High-density polyethylene (HDPE) pipe extrusion is a crucial process in manufacturing durable and versatile piping solutions used across industries such as water distribution, gas transportation, and industrial fluid handling. This guide comprehensively explores the step-by-step production process, ensuring a clear understanding of the fundamental concepts and the technical procedures involved. Readers will gain insights into critical factors, including material selection, extruder configuration, process control, and quality assurance measures that guarantee optimal pipe performance. The aim is to equip manufacturers, engineers, and industry professionals with the knowledge to optimize production efficiency, maintain consistency, and meet stringent industry standards.

What is HDPE pipe extrusion and why is it important?

High-Density Polyethylene (HDPE) is transformed into pipes of specific dimensions and physical properties in the HDPE pipe extrusion process. The process itself is crucial due to the strength-to-density ratio, corrosion resistance, and flexibility of HDPE material. These attributes allow for the effective utilization of HDPE pipes in water distribution, gas transmission, and industrial fluid handling. When extrusion is done correctly, it guarantees the production of pipes that will endure the test of time and various other performance requirements while also ensuring cost effectiveness in demanding conditions.

Understanding the HDPE pipe extrusion process

The HDPE pipe extrusion process begins with feeding raw HDPE resin pellets into the extruder. These pellets are heated and melted in the barrel, where specific temperature zones ensure uniform material consistency. The molten HDPE is pushed through a die, shaping it into the desired pipe dimensions. Following this, the pipe enters a cooling phase, typically using water baths or spray chambers, to solidify and maintain its structural integrity. After cooling, the pipe is cut to the required lengths and subjected to quality checks to ensure compliance with industry standards. This process is designed to produce pipes with uniform properties, excellent mechanical strength, and long-term performance.

Advantages of HDPE Pipes in Different Industries

Because of their distinct characteristics, HDPE pipes carry different benefits in various industries. Their ability to withstand severe corrosion and chemical deterioration makes them perfect for transporting aggressive fluids in chemical processing plants. HDPE pipes are light in weight, which greatly reduces the overall expenses that come with their transportation and installation and, as a consequence, project costs. Their flexibility and resistance to impact enable them to endure extreme environmental conditions, including seismic activities. In addition, HDPE pipes have a very low coefficient of friction, allowing them to maximize fluid flow and consequently limit the energy costs used in water distribution systems. Coupled with their extended service life, they are highly reliable in agriculture, infrastructure development, and mining, which makes them the preferred choice.

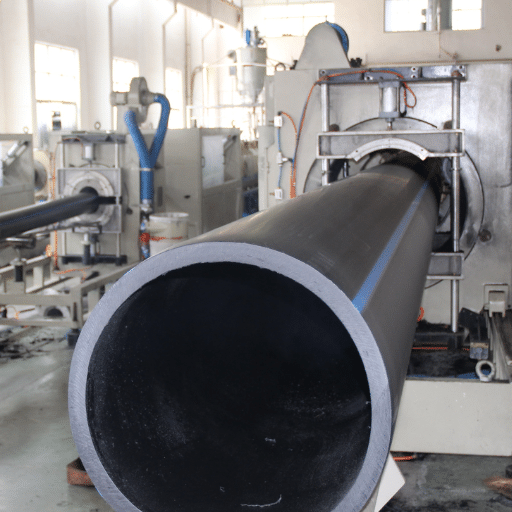

Major Parts of an HDPE Pipe Extrusion Line

Extruder

Extrusion lines have their cores in extruders, which melt and homogenize the high-density polyethylene (HDPE) material. The extruder serves as the core of the extrusion line. It is the part of the machine that melts and homogenizes the high-density polyethylene (HDPE) material. The screw and barrel of the extruder are designed to allow for better temperature control, which makes the production of quality pipe easier as plasticization becomes more consistent.

Die Head

The die head is responsible for transforming the HDPE into a pipe and finishing the extrusion process. The engineering design maintains the flow of the extruded material, which is stress-free, and minimizes any potential flaws during extrusion.

Vacuum Calibration Tank

The vacuum calibration tank cools and provides the initial shape to the extruded pipe. The tank applies negative pressure to keep the pipe’s diameter and shape while the material solidifies. It is crucial to maintain the pipe’s dimension.

Cooling Tanks

There are several other cooling tanks after the calibration tank, where the pipe is further cooled. The active circulation of water around the pipe’s surface solidifies the portion. This prevents the pipe from bending and shrinking and helps it retain its mechanical strength.

