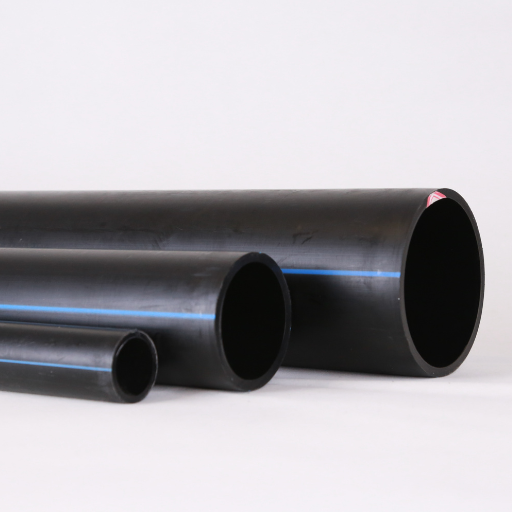

Pipes and fittings made of High-Density Polyethylene (HDPE) are becoming essential parts in modern potable water distribution systems. Compared to traditional materials such as metal and concrete, these components are incredibly strong, flexible, and corrosion-resistant. The post elaborates on the unique characteristics of HDPE pipes and fittings and their benefits to the efficiency and safety of water delivery. Moreover, it highlights these materials’ compliance with stringent standards for potable water and their suitability for residential, commercial, and industrial purposes.

What are HDPE pipes and fittings, and why are they ideal for potable water?

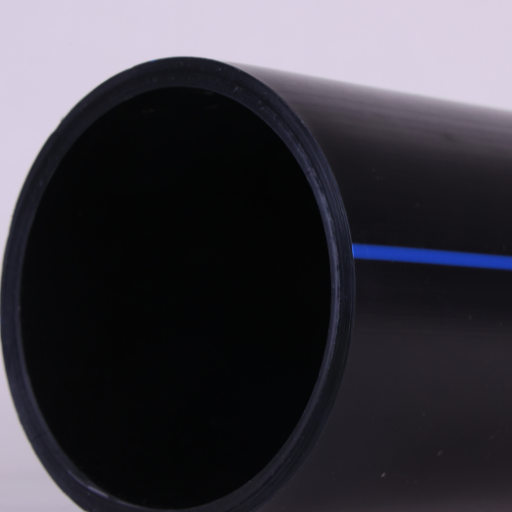

Pipes and fittings made out of HDPE (High-Density Polyethylene) are thermoplastic materials with excellent durability, flexibility, and resistance to corrosion. These qualities offer them high suitability for potable water systems as they do not allow leaching and contamination of the water. HDPE pipes are stout and perform excellently under pressure and in harsh environmental conditions. Apart from being lightweight, their seamless design decreases the chances of leaks. Additionally, the non-reactive nature of the pipes prevents scaling and microbial growth, ensuring that the water supply is in pristine condition. Moreover, their suitability for trenchless installation methods increases the process’s efficiency by reducing environmental damaging, making them an ideal choice.

What is HDPE and how is it different from other pipe materials?

High-density polyethylene (HDPE) refers to a thermoplastic polymer with a high strength-to-density ratio, notable flexibility, and chemical resistance. HDPE’s corrosion resistance exceeds that of traditional materials like metal and PVC, allowing it to excel in the presence of water and harsh chemicals. HDPE pipes do not corrode or decay like metal pipes, maximizing maintenance costs. HDPE is also more durable and flexible than PVC, enabling it to withstand extreme temperatures and pressure changes. Its ability to be fused into smooth joints also makes it distinct in comparison to other materials that depend on mechanical joints, which are subject to significant stress and wear.

Why is HDPE preferred for potable water applications?

It is preferred because of chemicals, non-toxicity, and the ability to maintain water quality. The material is certified for potable waters such as NSF/ANSI 61. It has a low internal surface smoothness, which physically reduces biofilm accumulation, which is a long-term risk for microbial contamination. HDPE is also resistant to chlorine and a wide range of other chemical disinfectants used in water treatment whcih ensures sustainable integrity of the structure over time.

