Choosing the right honey processing machine is a critical decision for beekeepers and honey producers that can significantly impact the efficiency and quality of their production operations. This guide will provide an in-depth exploration of the various types of honey processing machines available in the market, their key features, and how to assess their suitability based on the scale and scope of your business operations. We will also discuss the factors to consider when making a purchase, including cost, capacity, energy consumption, and technical support. By the end of this guide, you will have a clear understanding of how to select a machine that aligns with your business needs and goals, ensuring optimal productivity and profitability. Whether you are a small-scale hobbyist or a large commercial producer, this guide aims to equip you with the knowledge necessary to make an informed choice in your honey processing endeavors.

What is a Honey Processing Machine?

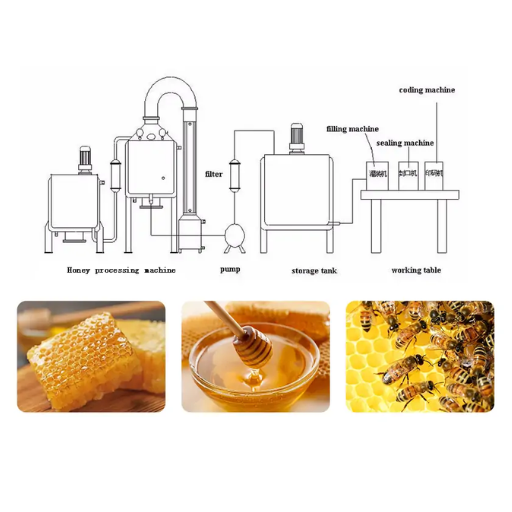

A honey processing machine is an industrial equipment used for extracting, filtering, and even bottling honey with minimum manual effort. This is a machine that renders the work of honey production easier in a way that honey is effectively extracted from the honeycomb and wax cell structures, processed and then honey of required standard and taste is obtained. They are available in different shapes and sizes to suit various levels of production from the smaller bee farmers to commercial scale. Operating with this equipment increases the productivity rate tremendously while standardizing the quality, hygiene and reduces the amount of time and manpower required.

Understanding Honey Processing

As an end product, honey is always designed to be consumption-ready, uncontaminated, and of high-grade through several processes. First is extraction where honeycombs are placed in an extractor that is spun in high velocities to detach the honey from the wax. Then, filtration gets rid of all the visible impurities like beeswax, pollen, and other particulate matter. Honey is heated to a low temperature to enhance its fluidity for filtering purposes, but has no effect on its properties. Thereafter, homogenization provides the honey with the same characteristics and properties irrespective of the batch taken. Last but not least, packaging transfers honey to jars or other containers before it is ready to be distributed. This ensures the quality of honey in terms of its flavor, scent, and nutrients, while the machines provide more efficiency and less labor.

Components of a Honey Processing Machine

I’m going to break down the key components of a honey processing machine based on what I’ve learned. First, there’s the extractor, which uses centrifugal force to separate honey from the combs. Next is the filtration system, crucial for removing impurities like wax and debris. Then, there is the heating element that gently warms the honey, making it easier to filter without losing its quality. A homogenizer ensures consistent texture and quality throughout the batch. Finally, an automated packaging unit fills jars or containers, readying them for distribution. Each part plays an essential role in making honey processing efficient and maintaining high product standards.

How to Select the Best Honey Processing Plant?

To select the best honey processing plant, consider several key factors to ensure quality and efficiency. First, assess the plant’s capacity to match your production requirements, ensuring it can handle your anticipated volume. Evaluate the technology and equipment used, such as modern extractors and filtration systems, to confirm they align with industry standards. Look into the plant’s commitment to quality assurance protocols and certifications, which indicate adherence to safety and hygiene standards. It’s also crucial to consider the plant’s reputation and track record by reviewing testimonials or case studies from previous clients. Moreover, understanding the cost implications, including potential hidden costs, can help in making a budget-conscious decision. Finally, the location of the plant may impact logistics and distribution efficiency, so choose a location that suits your supply chain needs.

Key Considerations for Beekeepers

When selecting a honey processing plant, beekeepers should first analyze the plant’s processing capacity. Ensure it meets or exceeds your production needs for efficiency in handling large volumes. Secondly, prioritize plants equipped with state-of-the-art technology, such as high-quality extractors and filters, which are crucial for maintaining honey purity and quality. Also, verify that the plant adheres to rigorous quality certification standards, reflecting high safety and hygiene compliance. The plant’s reputation is another critical factor—research client feedback and case studies to gauge reliability. Evaluate the overall costs, including undisclosed fees, to ensure financial feasibility. Lastly, consider strategic location to facilitate efficient logistics and distribution, minimizing delays in your supply chain.

