Combining characteristics such as strength, flexibility, and cost-effectiveness has made High-Density Polyethylene (HDPE) pipes one of the most essential parts of modern piping systems. This article analyzes the sizes, technical parameters, and almost limitless applications of HDPE pipes in different industries. By showing the readers the various features of the pipes, such as their dimensions, pressure ratings, and material properties, the readers will have an authoritative knowledge of how these pipes are engineered to various operational demands. Furthermore, the discussion shall include safeguards regarding quality and safety standards for HDPE production and use. In this manner, professionals, engineers, and other decision-makers will have an informative guide for interpreting these data so they can select the best-suited HDPE pipe solutions for particular projects.

What are the standard HDPE pipe sizes available?

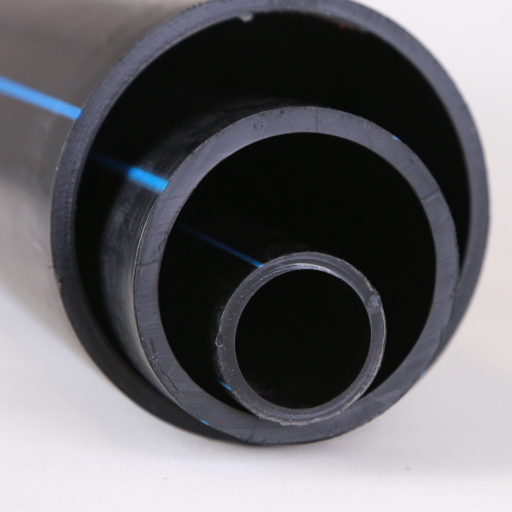

HDPE pipes are available in a wide range of standard sizes, typically defined by their outer diameter (OD) and categorized using Nominal Pipe Size (NPS) or Diameter Nominal (DN) metrics. Common sizes range from small diameters, such as ½ inch (DN 15), to large diameters exceeding 63 inches (DN 1600). These sizes are designed to accommodate various residential, commercial, and industrial applications. The corresponding pressure ratings, or SDR (Standard Dimension Ratio) classifications, further define their suitability for specific operational conditions.

Common diameter ranges for HDPE pipes

HDPE pipes typically come in diameter ranges starting from 16 mm (approximately 0.63 inches) for smaller applications and extending up to 2000 mm (approximately 78 inches) for large-scale projects. These diameter ranges cater to diverse requirements such as irrigation, water distribution, sewage systems, and industrial pipelines, with specific sizes tailored to meet varying flow capacity and pressure demands.

Understanding IPS and DIPS sizing systems

IPS (Iron Pipe Size) and DIPS (Ductile Iron Pipe Size) are two sizing systems used to define HDPE pipe diameters, primarily influenced by legacy standards and compatibility with existing fittings or systems. IPS sizing is modeled after the traditional iron pipe measures, with dimensions defined in inches, making it more common for applications requiring adherence to U.S. customary units. On the other hand, DIPS sizing aligns with ductile iron pipe standards, facilitating use in larger-scale projects and systems that necessitate higher strength and compatibility with ductile iron components.

Technical Parameters:

- IPS Dimensions:

- Outer Diameter (OD): Typically ranges from ½ inch to 24 inches.

- Applications: Frequently used for residential and smaller-scale commercial systems.

- SDR/Pressure Ratings: Can sustain working pressures varying from 63 psi (SDR 26) to 250 psi (SDR 7).

- DIPS Dimensions:

-

- Outer Diameter (OD): Commonly begins at 4 inches and can extend to 63 inches.

- Applications: Ideal for larger municipal and industrial use cases, such as water mains and sewer systems.

- SDR/Pressure Ratings: Depending on the SDR classification, they are often designed for pressure classes up to 200 psi.

Operators ensure optimal interoperability with chosen fittings and operational environments by choosing the appropriate system.

How do I interpret HDPE pipe size specifications?

The specifications for High-Density Polyethylene (HDPE) pipes are based on several key parameters. One of the main measures is the Outer Diameter (OD), which is used along with the pipeline’s fittings to measure the surface area. Standard Dimension Ratio (SDR) also plays a part in pipe sizing. SDR refers to the correlation between the pipe’s wall thickness, diameter, and its pressure rating. “Thin-walled” pipes capable of low pressure have higher SDR values, while thick-walled pipes with high-pressure capabilities have lower SDR values. All these dimensions along with the pressure rating and application of the system ensure the proper selection and usage of HDPE pipes.