Haul-Off Unit

The haul-off unit sequentially pulls the pipe after a certain period for other production stages without stopping the production line. This unit also increases the total length of the pipe by cutting it whenever the pipe is out of the extruder. This method avoids bending the pipe. Non-damaging rollers or belts are attached to the haul-off unit, able to grasp the pipe.

Cutting Unit

The cutting unit remains stationary, and the pipe rotates while the cutters are mounted on a pedestal to take advantage of an increased radius. With the help of advanced mechanisms like rotary or planetary cutters, pipes are sliced into various lengths without the worry of negatively impacting their structural properties.

Stacking or Coiling System

The final step in the stacking or coiling system entails automating the process of storing and moving finished pipes. Shorter pipes are systematically placed one on top of the other while longer pipes are stored in coils using automated systems.

How does the HDPE pipe production process work?

The HDPE pipes production process first initiates with the preparation of raw materials where polyethylene resin needs to be in the right state, so it is melted and homogenized through an extruder with controlled temperatures and pressures. The material is later poured into a die where it is shaped into pipes. Then the molten pipes are cooled in water baths or with sprays to solidify the extruded structure. After hauling, the pipes are divided into specific lengths through segments. Finally, the pipes are coiled or stacked for better transportation. The whole process aims to create pipes that follow strict quality and performance measures.

Preparation and Additives Allocation of Raw Materials and Loading

At this stage, all processes of preparing raw materials during the production of the HDPE pipes entail the selection of resin polyethylene of a certain grade, sometimes blended with other materials like colorant or plasticizer for enhanced characteristics like UV protection. The feedstock is loaded to an extruder via a gravimetric or volumetric feeder that guarantees the accuracy of the blend ratio. It also guarantees production variations minimization and materials supply for the extruder, enhances the homogenization level and set control parameters of the process. This step is crucial because it decides the success of the following steps: melting, blending and later extrusion of HDPE pipes.

Pipe Extrusion and Shaping

During the extrusion and shaping phase, the first step is the polyethylene resin is placed into the barrel zone of the extruder, which has different thermal control zones between 180°C and 240°C. The zone temperature is set depending on the grade of polymer used in the batch. The rotation of the screw in the extruder melts and mixes raw materials in stages to achieve a homogeneous mass. The fully melted material is then delivered using an annular die that gives the product a nominal pipe diameter and wall thickness. It is necessary to pay attention to the accuracy of the die, as the pipe has to be correct in detail.

The molten pipe is directed to the calibration and cooling unit as soon as the die is exited. An external vacuum tank pressurizes the pipe to ensure there is no change in the shape, while uniformity of the internal diameter is also kept intact. The cooling process is done in stages using water baths or sprays, with the most common range being from 15 degrees Celsius to 25 degrees Celsius to avoid thermal shocks. Such cooling allows the pipe to preserve its mechanical properties and structural integrity. The entire procedure uses different techniques such as laser gauges that measure the dimensions and check for accuracy alongside surface imperfections.

Cooling and solidification techniques

Techniques for cooling and solidification employed within the production of pipes are significant when it comes to product performance and defects. Water cooling systems, encompassing immersion baths or spray systems, are one of the most utilized approaches. For example, immersion baths can be set to a temperature range of 15 – 25 degrees Celsius to avoid damaging the pipes’ mechanical properties, where they will be set for rapid cooling.

Furthermore, calibration tanks equipped with vacuum pumps contribute immensely to solidification by holding the dimensions of the pipe’s exterior and shape geometry. These tanks work at specific levels of vacuum pressure that have been set according to the material and size of the pipe. The application of vacuum guarantees that pipe walls are homogeneous during the crucial stage where the material changes from liquid to solid state.

The process of Efficient process monitoring is yet, another element. Non-contact measuring devices like laser gauges allow for the real-time measurement of the shrinkage, ovality or irregularities of the surface. These systems are active at ranges with tolerances limited to certain production requirements, ensuring cooling phase quality. The combination of restricted cooling velocity, the precise application of vacuum, and all-time observation results in the achievement of the set criteria of the technical requirements for the product.

What are the critical factors affecting HDPE pipe quality?

The quality of HDPE pipes are affected mainly by the composition of the material, control during the production processes, and environmental conditions of manufacturing and installation. The resin used in producing HDPE pipes must meet density and melt flow index parameters since these parameters affect strength and flexibility. Controlling processes, such as controlling temperature, extrusion rates, and cooling rates, adequately controls wall thickness so that defects like voids or warping do not occur—environmental concerns such as UV radiation, improper handling, and unsuitable storage methods all risk pipe integrity. Therefore, careful management is important at all stages of production and deployment.