Evaluating Production Capacity and Efficiency

To evaluate production capacity and efficiency, I first consider the plant’s processing capacity to ensure it can handle my output volume efficiently. I look for state-of-the-art equipment, like top-notch extractors, to maintain purity. I check for quality certifications to confirm compliance with safety standards. Researching client reviews helps me understand the plant’s reliability. I compare costs upfront, watching for hidden fees, to keep my budget on track. Lastly, I assess the plant’s location for streamlined logistics and speedy distribution, which aligns with my supply chain needs.

Importance of Quality Processing Equipment

Quality processing equipment plays a vital role in ensuring the purity and safety of honey. High-quality extractors and filters remove impurities effectively, preserving the honey’s natural qualities. Equipment with advanced technology shortens processing time and boosts overall efficiency, meeting increasing demand without compromising quality. Reliable machines reduce the likelihood of maintenance downtime, ensuring consistent productivity. They also adhere to safety and sanitation standards, safeguarding consumer health. Investing in superior equipment means achieving optimal output and maintaining trust with clients through consistently high-quality products.

Exploring Different Types of Honey Extractor Machines

There are mainly three types of extractors—manual, electric, and radial. Manual extractors are budget-friendly and suitable for small-scale operations but require physical effort and time. Electric extractors are efficient for medium to large-scale production, offering speed and ease of use while reducing labor intensity. Radial extractors allow simultaneous extraction from multiple frames, maximizing yield in less time, which is ideal for large operations with high output demands. Assess the machine’s durability, capacity, technological features, and compatibility with your existing setup to choose the best option. An ideal extractor should not only enhance extraction efficiency but also maintain the honey’s quality and align with your production volume and budget.

Manual vs Automatic Extractors

When considering manual versus automatic extractors, it’s vital to evaluate efficiency, ease of use, and cost. Manual extractors, while cost-effective and perfect for small-scale beekeepers, demand significant time and physical effort. They are best for hobbyists who enjoy the hands-on process and don’t prioritize speed. On the other hand, automatic extractors streamline the honey extraction process significantly. They operate with minimal manual intervention, boosting productivity and reducing labor. Automatic extractors are costlier but offer great value for commercial beekeepers with large-scale production needs. They ensure fast, consistent results, thus maximizing yield and preserving honey quality. Choosing between manual and automatic extractors hinges on balancing your operational scale, budget, and desired degree of automation.

Features of a Stainless Steel Extractor

When considering a stainless steel extractor, I value its durability and resistance to rust. This material is easy to clean and ensures that my honey maintains its purity. The strength of stainless steel withstands the demands of large-scale production, and it often features a sleek design that fits well with my existing equipment. I look for extractors with adjustable speeds because they give me control over the extraction process, ensuring optimal honey yield without damaging the combs. Additionally, I ensure the extractor has a stable base to prevent wobbling during operation. Choosing a stainless steel model gives me peace of mind regarding long-term investment and maintaining high-quality production.

Choosing the Right Honey Extractor Machine for Your Needs

When choosing the right honey extractor machine, consider your production scale and budget. For hobbyists and small-scale operations, a manual extractor suits those who appreciate a hands-on approach and lower cost. If time and efficiency are crucial, opt for an automatic extractor. It saves labor and increases output, making it ideal for large-scale commercial needs. Prioritize stainless steel models for their durability, rust resistance, and easy cleaning, ensuring the purity of your honey. Look for features like adjustable speeds and a stable base to enhance control and efficiency during extraction. Balancing these factors will guide you to the most suitable extractor for your beekeeping operation.

How Does a Honey Filtering Machine Work?

A honey filtering machine operates by passing the harvested honey through a series of filters to remove impurities such as wax, bee parts, and other debris. The process begins when honey is poured into the machine’s tank, where it is gradually heated to help liquefy any crystals and ensure smoother filtration. As the honey moves through progressively finer mesh screens or filters, these impurities are effectively trapped, allowing only clear, pure honey to pass through. Some machines include pressure systems to enhance the filtration speed and efficiency. The clear honey is then collected in a separate container, ready for bottling or further processing. This method ensures the final product is clean, pure, and ready for consumption or sale.