Decoding OD, ID, and wall thickness

Wall thickness, inner diameter (ID), and outer diameter (OD) significantly influence the physical dimensions and performance of the pipe. While OD refers to the measurement of the outer surface of the pipe, ID refers to the hollow interior. Strength and pressure tolerance of the pipes can be measured accurately using wall thickness, which is determined as the difference between ID and OD divided by two.

In the case of HDPE pipes, the features’ values are established concerning the SDR and pressure rating for the pipe. For example, a pipe with an outer diameter of 160 mm, SDR 11, and a pressure rating of 16 bar will have an ID of 130.8 mm and approximately 14.6 mm wall thickness. These parameters are set to guarantee the dependability and efficacy of water and gas pipelines. Undoubtedly, these factors must be precise, especially for safety and efficiency, which are subject to calculations such as the designated operational pressure, needed flow, and chosen material.

How SDR is Important in Sizing HDPE Pipes

SDR stands for Standard Dimension Ratio, and this is one of the most significant factors in sizing HDPE pipes because it sets out the ratio of the pipe’s outer diameter (OD) to wall thickness. This ratio is related to the pipe’s pressure capacity, which indicates that pipes with low SDR values have high pressure ratings. For example, an SDR 11 pipe will have greater thickness and, therefore, can endure higher operational pressures than an SDR 17 pipe.

The selection of appropriate Standard Dimension Ratio (SDR) is different for different applications, as well as their operating pressure and safety factors. As an example, the requirements of pressure in water or gas transmission pipelines must match the SDR of the respective pipe, else there will be mechanical failure. Technical parameters like the pipe material’s hydrostatic design strength, anticipated working pressure, and ambient conditions must be noted. For instance, PE pipes are classified as PE80 or PE100 with these standards determining the maximum permissible operating pressure and it is also reliable when used with the correct SDR. These calculations show that SDR significantly impacts achieving the right strength, durability, and balance of costs at skeletal systems of pipelines.

Nominal size vs. actual dimensions

The term “Nominal size” describes the standard reference size for pipes which are always rounded for easy referencing. It does not reflect the actual physical dimensions. Actual dimensions represent the pipe’s exact external diameter, internal diameter, and wall thickness individually. These dimensions are set based on the manufacturer’s tolerances and materials. As an example, the nominal size of HDPE or PVC pipes is standard but not identical to the actual internal or external diameters because of wall thickness which is constrained by the Standard Dimension Ratio (SDR). It is essential to understand both nominal size and actual dimensions to guarantee compatibility and performance in specific pipeline applications.

What factors should I consider when selecting the right HDPE pipe size?

A few factors must be noted while determining and selecting the appropriate balance of the diameter and thickness of the HDPE pipe. Start with gauging the system’s flow rate since that will have a bearing on the pipe’s internal diameter for optimal fluid transport. Check the pipe’s operating pressure and pressure rating (for example, SDR classification); it is critical to ensure that it will work in the intended application without failures. Furthermore, to ensure durability and appropriate chemical compatibility, consider the materials removed, such as water, gas, or chemicals. To protect against external damage and for sustained performance, environmental parameters, such as soil conditions and variances in temperature, should also be considered. Taking note of these factors properly aims supply and social meeting productivity, effectiveness, and endurance of the pipeline system.

How Water Pipes for Houses Supplies are Sized

- Residential Water Supply: The pipes for water supply at a household level are usually between half an inch and one inch in diameter. The smaller sizes suffice due to the high water pressure and the flow rate at the system’s various endpoints, such as faucets, showers, and other plumbing devices and appliances.

- Municipal Water Distribution: On the municipal level, pipes with larger diameters between 6 inches and 16 inches are needed to allow water transversal over a vast geographic region. These pipes manage high flow rates while maintaining sufficient service pressure for various populations.

- Industrial Applications: Industrial pipelines can often require diameters of above 2 inches, depending on the material being moved. For example, chemical processing plants often have their own required sizes that meet specific flow rates and chemical resistance levels.

- Oil and Gas Transmission: Oil and gas pipelines usually have diameters ranging from 16 inches to 48 inches. They are designed to be high-volumetric over long distances and efficient in maintaining high amounts of oil and gas.

