To ensure accuracy, managing various factors is key to attaining high-quality results from HDPE pipe extrusion. This is particularly true when it comes to handling temperature. The extrusion process involves melting high-density polyethylene resin and forming the material, all of which occur under stringent controls. Failure to maintain proper temperatures can result in various defects, including wall thickness issues, surface distortion, and structural weaknesses, which fundamentally affect the effectiveness and life span of the final product. This article details one of the most essential parts of the process: temperature management in the extrusion of HDPE pipes. The article also discusses the technical details and the significant considerations necessary for achieving optimum processing conditions for superior products.

What is HDPE pipe extrusion and why is temperature control crucial?

Regarding the manufacturing process of pipes, HDPE pipe extrusion is specific to the melting and extrusion of High-Density Polyethylene (HDPE) into pipes of a particular circumference using an extruder. Control of the operating temperature is of utmost importance in the process as it guarantees even melting of the polymer, effective viscosity, and smooth flow through the die so that no structural weakening or unevenness occurs. Ultimately, rigorous temperature control determines the pipes’ quality, strength, and effectiveness after extrusion.

Grasping the Parts of the Execution of the Process of HDPE Pipe Extrusion

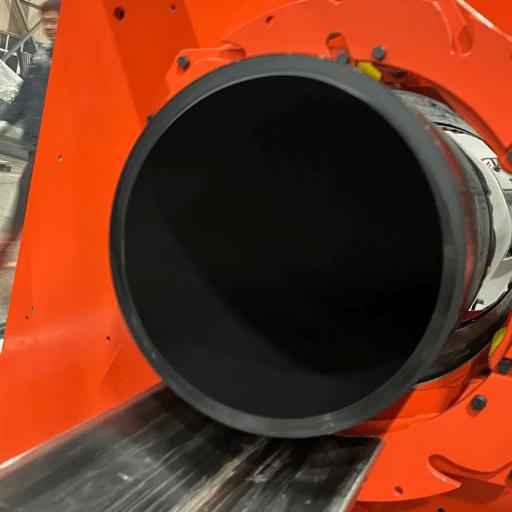

The execution of the HDPE pipe extrusion process has several parts, differing and requiring optimal results. First, an extruder is loaded with HDPE granules or pellets. Subsequently, the material is moved through several zones, and it is thermally processed by controlled heating within the temperature ranges of 180°C to 240°C. These ranges have been established to ensure the polymer is melted effectively without being roasted.

Upon reaching a certain temperature, the HDPE material is melted and pushed through a screw mechanism responsible for maintaining shear forces, which means that the viscosity of the polymer is maintained at an ideal level for the polymer to flow uniformly. The polymer’s viscosity depends on the temperature and shear rate, with optimal ranges between 100 and 300 Pa·s depending on the pipe diameter and application. Once the polymer is molten, it exits through a die that shapes it to a hollow cylindrical pipe. Inconsistencies in surface or flow defects can be avoided by carefully controlling the die head temperature, which is usually between 200°C to 230°C.

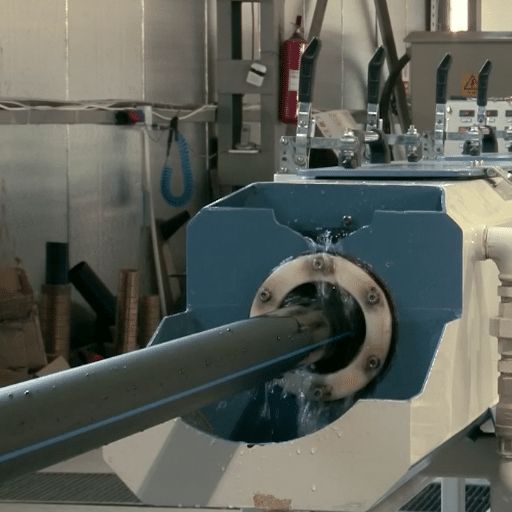

The extruded pipe is next taken to the calibration and cooling system. The cooling water is applied in stages to solidify the pipe while cooling it to avoid internal stresses or warping. This is known as the cooling bath and is usually maintained between 10°C and 20°C. The pipes are then cut to specified lengths. Each stage requires exact technical calibration to maintain consistent product quality and adherence to dimensional tolerances throughout the process.