Process of Filtration in Honey Processing

During the honey processing operation, honey filtration is of its utmost importance in maintaining the final quality and integrity of the end product. First of all, honey is passed through a settling tank where it self clarification is achieved through large particles such as debris and wax settling at the top. The clear honey is then traversed through a number of fine nylon or metal meshes that are left with some minute particles. Certain systems also use mild temperatures to allow the honey to flow easily which avoids crystallization and assists in the process of filtration. Likewise, high pressure pumps may also be employed in order to accelerate the rate of filtration and enhance the degree of purification applied. In the end, the pure, filtered honey is transferred into storage states to be ready for bottling.

Role of a Honey Filter in Ensuring Purity

The use of a honey filter serves the purpose of increasing the level of purity by facilitating the extraction of impurities. Dust, particles, wax and other debris in the honey are removed by the specially designed filters through active trapping during the honey filtration process. The use of fans or screens within filters ensures that particles which should not be present in the honey are thoroughly removed. The application of light pressure and heat helps to keep the honey warm and increase the rate of filtering. This step ensures that the honey’s flavor and all of its nutrients are preserved before it is ready for packaging. So, as seen, honey filters do not only help maintain the integrity of the honey but also makes the final product safe and visually appealing to consumers.

Maintaining Your Filtering Equipment

To maintain my filtering equipment, I start by regularly washing all components with warm water and mild detergent, which prevents residue build-up. I inspect the filters for any signs of wear and replace them if necessary to ensure optimal performance. After each use, I dry everything thoroughly to avoid corrosion. I also make sure to periodically check for leaks or loose fittings to ensure the system functions efficiently. By keeping my equipment clean and in good condition, I extend its lifespan and preserve the quality of the honey I produce.

References

-

University of Georgia – Processing Honey: Provides insights into honey extracting equipment for hobbyists and small-scale operations.

-

Betterbee – Honey Extracting Equipment: Features a selection of honey extracting equipment from trusted manufacturers.

-

Mid-Atlantic Apiculture Research – Beekeeping Equipment: Discusses essential beekeeping equipment, including tools for handling honey.

Frequently Asked Questions (FAQ)

Q: What are the essential factors to consider when choosing honey processing equipment for a honey business?

A: Key factors include the scale of your operation, type of honey products you want to produce, budget, and the type of honey processing equipment available. It’s crucial to match your needs with the right equipment to ensure efficiency and quality in honey processing.

Q: How does a honey filling machine benefit a small scale honey processing business?

A: A honey filling machine streamlines the packaging process, allowing for precise and efficient filling of honey jars or bottles. This reduces labor costs, improves product consistency, and enhances production speed, making it ideal for small scale honey processing businesses.

Q: What role does vacuum technology play in professional honey processing?

A: Vacuum technology is used to remove excess water from honey, which helps in concentrating and preserving its quality. This process is essential for maintaining the right consistency and preventing fermentation, which is crucial for professional honey processing.

Q: Why is 304 stainless steel commonly used in honey processing equipment?

A: 304 stainless steel is favored for its durability, corrosion resistance, and ability to maintain hygiene standards. This makes it ideal for equipment that comes in contact with honey, ensuring the product remains uncontaminated and safe for consumption.

Q: What should be considered when selecting a honey supplier for your processing line?

A: When selecting a honey supplier, consider factors such as the supplier’s reliability, product quality, price, and compliance with safety standards. A reputable supplier will provide consistent, high-quality honey that meets your processing needs.

Q: What is the significance of honey pasteurization in honey processing?

A: Honey pasteurization is important for killing yeast cells, which can cause fermentation. This process ensures the longevity and stability of honey products, making them safe and suitable for long-term storage and consumption.

Q: How do automatic honey processing machines improve efficiency in honey production?

A: Automatic honey processing machines automate various tasks such as extraction, filtration, and filling, reducing manual labor and increasing production speed. This results in greater efficiency, consistency, and scalability in honey production.

Q: What are the benefits of using a honey concentrator machine in apiculture?

A: A honey concentrator machine reduces the water content in honey, enhancing its texture and flavor. It ensures the honey is of high quality and meets market standards, which is particularly beneficial in apiculture for producing premium honey.

Q: How is honey packaging important for a successful honey business?

A: Honey packaging is critical for protecting the product, maintaining its quality, and appealing to consumers. Good packaging ensures freshness, prevents contamination, and provides necessary information about the product, aiding in brand recognition and customer satisfaction.