As the textile and garment industry keeps changing rapidly, the four-head embroidery machine has become one of the most vital investment decisions for a business looking to improve its productivity and the quality of its output. This comprehensive guide discusses the factors one must consider to make the right choice. Specifically, we will concentrate on essential areas like stitch speed, design, and design customization requirements for the business. Additionally, the readers will learn about the recent changes in the embroidery machines, including computerized operating panels, automated cleaning processes, and advanced stitching technologies. Businesses define the importance of these factors in determining the most suitable machine that will adequately serve them at the time while keeping in mind the future growth of the business as well as new opportunities in the embroidery market.

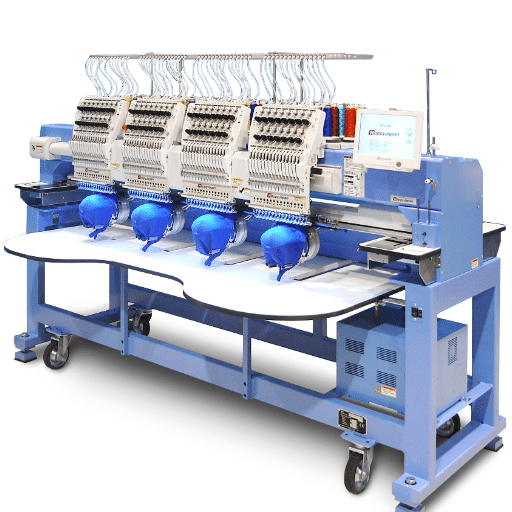

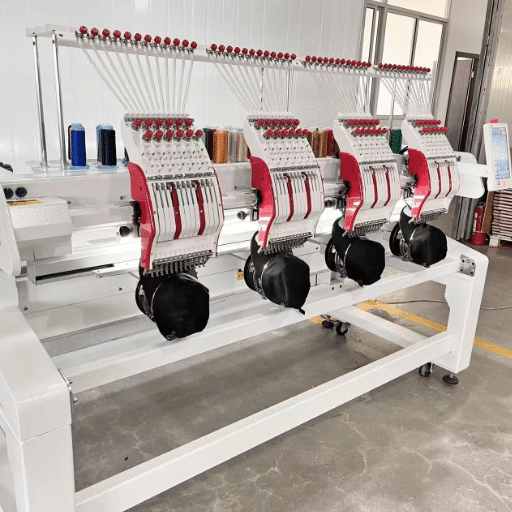

What is a 4-head Embroidery Machine?

The four-head embroidery machine is a technological marvel, allowing it to work on multiple embroidery projects in 4 different places on the fabric. These machines are helpful in mass production activities where the output is expanded by simultaneously attributing an embroidery design on several members or fabric materials. Most of these machines use sophisticated technology incorporated with fast stroking, accuracy, and memory space for many designs, which helps create complicated and elaborate embroidery images. A four-head embroidery machine is time-saving and cost-effective as the business must invest in one machine while mass production at excellent quality remains consistent.

Understanding the Machine and How It Works

Four embroidering heads of an embroidery machine are brought into sync to operate in a horizontal dual-stitch embroidery setup using four stitching heads. The first stage of this system sees the machine upload its internal instructions, previously arranged formats, for stitching clothes directly or downloading files from a connected computer as the user controls them. In this case, the constructed digital pattern serves as a guide through which the needle mechanism of a machine stitches threads into the fabric clamped in the embroidery hoop. Stepper motors and servo drives control the four arms and heads, making it possible for all the heads to perform simultaneously and have similar sewing quality in all the outputs. The machine avoids excessive changing of thread colors by manually turning off the machine, which saves on cost. In addition, automatic type monitors are incorporated in currently designed machines, which check the amount of tension used when sewing threads, where the fabric is supposed to be placed, and stitching faults to cut down the machine downtime and increase productivity. Operating and maintaining these machines includes knowledge of their computerized systems, maintenance of the mechanical parts, and periodic calibrations to meet the operational requirements.

Differences Between Multi-Head and Single-Head Embroidery Machines

A critical distinction between multi-head and single-head machines is the amount of output they can deliver. Four-head machines can sew similar designs on several clothing items simultaneously, increasing productivity. As a result, these are perfect for large-scale, time-sensitive businesses that maintain reasonable quality standards. On the contrary, single-head machines are appropriate for small and overtime work, as each head can sew different designs, which does not yield outstanding amounts. Multi-head machines also have additional features, such as automatic embroidery machines and built-in design libraries, which automate the process. The decision comes down to the extent and type of your business operations.