- Sewage and Wastewater Systems: Sewer systems require large diameter pipes that often start at 4 inches and can go as far as 72 inches for primary underground systems in urbanized areas. These systems are crucial to deal with high flow rates and solids without being obstructed.

- Fire Protection Systems: Fire sprinkler systems depend on standard pipe dimensions which range from ¾ inch to 2 inches. These dimensions allow for necessary speedy water distribution in emergencies and compliance with other required regulations.

Flow rate requirements and pipe sizing

Requirements for flow rates are directly linked to the diameter of the pipe, the material it is made of, and the system’s intended purpose. The design should ensure that our flow rate can meet the system demands without experiencing excessive pressure loss. For example, domestic water supply systems tend to use 1/2-inch to 1-inch diameter pipes and have flow rate expectations between 6-12 gallons per minute (GPM). At the other end of the spectrum, larger systems such as municipal water networks expect flow rates in the thousands of gallons per minute, and require pipes with at least a few inches in diameter.

The equation flow rate (Q), velocity (V), and cross sectional area (A) is defined by the equation Q = A x V. For instance, a pipe with a diameter of 2 inches and a flow rate of 4 feet per second has a flow rate that can be approximated to 1.36 cubic feet per second (or 610 gallons per minute) approximately. On the other hand, if the water is fed through at an excessive velocity of above five – eight feet per second, the friction losses can erode the pipe while simultaneously increasing the chances of pipe erosion. This highlights and illustrates the gravity of base use pipe dimension necessities inaccurate estimations.

Also, to eliminate pressure drop that occurs in systems fluids die to pipe deformation roughness and internal diameter, the Hazen-Williams equation is mostly employed. As an example, depending on the length and configuration of a 4-inch PVC pipe, it may be able to sustain flow rates of well over 400 gallons per minute with acceptable pressure losses. These technical parameters exemplify the need and insistence of ensuring that the requirements of the flow rate are satisfied with correct estimation of the pipe size to improve system efficiency and ensure longevity.

Class Ratings of Pressure and its Consideration Towards Size Selection.

Class ratings of pressure determine the extent of a pipe’s working pressure, thus playing an essential role in selecting pipe sizes. Like ASTM, AWWA, or ISO specifies, these ratings are basic benchmarks for measuring ideal pressure thresholds. As an example, a pipe rated at 150 psi class is able to withstand a pressure of 150 pounds per square inch with normal operational conditions. Pipe size selection criteria incorporate these ratings along with the operating pressure, surge pressures, and safety limitations of the systems in question.

Some of the technical parameters associated with determining the size withstanding capacity of the pipe include its tensile strength, the thickness of the walls coined as wall thickness ratio SDR, and the temperature of the fluid being transported. For the systems that operate at high pressures, pipes with lower SDRs, portraying wall thickening, are more suitable. In High Density Poly Ethylene pipelines, an SDR 11 is best supported when operating at approximately 200 psi, while SDR 17 is more suited for buckling at approximately 125 psi. Choosing the correct class rating in conjunction with pipe sizing positively enhances compliance with numerous safety regulations, and this, in turn, facilitates increased structural integrity and economic relief of the system.

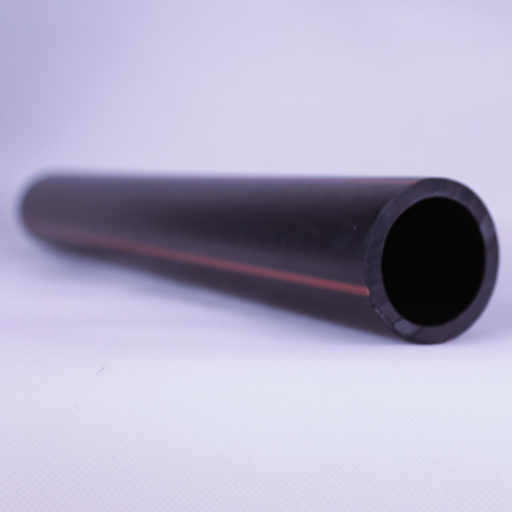

How do HDPE pipe sizes compare to other pipe materials?