Importance of Temperature in the Quality of HDPE Pipes

The quality of HDPE pipes is significantly influenced by temperature in every step of the production cycle. During the extrusion phase, the optimal polymer barrel temperature for flow kinetics, which is between 180°C to 220°C, must be maintained. Similar attention must be paid to the die head, where the polymer is shaped to the desired form at a temperature of 200°C to 230°C. This ensures optimal pipe shaping without imperfections resulting from die drool or uneven flow.

In the final cooling step of the pipe, the temperature gradient must be maintained at a steady rate to prevent any residual stresses or deformation of the pipe. The earliest cooling stages are usually done using water at 10-15 degrees celsius. Not adhering to these parameters can result in weakening of the pipe’s mechanical properties, dimensions, and shape. When temperature is controlled carefully at every stage, the long-term performance and integrity of the pipe is ensured.

Important temperature areas in the extrusion line

The barrel, die head, and the cooling stages are the most critical temperature zones in the extrusion line. In addition, the barrel temperature, which is meant to be between 180 °C and 220 °C, safeguards that the polymer flows well and does not degrade. The die head is also crucial for the shaping and surface quality and operates at 200 °C to 230 °C. Solidification during the cooling phase is performed with water at temperatures of 10 °C to 15 °C in order to minimize stress and preserve mechanical properties gradually.

How does temperature affect HDPE material properties during extrusion?

During the extrusion process, temperature is critical when determining the different properties of a material, in this case being HDPE. If the temperature becomes too high, thermal degradation occurs, which results in a polymer with a degraded molecular weight, lower mechanical strength and flexibility, as well as loss of chemical resistance. On the other hand, less than optimal temperatures restrict the melting flow of the polymer and result in defects such as unsatisfactory fusion, poor fissile surface quality, and brittleness in the product. Once the ideal temperature is reached, it is important to consistently maintain it during the rest of the extrusion process to ensure proper viscosity, shaping, and essential traits such as tensile strength and impact resistance.

Effect of Temperature on the Crystallization of HDPE

The crystallization behavior of HDPE (High-Density Polyethylene) is significantly impacted by temperature, which directly affects its mechanical and thermal properties. Crystallization is completed during the cooling stage where polymer strands crystallize into a semi-ordered structure. This process is influenced by the rate of cooling as well as the temperature of crystallization. Ideally, in the case of HDPE, crystallization is most efficient in the region of 110° to 130°C. Crystals that are more ordered and larger in size can be obtained with more leisurely cooling. This helps to improve the material’s tensile strength and stiffness. Rapid cooling, in contrast, produces less ordered and sub-optimal smaller crystals. Material toughness is improved, but at the cost of modulus and heat resistance. For HDPE , it is necessary to control the temperature during the cooling stage of crystallization to achieve a compromise between strength, flexibility, and thermal stability.

Changes in mechanical performance with respect to temperature variation

There is a direct relationship between temperature and the mechanical features of HDPE because its tensile strength, impact resistance, and even elasticity are affected. HDPE has lower tensile strength and stiffness at elevated temperature ranges due to the polymer chains’ weaker intermolecular force. More specifically, the modulus of elasticity greatly reduces when the temperature gets close to or exceeds the material’s melting range, which is approximately 120 degrees Celsius to 135 degrees Celsius. On the other hand, at a lower temperature range, HDPE turns more brittle and rigid with higher chances of crack proliferation under stress. Impact resistance generally lessens in colder environments due to lower flexibility and the development of stress concentrations at microstructural levels. These temperature-dependent behaviors highlight the need for close thermal control during the processing and application stages of HDPE so that its mechanical features are not diminished with temperature changes.

