Due to its flexibility, durability, and corrosion resistance, high-density polyethylene (HDPE) pipes are an increasingly important part of modern piping systems. This paper will look at the history of HDPE pipes from their beginnings as raw plastic materials and tracks their evolution into engineered design solutions for many industries. This polygon will provide an insight into the material characteristics, manufacturing technologies, and actual use of HDPE pipes within agriculture, construction, and utility services to explain why they are favored in these sectors. This insight will provide readers with an understanding of the technical features of HDPE pipes which help create efficient and sustainable systems and infrastructure.

What is HDPE Pipe and How is it Manufactured?

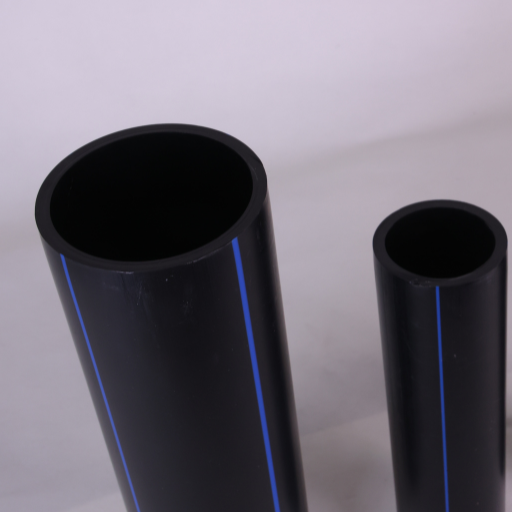

The most important feature of HDPE pipes is that they can withstand high pressure with their weight-to-volume ratio. These pipes, along with being extremely flexible and durable, are also produced through extrusion, which is the heating of polyethylene resin followed by the forcing it through a die. The pipe is cooled and rested once the proper shape is achieved to set into the desired shape. HDPE pipes are useful in many systems like irrigation channels, gas lines, and water canals as they do not corrode with the chemicals or the environment around them and are perfectly stress resistant.

Understanding High-Density Polyethylene (HDPE) Material

HDPE is produced from petroleum and has a thermoplastic polymer structure because it is manufactured through a catalytic polymerization process. High crystallinity, impact resistance, and tensile strength ranging from 20 to 37 MPa are a few of the remarkable physical attributes bestowed on it by its molecular weight. HDPE’s lightweight and robust structure stems from its density range of 0.93 to 0.97 g/cm³. Moreover, it has unparalleled stability against organic solvents, acids, and alkalis. An additional advantage of HDPE is that its melting range is from 120 to 140 degrees Celsius, and the thermal conductivity is quite low, approximating to 0.46 W/m·K. It is this specific set of criteria that makes HDPE the ideal material to use where toughness, flexibility, and long service life is key.

HDPE Pipes Manufacturing Procedure: Overview

An HDPE pipe’s manufacturing procedure consists of several stages designed to meet particular quality standards and technical specifications. The extrusion process is the first stage. In this process, HDPE resin, which is often mixed with stabilizers and colorants, undergoes melting processes at temperatures between 180 and 240 degrees Celsius. The HDPE resin is then forced through a die to produce a continuous pipe. After the extrusion step, the newly formed pipe undergoes cooling via water basketing to attain shape and form while also controlling the temperature to prevent internal stresses.

The production pipeline’s next step is sizing and calibrating the required dimensions. Cooling the pipes and adjusting the dimensions needs to meet set requirements like ISO 4427 or ASTM F714. Mean tolerances need to be set for wall thickness, ovality, and diameter for the pipes to be chamfered. Requirements range from wall thickness between SDR11 for higher pressure to SDR21 or SDR17 for lower pressure applications.

Pipes undergo mechanical and hydraulic procedures such as tensile strength checking with a minimum of 20 MPA, and hydrostatic pressure tests to prove they can endure operational circumstances. Finishing surface and marking occur in this step for tracking and regulatory compliance purposes. Ultimately, the HDPE pipes are fully fabricated, cut to the required length, strapped in bundles, and then set aside for clearance for shipping to end-users or project sites. Such procedures guarantee the pipe’s effectiveness in terms of the required technical and eco-friendly performance criteria.

