The extrusion machines used for high-density polyethylene (HDPE) pipes are essential in producing reliable HDPE pipes, common in construction, agriculture, and utilities. Picking the right extrusion machine requires knowledge of numerous technical details such as production capacity, material compatibility, energy use, and operational accuracy. This guide focuses on creating an easily understood evaluation strategy concerning these factors so that you can make an informed decision based on your specific needs. This article will direct you toward the most appropriate HDPE pipe extrusion machine, considering cost-effectiveness, key machine specifications, and technological advances to help achieve an effective manufacturing system.

What is an HDPE Pipe Extrusion Machine and How Does it Work?

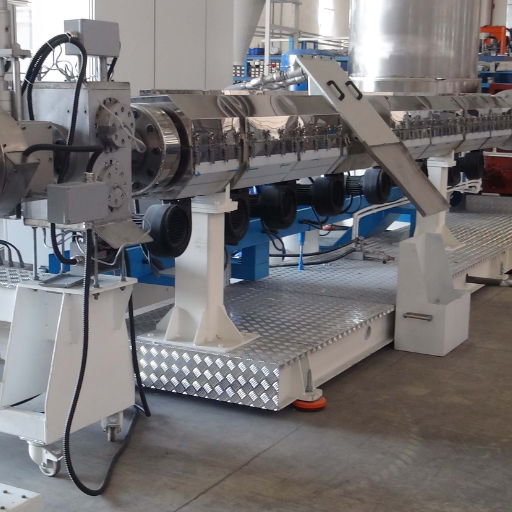

An HDPE extrusion machine is a specialized appliance designed to continuously manufacture high-density polyethylene (HDPE) pipes. The process starts with feeding HDPE resin pellets into the heated barrel where they are melted and homogenized by the screw mechanism. The molten material is then pushed through a die, where it is formed to the desired pipe size. After extrusion, the pipe is cooled and solidified, usually in a water tank or with a spray system, and then cut to size. The method used ensures accuracy in pipe diameter, wall thickness, and overall quality which makes it ideal for water distribution, gas transmission, and industrial piping.

In-depth knowledge on HDPE pipe extrusion

Extrusion of HDPE pipes refers to modifying high-density polyethylene resin pellets to produce pipes of different shapes through a well controlled procedure. Of importance are these processes, heating and melting the resin, homogenizing it with a screw mechanism, forming the pipe with a custom die, then cooling to fix its shape. This method provides the pipes with stable quality for more demanding uses, including water systems and industrial main lines.

Crucial parts of an HDPE pipe extrusion line

- Extruder: This is the main element, in which HDPE resin pellets are heated, melted, and then homogenized. It has a heated barrel and screw which mixes and moves the material toward the die constantly.

- Die Head: A die head broadly defines the shape of the tubing and its dimensions. In this case, the die design determines the dimensions of the pipe along with the volume of the cavity such that it satisfies all the requirements.

- Cooling System: After leaving the die, the pipe enters a cooling system, usually a water tank or spray chamber. At this stage, it is important to solidify the material and achieve dimensional stability to avoid any deformations.

- Haul-Off Unit: The haul-off unit is equipped with belts or rollers to pull it along the extrusion line while engaging the pipe. For average haul-off rates, any speed increase is limited to a controlled acceleration since the pipe walls must not yield under pressure.

- Cutting Machine: This unit will cut the pipe to length according to the customer’s requirements. The adjacent unit employs a saw blade or rotary cutter, depending on the pipe material and outer diameter.

- Control Panel: The control panel knows all, and can model the process by adjusting temperatures, speed, and pressure. A modern extrusion line is often equipped with a control system that is more exact and proficient than other manual systems.

The Purpose of the extruder in the fabrication of HDPE pipes.

At the heart of the fabrication of HDPE pipes is the extruder, which guarantees that a raw material is made to flow homogeneously and even melt for the shape to be formed. The Extruder is central in several things: material feeding, melting, pressurizing, and screw conveying.

- Material Feeding: Additional ingredients like stabilizers or pigments for better performance are incorporated together with HDPE resin into the hopper to be injected.

- Melting: The raw material is heated using a grade containing HDPE pipes. Chunky portions are placed inside the chest iron and intensively heated. Rotating meat grinder features are put for less friction features that provide fast heating.

