ice is revealed.

It is this excellent efficiency in ice maintenance that reduces the idle time required for preparing the rink. A typical modern Zamboni takes approximately 10-15 minutes to resurface a standard NHL-size rink, allowing for short breaks between games or events. Advanced-type Zambonis are environmentally friendly, utilizing electric power and alternative fuels such as biodiesel to minimize emissions.

Significant engineering and technological improvements have made Zambonis more efficient and more precise. Newer models, for example, are equipped with GPS technology to determine the optimal way to cover the ice and control sensors to save water usage. These technological improvements have significantly enhanced the angling and uniformity of the ice while reducing operational costs.

Nevertheless, the essence of the Zamboni is also felt beyond the sphere of professional sports. It caters to recreational rinks, providing safer and more consistent skating experiences for both skaters and ice hockey players. Maintaining consistency and precision, Zambonis continues to warrant the existence of the ice sports industry.

Importance of Ice Resurfacing

Ice resurfacing is essential for preparing aerated surfaces in any recreational or professional rink. With adequate resurfacing, users enjoy fewer injuries, improved performance, and increased hours of use. Provided below are five reasons why resurfacing is essential:

Skater Safety

Uneven and rough ice surfaces are hotspots for accidents. Resurfacing removes grooves, cracks, and scratches in the ice that pose hazards to skaters in reducing falls and injuries.

Desired Performance

For ice sports such as hockey and figure skating, smooth ice must provide greater downforce for precision and control. After the ice has been freshly resurfaced, there will be minimal resistance as players and skaters deliver top performances.

Extended Life of the Ice

Regular resurfacing prolongs ice life, preventing it from quickly deteriorating. It maintains an even surface on the ice, preventing uneven freezing and the need for frequent resurfacing, which saves time and money.

Saving Energy

Surfaces with good maintenance consume less energy because less cooling is required. Maintaining a consistent layer of ice requires much less energy to run a cooling machine at optimal conditions.

Improved User Interface

Smoothly resurfaced ice is enjoyable for recreational skating and sporting events. This gliding feeling contributes significantly to making their overall experience so wonderful that users have become ambassadors for the rink.

How a Zamboni Works

A Zamboni will shave off the skinny upper layer of ice to remove any slight imperfections. It then gathers the shavings in a storage tank. As the surface receives warm water through the other channel, warm water fills the cracks, and upon freezing, forms a smooth layer. The machine operates continuously, cleaning the ice surface for use.

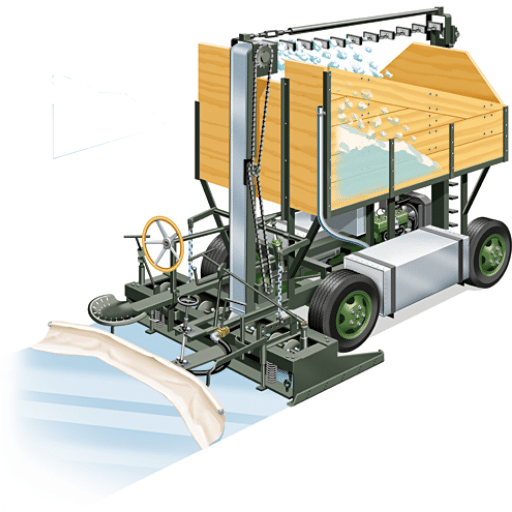

Mechanics Behind the Operation

A Zamboni operates on a joint system designed with firm engineering and efficiency in mind. At the heart of the machine sits the blade, a sharp instrument that shaves off approximately 1/16 of an inch from the top of the ice to achieve smoothness. Together with this blade is the screw conveyor that carries all the shaved ice into a collection box called the snow tank.

Another critical factor in a Zamboni’s operation is its water system, made up of both hot and warm water tanks. Warm water heated to approximately 140°F (60°C) is used to disperse the trapped air bubbles and create a denser, yet firmer, ice layer. From the back of the machine, the water is spread onto the rink via a towel, which lays a thin coating over the entire surface; the water fills in surface imperfections and, after it freezes, gives the ice an excellent polish.