Key Properties and Advantages of HDPE Pipes

HDPE pipes are powerful and flexible which allows for broad uses. They also do not rust, get damaged by chemicals, or corrode, enabling them to sustain enduring various ecological conditions. Furthermore, HDPE pipes can sustain high impacts, and great shifts in temperatures with no signs of cracking. Their low weight makes them easier and cheaper to move and install. Additionally, these pipes possess a smooth internal layer that guarantees good flow and lower friction, making them more effective. In addition, such pipes are non-toxic, eco-friendly, easy to recycle, and compliant with regulatory requirements.

What Are the Main Applications of HDPE Pipes in Various Industries?

Due to their high strength-to-weight ratio, flexibility, stress resistance, and high durability, HDPE pipes can be used in various industries. In the case of water supply, the pipes can be used in potable water distribution, irrigation systems, and even stormwater drainage systems. This is because they are corrosion-resistant as well as leak-proof. The oil and gas industry utilizes HDPE pipes to transport crude oil, natural gas, and other fluids because the pipes easily endure high pressures and significant fluctuations in temperature. Lastly, the pipes are also widely used for sewage and wastewater systems as they are durable and highly chemically resistant, making HDPE pipes ideal for safely transporting corrosive materials.

HDPE Pipes In Water And Sewer Systems

The resistance to corrosion and ruggedness of HDPE pipes make them ideal for water and sewage systems. In addition, the long service life these pipes provide makes them a viable option in this context. Because these pipes can reliably transport potable water without the risk of contamination or degradation over time, they are instrumental in municipal water distribution systems. Lastly, the smooth interior surface, low coefficient of friction, and durability of HDPE pipes, allow for an increased flow rate which optimizes the transportation of wastewater and lowers pressure loss.

In terms of physics, HDPE Pipes have high flexibility and impact strength needed to resist movements in the ground like soil settlement or seismic disruption, making them very durable. From a temperature standpoint, these pipes work in environments with temperatures from -40°F to 140°F (-40 °C to 60 °C) which allows them to function in extreme climatic conditions. Moreover, they are highly resistant to ultraviolet (UV) radiation, thus permitting outdoor installations without worrying about altering the material.

For sewer systems, HDPE pipes are excellent because they are capable of withstanding acidic or alkaline effluents often seen in wastewater; in other words, they have high chemical resistance. These pipes also do not fail structurally under high pressure and are typically rated at 16 bar pressure. These factors contribute to making HDPE Pipes highly sustainable, environmentally friendly, and cost-effective in modern water and sewer systems.

Gas Distribution Networks Using HDPE Pipes

Highly corrosion-resistant, flexible, and incredibly durable, HDPE pipes have become the industry standard in gas distribution networks. The strength of these pipes allows them to withstand harsh ground movements, considerably increasing their tensile strength while also minimizing the chances of leaks or failures. In addition, these pipes ensure the containment and safety of gas via their dependable joining method of heat fusion. Moreover, the lightweight build of these pipes allows for easy transportation and installation, resulting in lowered expenses. As these pipes are compatible with many pressure ratings, ranging from lows systems to medium ones without a drop in reliability and rise in maintenance, they ensure trustworthy performance over lengthy periods of time.

Industrial and Mining Applications of HDPE Piping

With its resistance to impact, chemicals, and abrasion, HDPE piping is well-suited for use in the industrial and mining sectors. These features allow for transporting abrasive slurries and chemicals in tough conditions. Due to their flexibility, HDPE pipes excel in dynamic soil conditions and in situations that require frequent movement or thermal expansion. In addition, the extreme low operational costs over several decades, in conjunction with reliable connections enabled through welding and jointing techniques, provide these pipes with an unmatched lifespan over several decades.

How Does HDPE Pipe Compare to Traditional Piping Materials?

HDPE pipes have a number of advantages over conventional materials such as steel, concrete, and PVC pipes. For instance, they are lighter than these materials, making them easier to transport. Moreover, its lightweight design makes it far cheaper to install than steel pipes. Additionally, HDPE pipes are far more resistant to corrosion, scaling, and chemical degradation, a common problem with metal and concrete alternatives. Besides that, HDPE pipes are far more impact resistant and flexible than traditional materials, meaning they can withstand multiple types of dynamic loading, including seismic forces. Furthermore, compared to conventional materials that require intensive maintenance, HDPE pipes are durable and have a long service life, meaning that the lifecycle cost becomes far cheaper. With the ability to weld joints through fusion welding, HDPE pipes can ensure leakproof and tight joints, which greatly increases the reliability of the entire system.