- Pressurization: The design screw develops the needed pressure between 100 and 300 bar which guarantees the needed flow of the melt to provide an accurate finishing dimension of the HDPE pipes.

- Conveying: The screw is rotated in such a manner that the molten HDPE is transported smoothly to the die, without any flow inconsistencies that could surely cause structural defects.

The extruder is the basis for the entire extrusion process by ensuring these parameters are precisely controlled, guaranteeing high quality output.

How to Determine the Right HDPE Pipe Extrusion Machine Capacity for Your Needs?

To assess production needs, it is first necessary to determine the production output potential, as this influences the diameter of the machines screw, extrusion volume, and pipe size. Next, consider the properties of the HDPE that will be processed, such as the melt flow index (MFI) and the composition of the additives, as these factors will affect both the melting time and processing temperature. Moreover, the degree of automation and control necessary to improve pipe output accuracy and consistency should be considered. Finally, confirm that the machine meets the relevant energy efficiency standards, is suitable for the cooling tanks and cutters on the production line, and optimizes performance and efficiency. In summary, a machine that meets the outlined production criteria and targets can be selected.

Essentials of HDPE pipe production output

- Raw Material Quality

Contaminants that affect the melt flow index (MFI) and deviations in grade level have the potential to affect the mechanical properties of a pipe, therefore it is crucial to consider the grade and type of resin used for HDPE pipes.

- Extrusion Temperature Control

Managing temperatures with precision is significant for ensuring HDPE’s uniform melting and extrusion. Any discrepancies in the temperature of the barrel or die can lead to defective pipes with uneven wall thicknesses or scratches on surfaces.

- Screw Design and Performance

The rate of melting and mixing of the material is regulated by the efficiency and design of the extruder screw. Factors such as screw geometry, L/D ratio, pitch, among others govern the extrusion throughput and the final quality of the product.

- Die Design and Calibration

The shape of the extrusion die directly affects the pipe’s dimensional accuracy and uniformity. Correct die calibration guarantees that the pipe diameter and wall thickness are consistent, which saves material and minimizes wastage.

- Cooling System Efficiency

Proper cooling during the extrusion process is crucial to ensure that the HDPE pipe does not warp and retains its shape while providing the necessary support to the ends. The design of the cooling tank and water flow rate must be compatible with the production speed and size of the pipes.

- Line Speed and Automation

Optimized line speed is very important for high throughput with acceptable pipe quality. Modern automated systems can monitor and control parameters, greatly improving the process’s efficiency.

- Equipment and Parts Reliability

Maintenance of extruder machines, including its barrel, screw, and other downstream machines, is a prerequisite for reliable performance of the system. Equipment in disrepair is more likely to incur extra downtimes in addition to quality loss.

- Quality of Power Supply

Constant and stable energy input is crucial for systems that require high power levels such as extruders. Voltage dips or blackouts can halt production, endanger machinery, and lower production efficiency.

Determining Necessary Pipe Diameter and Thickness

Determining the necessary pipe diameter and thickness involves consideration of the internal pressure, fluid type, temperature, and flow rate. In order to assess some of these variables, first, the design pressure for the system must be defined, along with the maximum stress the material can bear. A wall thickness can be calculated using Barlow’s formula. It requires the pipe internal diameter, pressure, and material strength. Some other considerations include environmental loads external forces, plus a factor for corrosion. Compliance with industry standards such as ASTM or ISO guarantees safety and performance for the intended application.

Matching machine capacity to your production goals

Blending machine capability with business targets requires a comprehensive view of the operation’s needs and the machine itself. I always start with calculating the maximum production output needed. This involves estimating the necessary material, cycle times, and potential downtime. Next, I cross-match these requirements with other machines’ throughput capacity and efficiency. A perfect blend between productivity and productivity cost is achievable by making sure that the machine has enough capacity to deal with peak demand periods without being significantly underutilized during routine operations. Lastly, I check the machine’s scalability and future growth requirements against the projection goals.

What Are the Key Features to Look for in a High-Quality HDPE Pipe Extrusion Machine?