Some modern Zambonis come equipped with advanced features, such as GPS-guided steering, electric motors for environmental sustainability, and sensors that measure ice thickness in real-time. All these improvements help enhance efficiency and reduce environmental impacts, with nearly 85% emissions reductions achieved with recent generation machines. For instance, an average Zamboni will clean an Olympic-size ice rink, measuring 61 x 30 meters, in 10-15 minutes, utilizing approximately 60 gallons of water in a single pass.

The operation of a Zamboni combines modern ingenuity and practicality, ensuring that ice surfaces always maintain optimum conditions for efficient skating performance while respecting current technological and environmental considerations.

Key Components of a Zamboni

A Zamboni includes a series of critical parts that work together in perfect harmony to accomplish ice maintenance and resurfacing tasks. Here are its significant parts and their functions:

- Augers

The augers collect all the shaved ice off the surface. Large screw-like mechanisms gather loose ice and shove it up into the snow tank. Modern Zamboni machines utilize high-capacity augers that can handle up to 2,500 pounds of shaved ice in a single session.

- Blade

A thin layer of ice gets shaved off the surface with a sharp, adjustable blade situated at the bottom of the Zamboni. The usual length of the blade is 77 inches, and it can shave between 1/16 inch and a thin layer off the top, so the plane created on the ice is smooth and even.

- Snow Tank

The snow tank is a bin in which the collected shaved ice is stored. Sizes vary depending on the model, but most standard tanks can hold approximately 100 to 115 cubic feet of snow.

- Water System

The water system lays the new ice sheet. During resurfacing, two types of water are used:

- Wash Water is sprayed on the surface to clean and remove debris before being sucked back into the machine.

- Flood Water is hot, usually about 140°F (60°C), and laid on the surface to produce a fresh, smooth layer of ice. One resurfacing uses about 60-80 gallons of water.

- Conditioner

The conditioner is the rear-side heavy assembly. It spreads floodwater evenly while simultaneously removing any excess droplets, hence producing a uniformly glossy finish on the ice.

- Propulsion System

The types of engines used to power Zambonis cover everything from traditional internal combustion engines running on propane and natural gas to electric-powered ones. Electric types have become the focal point for zero-emission operation inside ice rinks, typically powered by lithium-ion batteries for extended periods.

- Hydraulics System

Hydraulics control most of Zamboni’s mechanical operations, such as raising and lowering the conditioner and augers and tilting the snow tank to empty it once resurfacing is complete.

- Tire Studs

Zambonis are fitted with studded tires to guarantee maximum traction on the slippery ice surface. These studs keep the machine from slipping, allowing the operator to steer the machine accurately.

Notable Advancements

Modern Zambonis entail newer technologies for sustainability and performance:

- Electric Models, such as the Zamboni 650, charge to resurface almost 20 rinks while significantly reducing greenhouse gas emissions compared to gas-powered industrial models.

- Advanced Software Controls enable operators to monitor water usage, blade wear, and machine diagnostics in real-time, maximizing efficiency and facilitating the planning of maintenance schedules.

These components reveal the character mixture of mechanical sophistication and purposeful beauty that renders a Zamboni an absolute necessity in all ice rink operations.

Step-by-Step Process of Ice Resurfacing

|

Step |

Key Point |

|---|---|

|

Shaving the Ice |

Remove top ice layer with a sharp blade |

|

Collecting Shavings |

Augers move shavings to the snow tank |

|

Washing the Ice |

Flush dirt and debris with wash water |

|

Vacuuming Dirty Water |

Store dirty water in a separate tank |

|

Applying New Water |

Spread hot water to fill grooves |

|

Spreading Evenly |

Use gaskets to ensure a uniform water layer |

|

Freezing the Ice |

Refrigeration freezes water evenly |

Technology Used in Zamboni Machines

Zamboni machines combine a variety of advanced mechanisms to ensure that ice resurfacing is done efficiently and effectively. Some of the technologies involved are as follows:

- Hydraulic Systems: They provide movement, the essential action of the blade, and other components, such as conditioners.