Restoring the value of HDPE through temperature considerations

Incorrect temperature management leads to low tenderness, strength, and performance deterioration, making it vital to preserve its efficiency. Both operating temperatures and the range should be kept at a specified limit to avoid thermal-oxidative degradation. HDPE, for instance, can usually withstand -40°C to 60°C while anything beyond these limits can cause damage to the mechanical features. With the incorporation of UV radiation stabilizers and high-temperature resistant types of HDPE polymers, while the temperature increases, the performance is further optimized.

Breaking the polymer chain bonds renders it weak and brittle, and, as such, it is of utmost importance during processing operations to maintain the melt temperature within limits of 180°C and 220°C. To control, these structures must not be damaged during extrusion or molding processes so that internal stresses do not crystallize and crystallization inconsistencies do not damage the strength of the structure. Antioxidants are also helpful in making the HDPE oxidatively intelligent due to the free radicals formed under heat and …oxygen exposure. These methods help improve the overall performance of the material under different conditions.

What are the optimal temperature ranges for HDPE pipe extrusion?

For HDPE pipe extrusion, the recommended temperature range is set between 180°C and 220°C. This range allows for proper melting and flowing of the polymer while preventing any material degradation or inconsistency. During this phase, attaining the set extrusion temperature and maintaining it within the set parameters are both essential to achieving pipe’s dimensional and mechanical properties. Careful management of the cooling stage is also essential as it increases the pipes crystallization level while eliminating any internal craters due to heat. This improves the overall structure of the extruded pipes.

Recommended barrel temperature settings

The extrusion of HDPE pipe is best achieved with a multi-stepped temperature profile. The barrel temperature settings are between 180°C in the feed zone and approximately 220°C in the metering zone and head section. This further prevents material damage and provides for better melting. Further, die head temperatures also have to be controlled to ensure constant pipe quality. These settings again depend on the specific grade of HDPE and the set pipe dimensions required, but they are usually set around 200-220°C.

Temperature when Abating Thermal Energy in Different Varieties of HDPE

Variable grades of high-density polyethylene (HDPE) have different requirements concerning melting temperature. High-density polyethylene grades are further subdivided according to their molecular weight and density which directly control the degree of melting. The optimal flow temperatures for standard grades are set between two hundred degrees Celsius and two hundred and forty degrees Celsius. Additionally, to prevent thermal degradation, the range must always be ensured. Medium molecular weight high density polyethylene typically will require slightly lower temperatures. These will be set in two hundred degrees to two hundred and twenty degrees while maintaining melting efficiency.

Regarding polymers of high molecular weight whose applications pertain to superior strength and performance, the temperatures are liable to reach as high as two hundred and thirty degrees to two hundred and fifty degrees. This range is to ensure plasticity is maintained while still retaining the material’s structure and composition. These parameters should always be monitored carefully. This is critical given that the material may suffer excessively high temperatures, which could cause oxidation and degradation. If the thermal treatment becomes too extreme, the physical and, indeed, the tensile strength and impact resistance of the pipe would be significantly affected.

As previously mentioned, the selection of melt temperatures must consider factors such as cooling profile and processing speed since they affect the material’s crystallization and final dimensional accuracy. These parameters have to be set for the specific HDPE grade to ensure that the pipes produced will pass rigid quality assurance tests.

Die and calibration sleeve temperature control

To maintain consistency in the dimensions and the surface quality of the HDPE pipes, I know that temperature control in the die and the calibration sleeve has to be very accurate. The die temperature is set higher than the melt temperature to achieve proper flow of the material. Shear forces are also considered to avoid obstruction during the flow of material streams. I set the temperature for the calibration sleeve to control the solidification rate. This way I can ensure the appropriate level of dimensional stability while achieving smooth external surfaces. When these temperatures are set to too low, defects such as warping or nonuniformity in wall thickness occur. Conversely, when temperatures are set too high, the final product fails to meet required specifications.

How to maintain precise temperature control in HDPE pipe extrusion?