Importance of resin selection and properties

The selected resin is essential to the functioning of HDPE pipes because it affects strength, flexibility, stress, and even temperature. High-quality resin has to have optimal porcessing characteristics regarding mechanical properties, thus having balanced density and melt flow rate. Using stabilizing additives such as antioxidants to improve resistance to thermal and oxidative degradation increases the useful life of the pipe under different operating conditions. Tailoring the selected resin to fit certain applications ensures that industry regulations are met and long-term dependability is achieved.

Heating and Cooling Systems for Extrusion: Pipes and Everything Else

Regulating heat and pressure is crucial throughout the extrusion process as it influences the overall quality and performance of the HDPE pipes. Care must be taken to maintain the right extrusion temperature range for the resin to melt, but still retain its structure. Temperature zones on the extruder usually differ between 200 – 260 degrees Celsius based on the specific requirements of the application. Temperature control along the die and barrel increases the flow of the melt and reduces chances of material defects.

An optimal pressure level is maintained to balance the flow of raw materials and prevent overheating or polymer stagnation. Constant change in pressure doesn’t only break the pipes, but it also changes dimensions and puts internal stress on them. Both upper and lower pressure limits allow for smooth material flow without overheating or causing polymer stagnation. More advanced integration that merges pressure sensors and feedback loops makes it easier to control operational conditions. The range of temperature and pressure highly determines the pipe’s dimensional precision, surface quality, and mechanical strength to ensure compliance with high industry standards.

Enhancing the Design and Configuration of Screws for Improved Output Quality

It is necessary to optimize the design and configuration of screws in extrusion processes to ensure accurate control over the properties, energy consumption, and quality of produced items. In typical cases, screws are designed with distinct zones, namely feed, compression, and metering sections. These zones guarantee stepwise polymer melt flow, mixing, and melting in the screw. There is also barrier screw enhancement, which ascribing greater inline homogeneous material mixing and reduced shear defects. Viscosity behavior, thermal characteristics, and throughput requirements of the material can be tackled with appropriate screw designs. These designs guarantee energy consumption minimization, as well as output consistency maximization. To achieve optimal operational reliability of the machine, accurate alignment of the screw with the barrel, as well as optimal clearance tolerances,, is imperative to prevent material leakage and excluding wear.

How can manufacturers optimize their HDPE pipe extrusion process?

To maintain uniform melt characteristics and prevent material degradation, precise temperature control must be exercised across all extruder zones in the HDPE pipe extrusion process. Advanced screw designs that meet the required homogenization and throughput targets-specific melt flow of HDPE will also improve the efficiency of the process. Proper maintenance on all extrusion equipment should encompass alignment, wear, and other essential factors to consistently provide quality. Moreover, the use of high-quality dies and calibrators enhances pipe dimensions, surface finish, and efficiency in material utilization. Lastly, consistent monitor and control systems should be put into place to ensure that process parameters such as pressure and melt flow rate are continuously maintained for better efficiency and uniformity of the products.

Fine-tuning extruder parameters for maximum efficiency

In a bid to achieve optimal productivity in fine-tuning extruder parameters, certain elements, such as temperature settings, screw speed, and pressure control, need to be refined. When producing HDPE pipes, the profile of barrel temperatures will typically range from 180 degrees centigrade to 220 degrees centigrade, depending on the grade of HDPE being used. This specific range guarantees optimal melting without significant thermal degradation. Temperature controls and screw speed should be adjusted to balance throughput and melt quality; 50 to 100 rpm is frequently used but is not universal. Melt pressure, usually 25 to 30 MPa, must be maintained for extruded structures to avoid defects.

In addition, die temperatures between 190 degrees Celsius and 210 degrees Celsius provide the pipe with a smooth surface free of imperfections. Their dimensional stability needs to be maintained in vacuum sizing calibrating systems and water cooling, and the temperature of water baths should be controlled between 15 degrees Celsius and 25 degrees Celsius. Finally, water bath temperature which greatly impacts dimensional stability needs to be monitored in real time to facilitate immediate adjustments where necessary. Such active assistance enables consistent production quality and reduced materials waste.

Integrating precision cooling techniques

The finesse of extrusion processes lies in the accuracy of heat transfer during cooling. This ensures greater productivity and dimensional accuracy of the extruded features. To ensure precision temperature control along the product, dynamic water flow regulation and multi-zone cooling systems are utilized, as well as the combination of water and air cooling for rapid phase changes and chilled water systems for achieving the desired cooling rate. Thermal imaging cameras also contribute to surface temperature control by minimizing stresses within the product and ensuring cooling performance consistency while increasing production efficiency.