Typical Applications for a Four-Head Embroidery Machine

The general use of a four-head embroidery machine is mainly suited for people and organizations that focus on efficiency and mass production. It’s clear that these devices are widely used to manufacture fashion garments, promotional items, and home textiles. In the fashion industry, they are used in the mass production of shirts, jackets, hats, and other garments with complex designs, ensuring that each piece is breathtakingly identical to the others. Companies that deal with promotional items utilize these devices to embroider logos and branding on products such as bags and caps in anticipation of bulk orders from firms. Last but not least, four-head embroidery machines are also found in the home textile industry, where they are used to apply intricate patterns on tablecloths and bedspreads. These machines are always required in any textile production because they provide high-quality embroidery even under mass production conditions, a significant requirement in the current global fashion industry.

How to Choose the Right Model for Your Needs?

Assessing the company’s productivity is crucial when choosing a four-head embroidery machine to achieve particular business goals. To start, determine your required production levels; for instance, high-output businesses should opt for high-speed models with larger stitch patterns and ample design storage. Determine the level of the embroidery machine’s technology necessary to produce the degree of sophistication of the designs the business intends to carry out. Check how easy or difficult it will be to use and maintain the machine; if needed, look for machines with a more straightforward design and automated maintenance for minimum downtime. Also, determine the machine’s compatibility with the programs utilized to create the designs because having the machine and the program work together will be more beneficial. Also, check the manufacturer’s support services and the warranty options to ensure support when needed and to protect the equipment over time. Businesses can focus on their future model choice by highlighting many of the aspects above that will enable them to meet their current production requirements.

Key Features to Look for in a Head Embroidery Machine

It is essential to summarize that the production targets, completed most efficiently, will be focused on the key features when choosing the head embroidery machine. Firstly, attention should be paid to the embroidery speed and the stitch accuracy; models with high speed and constant stitch quality are likely to be more productive. Be sure to choose machines with outstanding color change devices and ample onboard memory storage for various designs to implement many patterns without practically needing manual work. The machine should have an expected component of easy-to-use software with readily visible menu buttons, which reduces training for the user. Furthermore, solid construction and dependable robustness are critical for continuously deploying machines with heavy workloads. Moreover, design transfer security through USB and LAN ports for images and program compatibility can improve the quality of the work process. Finally, it is better to choose models manufactured by known brands that provide complete technical assistance and warranty and allow having the support necessary for the proper operation of the machine.

Comparing Speed and Efficiency Among Different Models

I was interested in comparing the speed and efficiency of different embroidery machine models. Expressed in terms of stitches per minute (SPM), is a critical determinant of machine efficiency. High-speed types often achieve over 1,000 SPM, ideal for mass production. However, one has to be mindful of the stitch quality. They are making every stitch quickly and should not come at the price of losing stitch precision when intricate designs are concerned. Machine efficiency is also determined by features like automatic trim, automatic color change, and fast setup time to reduce dead time in production. Furthermore, incorporating new technologies such as self-diagnosis and reduction of maintenance are also regarded as necessary for efficiency. For this reason, speed and considerable operational features are fundamental for the success of embroidery activities.

How Cap Embroidery Capability Can Impact Your Decision

When we talk about the capability of cap embroidery, there is a feature of the machine that many sites in this industry consider essential in their reviews tion of the new cap technology. These machines should be able to embroider the cap’s curved surface but still achieve the required quality of stitches. One should choose a model with an ideal cap frame designed to keep the fabric tightly in place and avoid fabric as it is being stitched. Another important consideration is the ability to work with such programs since they will permit precise placement, making the design more accessible to assemble. One of the views not to be overlooked is the ability to alter the mode from flat to cap embroidery and vice versa with minimum change in the setup, thus enabling the smooth flow of operational processes and improving efficiency. Therefore, businesses that would like to invest in powerful headwear brands consider that the machine should preferably have an intense cap embroidery.

What Accessories and Kits are Essential?

The right accessories and kits for your embroidery machine should be selected with practicality and efficiency in mind. An absolute necessity is a variety of hoop sizes that enable the embroidery of various fabrics and size designs, making it possible to undertake different projects. Additional needle sets are a must-have as they are used for stitching in fabrics and materials of varying thickness to obtain neat stitches. The frame stabilizers and backing materials are permanently attached to the machines to stretch the fabrics and reduce puckering while embroidering detailed designs on thin fabrics. A collection of threads is also necessary, and some may include specialty threads that are essential in achieving a range of patterns and vivid designs, such as metallic or variegated threads. Owning a dedicated bobbin winder to improve production speed by preparing multiple bobbins at once would be advisable. Finally, a thread trimmer and a cleaning catalyst have become obligatory in the routine maintenance of machines to keep their operation smooth and extend the machine’s life span. All these accessories allow the machine to be used for other purposes, meet different production requirements, and ensure the embroidery applications do not lose their resources in the future.