Several identifying features must be considered when choosing the best HDPE pipe extrusion machine. A mold-temperature controller is needed to ensure a defect-free extrusion process. The screw and barrel geometry must enable mixing, the melting of the HDPE resin, and free flow for a broad range of applications. Another important aspect is the saving benefits gained with modern heating elements and motor constructions. Over time, high-quality build, including anti-corrosive materials, will guarantee low service needs and long operational life. Automation, such as process supervision and control in a humanless environment, also favors productivity and reduces the chances of mistakes. In addition, working with different die heads and other downstream devices provides adequate flexibility to cope with varying production requirements.

Key aspects of successful HDPE pipe manufacturing

Efficient HDPE pipe production depends on several interrelated components working seamlessly. A high-performance extrusion system, featuring precision-engineered screws and barrels, ensures uniform melting and flow of the HDPE material. Advanced temperature control mechanisms are vital to maintain consistent quality and avoid irregularities in the pipe structure. The design and adaptability of die heads play a crucial role in achieving high accuracy of different pipe dimensions and wall thicknesses. Additionally, downstream equipment, such as cooling systems and haul-offs, must harmonize to solidify and shape the pipe effectively. Automation and monitoring technologies significantly enhance efficiency by maintaining stable production parameters and reducing downtime. An optimized system tailored to production demands ensures both operational efficiency and long-term reliability.

Development in the field of automation in modern HDPE pipe extraction lines

New-generation HDPE Pipe extruders employ multi–functional automation and modern inventions to improve their efficiency and accuracy. These systems usually include electric drives and motors with high-energy performance that cut down expenses while ensuring elevated productivity. At the same time, the systems are equipped with set of laser measurement tools, which monitor the pipe’s diameter in real time, readying the pipe by the existing industrial regulations. Advances in smart control systems allow for the automatic modification of parameters during the extrusion base process on the process history data, thereby having the output with minimal waste. In addition, the availability of multi–layered extruders gives the pipes special features, enhanced strength, UV blocking, lightweight, etc., for different applications. These cumulatively improve efficiency, product value and sustainability of the entire operational process.

New developments in automation in the making of HDPE pipes

Automation has become an integral feature in making HDPE pipes, mainly due to its efficiency, accuracy, and uniformity. Automated systems facilitate production by monitoring and controlling temperature, pressure, and extrusion rate in real-time. For example, these systems guarantee different wall thicknesses by controlling the extrusion rate, which is required for HDPE pipes in compliance with ISO and ASTM standards.

By minimizing human interaction in processes such as pipe cutting, stacking, and packaging, novel robotic handling systems significantly enhance productivity. In addition, these systems help in cost-saving by decreasing the amount of manual labor needed. Furthermore, closed-loop control systems facilitate the processes by modifying the values of specific parameters through data obtained from the processes themselves, which leads to more significant savings in materials and energy. The systems’ features, including high-precision sensors with an accuracy of 0.01 mm, help explain how these systems can perform such tight tolerances.

Such a high level of automation not only guarantees adherence to set standards, but also enhances flexibility by allowing for increased production quantities while maintaining the desired quality. As the primary reason for the cost-effective HDPE manufacturing processes is human error mitigation and effective resource allocation, these high-throughput systems offer great economic sustainability.

How to Choose Between Single Screw and Twin Screw Extruders for HDPE Pipe Production?

The choice of single screw or twin screw extruders for HDPE pipe production must take the processing efficiency, throughput, and material handling requirements into account. Single screw extruders are often preferred because of their lower initial cost and greater ease of operation. They are well suited for processing HDPE stems with relatively constant material properties and achieving intermediate throughput levels in other moderate applications.

On the other hand, twin screw extruders are more efficient because of their increased mixing and pumping capacity and their ability to control other critical processing parameters more accurately. Twin screw extruders are incredibly efficient in the presence of high additives or when complex compounding needs to be done. Though they are usually more expensive, intricate to operate, and costly to maintain than single-screw extruders, their greater flexibility and higher productivity make them ideal for harsh and demanding production environments. The right extruder for a specific application is determined by looking at the price, expected production volume, and the complexity of material processing.

Contrasting single screw with twin screw extruders

It is important to compare single-screw and twin-screw extruders regarding these features and their specific operating capabilities. Single screw extruders are simpler in configuration which reduces maintenance and operational expenses. They work well with dependable materials, and their design is best suited for processes with consistent outputs and reasonable throughput levels. In single screw extruder, practical processing activities are controlled by a few fundamental parameters: screw diameter, length and diameter ratio (L/D), and extrusion pressure.