From a technical point of view, HDPE has a density range of 0.93 – 0.97 g/cm³ and high tensile strength, which enables the pipes to perform efficiently under different pressure classes, e.g. up to PN25 in some situations. Its flexibility with a high elongation at break (>500%) supports the installation on challenging terrains without fear of cracking or damage. In addition, the fusion welding method employed with HDPE guarantees a monolithic, leakproof piping system, which outperforms more traditional materials in water conservation and preventing contamination. These attributes combine to make HDPE a very reliable and cost efficient attributive solution for potable water distribution.

Where Does HDPE Stand Compared to PVC and Ductile Iron Pipes?

About PVC and ductile iron pipes, HDPE pipes outrank them on various aspects. Fractures are less likely to occur when installing HDPE pipes, as they offer much greater flexibility and impact resistance than PVC. Additionally, HDPE pipes weigh substantially less than ductile iron pipes, which makes transportation as well as installation easy while also making them resistant to corrosion. Furthermore, HDPE pipes eliminate the possibility of leaks from ductile iron’s bolted joints, which are unreliable and prone to leaks with time. These factors make HDPE far more superior to PVC economies in terms of modern piping systems.

What are the key benefits of using HDPE pipes for water distribution systems?

The use of HDPE pipes in the water distribution system is exceptionally advantageous due to their resistance to corrosion, extreme durability, and flexibility. The pipe’s HDPE possesses high-impact strength and is resistant to chemicals, which ensures it lasts long under difficult conditions and high pressure. An additional benefit of HDPE pipes is that they are relatively lighter, leading to transport and installation costs, too. They are economical and cost-effective in the long term because no seams could potentially cause leaks, enhancing system efficiency while simultaneously reducing maintenance and repairs. These make the HDPE pipes a reliable and economical solution modern infrastructure needs.

In what ways does the durability of HDPE pipes assist in saving costs?

The roughness and toughness of HDPE pipes reduce costs in the long term easily with little to no maintenance with the least disruption-related infrastructure. There is far less need to upgrade the infrastructure frequently, significantly lowering lifecycle costs. Overall, the service life of the pipes greatly reduces long term costs. Their durability also contributes to weakening the need for replacement or failure. Combining with the fact that most HDPE pipes possess seamless fusion joints, this leads to little leakages, which greatly reduces the loss of water alongside the expensive repairs, Therefore leading this to claim to be more durable.

Why Are HDPE Pipes Touted For Their Durability Against Corrosion and Chemical Decomposition?

First, HDPE pipes are built for uncompromising strength against all forms of corrosive compounds, and they pulverize ready acids due to the unique formation at the molecular level of the HDPE. It is designed to stand against tough organic solvents and strong bases, without losing its shape or becoming flat. Unlike metals, High-density polyethylene does not rust or corrode when it comes into contact with water or undergoes any electrochemical reaction. It is perfect for water and wastewater systems. In addition, HDPE pipes come with unparalleled oxidation and stress crack resistance, along with high parameters on Environmental Stress Crack Resistance (ESCR) and hydrostatic Design Basis (HDB) of over 1600-psi depending on the pipe grade. All these factors ensure High-density polyethylene is bestowed great durability against corrosion. These pipes guarantee unprecedented trustworthiness in severe chemical environments.

In which ways does the pliability of HDPE pipes facilitate its installation methods?

The flexibility of HDPE pipes makes it easier to install them in many rugged terrains and conditions. Their ability to be bent without breaking eliminates any additional fittings, making them ideal for curved and uneven surfaces. In addition, HDPE pipes can be installed through trenchless technologies like horizontal directional drilling or pipe bursting, reducing environmental disruption while saving on labor and restoration costs. This type of flexibility not only simplifies the installation of complex systems but also helps accomplish goals of higher efficiency and performance in the long run.