HDPE versus Steel and Ductile Iron Pipes

Compared to steel and ductile iron pipes, HDPE pipes have a number of considerable benefits. For starters, both steel and ductile iron have very high shine ratios, but those materials are incredibly prone to rusting. They would need protective shields or cathodic protection, particularly in pipes dealing with extreme conditions. Furthermore, unlike the latter options, HDPE pipes do not rust, corrode, chemically attack, or bio foul making it far easier to utilize for most systems, including water and wastewater. Regarding weight, HDPE pipes are significantly lighter than steel and ductile iron pipes, making them more cost effective and easier to install, transport, and handle.

HDPE pipes have a working pressure capacity of 25 bars (this figure can vary depending on grade and wall thickness), and possess an impressive degree of flexibility—they can bend at a radius of 20-25 times the pipe’s diameter. While ductile iron and steel pipes have superior rigidity and strength, they lack flexibility and perform poorly in environments with seismic activity or shifting soils. In addition, the smooth internal surface of HDPE significantly reduces friction and steel pipe C-factors suffer due to scaling and rust, whereas HDPE achieves a C-factor of 150 throughout its lifetime.

Moreover, fusion welding eliminates the risk of leaks due to gasketed joints in ductile iron or steel pipes. This high degree of reliability and efficiency is particularly useful during critical applications such as the distribution of gas and potable water. Both ductile iron and steel are favored for their superior strength in high-pressure applications, but ductile iron has a lower lifecycle cost, is more flexible, and does not corrode, which makes HDPE a more economic and practical choice for many projects.

Cost-effectiveness and Long-term Savings with HDPE

The operational cost along the lifespan of the project pipes with HDPE systems is exceptionally low. From a broad perspective, the initial expenses while installing HDPE systems seemly match or exceed the parallel quenched systems, however, substantial savings are gained from lessened sustenance, restoration and replacement spending. Minimizing extensive auxiliary HDPE fittings makes the material and labor requirements for installations much cheaper. Moreover, since HDPE is entirely free from corrosion, scaling, pitting, or even rust, the repairs of the pipe become a thing of the past, granting HDPE systems a prolonged service life.

More specifically, the high resistance of HDPE abrasion broadens its application in the movement of intensively abrasive materials like slurry. For example, numerous studies concerning the efficiency of HDPE pipes exhibited that the pipes can expect to last for one hundred years depending on the surroundings. Also, the construction of these products being remarkably lightweight makes the transportation and handling cheaper, which can further contribute to the economic feasibility of these products. Additionally, faster installation and enhanced cost savings due to leakproof fusion joints increase the overall value of HDPE systems. All of these attributes standardize it as an economical, low cost construction when efficiency is paramount.

Environmental Impact and Sustainability of HDPE Pipes

Due to reduction in energy use and carbon emissions during production and installation, HDPE pipes have notable environmental benefits. Their lightweight nature reduces energy consumption during transportation. Moreover, the long service life of these pipes minimizes the need for regular replacements, decreasing material waste. In addition, HDPE is completely recyclable which means that discarded pipes can be made into new products helping to achieve circular economy goals. The amalgamation of these factors makes HDPE pipes a sustainable option for infrastructure problems.

What Are the Installation and Maintenance Requirements for HDPE Pipes?

Due to their lightweight and flexible design, HDPE pipes are quite easy to install. They can be joined using methods such as butt fusion or electrofusion, which are both very reliable and prevent leaks. Providing adequate bedding and depth is very important during trench preparation to avoid the deformation of pipes under pressure. Sharp objects and high stress levels must be avoided during the final stages of installation as they can damage the pipe.

The work needed to be done while performing maintenance checks on HDPE pipes is rather minimal. Their smooth inner surface prevents sediment and scaling accumulation, eliminating the chances of blockages. However, routine maintenance checks are still important to ensure the integrity of the pipes, check for dislocated joints, or detect externally inflicted damage. When properly installed and maintained, HDPE pipes can offer a lifespan of up to 100 years, making them a reliable choice for long-term infrastructure.