Using advanced customized extruders

In cases where the finest detail is required for specialized extrusion processes, high quality customized extruders provide the best solution as they have flexible operational limits. These limits can be in the form of temperature, pressure, and screw speed. Additionally, these extruders are custom-made so that they perform well with the material being processed, increasing mixing, homogenization, and even throughput efficiency. Advanced screw designs, unique barrel geometry, and enhanced control systems account for customization that improves product quality and operation reliability. Enhanced durability and energy efficiency, and standard compliance comes from precision engineering and robust material, making them a fundamental part for maintaining dependable and high caliber extrusion yields.

What are common challenges in HDPE pipe extrusion and how to overcome them?

Challenges such as irregular wall thickness, surface irregularities, and melt fracture are common in high-density polyethylene (HDPE) pipes extrusion. These are usually due to fluctuations in process parameters, material characteristics, or equipment calibration. Surface scratches or markings can be reduced by maintaining the cleanliness of the die and using an optimal puller speed to decrease the chances of damage during cooling. To address flaws like surface defects and inconsistency in wall thickness requires thorough optimization of die and mandrel settings, as well as cooling uniformity throughout the length of the pipe. For melt fractures and surface irregularities on the pipe surface, the extrusion speed should be decreased, the melt temperature should be lowered, and a more easily flowing resin should be used. In real-time, process stability and product quality can be improved substantially by adding process monitoring systems.

Managing Instabilities in Melt Flow

Melt flow instabilities during HDPE pipe extrusion can be managed by concentrating on the process parameter techniques. I set the extrusion rate and temperature of the melt to flow adequately to prevent surface defects due to excessive shear flow. Additionally, I use suitable resins with better rheological flow properties to aid in uniform flow. Equipment condition is also critical to note since worn extruder parts can cause irregularities. These production concerns allow me to reduce the extrusion process’s instabilities and improve the product’s defect rate.

Controlling Thickness Deviation of Pipe Walls

Deviations in thickness of a pipe wall can be reduced by ensuring there is a uniform flow of materials which is maintained through proper die and extruder controls. Consistent melt temperature is critical, as streaks in temperature can lead to inconsistent material flow. Through the use of calibration with routinely checked equipment, wear and alignment problems can be identified. In addition, using good quality materials with consistent rheological properties leads to more stable final product flow. Consequently, implementing more sophisticated monitoring systems reduces deviations in wall thickness.

Resolution of the concerns regarding air gaps

The proper resolution to the concerns regarding air gaps should be undertaken by optimizing the shooting process parameters, since the air gap participates in determining product size and surface. An appropriate combination of line speed and precision control of the cooling system facilitates the mitigation of environments that induce changes. Tightening the tension in the material during passage from the die to the coolant further stabilizes the process. Moreover, the impact of air gaps inconsistency on the end product can be significantly reduced through more accurate equipment settings and more sophisticated control systems.

How to ensure consistent quality in HDPE pipe production?

Attention to detail when selecting materials, high grades of equipment maintenance, and optimized process parameters ensure quality in HDPE pipe production. The use of homogenous high-grade HDPE resin is necessary to ensure that the final product remains uniform. Flow and extrusion dimensions are maintained due to proper calibration of the extruders and die heads. Implemented robust monitoring systems allow operators to detect anomalies in real-time, eliminating the problem pro-actively. Maintaining a specific cooling temperature during the entire production process minimizes deformities, and more inspection during production processes ensures the meeting of thresholds.

Ensuring Initial and Continuous Monitoring through Systemic Measures

The systematic evaluation of every production step undertaken guarantees defect free production of HDPE pipes. Automated systems are utilized within the plants to check tube dimensions, material, and surface finish and check various other distinguishing features. Tracking raw materials and production steps and editing them when necessary in the oversights help increase accuracy and speed. Moreover, plant operator training helps improve the effectiveness of the protocols that are set in place. Finally, the ability to check for deviations and rectify them shifts accuracy reliability from the automated systems to the trained personnel.

Tracking and changing significant parameters of a process

Tracking and modifying significant process parameters is very important to achieve uniform quality and proper functioning of HDPE pipes. The extrusion temperature, screw speed, die head pressure, and cooling rates are some of the process parameters that require strict control if accuracy and material quality are to be maintained. As an example, extrusion temperature is usually between 190°C and 250°C depending on the type of HDPE, because these parameters set too low or too high can cause improper melting or degradation of the material. Particular care should be taken in setting screw speed because it affects the consistency of flow and, consequently, wall thickness. Die head pressure should also be controlled within ranges to allow alterations to be made without causing deformation of the final shape.