Due to their flexibility, lightweight construction, and durability, HDPE pipes sizes differ from steel pipes, PVC, or ductile materials. Rigid materials such as PVC, steel, or ductile iron can’t be produced in longer lengths and smaller diameters, which can achieve a relative wall thickness-to-pressure ratio. Such a feature reduces the requirement for joints and ensures easy installation. This kind of unique design makes these pipes applicable for various purposes, as high SDR values can be used during the manufacturing process to provide the appropriate resistance to internal pressures. In contrast with steel pipes, which are prone to corrosion HDPE pipes are not, which increases durability in different conditions.

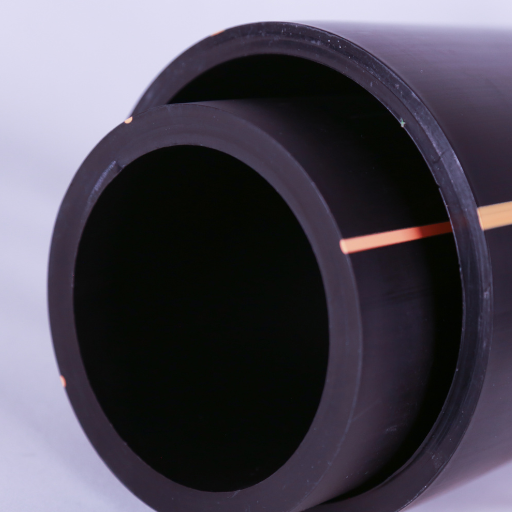

Comparison Of HDPE and Copper Tubing Size (CTS)

HDPE pipes are more flexible, lightweight, and cost-effective than copper pipes. Designed for different applications, both HDPE pipes and CTS have a standard diameter in CTS, which means they can also be used as a complement. The expense of adopting these technologies is greatly diminished over using copper because the cost of the material is lower, less time will be spent on jointing, and maintenance is cheaper. These features, alongside the corrosion resistance, prove that HDPE is a practical option for water distribution systems where long-lasting controlled performance is critical.

Variations of the Sizes of HDPE and Steel Pipes

Regarding size ranges, weight, and wall thickness, steel and HDPE pipes have great differences. While HDPE pipes are manufactured with outside diameters that correlate with specific pressure ratings, steel pipes are constructed with differing schedules and wall thicknesses that determine the amount of internal and external pressure the pipes can handle. Because HDPE pipes are lightweight and more flexible, they are cheaper and easier to install than steel pipes, which require more robust handling equipment because of their weight. Moreover, steel pipes are outperformed by HDPE pipes which have an increase in internal diameter but a decrease in nominal diameter, which results in the more efficient flow of water. These differences in properties are why each material is meant for a certain application and environment.

What are the sizing considerations for different HDPE pipe applications?

The intended application of the HDPE pipe, such as irrigation, industrial processes, or potable water systems, will affect the optimal size needed. Other factors to consider include the pressure rating and diameter as they impact the flow rate; the wider and stronger the pipe, the more resilient the HDPE pipe will be. Standard Dimension Ratio (SDR) indicates the ability of the pipe to withstand operational pressure, with thicker and more durable pipes exhibiting low SDR values. Aside from these factors, height, area of soil type, soil temperature, and structure flow will also need to be considered for best performance. Finally, strength and efficiency of the pipe will directly correlate with the aptitude of the chosen thickness and size. Lower SDR values will ensure the optimal performance of the pipe.

HDPE pipe sizes for potable water systems

In addition to choosing an appropriate SDPE size for the HDPE pipe, understanding the application’s flow rate requirement, temperature, and specific pressure rating along with their thresholds is a must. To comply with the set safety standards with a minimum guarantee of long-term durability, the SDR rating will have to be selected within the acceptable range that allows the structure to withstand the set perimeter of constraints.

Sizing HDPE Pipes for Gas Distribution Networks

When allocating HDPE Pipes for gas distribution networks, attention should be paid to parameters such as flow demand, operating pressure, temperature, and environmental conditions. The needed diameter of the pipe is determined by the volume of gas to be transported within the designed pressure range. Each polyethylene gas distribution pipe’s dimensions and tolerances are defined through standards such as ASTM D2513.

Key technical issues include a pipe’s Standard Dimension Ratio (SDR) which sets its pressure rating, and Minimum Wall Thickness (MWT) maintained to provide adequate support for the pipe at the most challenging conditions. For instance, the standard pressure rating of HDPE pipes within gas networks usually varies between 0.5 MPa to 1.0 MPa with the former and latter figures depending on a given SDR value. Besides those mentioned above, external factors such as UV radiation and soil composition should be considered because of the need to guarantee the long-term safety of the network. Compliance with national standards and systematic system inspections enhance its reliability and operational lifetime.

