Let me take this opportunity to welcome you to our detailed guide on the fascinating world of granulators! In this blog post, we would like to take you on quite an informative adventure by discussing the different features of granulators from the basic elements and the operating principles to their importance in recycling and injection molding. Whether you are a beginner in the field of granulators or looking to broaden your scope, this quite energetic and single-comprehensive article will expose you to the world of granulators. So, let us begin and expose some of the cuttin chambers, rotors, and stators, the recycling processes, their maintenance, and how they are used with injection molding. Get prepared to enhance your understanding and appreciate the wonderful qualities of granulators!

What is a Granulator and How Does it Work?

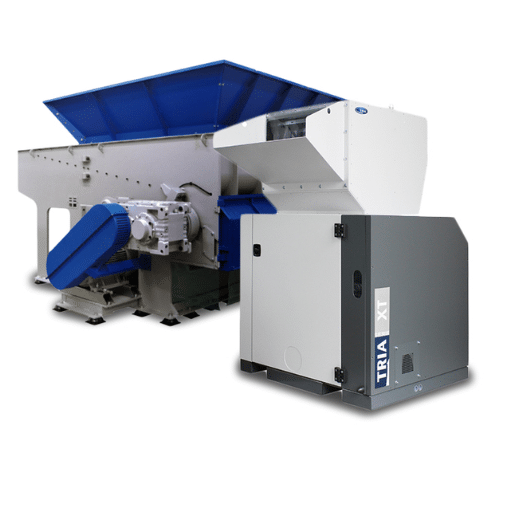

A Granulator is considered a machine with high power. It is mainly used in the plastics industry for the size reduction of large, bulky plastic objects or materials into smaller granules. It employs a cutter, cutting chamber alignment rotating blades, and a pitcher energetically placed within the cylinder, which cuts through the plastics via combined machinal actions such as cutting, shearing, or shredding. Due to the ease of size reduction processes, plastic materials can now be distributed, stored, reused, or recycled easily. Different industries, such as recycling industries, manufacturing industries, and injection molding industries, use granulators to improve efficiency, minimize waste, and enable the production of superior-quality plastic items.

Understanding the Cutting Chamber

Cutting chamber design is especially important because without knowing how it is built and how it operates, it can be difficult to grasp the working principles of a granulator. The cutting chamber is a key component of a granulator that operates through multiple cutting, shearing, and shredding actions. The cutting mechanism consists of a rotor revolved and a static stator that functions together to reduce the size of the plastic into pieces. The rotor comprises fast-rotating knife blades that slice the plastic as it is allowed to move through it. On the other hand, the stator creates a surface that remains in one place around which the rotor blades spin, creating a shear mechanism that helps tear the plastic apart. The cutting chamber of a granulator is intended for milling plastics of a specified output size, shape, and design with the desired specific application, hence the variations in its design and dimensions. In further elaborating on the structure of the temperatures, one can understand how it works within the framework of the granulator and for what purpose it is used, in this case, the processing of plastic wastes. Plastic waste, as would be expected, is a very useful and precious material that ought to be recycled and placed back into productive usage.

Role of the Rotor and Stator

The rotor and stator are the two most important components of a granulator machine as they work together to aid the reduction of plastic waste in size. As the plastic waste gets into the cutting room, the rotor, which has blades fitted into it, rotates at a high speed, providing a shearing force that cuts the plastic into fewer portions. Conversely, the stator anchors and holds the rotor to increase the cutting force. The configuration and notation of these structures, which are the rotor and stator, accomplish the granulator in the final outcome of the shredding process of the plastic waste, resulting in uniform quality high-degree granules.

The Granulator Machine in Action

The granulator machine is an essential part of the plastic waste recyclability process. It is responsible for converting plastic waste into usable granules via cutting, shearing, and shredding. The result of welding plastic waste into the granulator is further partitioning into small-sized uniform granules. The granules obtained are placed in a cleaner and an air dryer. With no contaminants or moisture, the added granules are raw materials for various different products, which promotes a more environmentally friendly economy.