What are the various applications of HDPE pipes in water management?

Because of their strength, flexibility, and corrosion resistance, HDPE pipes have numerous applications in water management. They have numerous applications in the potable water supply systems as they can safely and efficiently transport drinking water. Their robust construction also makes them suitable for eh waste and sewerage systems where they can effectively avoid leaking and contaminating the surroundings. Besides, HDPE pipes are used in stormwater drainage systems and irrigation networks where high pressure and environmental changes are the norms. These diverse applications highlight how adaptable and trustworthy HDPE pipes meet various water management challenges.

How are HDPE pipes used in municipal water distribution systems?

The strength-to-density ratio, flexibility, and density of HDPE pipes makes them integral in municipal distribution systems. They are mainly used for transporting potable water since the inert material does not allow any contaminants to enter. The pipes are also highly resistant to corrosion and other chemicals so they are ideally suited for harsh conditions. The lightweight nature of the pipes makes installation easier, project costs cheaper, and the ability to withstand high pressure improves the efficiency of urban water networks. Therefore, these features make HDPE pipes a reliable solution for modern municipal water infrastructure.

How HDPE pipes are used to manage wastewater?

The advanced structural features of High-Density Polyethylene Pipes (HDPE) make them an innovative invention for wastewater management. They are durable, chemical resistant, and non-corrosive, making them ideal for managing waste. HDPE Pipes are frequently used in sewage transport and systems for industrial wastewater because they can stand against abusive conditions such as high levels of aggressive chemicals and elevated pH values. Its internal surface facilitates flow and minimizes blockages, and its flexibility makes HDPE pipes easier to install even in inaccessible or harder sections of land. Moreover, HDPE pipes reduce risk of leakage while safely transporting wastewater over longer distances, making them reliable for assortment systems. This helps in improving sustainable and efficient solutions to manage wastage.

Can HDPE pipes be used for both small-scale and large-scale water projects?

Certainly, HDPE pipes are ideal in residential as well as urban plumbing projects owing to their strength and versatility. In case of household plumbing and small localized irrigation projects, HDPE pipes solve the requirements efficiently due to their portability and ease of installation. In the case of more extensive infrastructure works such as municipal water supply systems or extensive agricultural projects, HDPE pipes are remarkably efficient for high pressure, low external stress, and distance pipe applications because of their structural integrity while withstanding large volumes of water and distance.

How do HDPE pipes contribute to sustainable water infrastructure?

Through their strength, cost-efficiency, and eco-friendly characteristics, HDPE pipes help achieve sustainable water infrastructure. Their formidable resistance to corrosion and wear greatly minimizes the need for regular replacements or repairs which, in turn, decreases resource consumption and maintenance costs over time. Furthermore, HDPE pipes are highly recyclable, which helps to facilitate circular economic practices by repurposing them at the end of their lifecycle. Their seamless and strong structural joints greatly reduce water loss as they prevent leaks. These characteristics collectively help achieve resource efficiency and overcome infrastructure inefficiencies.

What is the expected service life of HDPE pipes in water applications?

The expected lifespan of HDPE pipes in water applications under normal operating conditions is usually over 50 years. This is often the case due to their high resistance to corrosion, stress, cracking from the environment, and chemical degradation. Following installation guidelines and the design protocol will aid in extending the lifespan and will guarantee efficient performance in various water infrastructure systems.

In what ways can an HDPE pipeline be more economical when it comes to maintenance costs and the overall ecological impact?

The use of HDPE piping helps save on maintenance costs and lowers ecological and environmental damage because of their structural attributes and efficient utility. With the capacity to resist chemicals and corrosion, scaling, and microbiological growth minimizes the chance of pipes suffering blunt force injuries or getting clogged. Less frequent repairs translates to lower upkeep expenses. Besides, their flexibility enables easy installation even on rugged terrains and significantly reduces mechanical stress over the years. Environmentally, the lightweight nature of HDPE pipes lowers energy requirements during transportation.