For flawless HDPE pipe extrusion, ensuring accurate temperature control requires systematic temperature monitoring and regulation Cross all extrusion zones. The initial step is to ensure the barrel heater zones are set to ideal temperatures so the material melts steadily and gradually corresponding to the specific grade of HDPE. The temperature should be set above the polymer melting temperature to provide a uniform flow while avoiding shear thinning at the die. Additionally, set the temperatures in the cooling and calibration systems very closely as the solidification rate directly impacts surface quality and dimensional stability. Utilizing real-time monitoring tools and automated feedback systems increases the precision of set temperatures, thus reducing defects and improving consistency in production. Furthermore, all temperature-control measures should be regularly inspected and maintained to prevent malfunctioning devices from disrupting the set extrusion parameters.

Control system arrangement and monitoring of temperature zones for extruder machines

Mechanical regulators are coupled along with PID controllers (Proportional, Integral, and Derivative), Infrared sensors, and high-tech thermocouples for optimal extrusion temperature management. PID controllers increase and decrease heat inputs during the process in real-time, tailored to the changes which may happen in material characteristics as well as the set process conditions. Consistency in temperature control measures through all parts of the extrusion zones is achieved using infrared sensors. In addition PLCs are widely used to further the sophistication of automation systems which in turn helps the operator to lower or increase the temperature controls for different output needs. Moreover, modern systems nowadays are designed in a way that ensures the outputs are energy-friendly, allowing for any problem detection diagnostics and also being able to fix the problems ensuring operational efficiency and high-quality output, while in modern systems, more advanced systems set energy efficiency as a priority.

Monitoring, and trimming of temperature zone ranges

Monitoring and trimming of temperature zone ranges includes observing the heat ranges on each extrusion zones to process multilayered outputs. I check real time discrepancies and target measures with sensors such as thermocouples or infrared systems. I employ automation in Turbo compilers where PLCs and various control algorithms serve. New control features in automating processes ensure that the material is processed with maximum and optimal energy efficiency on every pass. Regular checks greatly help in defect identification, energy overspending, and output quality restraints.

Attending to changes in environmental temperature

The variations in ambient temperature is dealt with by taking steps beforehand to maintain product quality and process consistency. I use closed loop control approaches that automatically adjust to changes in phenomena to mitigate these changes. Insulating significant components and moving machinery helps reduce heat loss or gain because of the environment. I also keep track of ambient conditions so that adjustments to the process’s actual parameters, such as preheating and cooling rates, can be done promptly. In this manner, thermal control is accurate and uninterrupted the entire extrusion process.

What are common temperature-related issues in HDPE pipe extrusion?

Some common concerns regarding temperature in HDPE pipe extrusion processes include overheating and material degradation, variations in the wall thickness due to uneven distribution of heat, and low weld strength at pipe joints due to inadequate cooling. Excessive heating of the pipes can initiate a breakdown of molecular chains, which can greatly undermine the mechanical abilities of the material. Furthermore, inflating temperature controls within the extrusion processes can lead to non-uniformity in the pipe’s dimensions, thus lowering the overall quality of the product. It is, however, possible to reduce overheating risks by observing adequate regulation of cooling and heating and insulating the system.

Impacts of overheating on the overall and structural quality of the pipes

Overheating risks at HDPE pipe extrusion processes can lead to many concerns and issues regarding the quality and structural integrity of the final product. First and foremost, excessive temperatures lead to polymer degradation which compromises molecular weight. This weakening of molecular weight results in a decrease in the mechanical properties of the polymer such as tensile strength and impact resistance. In addition, such material degradation can lead to low ductility alongside a discoloration of the elastomer with brittle pipe ends, which can be for sensitive applications. Degradation temperatures for HDPE are known to start around 200 °C which varies with the particular grades of resin and additives. It is, therefore, crucial for operators to utilize the recommended processing range of 180 – 200 °C.

Defects in wall thickness and uniformity could arise out of overheating because it is also linked to inconsistent melt flow. The strength of the pipe’s structure in terms of resistance to hydraulic performance and pressure is directly impacted. At high temperatures during extrusion, other issues, such as additive or stabilizer volatilization, can negatively impact the pipe’s longevity and stress cracking resistance. To avoid these issues and guarantee product quality, the operating conditions for the barrel, die, and cooling zones, as well as the temperature settings, should be closely monitored, along with stringent adherence to the material’s specifications.