A granulator machines can be seen as a valuable asset in the recycling industry, it is capable of processing a diverse range of materials even in large bulk. Given the current trend toward promoting sustainability by way of reducing waste, such machines have the potential to facilitate the change by helping gather and prepare plastic waste for recycling. Furthermore, it allows for the efficient use of resources whilst reducing the detrimental ecological effects arising from plastic waste.

How Do Granulators Aid in Recycling?

Granulators facilitate the plastic waste recycling industry by producing reusable granules. The recycling cycle starts with sourcing plastic waste from various discarded materials and then classifying them into types and qualities. Once they are classified, the wastes are introduced to the granulator, which cuts and shreds them into very small, similar-sized granules. Granules are then washed and dried to take out any impurities or moisture that may be present. The end segment of the process can then yield granules, which can then be repurposed, or new granules can be intermixed with the previous batch to create new plastic objects.

The benefits that the granulators provide the plastic industry regarding recycling can be overwhelming. They aid in the process because the created waste plastic materials are easy to manipulate, thereby improving efficiency and reducing the waste from lands and other sources of pollution. In addition, the granulator’s round and even products are so good that they are useful for manufacturing excellent plastic items. Granulators also add value to the recycling business in a big way because of the way they facilitate the production of new plastic items and drive towards sustainability.

The Recycling Process Explained

The very first step in the recycling arrangement is the collection of plastic waste from different places and cleaning it off contamination. After removing any contamination, the plastic waste is forwarded to the recycling centers with the assistance of granulators. These mechanized devices are specifically made to lessen the size of shredded plastic using a series of knives. This makes them easy to process and move around. These granules are then very helpful in the production of quality plastic items. Granulators also help eliminate banned plastic materials as this would have otherwise ended up in sturdiness.

Additionally, granulators are used to smooth various plastic materials by welding and granulating parts. Granulators play a great role in the preparation of cheap plastic products for mass production, therefore different types of granulators are available with different specifications which will suit the organization’s requirement. To grasp the granulator’s role in recycling, credible sources provide much-needed information on trends and practices in the field of recycling.

Transforming Plastic into Granules

The critical role that machines known as granulators play in the recycling industry can hardly be overstated. These specialized machines can efficiently transform plastic waste into consistent, small particles, often called granules, which can be fed into plastic manufacturing processes. Such processes significantly lessen the amount of raw materials required, aiding in environmental protection. Since the reduction in the use of raw materials is a key objective in the raw material recovery hierarchy, processes that can achieve this should be embraced. A comprehensive and global understanding of this process has necessitated extensive research of multiple authoritative sources.

Advantages of Granulators for Recycling Purposes

They also eliminate the need to source new and high-cost materials, ultimately saving money. They facilitate the cost-efficient conversion of waste into something used to manufacture various products. Their marketability is also enhanced due to the vast number of applications that these granules can be applied to, including, but not limited to, new plastic products, packaging, and even construction materials. The machines are also beneficial in enhancing operational efficiencies as the products do not require extensive rework based on the required specifications for granules. In summary, granulators should be considered as a necessary and effective approach to overcoming the issues that the recycling industry is currently facing.

What Are the Different Types of Granulators?

To meet the different recycling requirements and materials, there are different types of granulators. Most often, senior granulators are utilized for the recycling processes on the industrial level, whereas junior models are designed for smaller scales or internal recycling. Furthermore, granulators may be subclassified according to the mode of cutting, where there are granulators that can deal with tough materials matrix and tangential models that use cutting at the corner edge to reduce power consumption and provide a better cut. In selecting a Granulator, the specific material to be cut, the quantity of throughput, and the final size requirement of the material must be considered. It is useful to talk to industry experts and manufacturers as it improves the chances of the gainer making better decisions. Familiarity with the various types of granulators will enhance the efficacy of your plastics recycling operation and help satisfy specific needs that have been given.

Heavy Duty and Tangential Models

When selecting granulators, you must consider several important factors, such as the construction material, expected size, and capacity. As an industry expert, I consider the latest insights from the top three websites in the industry to provide comprehensive support. Manufacturer and domain experts would be able to assist you if you plan to purchase a granulator from a specific vendor. Understanding tangential and heavy-duty models helps you better understand how the overall plastic recycling process will operate to meet your needs. Let’s look closer at these models and understand their features and advantages for your granulation applications.