On the other hand, cooling rates influence crystallinity and mechanical strength; excessive cooling can create internal stresses while too slow cooling rates can cause some warping. Machines sensors should be routinely calibrated and monitored so that the changes can be done immediately. This makes it possible to do something before the deformation increase becomes a problem. This integrated approach enhances the efficiency and reliability of HDPE pipe production processes.

Performing periodic examinations and tests

Performing periodic examinations and tests is essential to establishing systems or processes’ reliability, safety, and compliance. It is possible to perform inspections regularly to help spot any defects or defection at an early stage, which assists in reducing the risks of failures and promptly addressing them. Evaluations measure the goal and provides information regarding the levels of performance attained which helps in compliance with regulatory requirements and the judicious use of resources. A balanced approach, proper record-keeping, and adherence to industry standards are essential in improving this practice.

Reference sources

Frequently Asked Questions (FAQs)

Q: What is HDPE pipe extrusion and why is it important?

A: HDPE pipe extrusion is the process of creating high-density polyethylene pipes using thermoplastic materials. It’s important because HDPE pipes are widely used in water supply systems and other applications due to their durability, flexibility, and resistance to corrosion. Understanding this process is crucial for optimizing production and ensuring high-quality plastic pipes.

Q: What are the main components of a single screw extruder used in HDPE pipe production?

A: The main components of a single screw extruder include the hopper for feeding raw materials, the barrel with a rotating screw for melting and mixing the plastic, the extrusion die that shapes the molten plastic into a pipe, and cooling systems. These components work together to process HDPE resin into pipes of various diameters and wall thicknesses.

Q: How does the extrusion die affect the quality of HDPE pipes?

A: The extrusion die plays a crucial role in determining the pipe’s final shape, diameter, and wall thickness. A properly designed die ensures uniform distribution of molten plastic, resulting in consistent pipe dimensions. Incorrect die design or wear may result in defects such as uneven wall thickness or surface imperfections, affecting the pipe’s performance and durability.

Q: What are the key factors to consider when setting up the cooling process for HDPE pipes?

A: Proper cooling is essential for maintaining the desired pipe dimensions and properties. Key factors include the cooling method (water or air), cooling rate, and air gap distance between the die and cooling system. The cooling process must be carefully controlled to prevent warping, ovality, or internal stress in the pipe. Water cooling is often preferred for faster production rates, while air cooling may be used for smaller diameter pipes.

Q: How can I optimize the single screw extruder process for HDPE pipe production?

A: To optimize your process, focus on temperature control throughout the extruder, screw design and rotation speed, material feed rate, and die design. Regularly monitor and adjust these parameters to maintain consistent output. Additionally, ensure proper maintenance of equipment and use high-quality raw materials.

Q: What are some common challenges in HDPE pipe extrusion and how can they be addressed?

A: Common challenges include maintaining consistent wall thickness and diameter, managing high-temperature processing, and dealing with the higher melt viscosity of HDPE. These can be addressed by carefully controlling process parameters, using appropriate screw and die designs, and implementing precise cooling systems. Regular quality checks and adjustments based on feedback can help maintain product consistency.

Q: How does the choice of HDPE resin affect the extrusion process and final pipe properties?

A: The choice of HDPE resin significantly impacts the extrusion process and the final pipe properties. Different grades of HDPE have varying melt flow rates, molecular weights, and additives, which affect processing conditions and end-product characteristics. Selecting the appropriate resin is crucial for meeting specific requirements such as internal pressure resistance, long-term strength, and environmental stress crack resistance.

Q: What quality control measures are essential in HDPE pipe extrusion?

A: Essential quality control measures include continuous monitoring of pipe dimensions (diameter and wall thickness), surface quality inspection, pressure testing, and material property testing. Implementing in-line measurement systems, regular sample testing, and comprehensive documentation of production parameters are crucial. These measures ensure that the extruded HDPE pipes meet industry standards and customer specifications.

Q: How can I troubleshoot issues with pipe dimensions in the HDPE extrusion process?

A: To troubleshoot dimension issues, first check the die and calibration sleeve for wear or damage. Adjust the melt temperature, screw speed, and cooling parameters if necessary. Ensure proper alignment of the extruder and downstream equipment. If problems persist, examine the raw material quality and consistency. Keeping detailed records of process parameters can help identify the root cause of dimensional variations.

Q: What are the latest innovations in HDPE pipe extrusion technology?

A: Recent innovations include advanced control systems for precise parameter management, improved screw designs for better mixing and melting, energy-efficient heating and cooling systems, and in-line quality control technologies. Some extruders now incorporate smart features for predictive maintenance and real-time process optimization.