- Auger Mechanism: It collects the shaved ice and deposits it into the snow tank during the resurfacing process.

- Water Filtration System: It ensures there is distribution of clean, hot water for resurfacing, which in turn produces a smooth ice surface.

- Electric or Alternative Fuel Motors: Modern Zamboni designs incorporate these motors to reduce emissions and maximize energy efficiency.

- Real-Time Monitoring Software: This software allows operators to monitor performance, diagnose issues, and request maintenance, thereby ensuring smooth operations.

Together, they forge up-steam technologies to deliver a smooth and professional ice surface.

Innovations in Ice Resurfacer Technology

Ice resurfacing equipment has undergone numerous innovations, and these changes have continually improved efficiency levels and reduced environmental impact. Here are five significant advancements that have borne improvement in the field:

- Electric-Powered Resurfacers

- Electric motors are increasingly chipping out traditional internal combustion engines.

- These power systems eliminate emissions, provide opportunities for sustainability, and operate more quietly.

- Data: Electric-power models could reduce CO2 emissions by approximately 70% compared to those from their gasoline-powered counterparts.

- Hydrogen Fuel Cell Technology

- Hydrogen fuel cells offer a clean alternative to traditional energy sources, with water vapor as the sole byproduct.

- Hydrogen-powered ice resurfacers have a much longer operational range and require less refueling time.

- Data: One hydrogen refill can last continuous resurfacing operations from 6 to 8 hours.

- Water Filtration Systems

- Purification systems increase the purity of the water used to produce more precise and smoother ice surfaces.

- They filter out impurities, such as minerals and air bubbles, that can cause weak points in the ice.

- Data: These systems can increase ice durability by up to 30%.

- Automated Resurfacing Controls

- Automation features improve the accuracy of resurfacing operations and reduce human errors; GPS-guided navigation and preprogrammed resurfacing cycles are two such examples.

- Automated blade adjustments further ensure that the ice thickness remains consistent.

- Data: Automation produces a greater than 20% improvement in resurfacing efficiency.

- Energy Recuperation Systems

- The recuperation systems harness the excess heat or kinetic energy generated during operation.

- This recapture wastes less energy and reduces the overall power consumed.

- Data: Machines equipped with recuperation systems can save approximately 15% of their annual energy costs.

Thus, with all these improvements, the focus is on elevating performance while reducing environmental impact and producing high-quality ice surfaces for rinks worldwide.

Environmental Considerations and Efficiency

- Energy-Efficient Compressors

- The technology that enables modern compressors to be less energy-intensive and maintain optimal performance in Dallas.

- Data: Modern compressors can optimize energy efficiency by 20% compared to older models.

- Wastewater Recycling Systems

- The system collects wastewater and treats it for reuse as water in ice resurfacing operations.

- Data: Water savings of up to 25% per year can be achieved by using these systems.

- Eco-Friendly Coolants

- Switching to natural or low-global-warming-potential (GWP) coolants helps avoid harmful emissions.

- Data: Up to 30% reduction in greenhouse emissions can be recorded by using environmentally friendly coolants.

- LED Lighting

- LED lighting ensures that the rink’s electricity consumption is low and that the lighting period is extended.

- Data: LED lighting consumes 50% less power than conventional lighting.

- Smart Energy Management Systems

- These automated systems regulate power usage and provide real-time information on energy consumption.

- Data: The installation of intelligent energy systems can save up to 15% of energy costs associated with operations.

Modern Features in New Zamboni Models

From my perspective, modern Zamboni models have advanced in technology to be fully efficient and environmentally friendly in design. Electric-powered systems are considered emission-free and therefore promote environmental friendliness. These newer types of Zambonis often feature precise water control systems to provide better ice resurfacing, as well as regenerative braking systems to recover energy efficiently. Hence, advances in these machines represent a strong commitment to providing the very best ice conditions with the least operational impacts.