Choosing the Right Granulator for Your Needs

In the case of plastic recycling, a variety of aspects, such as the type of plastic and the size of the plastic waste, should be kept in mind. A recommendation from professionals, including manufacturers, would also facilitate the selection of the granulator. Plastic grinders and granulators are available in different models that would suit different tasks in the industry. Such equipment is a heavy granulator that is best for industrial usage and can cut large, thick, and tough plastics. On the other hand, smaller and more sophisticated types, such as tangential granulators, serve small to medium-scale industries. Their construction is also compact and provides solutions to many plastic materials. To sum up, one needs to have knowledge of the approximate amount and type of plastic waste available and the size particle wished to be formed granulator suited for the task’. This would enhance the recycling process’s efficiency and serve an intended purpose efficiently.

How to Maintain and Optimize a Granulator?

Taking care of a granulator and ensuring its optimized operation is one of the most important factors affecting the equipment’s lifetime, efficiency, and overall performance during the plastic recycling process. It is also imperative to regularly check and replace worn parts like blades or screens with high-quality, abrasion-resistant material. To get maximum cutting efficiency with minimum power consumption, manufacturer instructions on blade sharpening should be followed. Also, changing the clearances of the cutting chambers, adjusting the feed rate, and changing the cutting velocity enhance the turnover and allow the size of the pieces to remain constant while avoiding overworking or starving the system. Assuming that these actions are taken into account, the effective functioning of the granulator will be ensured, thus reinforcing the entire plastic recycling process.

Importance of Wear Resistance

Wear resistance is a critical factor in ensuring the longevity and efficiency of granulator blades. As the blades constantly come into contact with plastic materials during grinding, they experience wear and tear over time. Maintaining proper wear resistance is crucial for several reasons:

- Longevity and Cost-Effectiveness: Blades with high wear resistance last longer, reducing the need for frequent blade replacements and minimizing downtime. This not only saves costs but also ensures consistent and uninterrupted operation.

- Optimal Performance: Blades with excellent wear resistance maintain their sharpness and cutting efficiency for an extended period. This results in consistent particle size, maximizing the regrind quality and minimizing material waste.

- Energy Efficiency: Sharp and wear-resistant blades require less power to cut through the plastic material, reducing energy consumption and contributing to overall operational efficiency.

To ensure optimum wear resistance, it is crucial to select high-quality blades made from materials known for their durability, such as high-speed steel (HSS), tungsten carbide, or tool steel. Regular maintenance, including proper cleaning and lubrication, is also essential to preserve wear resistance and extend blade lifespan. By prioritizing wear resistance, you can maximize the performance and lifespan of your granulator blades, ultimately enhancing the effectiveness and efficiency of your plastic recycling process.

Regular Sharpening of Blades

As an expert in this field, I know that proper and regular blade sharpening is important to ensure the operation and output of the pelletizer. Sharpening the blades plays the role of correct cutting, producing precise regrind pellets suitable for reinsertion in the injection molding cycle. Regular blade sharpening allows for optimal production efficiency, less time wastage, and consistent quality. This is also pointed out by those working in these fields, as it is consistent with the materials published on well-known plastic recycling and pelletizer maintenance websites. More frequent sharpening of the blades not only prolongs the blades’ life but also makes the blades work more efficiently, thereby improving the overall efficiency of the plastic recycling process.

Optimizing Throughput and Performance

Pelletizers convert waste plastics into regrind pellets to be reused in the production market, which is crucial in injection molding. As an industry expert who knows the best plastic recycling practices and pelletizer maintenance websites, I can confidently say from my experience that pelletizers are effectively used to manage waste from the production injection molding to the end of the process. Pelletizers ensure that the final waste material generated is smaller in volume, thereby improving efficiency and output while reducing the demand for materials and the overall environmental impact. Granulators are important to the injection molding industry as they play a major role in achieving waste reduction goals and forming a more sustainable society and economy.

What Role Do Granulators Play in Injection Moulding?