Most Effective Techniques for the Installation of HDPE Pipes

HDPE pipes must be installed following particular guidelines to achieve maximum effectiveness and durability. Advanced handling and storing techniques are key; pipes must always be positioned away from hazards and placed on a flat surface to avoid deformation. Prior to assembly, make sure the ends of the pipe are ready for joining and clean, aligned, and devoid of any obstructions. The most common methods for seamless and effective joint creation are butt fusion and electrofusion. Procedures set by manufacturers must always be performed. During trench preparation, ensure the base is compacted and well-uniformed to offer stable support. Furthermore, pipes must be backfilled with materials that do not contain sharp debris that could potentially damage the pipe. Movement for stress points is often great; bends or connections require incredible anchoring and restraint to reduce movement and stress. Lastly, an inspection after installation with an added pressure test is advised to ensure system status is intact before usage.

Fusion Procedures to Ensure Leakage Proof Connections on HDPE Pipes

Generally, it is believed that butt fusion is the first technology which allows for the effective leak-proof joining of HDPE pipes. This approach includes bringing the pipe ends to the melting temperature and then placing pipes under set pressure to create a joint. Electrofusion, conversely, bonds the ends of the pipe by means of specialized fittings with built in electric coils. These fittings are easily set into an electric circuit and an adequate joint is achieved. Both methods require extensive accuracy, including but not limited to the cleaning and orientation of the ends of pipes, as well as the temperature and pressure control during the entire fusion process.

Sustainability and Care of HDPE Piping Systems

The most important maintenance activity for HDPE piping systems is routine checking. To ensure long-lasting functionality, any signs of damage or stress at connection points, joints, and other parts of the pipes should be monitored consistently. Removal of sedimentation deposits from inside the pipes regularly improves the flow quality within the pipes and balances the chances of blockage. Keeping the proper pressure level inside the pipes, combined with regular pressure tests, ensures deficiencies are discovered in advance. In addition, following the manufacturer’s suggested operational limits and extremities such as temperature and pressure will ensure HDPE’s lifespan. The durability of HDPE piping systems is further aided by proper and careful stowage and handling of the systems. With these measures taken, the systems can serve for many years without functional failures.

How to Choose the Right HDPE Pipe for Your Project?

Choosing the right HDPE pipe for a project involves assessing some critical considerations. First, determine if the pipe is intended for water supply, sewage, gas, or other industrial activities. Each of these applications has its own requirements for pressure rating, which the pipe must satisfy in order to function correctly. Your choice should also be influenced by the surrounding environment, including changing temperatures, chemicals, and soil type. In addition to these factors, you will also need to decide on the proper dimensions of the pipe, including its diameter and wall thickness, to satisfy the flow requirements as well as the mechanical strength of the application. Moreover, their construction to industry regulations like ASTM or ISO will ensure that they are reliable and efficient. Consulting with manufacturers or suppliers who have sufficient information and expertise can help make this process easier, and the outcome can be far more beneficial.

Grasping the Standards and Specifications of HDPE Pipes

High-Density Polyethylene (HDPE) pipes are notable for their strength, flexibility, and environmental and chemical resistance. As with all specifications, one must assess the specified material grade, whether it is PE4710 or PE100, as these factors determine the pipe’s strength, chemical resistance, and longevity. The most standard dimensions relate to the SDR (standard dimension ratio) ratings that, for instance, SDR11, SDR17, and SDR21 define the relationships between the pipe diameter and wall thickness. The higher the SDR number, the higher the pemissible internal pressures. An SDR11 pipe can handle more internal pressures than an SDR17 pipe.

HDPE pipes follow Set Standards like ASTM D3350, which describes the properties of the resin, and ISO 4427, which provide the measurements for the pipes and the pumps. Moreover, temperature is another vital parameter, as they work efficiently from -40°F (-40°C) to 140°F (60°C). The structural integrity of the material is not compromised. Like most materials, they are also designed for effective impact resistance and crack propagation prevention. With HDPE pipes of utmost reliability, care must be taken when selecting the correct pressure for the right application. This is often expressed in pounds per square inch (psi) or bars. For Large diameter industrial applications the SDR17 pipes have a supported pressure rating of around 50 psi.

Providers frequently detail regulatory compliance intended for potable water use, typically checked via certified documents like NSF/ANSI 61, which certify that a pipe is suitable for water supply. Moreover, HDPE pipes can be constructed with added features like coating for outdoor use or protection from chemical corrosion, making them useful in many sectors. Ensure these specifications are within the project scope for proper functionality and durability.

