Grinding machines are a key component in the machine manufacturing world as they provide high accuracy and consistency in forming diverse materials. The automotive and aerospace industries are just some of the many sectors that utilize the vast potential of the grinding machine as it helps them improve the level of detail and accuracy in the components being created. This all-inclusive guide would simplify the foreign concepts of grinding, specifically precision and profile grinding, by Explaining how those operations are performed, how they work, their benefits, and where they are applicable. Further in this post, readers will learn the structure of grinding machines and what principles lay at the heart of grinding processes. Readers will also learn about grinding and its various methods. Also, the article will review the evolution of grinding techniques concerning time and its significance to the current industrial standards, which aids readers seeking to utilize the power of the machines. All aspects of grinding machines will be discussed in this post from the expert perspective and the first-timers’ side. This guide provides basic information on grinding machines.

What is a Grinding Machine and How Does it Work?

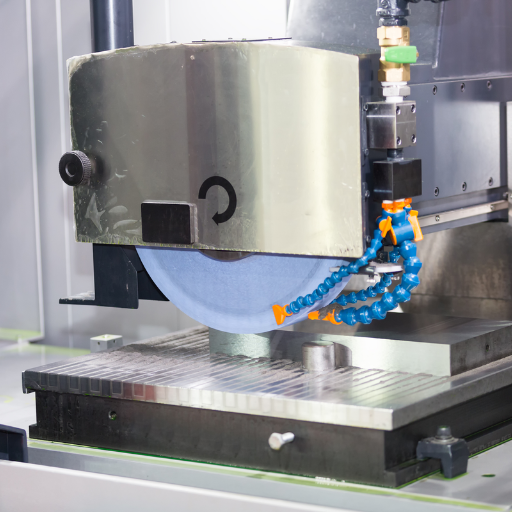

The term grinding machine is usually referred to as a grinder. It is a machine used with great efficiency in the industry to obtain desired surface finishes. Specifically, it abrades surfaces using a wheel that cuts through the friction with the workpiece. Various grinding machines exist for different grinding operations, such as surface grinders, cylindrical grinders, or bench grinders. In essence, grinding machines utilize an abrasive wheel to cut surfaces by rapidly rotating the wheel until it touches the workpiece. They grind the contact areas by cutting and smearing to provide the workpiece with the required shape and smoothness. This is particularly important in manufacturing parts that have certain dimensional requirements, enabling one to make quality components in industries where precision is paramount, such as motor vehicles, aerospace, and electronics.

Understanding the Basic Components of a Grinding Machinemachine’s cutting tool

Depending on the application, grinding wheels come in various materials, sizes, and grit levels. Made primarily of abrasive compounds, they execute a grinding machine comprising several critical components, each playing a vital role in its functionality and performance. The primary components include:

- Bed: The base structure that supports all other components. It provides stability and rigidity to ensure precision during grinding operations.

- Worktable: Mounted on the bed, the worktable supports the workpiece. It can often move in several directions (longitudinal or cross) to position the workpiece accurately under the grinding wheel. The table may rotate or tilt in some machines to accommodate complex shapes.

- Grinding Wheel: This is the machine’s cutting tool. Depending on the application, grinding wheels come in various materials, sizes, and grit levels. Made primarily of abrasive compounds, they execute cutting or finishing by rotating at high speeds.

- Spindle: The spindle holds and drives the grinding wheel. Its speed can be adjusted to suit different materials and grinding requirements, ensuring efficient material removal and surface finish.

- Wheel Guard: A protective cover that encloses the grinding wheel. It is crucial for safety, preventing debris or fragments from escaping during operation.

- Control Panel: Equipped with controls and settings to manage machine operations, including wheel speed, worktable movement, and other parameters. Modern machines may feature digital interfaces for precise adjustments.

- Coolant System: Essential for maintaining the temperature of the grinding area, the coolant system reduces heat and friction, extending the life of the grinding wheel and preserving the integrity of the workpiece.

The combined work of these parts contributes to the high precision and effectiveness of grinding machines, which makes them vital equipment in different manufacturing industries. Knowledge of the role and importance of each part is critical in improving operations and helping to achieve the targeted objectives in grinding processes.

How Does a Grinding Wheel Operate?