Effects of inadequate heating in extrusion processes

The construction defects of the pipes that are formed during the extrusion process stem from the fact that there is very little heating, which leads to melting the polymer resin. One primary effect of these construction issues is the unmelted resin fragments that become surface irregularities, internal structure voids, and uneven pipe wall thickness. Due to these flaws, the mechanical properties of the pipe – impact resistance and bearing pressure – are greatly reduced.

Another important problem is poor control of viscosity. Resin may fail to achieve optimal melt viscosity flow through the extrusion die without sufficient heating. As a consequence, there may be a nonuniform distribution of flow which in turn results in warping or deforming the final product. Also, poor heating may prevent additives integration such as UV stabilizers, antioxidants, or flame retardants that increase the resistance of the pipes to environmental and mechanical stressors.

To avoid these problems, the technical parameters need to be followed stringent. For instance, processing temperature range of HDPE is 180–200°C (356–392°F). It is important to note that material temperatures below this range would result in inadequate melt densities for extrusion, thus overly inefficient processes and poor quality products. Defect-free product specifications product requires uniformly distributed heat to the barrel and the die as well as continuous observation of processing zone parameters.

Difficulty with Recognizing Faults in Temperature Inconsistency

It’s crucial to confirm that all heating devices are in good working condition and working in unison throughout the entirety of the extruder barrel and die. Moreover, I check the calibration of the thermocouples and temperature controllers to avoid setpoints not matching and wrong readings being taken. Also, check for overheating or contamination of material in the extrusion system which interrupts heat transfer. If it does not resolve, then I check for system insulation to reduce unwanted heat loss, and check that process parameters are suitable for the material’s thermal properties.

What are the best practices for temperature management in HDPE pipe extrusion lines?

The result of optimal performance of temperature management in extruders of HDPE pipes is obtained from carrying out uniform heat allocation to all extrusion zones, which guarantees a stable melt temperature. Some of the best practices in this area include proper calibration of the temperature controllers and thermocouples to ensure accurate and stable temperatures without having uncontrolled fluctuations. A set of actions aimed at preventing failures must be done, including checking for blockages, as well as wear and damage of parts of the extruder barrel and die, which may inhibit the transfer of heat. Also, effective insulation of important parts guarantees that heat will not be lost, whereas aligning the processing parameters with the material’s rheological characteristics results of low resistance to deformation and ensures quality output. Automated systems that monitor temperatures throughout the entire extrusion process increase control and efficiency of the system.

Adjusting the Temperature Settings for Different HDPE Resins

Adjusting the temperature settings for different HDPE resins is a detailed process as it needs to consider the materials melt flow index (MFI) and thermal characteristics. Resins with lower MFI must always be kept at a higher temperature set to guarantee proper melt flow, whereas higher MFI resins require lower temperatures to prevent thermal degradation. The extrusion barrel is is typically separated into multiple regions of heating zones, and it remains necessary to change and increase the temperature at each of these zones to achieve proper offset melting. Moreover, the resin needs to be in a melted state before it can be processed, and, during this stage, it is also necessary to control the die head temperature to the target value to control the set parameters of pipes and the surface finish. Furthermore, product parameters and the extrusion speed should always be brought in line with the resin characteristics to keep control over the process and make it as constant as possible to improve the consistency of the product.

Managing the temperature control systems for the optimal quality of HDPE pipes

Managing the temperature control systems for the optimal quality of HDPE pipes requires stringent control of multiple parameters of the extrusion process to safeguard the material’s integrity and dimensions. The essential steps involve temperature control across the barrel zones, cooling rate control, and die head settings. Typical barrel temperature ranges for HDPE extrusion are 180°C and 230°C, depending on the resin grade and melt flow index. To control flash formation while improving the surface finish, the die head temperature is set slightly lower than the barrel ranges, within 170°C to 210°C. Cooling rates at which the material gets solidified must also be controlled. Too fast or too slow of a cooling rate would lead to warping or internal stresses of the product that gets formed. By employing advanced temperature control systems and real time data collection, robust feedback loops can mediate and close the control parameters to improve the consistency and quality of the HDPE pipes. Routine checks and calibration of the extrusion equipment also ensure system reliability over long production periods.