Additionally, their recyclability guarantees that they promote sustainable practices. In technical terms, HDPE can sustain pressure of approximately 16 bar depending on the wall thickness (SDR rating) and has an expansion coefficient of around 0.20 mm/m °C, which makes it highly flexible under various operating conditions. These factors combine to promote resilient and effective infrastructure while ensuring increased operational efficiency and a smaller footprint.

Can HDPE Pipes Be Recycled After Their Service Life?

HDPE pipes are recyclable after their life service. They can be reused to make new pipes, plastic bottles, or building materials. Recycling these pipes helps reduce plastic pollution and aids in a circular economy by enabling the recycling of precious resources, which saves energy and materials during production processes.

What are the different types and sizes of HDPE pipes available for potable water systems?

HDPE pipes intended for water systems come in two principal classifications based on the wall thickness and the rated pressure of the pipes: Standard Dimension Ratio (SDR) and Pressure Nominal (PN). SDR-rated pipes are available in various sizes, with diameters ranging from ½ inch to 63 inches, providing for many flow requirements. The proportions between the wall thickness and the outside diameter of the SDR rating HDPE pipes are set so that the pressure handling capabilities are maintained. Furthermore, HDPE pipes can be supplied in coiled forms or in straight lengths with smaller diameters often supplied in longer continuous lengths. This quality is essential for the quick and easy installation of the pipes for different uses in water distribution systems.

What pressure ratings exist for HDPE water pipes?

HDPE pipes offer diverse pressure ratings that are normally classified with corresponding values, commonly known as PN. The values in bars represent the maximum sustained operating pressure the pipes can accommodate. HDPE pipes commonly have PN figures that start from 6 and go all the way to 25, like PN 6, PN 10, PN 12.5, PN 16, PN 20, And PN 25. Each of the enumerated ratings serves a different operational requirement. The ratings correspond with the pipes thickness, material grade, and other factors determining its strength and ability to endure different pressure levels. For example, PN 10 can sustain 10 bars of pressure, while PN 25 can sustain up to 25 bars. In cases where flow demands, the application, and working conditions are more burdensome, selecting a corresponding pressure rating that guarantees maximum performance and safety for potable systems testing is essential.

Tips for Choosing the Right HDPE Pipe For Your Water Distribution Project

To select the most suitable HDPE pipe size for your water distribution project, various considerations, such as the flow rate, the pressure required, material properties, and site conditions, must be considered. To ensure proper water flow to the area, the pipe’s internal diameter should ensure enough water is passed through whilst keeping the velocity at an acceptable level. Some basic technical details to keep in mind are:

- Flow Rate (Q): The flow rate metric consists of liters per second (l/s) and cubic meters per hour (m³/h). For a transportation conduit, the flow rate indicates the volume of water that should be delivered, and the pipe diameter should be proportionate to the flow rate. The desired flow rate should be achievable without suffering difficulties like friction losses.

- Flow Velocities: Depending on the use case of the HDPE pipes, a flow velocity of >=0.6 m/s and >= 2.0 m/s is recommended to reduce effective wear or energy loss.

- Working Pressure (P): The pressure rating could match the pipe. Safety margins on the maximum piping operating pressure should also be considered.

- Pipe Resistance Coefficient: The hydraulic performance of the pipe, as well as its diameter, is determined through both the transmittance of energy and the pipe’s roughness. It is usually represented by the Manning’s coefficient or Darcy-Weisbach friction factor.

- Thermal Effects: Considering that HDPE pipes expand and contract due to temperature changes, the pipes require proper thickness selection along with accommodation in system designs

Other modern approaches, such as pipe hydraulic analysis or design automation, keep it at the required level, regulate the system, and ensure that it will function without a hitch. The right choice of pipe dimensions enhances and ensures effectiveness, minimizes expenses, and guarantees uninterrupted reliable service over a prolonged period.