For my part, the working process of a grinding wheel constitutes a wide range of components that need to interact harmoniously. For starters, proper mounting and alignment of the grinding wheel is paramount, as improper ones can result in non-productive or even unsafe conditions. With the setup complete, the wheel may be rotated within the appropriate parameters for the particular application by the motor spindle. In those cases, the wheel will spin at significant angular velocities. Due to its design, the rotating wheel comes into contact with the workpiece, cutting bits of material and carving the workpiece. This relatively low-force, low-tech motion is combined with the application of a cooling system, which reduces the considerable heat build-up, eliminating the risk of overheating the wheel or the workpiece. I have just only to alter the spindle speed and the feed rate of the workpiece for me to achieve the required level of accuracy in the operations.

The Role of Coolant in Grinding Operations

Furthermore, it is well known that coolant is necessary for grinding operations, and I have experience concerning its role in practice. Its main purpose is to reduce heat and friction during the grinding process, increase the life of the grinding wheel, and maintain a better finish for the workpiece. The coolant effectively provides lubrication and cooling by flushing the swarf from the grinding zone. Important flow rate and temperature are some of the major parameters that also vary with the size and velocity increase ranging from 30 to 50 liters flow rates in a minute. The coolant temperature is generally maintained from 20 °C to 25 °C, which ensures that the wear of the wheel and the workpiece is minimal while better performance is achieved. Through these parameters, I should achieve optimal performance and precision in my grinding operations.

Types of Grinding Machines: Which One is Right for Your Needs?

Guided by our experience, we strongly believe that selecting a suitable grinding machine is of utmost importance since it significantly factors both the effectiveness and quality in the production processes. Surface grinders are perfectly adapted for obtaining smooth flat surfaces and working with fine detailing on the surfaces. Their use is commonplace in sectors requiring the fine finishing of surfaces with relevant precision, such as the tool and die-making industries. Cylindrical grinders, on the other hand, are used to shape the outer diameter of an object, which is suitable for parts having a rotational axis in the center. Therefore, these grinders are useful in machining processes where round components such as shafts are used. Bench grinders are good for tool sharpening, are primarily employed in domestic workshops or small-scale manufacturing units, and are good multi-purpose machines. By contrast, the application of very effective and resource-saving workshops has to be incorporated in the work by selecting the right type of grinder based on the material characteristics and requirements of the particular production process. Acknowledging these discrepancies is important for experts who strive to achieve the best result in various applications.

Exploring the Surface Grinder and Its Applications

Surface grinders are used in various industries, including avionics, automobiles, and tool manufacturing, because of their ability to produce smooth surfaces and achieve great accuracy. The machine grinds using an abrasive wheel to cut a workpiece to create a flat or plane surface. Among them are the size of the workpiece, the type of material to work on and the desired surface finish. Some relevant applications include surface grinds producing sub-micron level clamping and collar parts, parts for molds, and maintaining the flatness of tools. Continuous development of grinder technologies, such as increasing automation and grinding wheel technologies, has enhanced the devices’ range of applications, efficiency, and accuracy. Understanding these machines’ functions and their particular benefits simplifies the workflow and assures high industry requirements are met.

CNC Grinding Machines: Precision at Its Best

As a researcher in CNC grinding machines, I am passionate about how these machines offer unmatched accuracy and flexibility in today’s manufacturing world. The use of computers has achieved this, as CNC tools can convey the position of the tool with extreme precision, which is necessary for creating complicated intricacies with high precision. Per my analysis of the top resources about these machines, CNC grinding machines possess repeatability, high efficiency, and the ability to perform complex processes without any sign of lag, as well as enhance performance. These machines have greatly changed the work processes in the automotive, aerospace, and tool industries due to decreased setup times and increased accuracy. Working out what they can do with different materials and automated systems is critical in using the machines to design and make complex, high-quality parts.

Advantages of Using a Bench Grinder

In many workshops, one can find bench grinders, which are essential tools with numerous benefits that increase both productivity and accuracy. The first and foremost point of consideration in using a bench grinder is its usability; it can be used for sharpening the edges of tools, metal shaping, and finishing rough grinding tasks. The tools’ durability is guaranteed as their utilization increases once the tools are in optimal conditions. Moreover, they come with a way to achieve consistent angles by providing adjustable tool rests meant for efficient sharpening of the tools. Aside from that, various grinding wheels (coarse, medium, fine) can sometimes be used to tailor the processes based on the needs of the job.