The History of Zamboni Machines

|

Year/Period |

Key Event |

|---|---|

|

1901 |

Frank Zamboni born in Eureka, Utah |

|

1920s |

Zamboni brothers start refrigeration business |

|

1939 |

Opened Iceland Skating Rink in California |

|

1949 |

Invented first ice-resurfacing machine |

|

1953 |

Patent granted for Zamboni machine |

|

1954 |

Mass production of Zamboni machines begins |

|

1960 |

Used in Winter Olympics, gaining fame |

|

Today |

Over 14,000 machines produced worldwide |

Invention and Evolution of the Zamboni

In the world of ice-rink upkeep, the Zamboni machine is a juggernaut in its own right. It was invented by Frank J. Zamboni in 1949 in Paramount, California. Before its invention, ice resurfacing was a laborious task that required several workers and manual tools to achieve the final stage of ice formation. A single innovative operation by Zamboni put an end to that mess and revolutionized ice maintenance worldwide.

Frank Zamboni’s original machine, the Model A, was built on the chassis of a scrapped vehicle: either a Jeep or perhaps some war-surplus equipment. It was designed to scrape, collect, and wash the ice surface, resulting in a smooth frozen finish to the area. As his invention took shape, he would fine-tune it, releasing the Model B and later the Model F, the first commercially sold Zamboni in 1953. The technology lurking behind these early machines formed the basis for what is now one of the most efficient and advanced engineering marvels.

Bigger specs and innovations characterize today’s modern Zamboni machines. For example, the Zamboni 650 electric-powered model is capable of resurfacing an entire ice rink, measuring approximately 17,000 to 20,000 square feet, in minutes, expending even less energy than the older gas-powered versions. Statistics show that electric-powered models reduce operational costs by up to 50% since no processing of fossil fuels is needed; this also improves air quality inside the arena. Furthermore, many of these machines recycle water from the resurfacing process, saving approximately 2,000 to 4,000 gallons of water each year in cases of high usage.

The evolution of Zamboni has kept pace with technological advances and the growing trend toward sustainability. From a clumsy solution to a neatly engineered, sustainable machine, Zamboni is the epitome of human ingenuity and the enabler for maintaining the flawless appeal of ice rinks worldwide.

Impact on Ice Sports and Recreation

The Zamboni has had a profound impact on ice sports and recreation by maintaining the quality and consistency of ice surfaces. The five key takeaways are as follows:

- Enhanced Performance for Athletes

The smoothness of the surface, thanks to the intervention of the Zamboni, allows skaters, hockey players, and other athletes to perform at their very best. Less smooth, irregular surfaces might have caused injuries or hindered performance.

- Longer Lifespan for Rinks

Under normal circumstances, Zamboni-mediated resurfacing helps defend the ice surface against attrition until it requires more costly repairs, eventually keeping the rink operational for a considerable extra length of time.

- Energy-Efficient

Modern Zambonis are typically equipped with energy-efficient technology, such as electric propulsion, to help reduce the carbon footprint of ice arenas while maintaining high-quality ice.

- Player and Fan Experience

Delightful and clear ice surface experiences provided by sports and recreation events give the masses more to engage with, in fact making games or shows much more attractive and professional.

- Promoting Recreation

A well-maintained ice surface encourages public recreational use, thereby facilitating community programs, such as events for public skating and local leagues, which provide good support for engagement with ice sports and recreation.

Notable Milestones in Zamboni History

|

Year |

Milestone |

|---|---|

|

1901 |

Frank Zamboni born in Eureka, Utah |

|

1920s |

Zamboni brothers start refrigeration business |

|

1939 |

Opened Iceland Skating Rink in California |

|

1949 |

First Zamboni ice resurfacer invented |

|

1953 |

Patent granted for Zamboni machine |

|

1954 |

Mass production of Zamboni machines begins |

|

1960 |

Used in Winter Olympics, gaining fame |

|

1970s |

Developed AstroTurf maintenance machines |

|

Today |

Over 14,000 machines produced worldwide |

Variations of Zamboni Models

Over the years, Zamboni has developed various models to meet the diverse needs for ice resurfacing. Some of the key distinctions have been the electric-powered machines mostly for indoor, eco-friendly operations, and the propane or natural gas-powered units for larger ice surfaces and outdoor rinks. They also provide smaller compact models for facilities with limited space or unusual surface dimensions. Said variations further enable Zamboni to efficiently serve the diverse needs of arenas, community rinks, and other ice-related venues through the manufacturing process itself.