Which fitting types are suitable for use with HDPE pipes designed for potable water applications?

HDPE pipes intended for potable water applications are available for use with several fitting types, including leakproof ones. Some of the best options are compression, electrofusion, and mechanical fittings. These compression fittings work best in smaller systems as they are simple to use. Electrofusion fittings are permanently attached by electrical heating them to fuse the fitting to the pipe. Mechanical fittings like flanges and couplers are also extensively employed to connect HDPE pipes to pipework or other components made from different materials. These types of fittings provide minimum restriction to potable water safety flow requirements and support the system’s hydrostatic pressure. These devices also provide safe operating conditions and structural integrity for the apparatus. There is a need for carefule selection to meet specific system requirements and operating parameters.

How does the manufacturing process ensure the quality of HDPE pipes for drinking water?

There is an ensured level of quality control during making HDPE pipes for drinking water application. Shipped material is tested for compliance with potable water standards, and high-density polyethylene is selected as the raw material . During the manufacturing process, pipes are extruded, that is, shaped during the flow of the material. The pipes produced have walls of the same thickness, and the internal surfaces are smooth for the best flow of the liquid and for the durability of the pipe. To the end of the process, hydrostatic pressure testing, dimensional checks, and other quality tests are performed to confirm the mechanical strength and accuracy of the pipe. During the tests, pipes are checked for chemical corrosion and UV degradation to guarantee their useful life in various environments.

What standards and certifications apply to HDPE pipes for potable water use?

To ensure safety, performance, and usability over time, HDPE drinking water pipes must adhere to several international and national standards. ISO 4427 includes specifications about polyethylene pipes and fittings for water supply, and ASTM D3035, which addresses the dimensional and performance standards in the USA, are some commonly cited standards. Additionally, HDPE pipes frequently conform to NSF/ANSI 61 certification, certifying that the materials used are safe for drinking water. Other guidelines provided by AWWA (American Water Works Association) deal mainly with purpose for use in municipal water systems. These different mandates regulate areas such as the material’s structural integrity, dimensional accuracy, pressure ratings, and the resistance to corrosion and other environmental factors. These certifications must be compliant to meet health and safety standards.

How is the safety of HDPE pipes ensured in Drinking Water uses?

Specific tests are given to ensure they can hold water without any leakage when it comes to HDPE pipes. The tests commonly performed on the pipes encompass physical and mechanical functioning checks, like checking for any cracks or deformities when the pipe is placed under a hydrostatic pressure for strength verification. Chemical leaching tests are done to ensure that the piping material does not pose any risk to people. On top of that, it needs to go under conditions that test the pipe’s long-term dependability and real-world environmental stresses, like pressure, temperature, and compliance, while checking for cracks or perforations. Detailed nursing laboratory analysis is done to check NSF/ANSI 61 standards thorough examination, checking if the materials used are safely without health hazards that potentially jeopardize clean water systems.

What innovations are happening in HDPE pipe extrusion technology?

In the past few years, new advancements have come forth with the extrusion technology of HDPE pipes, focusing more on material performance, accuracy, and efficiency. New materials are deployed for the screw and barrel for the extrusion machinery to make them more energy efficient. Real-time monitoring processes, as well as advanced sensors and IoT devices, are becoming more integrated into modern extrusion processes to improve production quality and minimize the amount of waste generated.

Further innovations extend to the creation of multi-layer extrusion methods that allow pipes to be manufactured with specific characteristics, such as greater strength or weight reduction. Key developments in these processes focused on the melt flow index (MFI) for material consistency, extrusion temperature profiles (typically 180°C to 250°C), and cooling systems, which improved the accuracy of the pipe dimensions.

Furthermore, advances in the technology of polymer formations, such as high-performance grades of HDPE that possess greater resistance to environmental stress cracking and longer life expectancy, fall hand in hand with these technological advances. All these innovations allow the fabricated HDPE pipes to withstand elevated industry requirements, along with application touches in areas of water, gas, and telecommunication.