Such technical parameters are the diameter and the speed of the grinding wheel. Bench grinders are mostly fitted with grinding wheels ranging between 6 inches and 8 inches, which are adequate for effective operation and fit in most workstations. Most commonly, speeds of around 3,000 to 3,600 RPM are required, which can effectively operate depending on the different types of materials as well as their density. Some can even provide the option to alter the speed, giving more control and accuracy when grinding sensitive objects. Such factors are essential in bench grinders as they help greatly in retaining the condition of the grinding tools while also improving the finish quality.

How to Achieve High Surface Grinding Quality?

To obtain a surface that has been ground to a high-quality level, several operations must be done with great care, including setup of the machine, selection of the wheels, and maintenance of the wheels. First of all, the grinding machine’s apology must be correct so that there is no mechanical error. Appropriate grinding wheel selection should also be regarded as important: it should be appropriate for the workpiece material in terms of grit size, hardness, and composition. Regular dressing and balancing of the grinding wheel should be done to avoid surface faults and stamping of the tools. The precise coolant type needs to be used so that heat and cuttings are disposed of properly to avoid burning and improve the lifespan of both the wheel and the machine. Continuing preventive maintenance of the equipment helps detect the problem as soon as it emerges, ensuring over-greasing accuracy of the grinding processes at all times. This enables professionals within this industry to achieve far better surface finishes gradually.

Techniques for Achieving High Surface Finish

For the casing to have a high-level finish, a complex, multidimensional approach that encompasses several crucial parameters must be undertaken. To start with, a material removal rate, or MRR, must be defined; it encompasses a trade-off between the quality of the surface and the amount of work done. In North America, using between 0.1 and 0.5 cubic inches per minute for precise jobs is often recommended. The speed of the grinding wheel is another important aspect, as one can go up to 3600 RPMS in regular situations. But the speed can be adjusted depending on material so that the finishing better. The feed rate is the speed at which material is turned into the final product. For a good finish, the feed rate is often between 0.1 and 0.5 inches per minute, and when this is achieved, the wheel is not overloaded. A specific flow rate coolant is necessary to minimize thermal deformation. Alongside this, the cut depth must not exceed 0.001 inches as it can lead to extreme force on the tool or material, additionally this would improve the precision. When all these parameters are met, the product quality goes up significantly.

Tips for Handling Complex Shapes and Surfaces

To achieve perfection when dealing with more intricate shapes and surfaces I make it a point to stick to some key notions. First of all, I perform a relative equipment selection focusing on workpiece configuration. It is mandatory to utilize tools of a more stable and rigid construction to improve accuracy and minimize the influence of vibration. The second task is optimizing the tool path, which is very important – it is useful to resort to several CAD/CAM means to design some not long paths to avoid overdoing in machining and making mistakes. For spindle parameters, sustaining the spindle speed somewhere between 1000 and 4000 rev/min depending on the material and geometry may be deemed reasonable, while the feed rate may be kept between 0.02 and 0.1 inches per minute so that the finishing quality is well preserved. In addition, my grasping of single parts for components I work on makes use of high-end workholding devices which reduces variation during the processes. It is critical to spot and modify machines and the environment during cutting on a consistent basis since these intricacies mandate precision for successful resolution.

Using Fixtures for Enhanced Accuracy

While using fixtures, my first choice is always those fixtures that are particularly recommended for the purpose and appropriate for the material and geometry of the workpiece. These terms allow complete interchangeability of relative position between various parts concerning each other. The example of clamping needed to hold parts is worth considering because the methods can be very strong and non-detrimental or very gentle and non-deforming of the workpiece. Also, checking the fixture’s location and calibration from time to time is very critical. By being able to properly fit the use of fixtures in machining processes to the ideas gained from relevant literature, I am able to enhance the output and the quality machined considerably.

Maintaining Your Grinder Machine: Tips and Tricks

An appropriate maintenance strategy includes some measures that would ensure the performance and life of a grinder machine. The first thing you may do is implement a cleaning protocol, for instance, removing any dust, debris, or other particulates that may have the potential of greatly diminishing the accuracy of the machine overuse. Work on evaluating and balancing the grinding wheel on a routine basis and dress it if necessary. Employ routine lubrication on moving parts to lessen wear and tear and aid the machine in having a longer life span. Routine checks on alignment are also crucial in averting mechanical errors that are likely to yield an inaccurate grind.