Instruction of operators warming and cooling production to keep a steady flow of unit terms

An operator’s training in temperature control aspects is critical for consistent production quality. A few areas which require special attention are the effect of temperature changes on materials or products, the proper use of temperature management devices, and the ability to react to the deviations in expected response >. It is equally important to highlight the need for standardized operating procedures and regular calibration of the devices to achieve proper accuracy and reliability. Moreover, visual aids, mock drills, and training tips along performance assessments to give them a thorough understanding of measures that need to be undertaken so that production standards are not compromised due to temperature changes from the set standards.

Reference sources

Frequently Asked Questions (FAQs)

Q: What is the importance of temperature control in HDPE pipe extrusion?

A: Temperature control is crucial in HDPE pipe extrusion as it directly affects the quality, performance, and dimensions of the pipe. Proper temperature management ensures consistent melting and mixing of the high-density polyethylene, leading to uniform extrusion through the die. This results in high-quality HDPE pipes that meet industry standards and performance requirements.

Q: How does temperature affect the properties of HDPE during extrusion?

A: Temperature plays a vital role in the behavior of crystalline polymers like HDPE during extrusion. It influences the polymer’s viscosity, flow characteristics, and molecular orientation. Proper temperature control ensures optimal melting and mixing of the plastic, which in turn affects the pipe’s strength, durability, and resistance to temperature changes in its service life.

Q: What are the key temperature zones in an HDPE pipe extrusion machine?

A: An HDPE pipe extruder typically has several temperature zones, including the feed zone, compression zone, metering zone, and die zone. Each zone requires precise temperature control to ensure proper melting, mixing, and shaping of the polymer. The specific temperatures may vary depending on the HDPE grade, pipe dimensions, and production line specifications.

Q: How do single screw and twin-screw extruders differ in temperature control for HDPE pipe production?

A: Single screw extruders and twin-screw extruders have different approaches to temperature control in manufacturing HDPE pipes. Single screw extruders rely more on external heating and friction for melting the polymer, while twin-screw extruders offer better temperature control and mixing capabilities due to their design. Twin-screw extruders often allow for more precise temperature management along the barrel length.

Q: What role do cooling tanks play in the HDPE pipe extrusion process?

A: Cooling tanks are essential in the HDPE pipe extrusion process for controlling the cooling rate of the extruded pipe. Proper cooling ensures that the pipe maintains its desired dimensions and properties. The temperature in cooling tanks must be carefully controlled to prevent warping, stress, or other defects that could compromise the quality and performance of HDPE pipes.

Q: How does screw speed relate to temperature control in HDPE pipe extrusion?

A: Screw speed is closely related to temperature control in HDPE pipe extrusion. Higher screw speeds generate more frictional heat, which can affect the temperature profile along the extruder barrel. Extruder operators must balance screw speed with temperature settings to achieve optimal melting and mixing of the polyethylene while maintaining consistent output and quality.

Q: What are the consequences of poor temperature control in HDPE pipe extrusion?

A: Poor temperature control can lead to various issues in HDPE pipe extrusion, including inconsistent pipe dimensions, reduced mechanical properties, increased risk of thermal degradation, and potential for defects such as voids or weak spots. These problems can compromise the performance of HDPE pipes in water pipe systems and other applications, potentially reducing their service life and reliability.

Q: How do temperature sensors contribute to quality control in HDPE pipe production?

A: Temperature sensors play a crucial role in quality control during HDPE pipe production. They provide real-time data on temperature conditions throughout the extrusion process, allowing operators to make immediate adjustments to ensure consistent quality. Advanced temperature sensors and control systems help maintain precise temperature and pressure conditions, contributing to the production of high-quality HDPE pipes that meet industry standards and customer requirements.