Suitable Dimensions of HDPE Pipes for Waste and Drainage Systems

Factors such as site conditions, flow capacity, and hydraulic gradient should be considered when determining the size of HDPE pipes for sewer and drainage applications. The commonly used systems have diameters between 4 inches (100 mm) and 60 inches (1,500 mm), and sometimes even larger. Smaller diameters, 4 to 12 inches (100 to 300 mm), are used in residential or small-scale drainage systems. Sizes above 24 inches (600 mm) are common in municipal or industrial sewer systems.

Flow velocity and compatible slope are critical technical parameters, and for accurate hydraulic calculations ,one must comply with the Manning equation. As an example, In self cleaning sewer systems, a flow velocity of 2-4 ft/s is usually employed to ensure sedimentation is effectively curtailed. The structural classification, often guided by ASTM F2306 or EN 12201, requires that the pipe has sufficient stiffness (PS) to bear the external forces, especially for buried pipes. A standard pipe stiffness value of 46 psi (320 kPa) is common in such conditions. Furthermore, appropriate attention to burial depth, quality of bedding, and backfill materials will guarantee the system’s stability.

How does wall thickness affect HDPE pipe size selection?

The operational necessities and conditions of a system for the HDPE pipe geometry must precisely match with ascertained parameters, which in this case is the system’s pressure rating and structural strength. These aspects are interspersed due to wall thickness composing the cross section of the HDPE pipe. Pipes with thicker inner walls can endure greater internal pressures thus increasing their suitability for high-pressure fluids or gas applications. In addition, upper limits on wall thickness control the pipe’s SDR (Standard Dimension Ratio), with a lower quantify of SDR efferent with thicker pipes with higher pressure ratings encouraging thick pipe walls. Enhanced resistance to external loads and stresses, especially in the case of buried installations with heavy sand cover or supported with soil, is also afforded by thicker wall construction. It should be noted, however, that these elements accumulated bulk up the value of deformation of the pipes under heavy soil or traffic loads. Therefore, in almost every design consideration for a water siphon system, pipe wall thickness and any relevant thickness increase emerge with an increase in pressure requirements met, regardless of the environmental condition.

The Link Between SDR and the Thickness of the Walls

SDR, also known as Standard Dimension Ratio, measures the ratio of the outer diameter of a pipe to the wall thickness of that particular pipe. An SDR equal to or lower than 20 indicates that the pipe’s ratio is most likely thicker relative to the diameter, giving it adequate pressure tolerance and structural strength. An SDR of higher value will mean that the ratio within that particular pipe is more flexible. High str SDR signifies a reduced capacity to tolerate pressure from the inside. This relationship is essential for considering pipe selection since it deals with the actual performance when withstanding internal pressure and the external loads. Selection of the pipe is dictated by the performance under change of the pressure outside the forces that are applied to it, and the right SDR will provide friendly impacts. SDR directly dictates your best pipe confidence for project needs.

Effects of pipe performance linked with the wall thickness

The wall thickness of a pipe is directly connected to its performance effectiveness and capability to endure internal and external pressure loads. At an increased wall thickness, a pipe performs at superior resistance against internal pressures identified through MOP and pressure class ratings, which are directly linked to wall thickness as defined by SDR values. For instance, pipes with SDR 11 have higher pressure capability than pipes with SDR 21. Simultaneously, increased wall thickness also enhances a pipe’s structural integrity, improving its capacity to resist deformation under soil pressure or dynamic loads like traffic impacts.

In addition to that, within temperature-varying environments, thicker walls reduce risks linked with thermal expansion and contraction. This feature benefits pipes used in gas distribution or industrial processing plants because they tend to endure higher temperatures. The disadvantages include reduced flexibility and increased material usage, negatively impacting installation costs. Proportional alignment on economic wall thickness, project requirements, environmental settings and pressure ratings guarantees the system is economical and reliable at the same time over extended periods.

Reference sources

Frequently Asked Questions (FAQs)

Q: What are the common sizes available for HDPE pipes?