Most importantly, you should make use of a tool that regularly checks the alignments of the screws both prior and after using the tool. Abide by the maintenance protocols and the timing for the replacement of parts as outlined by the manufacturer to ensure that the machine continues to function effectively. By complying with these suggestions, the time and efficiency variables of the grinder machine will be maximized.

Regular Maintenance for Grinding Equipment

The grinding machine is supposed to always be clean and to achieve this; a proper cleaning schedule should be created to remove dust and other particles. To keep it sharp, the grinding wheel should be examined and dressed as necessary. Regular application of lubricant to the movable parts results in a decrease in friction, thus increasing the longevity of the parts and enhancing functionality. Regular alignment checks also prevent misalignment of components, which would sometimes result in errors during the grinding process. Besides, I ensure that I do detailed inspection after use or before it to see evidence of wear and tear. The correct performance of equipment is also guaranteed and maintained if the manufacturer’s instructions for service and for the replacement of individual parts are observed. These measures assist me in sustaining my grinding tools, enabling me to produce results of excellent quality.

Identifying and Replacing Worn Abrasive Wheels

When assessing worn abrasive wheels, it’s prudent to look for cracks, chips, or unbalanced wear patterns; these defects are likely to impair performance. While replacing wheel components, careful attention should be paid by examining the wheel regularly to reduce unanticipated wheel malfunction. To remove the old wheel, switch the machine off and lock it according to the manufacturers recommendations, without this measure a smooth transition could be challenging. Once you have confirmed that the wheel you want to install is undamaged and compatible with the grinding equipment, install the new wheel. Correctly installing the abrasive wheel will allow the equipment to operate in balance with the reduced risk of vibration or other subsequent mechanical issues. Best practices in this area, as well as a leading variety of sources, further confirm that this set of procedures will guarantee that your grinding processes will be maintained as safely and effectively as possible.

Ensuring High Precision Through Calibration

By ensuring that I frequently calibrate my equipment, I have the potential to lower the discrepancies in my end products. I do this by ensuring that, over time, my machinery’s output is congruent with standard measures. In doing so, calibration becomes essential for me to achieve the required level of accuracy within my grinding of materials. My structured procedure unfolds: first, I read the machine’s manual and establish the required calibration. Then I also prepare the equipment and test it out to perform the simplest tasks such as grinding. Finally, I test the equipment at small scales once my settings are ready and everything is well aligned. This is the trust I place in the leading manufacturers of precise engineering tools and valuable advice on forum professionals. That is how my grinding equipment is set to tight tolerances and standards.

Common Challenges and Solutions in Grinding Processes

Grinding processes experience a number of challenges that affect their performance and accuracy. One such problem is thermal deformation, which is experienced due to excessive heat affecting the part being ground, which causes it to warp or change structure. This can be avoided by employing sufficient cooling techniques, such as the optimum coolant flow rate or wheel speed and feed rate. Another challenge that works against the efficiency of a grinder is known as wheel glazing, where the grinding wheel surface is smoothened and less active. This can be remedied by dressing the wheel dressing to re-establish its cutting power. Also, vibration during the grinding operation causes a poor surface finish and dimensional inaccuracy. This problem can be reduced by balancing the wheel, proper machine setup and operating parameters. It is also important to realign the machine and check it continuously to avoid mechanical problems due to damage. By strategically addressing these issues, one is able to increase the effectiveness and accuracy of their grinding processes.

Dealing with Grinding Wheel Wear and Tear

I focus on maintaining a grinding wheel by learning from the best practices and experts in the industry. First, I ensure regular checks are done on the wheel, its condition, and its surface, as dry cutting, chipping, or even ribs might level a wheel. An exemplary grind surface standard that these manufacturers set is key; therefore, I pay close attention to it. In addition, I put great focus on using the right wheels fit for the job, as not doing so increases the wear and tear of the wheel. Many credible articles that I have read have also helped me prove my standpoint. To try to preserve the wheels for longer and make them efficient, I practice maintenance tips like wheel dressing, which reshapes the surface of a wheel. I attend technical forums, and I highlight the importance of keeping up with the latest trends, and so doing so allows me to cut edges on safety and quality.