Key Points to Remember When Opting for HDPE Pipes

- Application Needs: Identify the particular application of the pipes, such as drinking water supply lines, wastewater disposal, industrial liquid pipes, or gas pipes. This guarantees that the selected pipe’s material and configuration meet operational requirements.

- Pressure Rate and Pipe Size: Determine the pipe’s pressure rating to cover the system’s maximum working pressure. A rating lower than optimum will result in excessive wear and damage. Likewise, confirm that the pipe diameter satisfies the minimum and maximum requirements for flow rate and volume to prevent performance loss.

- Resistance To Temperature Changes: Confirm that the pipe is skilled enough to endure changes in temperature within the working environment. Some formulations of HDPE have been made for impact resistance extreme cold or hot temperatures and other varying conditions.

- Chemical Compatibility: Determine the specific application of the pipe. Although HDPE pipes can resist various chemicals, some may call for unique protective coatings or special grades. Inspect the chemical composition of the elastomeric substances in which it must be in contact.

- Installation Environment: Assess the area where the pipes will be placed regarding soil type, sunlight, and any abrasive substances that may come into contact with them. Outdoor pipes should have UV stabilizers, whereas pipes in corrosive soils must have protective linings.

- Joining Methods: Determine the most suitable joining method for your project (butt fusion, electrofusion, or mechanical couplings) as it is crucial to the achieved performance of the task. The right method ensures the system is free of impediments such as leakage, which is vital for its durability.

- Regulatory Compliance: Ensure the pipes comply with specific industry regulations and permits. Some are NSF/ANSI, ASTM, or ISO regulations, and most pertain to potable water pipes. The surest way to know which is pertinent to your case is to consider the area where it will be used.

- Longevity and Lifecycle Costs: Based on the operating environment, determine the anticipated life of the pipes, and consider factors other than initial price, such as maintenance and replacement costs over the usage period, for optimal return on investment.

- Customization Options: Seek features such as color coding to help distinguish different systems, enabling better traceability, or construct dual wall proficient features more resistant to certain systems.

- Sustainability and Recycling: Assess whether the materials used are sustainably sourced, including the ability to recycle the pipe at the end of its lifecycle, which is important for environmentally-utilizing projects.

Options for Custom Fabrication of HDPEs for Specific Needs

Options for Custom Fabrication of HDPEs for Specific Needs have professionals offering services like custom cutting, thermal welding, and pipe assembly, that aid in developing bespoke piping systems or parts. These developments are constructed to incorporate unique operational and physical demands such as size, pressures, and even multi-part designs. Newer forms of fabrication support the inclusion of reinforced ribs, specially shaped parts, and markings for identification, which increase operational, structural, and regulatory compliance simultaneously in more complex applications. Customization of integrated systems is possible through this technique, which increases system efficiency and durability and allows compliance with more project-specific standards.

How to Find a Reliable HDPE Pipe Manufacturer and Supplier?

It is essential to do a thorough check when searching for an HDPE pipe manufacturer and supplier as this will help you to get a credible and reliable supplier. Competency will often come with reputation and experience. Look at product certifications and compliance with known standards, particularly ISO, to ensure the pipes qualify for critical quality standards. Also scope the services available in the market, such as custom fabrication, technical assistance, and guaranteed delivery, as these may be pertinent to your project. In addition, analyze customer reviews and specific case studies for the projects performed and their actual results to gauge how well they performed and how reliable they are for the same type of work.

Important Aspects for Looking for an HDPE Pipe Manufacturer

- Product Quality and Standards

Check whether the manufacturer complies with quality assurance measures such as ISO, ASTM, or API. Quality HDPE pipes are paramount to achieving durability and sophisticated performance in harsh and extreme applications.

- Manufacturing Capabilities

Check the manufacturer’s production capacity and whether they can handle particular pipe specifications like size, thickness, and custom pressures. Also, consider modern forms of production, such as extrusion and fusion technologies.

- Material Verification

Verify that the HDPE pipes are produced from raw materials of the required grade, and that these materials have the appropriate certifications. Suppliers must provide material data sheets and test results that prove compliance to environmental and safety regulations.

- Technical Knowledge and Assistance

Select a manufacturer with strong technical knowledge and that provides additional services such as design, installation, maintenance, and troubleshooting. Good technical support greatly minimizes operational difficulties.