A: HDPE pipes come in a wide range of pipe sizes to suit various applications. For IPS (Iron Pipe Size) pipe, sizes typically range from 1/2 inch to 65 inches in outside diameter. DIPS (Ductile Iron Pipe Size) sizes range from 4 to 36 inches. The size of the pipe is usually determined by its outside diameter, with wall thickness varying based on the pressure rating.

Q: How do I understand HDPE pipe sizes and dimensions?

A: Understanding HDPE pipe sizes involves knowing the pipe’s outside diameter, wall thickness, and dimension ratio (DR). The outside diameter remains constant for a given diameter, while the wall thickness varies based on the pressure rating. The DR is the ratio of the pipe’s outside diameter to its minimum wall thickness. This information helps in selecting the right pipe size for specific applications.

Q: What is the difference between IPS and DIPS sizing for HDPE pipes?

A: IPS (Iron Pipe Size) and DIPS (Ductile Iron Pipe Size) are two standard dimensional systems used for HDPE pipes. IPS sizes are based on the nominal inside diameter of steel pipes, while DIPS sizes correspond to the outside diameter of ductile iron pipes. DIPS pipes generally have a larger outside diameter compared to IPS pipes of the same nominal size. The choice between IPS and DIPS depends on the specific application and compatibility requirements.

Q: How does the pressure class affect HDPE pipe sizes?

A: Pipe sizes and pressure class ratings are closely related in HDPE pipes. As the pressure class increases, the wall thickness of the pipe increases for a given diameter. This means that pipes with higher pressure ratings will have a smaller inside diameter compared to pipes of the same outside diameter but with lower pressure ratings. The pressure class is typically indicated by the DR (Dimension Ratio) or SDR (Standard Dimension Ratio) value.

Q: What are SIDR sizes in HDPE pipes?

A: SIDR (Standard Inside Dimension Ratio) is a sizing system used for some polyethylene pipe dimensions, particularly in smaller diameter pipes. Unlike IPS or DIPS, which are based on outside diameter, SIDR sizes are based on a standard inside diameter. This system ensures a consistent inner diameter across different pressure ratings, which can be beneficial for certain applications where flow capacity is critical.

Q: How do wall thickness and diameter affect the selection of HDPE pipes?

A: The wall thickness and diameter of HDPE pipes are crucial factors in pipe selection. The wall thickness determines the pipe’s pressure rating and durability, while the diameter affects flow capacity. Pipes with thinner walls for a given diameter can carry more fluid but have lower pressure ratings. Conversely, pipes with thicker walls have higher pressure ratings but reduced flow capacity. Selecting the correct HDPE pipe size involves balancing these factors based on the specific requirements of the application.

Q: What are the different types of HDPE pipes available?

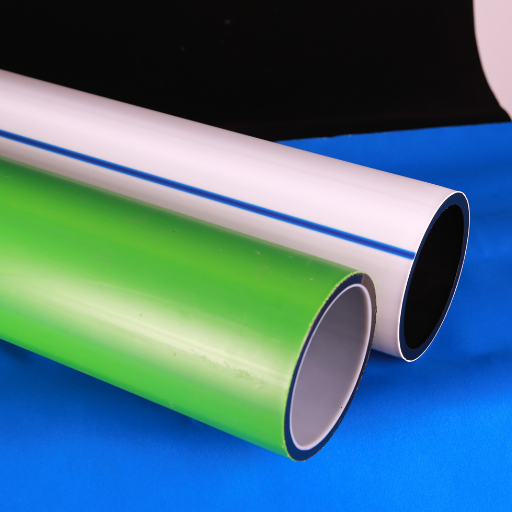

A: There are various types of HDPE pipes available, including PE4710, which is a high-performance grade of high-density polyethylene. HDPE pipes come in different color codes for various applications, such as blue for potable water, yellow for gas, and black with stripe for wastewater. They are also available in different SDR ratings, which indicate the ratio of pipe diameter to wall thickness, affecting the pipe’s pressure capacity.

Q: How do HDPE pipe dimensions compare to other pipe materials?

A: HDPE pipe dimensions often differ from those of other materials like PVC or steel. While HDPE pipes use similar nominal size designations, their actual dimensions may vary. For example, HDPE pipes generally have a larger outside diameter compared to PVC pipes of the same nominal size. Additionally, HDPE pipes have more flexibility in wall thickness options for a given diameter, allowing for a wider range of pressure ratings within the same size category.