Reference sources

Frequently Asked Questions (FAQs)

Q: What are the main benefits of HDPE pipes for potable water systems?

A: HDPE pipes offer numerous advantages for potable water systems. They provide leak-free joints, excellent chemical resistance, and a long service life of over 100 years. HDPE pipes are highly durable and flexible, making them ideal for water distribution networks and residential water supply. Their corrosion resistance and ability to withstand ground movement make them a cost-effective and reliable choice for potable water piping systems.

Q: How does the chemical resistance of HDPE pipes contribute to their suitability for water supply?

A: The chemical resistance of HDPE pipes is one of their standout features, making them ideal for water supply to industrial and residential areas. HDPE material is resistant to a wide range of chemicals, preventing contamination of the potable water. This resistance also ensures that the pipes maintain their structural integrity over time, even when exposed to various water treatments and environmental factors, contributing to their long service life and reliability in water piping systems.

Q: What makes HDPE pipes a good choice for trenchless installation methods?

A: HDPE pipes are an excellent material for trenchless installation due to their flexibility and durability. Their high bend radius allows for easy maneuvering through existing underground pathways. The ability to fuse HDPE pipes creates seamless, leak-free joints, which is crucial for trenchless applications. These properties, combined with their resistance to ground movement and corrosion, make HDPE pipes ideal for minimally invasive installation techniques in various water distribution networks.

Q: How do HDPE pipe fittings contribute to the overall performance of the piping system?

A: HDPE pipe fittings are essential components that complement the performance of HDPE pipes. They maintain the system’s integrity by providing leak-free connections when properly fused. The fittings are made from the same HDPE material as the pipes, ensuring consistent chemical resistance and durability throughout the system. This uniformity in material properties helps to extend the service life of the entire piping network and maintain water quality in potable water applications.

Q: What are the advantages of HDPE pipes in terms of durability and flexibility?

A: The durability and flexibility of HDPE pipes are significant advantages in water piping systems. Their flexibility allows them to withstand ground movement, reducing the risk of breaks or leaks. The durability of HDPE material ensures resistance to corrosion, abrasion, and impact, contributing to a long service life. These properties make HDPE pipes suitable for various applications, from irrigation systems to large-scale water distribution networks, offering reliable performance in diverse environmental conditions.

Q: How does the fusion process of HDPE pipes contribute to leak-free systems?

A: The fusion process used to join HDPE pipes creates monolithic connections that eliminate potential leak points. This process involves heating the pipe ends and fittings, then pressing them together to form a seamless, homogeneous joint. The resulting connection is as strong as the pipe itself, ensuring a leak-free system. This feature is particularly valuable in potable water applications where water loss and contamination prevention are crucial, contributing to the overall efficiency and safety of the water supply infrastructure.

Q: What types of HDPE are commonly used in potable water applications?

A: In potable water applications, several types of HDPE are commonly used, with PE4710 being one of the most popular. This high-performance grade offers excellent strength and durability. Black HDPE pipes are often preferred for their UV resistance in outdoor installations. The choice of HDPE type depends on factors such as pressure requirements, installation method, and specific application needs. Reputable manufacturers like WL Plastics offer a range of HDPE pipe options suitable for various potable water system designs.

Q: How does the cost of HDPE compare to other piping materials for water supply systems?

A: While the initial cost of HDPE pipes may be higher than some traditional materials, their long-term cost-effectiveness makes them an economical choice for water supply systems. The durability, low maintenance requirements, and long service life of HDPE pipes significantly reduce lifecycle costs. Their leak-free joints and resistance to corrosion minimize water loss and repair expenses. Additionally, the ease of installation, especially in trenchless applications, can lead to substantial savings in labor and equipment costs, making HDPE a competitive option for modern water infrastructure projects.