- Reliability of Delivery and Supply Chain

Evaluate the supplier’s logistics and ability to deliver materials within a reasonable time frame. Providing the materials on time is essential to avoid problems and increase the project cost.

- Service After Sale

Warranted manufacturers provide services after the sale, such as on-site assistance, warranties, and repairs, to help in the smooth operation of the product in the field and to resolve problems quickly if they arise.

- Sustainability Efforts

Engage suppliers who integrate eco-friendly production processes and materials into their products in order to comply with sustainability objectives and reduce environmental effects.

Value of Professional Guidance and Post Sales Support

Professional guidance and post sales support ensure product/service durability, efficiency, and performance. These systems offer users with the technical support required for solving problems so that downtime is reduced as much as possible and the product is fully functional throughout its lifespan. Post sales service offers installation, maintenance, repairs, and even provision of original spare components. Technical products, especially machines and electronics, subsidize these services with software revisions, calibration, and user training. Support beyond technical accuracy results in enhanced trust and loyalty from customers, making it invaluable to both users and providers. Efficiently created service offerings go a long way in increasing the lifecycle and performance standards of the product.

Reference sources

Frequently Asked Questions (FAQs)

Q: What makes HDPE pipe a top choice for various industries?

A: HDPE pipe is a top choice for many industries due to its durability, flexibility, and corrosion resistance. It’s particularly valued in the plastics industry for its long-lasting and low-maintenance properties, making it ideal for applications in irrigation, energy, and water distribution sectors across North America and worldwide.

Q: How does HDPE pipe contribute to project success in different sectors?

A: HDPE pipe contributes to project success by offering innovative hdpe pipe solutions that meet the specific needs of every industry. Its versatility allows for applications in energy, water, and waste management, ensuring long-term reliability and cost-effectiveness. The ability to manufacture large diameter pipes also makes it suitable for major infrastructure projects.

Q: What are the advantages of using HDPE products in irrigation systems?

A: HDPE products excel in irrigation systems due to their resistance to chemicals, UV radiation, and environmental stress. They offer flexibility for easy installation, reduce water loss through leakage, and provide a long service life. These qualities make HDPE pipe a durable and efficient choice for agricultural and landscaping irrigation needs.

Q: How is the market for HDPE pipe expected to grow by 2025?

A: The market for HDPE pipe is projected to experience significant growth by 2025, driven by increasing demand in construction, water management, and oil & gas industries. Factors such as urbanization, infrastructure development, and the need for sustainable piping solutions are expected to boost the adoption of HDPE pipes across the country and worldwide.

Q: What do I need to know about HDPE pipe pricing and availability?

A: HDPE pipe pricing varies based on factors such as diameter, wall thickness, and application requirements. Many manufacturers maintain a substantial inventory to meet diverse needs. For accurate pricing and availability information, it’s best to contact suppliers directly. They can provide quotes based on your specific project requirements and current market conditions.

Q: How does HDPE pipe compare to other plastic pipe materials?

A: Compared to other plastic pipe materials, HDPE offers superior strength, flexibility, and chemical resistance. It’s lighter than many alternatives, making it easier to transport and install. HDPE also has excellent joint integrity when properly fused, reducing the risk of leaks. These qualities make it a preferred choice in the plastics industry for many applications.

Q: What standards govern the production of HDPE pipe for water applications?

A: HDPE pipe for water applications is typically manufactured according to AWWA (American Water Works Association) standards. These standards ensure the quality, performance, and safety of HDPE pipes used in water distribution systems. Compliance with AWWA standards is crucial for project success and long-term reliability in municipal water infrastructure.

Q: What innovative features are available in modern HDPE pipe solutions?

A: Modern HDPE pipe solutions offer innovative features such as improved chemical formulations for enhanced durability, advanced joining techniques for stronger connections, and striping options for easy identification. Some manufacturers also provide custom solutions with specific performance characteristics tailored to unique project requirements, showcasing the versatility of HDPE in meeting diverse industry needs.

Q: How does the use of HDPE pipe contribute to environmental sustainability?

A: HDPE pipe contributes to environmental sustainability through its long lifespan, reducing the need for frequent replacements. It’s also recyclable, minimizing waste. The smooth interior of HDPE pipes improves flow efficiency, potentially reducing energy consumption in pumping applications. Additionally, its corrosion resistance eliminates the need for harmful chemical treatments, making it an environmentally friendly choice for various piping applications.