On the other hand, twin screw extruders dominate in applications that need sophisticated mixing of ingredients and a higher degree of process control, including flexibility in elements that are to be processed. They make use of either co- or counter-rotating screws which effectively facilitate mixing, especially for materials with additives or when complex compounding is required. The technical parameters of twin-screw extruder designs usually require higher inputs such as power, torque, and control over screw speeds, as well as changes in material viscosity. Despite the increased investment costs, these machines have higher productivity and broader processing capabilities such as multi-phase polymers and compounds containing reinforcements.

The decision-making process should reflect the selection of material properties, the complexity of the production procedure and processing, and the funding of the initial investment versus long-term operational expenditures.

Benefits of Single Screw Extruders When Used For The Extrusion of HDPE Pipes

Single screw extruders can be operated at a lower cost and are easier to use when producing high-density polyethylene (HDPE) pipes. Single screw extruder are designed to perform more effortlessly for steady-state operations where the flow rates of materials are expected to be constant. The design ensures simple operation and low maintenance with a smaller footprint, making them an economically viable choice for various applications. Efficient melting and homogenization of the HDPE material is achieved through parameters such as L/D ratios that are usually between 25-30 and screw diameters that vary between 60-150 mm, depending on the desired pipe size.

Single screw extruders achieve effective results through the controlled shear which is formed by the screw action. Controlled shear also reduces the degradation effects of the material properties. Thus, the screw action helps to preserve the pipes outstanding mechanical performance. Without the precise temperature control that is proportioned along the barrel zones, the single screw extruders would be ineffective. Such machines guarantee uniform melting and avoid overheating.

Furthermore, single screw extruders are more efficient in saving energy because they are built with fewer complex parts that require greater power. Pipes made with polymeric materials that are simple in creaming or free of advanced additives greatly improve the performance of the systems. All these facts have helped reduce costs while improving reliability and efficiency. These are the reasons single screw extruders are preferred for producing pipes from HDPE.

When to examine twin screw extruders for HDPE pipe manufacturing

In circumstances where using advanced formulations, such as the ones with additives or fillers, requires accurate mixing and processing, twin screw extruders should be examined. They are superior to other counterparts, as they are proficient in processes requiring a high level of control over material properties and complex compounding, thus ensuring consistent quality and proper dispersion. Also, their flexibility to process variable material viscosities and compositions render them suitable for the strenuous requirements of HDPE pipe manufacturing when high customization and performance is a requirement.

What Are the Differences Between HDPE, PE, and PVC Pipe Extrusion Machines?

The differences in the purpose of use, processing needs, and material compatibility distinguish HDPE, PE, and PVC pipe extrusion machines. For instance, machines designed for HDEP extrusion are meant to work with high-density polyethylene thermoplastic extrusion rods because it is water and gas pipelines’ corrosion, deformity, and flexibility resistant. On the other hand, PE extrusion machines are designed to process low-density and linear low-density grade polyethylenes for more flexible applications such as tubing and packing, so it is less versatile. In contrast, polyvinyl chloride pipe extrusion machines are explicitly designed to produce the rigid thermoplastic polyvinyl chloride pipes mainly used in drainage and conduit systems. Still, their extrusion processes require accurate temperature management due to their thermosensitivity. Each machine type is manufactured to work with specific polymers, which helps achieve the highest efficiency and product quality within the polymer’s specific application.

Considerations for HDPE Pipe Extrusion Machine Production

There are numerous efficient constructions meant for maximum production with increased productivity. In most cases, these machines have new patterns in the screws and barrel components, which guarantee the accurate melting and homogenization of polyethylene. Furthermore, the machines contain energy-efficient heating and automated control systems which guarantee optimal processing temperatures and speeds, ensuring precise pipe wall thicknesses and dimensions. Also, the machines usually have efficient buildings for solidifying the polypipes and vacuum calibration tanks and spray cooling to ensure fast solidifying speed while the pipes maintain their structure. Due to these capabilities, such machines make it possible to manufacture pipes of different diameters, which can be used for water supply, gas distribution, and other industry applications.