Overcoming Issues with Workpiece Holding

My understanding of best practices for tackling workpiece holding challenges is that it is a matter of basic selection of the right clamping tools for the workpiece shape and material, as stressed in various authoritative websites in the industry. So, for every clamp, I also use a checklist so that we won’t miss checks regarding consistent wear and tear or that every fixture is still in an adequate condition to hold. Modern holding devices ensure that the workpiece is made to the proper specifications regarding its alignment and balance to prevent any possible slippage or even motion during the grinding procedure. Last but not least, I do not ignore technology shifts and suggestions offered by relevant think tanks in the forums about how I approach specific tasks, with accuracy and safety, which is an uncompromised factor.

Troubleshooting Grinding Machine Vibrations

To solve the problem of vibrations on the grinding machines, a systematic method built on thorough investigation and engineering considerations is proposed. First, the balance of the grinding wheel should be looked into, as its imbalances are the main mechanical reason for getting vibrations. A precision balancing system or service can work here and is sometimes expressed in microinches (µin) of deflection. Also, the spindle’s condition and alignment should be considered because alignment defects or worn parts will worsen the vibrations problem. As a rule, common tolerance levels of spindle run out to high precision are approximately 0.0004 inch and less.

Also, the analysis of the machine’s firm base is of equal significance; the machine has to be installed on a firm base that is not subjected to any vibration. Vibration isolators or pads are available to cushion the effects of the vibrations and thereby improve stability. Lastly, tooling and workpiece setups need to be checked adequately to ensure they are properly secured since loose setups will cause considerable unnecessary vibration.

Neglecting the maintenance of machines, including the lubrication of moving parts and replacement of defective ones, is a big no to ensure smooth operation free from vibration induced by wear and tear. This is because such measurements may help in planning detailed maintenance through the use of sophisticated diagnostic devices such as accelerometers, which pick vibration in terms of hertz or mm/s. Such approaches like pulling similar information from different reputable sources, such as technical manuals and standards provided by ANSI, cement the approach and help to minimize the vibration while optimizing the performance of the grinding machines.

References

Frequently Asked Questions (FAQ)

Q: What is a grinding machine and how does it work?

A: A grinding machine, also known as a machine tool, removes material from workpieces through abrasion. It typically consists of a rotary grinding wheel that rotates to achieve high surface quality and precision. Grinding machines can perform both roughing and finishing operations on workpieces.

Q: How does profile grinding differ from other grinding techniques?

A: Profile grinding is a specialized process to generate complex workpiece shapes and contours. Unlike standard grinding, which typically focuses on flat surfaces, profile grinding involves shaping the grinding wheel to match the desired profile, allowing for high precision in creating intricate designs.

Q: What are the benefits of using a mill in grinding operations?

A: Mills are versatile tools used in grinding operations to achieve different grain sizes for roughing and finishing. They can be used in conjunction with other grinding machines to enhance material removal efficiency, improve precision, and create a variety of surface finishes.

Q: What role does feed grinding play in the grinding process?

A: Feed grinding refers to consistently feeding the workpiece into the grinding wheel to ensure uniform material removal. This technique is crucial for maintaining the workpiece’s desired dimensions and surface quality during grinding applications.

Q: Can you explain the importance of using a disc in grinding operations?

A: Discs are essential components in grinding operations, holding the grinding wheel and rotating it at high speeds. They can come in various sizes for roughing and finishing, allowing machinists to achieve the desired precision and surface finish on workpieces.

Q: How does polishing enhance the finish of a workpiece after grinding?

A: Polishing is a finishing process that follows grinding to enhance the surface quality of a workpiece. It uses fine abrasive materials to smooth out imperfections and generate a high surface quality, often producing a shiny, reflective finish.

Q: What are the advantages of using high-speed grinding machines?

A: High-speed grinding machines offer increased efficiency and precision in material removal. They are equipped with power-driven grinding wheels that rotate at high velocities, allowing faster processing times, improved accuracy, and the ability to handle tougher materials.

Q: How do different grain sizes affect roughing and finishing operations?

A: Grinding wheels use different grain sizes to achieve varying levels of material removal and surface finish. Coarse grains are typically used for roughing operations to remove material quickly, while finer grains are used for finishing to achieve a smooth surface and precise dimensions.

Q: What safety measures should be considered when using power tools for grinding?

A: When using power tools for grinding, it’s important to wear personal protective equipment such as goggles, gloves, and hearing protection. Ensure the workpiece is securely held and the grinding machine is properly maintained. Additionally, be aware of the wheel’s condition and avoid exceeding the maximum rotational speed to prevent accidents.