Different Types of Zambonis Available

| Type | Key Features |

|---|---|

|

Electric Models |

Emission-free, lithium-ion or lead-acid battery |

|

Fuel Models |

Gas, propane, or CNG-powered engines |

|

Tractor-Pulled Models |

Attach to tractors suitable for outdoor rinks |

|

Edgers |

Precise edge cutting, electric or fuel-powered |

Choosing the Right Resurfacer for Your Needs

A proper Zamboni resurfacer depends on the size of the ice surface, the type of rink (indoor or outdoor), and the preferred power supply. The renowned Zamboni Company introduces five of the most common Zamboni models to suit every single requirement:

- Zamboni Model 552 Electric

- Power Source: Electric

- Ideal For: Indoor arenas preferring a green mode of operation

- Features: Zero emissions, almost silent operations, and lesser maintenance as compared to the operating procedures of a gas-powered model

- Zamboni Model 560 Propane

- Power Source: Propane

- Ideal For: Larger ice surfaces and outdoor rinks

- Features: Operates effectively against cold climates and offers long performance life

- Zamboni Model 546 Diesel

- Power Source: Diesel

- Ideal For: Professional arenas with larger ice sheets

- Features: High power and reliability for hard, heavy-duty use

- Zamboni Model 445 Compact

- Power Source: Gasoline or Electric

- Suitable For: Smaller rinks or facilities with limited space

- Features: Compact design for maneuverability without compromising performance

- Zamboni Model 650 Hybrid

- Power Source: Gasoline/Electric Hybrid

- Ideal For: Versatile operations wherein eco-friendliness overrides performance

- Features: Combining reduced emissions with superior operational capability.

Wide-ranging considerations of your project’s actual needs will ultimately guide you in selecting the most suitable Zamboni that maintains the best ice quality, even while optimized for operational efficiency.

Comparative Analysis of Model Features

Comparing five primary aspects of the Zamboni models in detail:

- Power Source

- Model 552AC Electric: Completely electric, no emissions.

- Zamboni Model 650 Hybrid: Gasoline/Electric hybrid to reduce emissions and for multiple ways to power it.

- Environmental Impact

- Model 552AC Electric: As a clean version, it produces zero emissions. This makes it perfect for an environmentally conscious facility.

- Zamboni Model 650 Hybrid: Significantly reduces emissions compared to conventional models, striking a balance between greenhouse and performance aspects.

- Battery Technology

- Model 552AC Electric: Based on very advanced battery systems ensuring longer run-time and reliability.

- Zamboni Model 650 Hybrid: Utilizes hybrid technology that provides longer service time between refueling and recharging.

- Operational Noise

- Model 552AC Electric: Low noise because it is electrically driven and suitable for noise-sensitive locations.

- Zamboni Model 650 Hybrid: Moderate noise level, hybrid integration done efficiently.

- Maintenance Requirements

- Model 552AC Electric: Avoids most maintenance requirements and resolutions because it has few moving parts.

- Zamboni Model 650 Hybrid: Maintenance increases relative to hybrid integration, but is still approachable for most facility operations.

Understanding the comparison of these components will provide a valuable perspective for operators in selecting a Zamboni model that best suits their operations and sustainability priorities.

References

-

Zamboni Official Website:

- Zamboni.com is the official website of the Zamboni company, providing detailed and accurate information about the machine’s operation, history, and technical specifications.

-

United States Ice Rink Association:

- US Ice Rinks offers resources and certifications related to ice rink maintenance, including Zamboni operation.

-

Popular Mechanics:

- Popular Mechanics has articles on the history and mechanics of Zamboni machines, which are well-researched and reliable.

Frequently Asked Questions (FAQ)

How Does a Zamboni Work to Resurface the Ice?