Comparing HDPE, PE, and PVC pipe production processes

The processes for making the pipes HDPE, PE, and PVC necessitate different dimensions concerning the qualities of the material, requirements for the processing phase, and their intended use. While high-density polyethylene (HDPE) and polyethylene (PE) pipes utilize polyolefins, an aspect that brings them together in terms of production, PE pipes HDPE possess higher density and tensile strength from increased crystallinity. The production of HDPE pipes employs extrusion processes with temperature parameters set between 180°C to 250°C, close supervision of the melt flow index (MFI) the mix is subjected to must also be observed to maintain the consistency of the material. Key technical parameters also involve controlling die head pressure to approximately 28 mpa and cooling measures through vacuum calibration tanks for achieving dimensional accuracy.

On the opposite side of the spectrum are polyvinyl chloride (PVC) pipes which are produced using unplasticized polyvinyl chloride which skews requirements for processing conditions. The extrusion of PVC is done at much lower temperatures, 150 – 200°C, as PVC tends to decompose when above that heat is applied. As with any process, these steps require a specific simple blending of additional materials means such as heat stabilizers, plasticizers, and impact modifiers that will ensure that the process and resulting products will be much better. Other important factors, such as screw design as well as die and system placement, must be controlled so that a high temperature does not destroy the materials too easily.

While the HDPE and PE pipes are famous for their flexibility, toughness, and resistance to chemicals, PVC pipes have an edge over the former due to its rigidity, ease of joining, and capability of functioning under high pressure. If a manufacturer grasps the crucial technical considerations for each material, he can plan production effectively to suit the intended purpose.

Choosing the appropriate machine for the specific market requires analyzing specific needs

The appropriate machine is to be chosen with specific consideration to the needs of your target market. Consider the materials normally worked on such as HDPE or PVC. The machine should be able to produce the required pipe dimensions like diameter, wall thickness, and operational temperature range. The machine should also be able to scale up production in the future, allowing for quicker fulfillment of production goals. The machine’s economic feasibility should also be considered along with controlling primary expenses like energy consumption and maintenance. The machine must be precise and reliable to consistently achieve the quality standards of the end product which would require industrial-grade or high-pressure machinery.

How to Evaluate HDPE Pipe Extrusion Machine Suppliers and Manufacturers?

Suppliers and manufacturers of HDPE pipe extrusion machines should first look into their years of operation and reputation in the market. Verify their certifications against international quality standards like ISO and CE, as they indicate reputable factories. Check the range of products on offer to ensure that your production processes will be met, including any modification that may be necessary. Look at the level of coverage of technical assistance and after sale services for effective operations and efficiency. Also, consider their timelines for delivery, warranty, and cost without hidden fees. Analyzing and comparing various suppliers will aid in finding the most suitable supplier for your business requirements.

Key factors to consider when choosing a supplier

While seeking a supplier for HDPE pipe extrusion machines, technical knowledge and experience should take precedence. The best supplier should prove to abide by international quality requirements like ISO 9001, which ensures quality design, production processes, and operations. Their equipment should be of higher order extruders with high-torque gearboxes, motors, and temperature control for efficient output.

Assess the degree of flexibility for customization and compatibility of materials, confirming that the machinery can accommodate multiple HDPE grades and the desired production parameters such as the range of pipe sizes and wall thickness. Items such as extrusion capacity, ranging from 50kg/h to 1200kg/h, or screw configurations (single or twin-screw designs) serve as some important technical indicators of machine capability and efficiency because they have a direct impact on output quality.

Another important consideration is the comprehensive after sales service that provides the requisite technical support, spare parts availability, and warranties for critical components: barrel, screw, control system, etc. Addressing these issues will facilitate operations, reduce stoppage time, and stabilize the production of HDPE pipes throughout their life. Efficient and well-defined pricing and delivery practices will guarantee a healthy and productive partnership.

Importance of after-sales support and spare parts availability

Dependable after-sales services and the availability of spare parts play an integral role in preserving a company’s production efficiency and reducing operational downtimes. Comprehensive support to equip customers with all necessary services ensures that all technical problems are resolved within a very short time frame. At the same time, the magnitude of disruptions in the capital stock utilization is minimized dramatically. Additionally, the presence of spare parts significantly reduces the risk of prolonged interruptions associated with equipment failure. Purchasing machines from suppliers who guarantee responsive after sales service increases the consistency of the equipment’s performance, prolongs the service life of the machines, and improves the net benefits from enhanced productivity and lowered maintenance activity.