Must-Have Accessories for Your Embroidery Business

The following accessories are a must-have, as they will help increase the efficiency and output of your embroidery business. A wide array of embroidery hoops to fit all fabric sizes and types would surely help make it easier to implement designs. To sustain precision during stitching and to avoid biopolymer glue on such fabrics, use high-grade needles that are usable with specific fabrics. Backings must provide uniform tension and control distortion throughout the embroidery process, especially for embroidered patches designed on materials with intricate details. Simple and wise, provide your garment with a complete set of threads, including metallic and variegated threads, to broaden the design environment. The winder may also use a high-quality bobbin to make several bobbins and reduce machine idle time. Lastly, regular maintenance parts such as cleaning tools and sharp thread-cutting tools are essential for machine servicing and survival. Employing such accessories will make it possible to achieve maximum operational efficiency while covering a variety of embroidery works.

The Role of Hoops and Embroidery Area in Production

Enhancing the production process’s efficiency requires considering the scope of hoops and the embroidery field. First, the choice of hoops affects the fabric’s stability and the design’s precision. A proper fabric-hooping technique, in which the selected size of the hoop corresponds to the designated embroidery area, allows the fabric layers to be held uniformly in place so that the stitching is even and all stitches have the same distance from one another. Also, the maximum possible confers a significant advantage to the design area, while the minimum possible considers the machine constraints directly correlating to output efficiency. Many specialists also consider easy changes of hoops with diameters of different sizes as the means that fruitfully influence the diminution of the setup time and the downtime of the equipment during production. Consequently, the practical application of the adjustable size hoops and the efficient zonation of the embroidery fields reduce cycle time, increase productivity, and meet embroidery quality in a significant way.

Understanding the Importance of a Comprehensive Tool Kit

Building a comprehensive tool kit from a first-person perspective to understand its relevance means appealing to the viewers. A specialized tool kit for the embroidery business to run smoothly is vital. A well-stocked tool kit, as reported by the leading sites, includes different sizes of hoops, needles with specific precision for sewing different materials, and an array of threads designed for versatility and imagination. Stabilizers and backings are crucial since they uphold the stability and quality of fabric during my projects. So are heavy-duty maintenance equipment such as cleaning kits and thread clippers, for they assist in keeping the machine in good working condition, reducing any chances of screwing up the scheduled work. Such configuration simplifies my processes and contributes positively to the overall quality and efficiency of the embroidery productions as it integrates perfectly with different design demands.

How to Maintain Your Head Commercial Embroidery Machine?

Following maintenance intervals and cleaning practices is wise to keep your head commercial embroidery machine in the best possible condition. As a starter, remove any lint as well as dirt deposits from the needle plate and the bobbin to prevent their build-up, which might hurt the quality of stitches. Fibrous materials should also be removed using a special brush or a can of compressed air. Follow all weekly lubes recommended in the machinery manual, for instance, at the tips of the needle bar and top of the presser feet, to lessen the friction and wear, particularly of moving parts. Maintenance on an annual basis includes assuring proper tension is set and the machine is calibrated for proper tension during stitching and consistent stitching. Needles have to be replaced frequently to avoid damage to the material being sewn and also for effective and accurate stitching. Regular software and firmware updates are necessary to boost a machine’s efficiency, including introducing new features while eliminating bugs. If none of the approaches works, the manual guides how to deal with the problem, or it is best to have one minor visit to address the fundamental mechanical issues of the machine every year for effective functioning and life.

Regular Maintenance Tips to Ensure Longevity

First, a procedure that must be performed every day should include cleaning the needle plate and the bobbin area to remove any lint or other debris that can adversely affect stitch quality. For this purpose, a soft brush or compressed air can be used. Weekly maintenance should revolve around lubrication, in both oil and grease formation, being applied to the needle bar and presser foot, respectively, as stipulated by the manufacturers to reduce wear and tear. Boss AI Monthly maintenance performance appraisal despised notice raisurezMix. Machine Tension settings should be inspected, and the machine should be calibrated adequately once every month to ensure that the stitches are always perfect.