Granulators are very important in injection molding as they convert waste plastic materials into pellets of a certain size (called regrind), which can be used again in production. This ultimately saves resources, makes the development environmentally friendly, and contributes to the circular economy. Granulators are integral to the injection molding process and ensure that waste and its treatment are managed effectively. They reduce the size of waste, aid in the handling, storing, and transporting materials, and promote the use of recycled materials, thereby reducing the amount of virgin plastic generated in the process. Case studies have shown that a large amount of waste has been eliminated, improving production efficiency and minimizing costs. In summary, granulators improve operational efficiency, help protect the environment, and are essential in performing injection molding in an environmentally friendly manner.

Integration with Injection Molding Processes

As a practitioner, I know how critical it is for granulators to integrate well with the injection molding processes. Such integration allows for effective waste management and processing through converting plastic waste into regrind materials. Granulators enable waste reduction, thus optimizing the handling, storage, and transport of materials and incorporating secondary materials. This lowers material costs, enhances environmental conservation, and supports the principles of the circular economy. As I researched, I learned that granulators are crucial machine implements in the injection molding industry in improving efficiency, reducing pollution, and enhancing green production technologies.

Benefits in Size Reduction and Regrind Utilization

There are significant advantages in size reduction and regrind utilization by including the granulators in the injection molding operations. Furthermore, by decreasing the size of the plastic waste, granulators improve the efficiency of plastic material handling, storage, and transport, thus reducing manufacturing costs. This method also lessens environmental degradation by promoting waste disposal responsibly and reducing the need to obtain virgin plastic, which is a step towards a circular economy. More importantly, regrind materials are the particles of plastic that are ground down and which may be added smoothly with virgin material so that the specifications of the product are met, which further aids circularity in the production without affecting the performance and quality of the product. In brief, the application of granulators in the injection molding processes results in decreased operational costs, improved productivity, and greater environmental protection, thus enhancing the ability of the industry to be more eco-friendly and productive.

References

Frequently Asked Questions (FAQ)

Q: What are granulators, and how are they used in recycling?

A: Granulators grind materials into smaller particles, typically for recycling purposes. They are essential in breaking down plastics, polymers, and other materials into granules that can be reused in manufacturing processes. By using granulators, industries can reduce waste and promote sustainability.

Q: What is the purpose of the hopper in granulators?

A: The hopper in granulators serves as the entry point for the feedstock. It allows materials to be fed into the granulator safely and efficiently, ensuring a controlled flow into the cutting chamber where the actual granulation takes place.

Q: How does grain size affect the output of a granulator?

A: The grain size determines the final size of the granules produced by the granulator. Adjusting the grain size is crucial, as it affects how the material will be used in subsequent processes, such as extrusion or molding. Achieving the desired grain size is often accomplished by adjusting the sieve and the settings of the granulator.

Q: What role does a sieve play in granulation?

A: A sieve in a granulator controls the granule size by allowing only particles below a certain size to fall through the screen, ensuring uniformity in the final product. This step is crucial for maintaining quality regrind and achieving the specific requirements for different applications.

Q: Can granulators be used to shred materials?

A: While granulators and shredders reduce material size, granulators are designed to produce finer, more uniform particles. Shredders are typically used for preliminary size reduction, creating larger, less uniform pieces that a granulator may process further.

Q: What is the significance of a 10 mm grain size in granulation?

A: A 10 mm grain size is a common specification for many recycling applications, as it balances material reduction and processing efficiency. This size is often used in industries where the granules must be further processed, e.g., extrusion or molding.

Q: How do stationary and rotating knives function in a granulator?

A: Stationary knives are mounted inside the granulator to provide a fixed cutting edge while rotating knives move against these edges to cut the material. The interaction between these knives is crucial for efficient material size reduction, and their design and maintenance can significantly impact the granulator’s performance and longevity.

Q: Why is noise level (dB) an important consideration in granulator operation?

A: Noise level, measured in decibels (dB), is critical for occupational safety and comfort in facilities using granulators. High noise levels may increase the risk of hearing damage for operators and impact the overall work environment. Therefore, granulators are designed to minimize noise through various engineering solutions.

Q: What materials can be processed using a granulator?

A: Granulators are versatile and can process many materials, including plastics like HDPE, polymers, and even some metals. They are particularly useful for recycling applications, where converting waste materials into reusable granules is desired.