Assessment of warranties, guarantees and Maintenance contracts

Assessment of warranties, guarantees, and Maintenance contracts requires consideration of important elements. Start with an overview of the scope of the warranty in terms of duration, coverage and protection against critical failures or defects. Establish if there is any routine maintenance service as part of the agreement, and how it is scheduled during non-operational periods. Examine the terms related to response time for repairs or replacements to determine if malfunctions are resolved quickly. It is also critical to assess if coverage includes parts and labor costs, should the agreement have exclusions or limitations. Also, check the breadth of the service network, availability of support and the level of the provider’s technical expertise and his willingness to help in order to maintain and restore systems as quickly and efficiently as possible.

Reference sources

Frequently Asked Questions (FAQs)

Q: What factors should I consider when selecting an HDPE pipe extrusion machine?

A: When selecting an HDPE pipe extrusion machine, consider factors such as production capacity, pipe diameter range, output rate, automation level (e.g., PLC control), energy efficiency, and the machine’s ability to handle high-density polyethylene (HDPE) and other materials like MDPE. Also, consider the machine’s long service life, corrosion resistance, and compatibility with your existing production line.

Q: What are the advantages of using HDPE pipes for water supply systems?

A: HDPE pipes offer several advantages for water supply systems, including excellent corrosion resistance, long service life, flexibility, and resistance to chemical degradation. They are also lightweight, easy to install, and can withstand high pressure. HDPE pipes are ideal for both underground and above-ground applications, making them a popular choice for water supply infrastructure.

Q: How does the output rate of an HDPE pipe extrusion machine affect production?

A: The output rate of an HDPE pipe extrusion machine directly impacts production efficiency. A higher output rate allows for faster production of HDPE pipes, increasing overall productivity. When selecting a machine, consider your desired production volume and choose a model with an appropriate output rate to meet your needs. Some advanced machines offer adjustable output rates to accommodate different production requirements.

Q: Can HDPE pipe extrusion machines produce pipes of various diameters?

A: Yes, many HDPE pipe extrusion machines are designed to produce pipes of various diameters, ranging from small (e.g., 20mm) to large diameter pipes. Some machines are specifically built for producing large diameter HDPE pipes, while others offer versatility in diameter range. When selecting a machine, ensure it can produce the pipe sizes required for your specific applications.

Q: What role does automation play in HDPE pipe extrusion machines?

A: Automation, often implemented through PLC (Programmable Logic Controller) systems, plays a crucial role in modern HDPE pipe extrusion machines. Automated systems enhance production efficiency, maintain consistent quality, and reduce human error. Advanced machines may offer automatic grade control, ensuring the proper mix of materials and maintaining optimal extrusion parameters throughout the production process.

Q: How do I determine the right HDPE pipe extrusion machine price for my budget?

A: Determining the right HDPE pipe extrusion machine price depends on various factors, including production capacity, features, and brand reputation. Consider your long-term production needs and potential return on investment. While higher-priced machines may offer advanced features and better efficiency, there are also cost-effective options available. Compare prices from different manufacturers, and don’t hesitate to contact them for quotes and additional information to find the best price for your specific requirements.

Q: Can HDPE pipe extrusion machines also produce fittings and other plastic products?

A: While HDPE pipe extrusion machines are primarily designed for pipe production, some versatile models can be adapted to produce fittings and other plastic products. However, specialized machines are often more efficient for producing fittings. If you require both pipe and fitting production capabilities, consider investing in a comprehensive HDPE pipe production line that includes separate equipment for pipe extrusion and fitting molding.

Q: How important is the material feeding system in an HDPE pipe extrusion machine?

A: The material feeding system is crucial in an HDPE pipe extrusion machine as it ensures consistent supply of plastic material to the extruder. A well-designed feeding system contributes to uniform pipe quality and reduces the risk of production interruptions. Look for machines with efficient feeding mechanisms that can handle various forms of HDPE, including pellets and recycled materials, to maximize flexibility in your production process.