A Zamboni machine works by resurfacing the ice with a thin layer of warm water, which helps to create a smooth skating surface. As it moves around the rink, the machine collects ice shavings and dirt from the top layer of ice and sprays a fresh layer of water to fill in grooves and imperfections. The combination of these actions ensures that the ice remains in optimal condition for hockey games and figure skating performances.

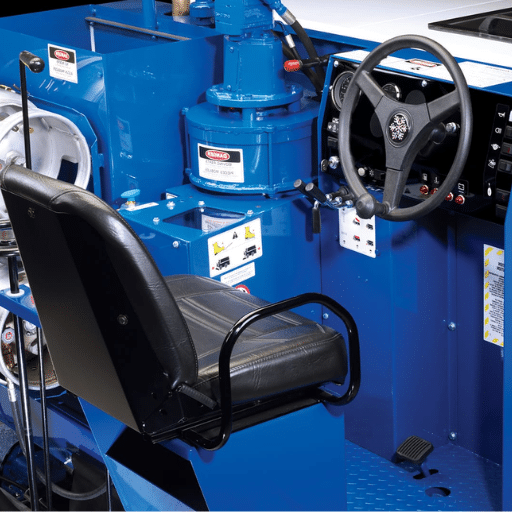

What Does a Zamboni Driver Do?

A Zamboni driver is responsible for operating the ice resurfacing machine during breaks in skating events, such as hockey games or figure skating competitions. They ensure that the Zamboni efficiently cleans the ice, collects ice shavings, and applies fresh water to maintain a smooth surface. The driver must be skilled in maneuvering the machine around the rink, paying attention to the remaining grooves in the ice and adjusting the machine’s settings as needed.

How Do You Drive a Zamboni?

To drive a Zamboni, the operator must first familiarize themselves with the controls of the resurfacing machine. This includes understanding the hydraulic system, the snow tank, and the water tank. As the driver operates the Zamboni around the rink, they must maintain a steady speed and ensure that the vertical auger is collecting ice shavings. At the same time, the squeegee spreads a layer of water evenly over the ice surface.

What Are the Key Features of a Zamboni Ice Resurfacing Machine?

Key features of a Zamboni ice resurfacing machine include a water tank, a snow tank for collecting ice shavings, and a series of augers for efficient ice collection. The machine also has a sharp blade that shaves the top layer of ice and a vacuum hose that helps to remove excess water and debris, ensuring that the ice is left clean and smooth. Models like the Model A Zamboni ice resurfacer have been designed with these features in mind.

How Does Frank Zamboni’s Invention Impact Ice Rinks Today?

Frank Zamboni invented the first ice resurfacing machine in 1949, revolutionizing how ice rinks maintain their surfaces. Today, Zamboni machines are essential in ice rinks worldwide, including those used in the National Hockey League (NHL) and at the Winter Olympics. His invention has made it easier to keep the ice clean, smooth, and safe for skaters and hockey players, significantly enhancing the quality of the skating experience.

What Is the Process of Making Ice with a Zamboni?

The process of making ice with a Zamboni involves first cleaning the rink and then applying a layer of ice-making water. The resurfacer uses warm water to fill in any cracks and grooves, which helps in the freezing process and creates the desired smooth sheet of ice. This technique is vital for ensuring a high-quality skating surface for sports and recreational activities.

How Do Ice Rinks Keep the Ice Fresh with a Zamboni?

Ice rinks keep the ice fresh by regularly using a Zamboni to resurface the ice, typically after every period in a hockey game or during intermissions in figure skating events. The Zamboni collects ice shavings, sprays a thin layer of warm water, and redistributes it evenly across the surface. This continuous maintenance helps to prevent the ice from becoming too rough or dirty, ensuring optimal conditions for skating.

What Are the Environmental Benefits of Using a Zamboni?

Using a Zamboni can lead to greener ice rinks due to its efficient use of resources. The machine minimizes waste by collecting ice shavings and using warm water to resurface the ice, which reduces the need for excess energy and water compared to traditional methods. As ice resurfacing technology advances, the ice resurfacing business continues to evolve, making ice rinks more environmentally friendly.