Furthermore, changing the needles sufficiently is necessary to ensure that fabrics are not damaged and the stitches are accurate. Where required, updating the software and the firmware is essential because work clinicians have continuously been optimized and technical faults fixed. Finally, the need for an annual service can be compounded for reasons associated with the shielding of the machine against mechanical faults; hence, the efficiency and life span of the machine is never compromised. Such robust maintenance techniques backed up by top industry websites are essential in ensuring performance and resilience in embroidery equipment.

How to Address Common Machine Issues

I understood that it is necessary to anticipate and act upon common problems with my embroidery machine. So, first, I prevent thread breakages by checking the tension settings and the thread quality. If I diffuse needle breakages, I inspect the needle sizes for accuracy and replace them frequently to guarantee sharpness. If I experience skipped stitches, I ensure the needle is seated correctly and appropriate for the fabric. Sometimes, the sound of the machine suggests the need for lubrication; in such cases, I ensure the manufacturer’s specifications appropriately lubricate the moving parts. In cases of relatively frequent ones, I must either consult the technical manual for problem-solving or employ a qualified service provider to solve the more challenging problems that might interfere with the machine’s performance.

Best Practices for Cleaning and Oiling Needles and Equipment

Following simple preventive cleaning and oiling measures is essential to ensure that the embroidery machinery functions at its topmost level. First, ensure the equipment’s power source is turned off and unplugged. Any thread or debris in the needle and needle plate should be scrubbed with a soft brush or blown off, toning the compressed air to avoid choking. There should be no scrubbing with anything gritty and rough. Once this is done, show where to oil by pointing out the manufacturer’s manual, most likely to include the needle bar, presser bar, and race hook. These areas are sensitive when lubricating oil is used but only in controlled quantities. Over-oiling should be avoided since it can gather dirt in the areas oiled. Depending on how often the machines are being used, the particular cuts should be made regularly; every forty to fifty hours should be okay. Eight hours of use or any time it’s apparent it is getting worn out will do a replacement to maintain stitch quality. It is recommended that the first action performed after maintenance is completing a test stitch so that verifying that performance has not been disrupted is straightforward. Following the steps described ensures that the time and efficiency of the machinery will be uncompromised.

What are the Advantages of Using a 4-head Commercial Embroidery Machine?

Incorporating a four-head commercial embroidery machine into an embroidery business has certain unique features that help improve productivity and flexibility. Moreover, it allows for the simultaneous processing of up to four identical designs. The machine increases efficiency because it is designed to accomplish up to four embroidery heads in a single session. Because of this ability, businesses can promptly meet excessive order demands and increase the volume of their operations. Moreover, 4-head machines are more efficient in maximizing quality during production for multiple items where there is a need for uniformity when mass-producing garments or textiles. In addition, four head machines possess advanced features such as the ability to sew designs with more than one thread color, enabling them to perform complex designs while simultaneously making the processes less complicated. Another significant benefit is cost savings since businesses do not have to spend on multiple machine processes, and the unit saves time. Overall, all these attributes enhance the commercial embroidery machine’s four heads to be a valuable asset for detail and volume-based production plants.

Boosting Production and Efficiency in the Factory

Increasing productivity in terms of the output of a factory requires both the introduction of various technical improvements and substantial optimization of the process. The American Textile Machinery Association and experts from Textile World, Printwear Magazine, and Industrial Machinery Digest see an opportunity to upgrade factory automation. To this end, it involves the application of more productive embroidery equipment with several heads that embroidery at the same time several designs, which saves time. In addition, reasonable lean manufacturing concepts, oriented towards managing production processes and eliminating unnecessary actions, are essential for increasing efficiency. Carrying out repairs regularly and training the employees is also crucial so that machines can function optimally and workers are trained to use advanced machinery. Regular pain reviews may show conditional process losses, leading to additional process improvements in future cuts. Overall, these types of enhancements result in an increase in production and a decline in how much it costs to run the operations within the company, which, among other things, increases competitiveness in the niche textile market.

How Automatic Features Enhance Embroidery Quality

We have to realize how automatic features in embroidery machines enhance the work significantly. Automatic tension adjustment of the embroidery machine is the foremost improvement, enabling the device to adjust the thread tension for the fabric and design used in the area, thus ensuring better and uniform stitches. Shifting the focus to the automatic thread trimmer, this feature also comes in handy as it reduces the manual tasks needed in the process and, thus, the amount of human error possible. In addition, automatic needle threading saves time and resources and improves processes involving many design threads. All these automated functions help streamline processes and increase the accuracy and quality of embroidery.

Expanding Your Embroidery Business with Versatile Equipment

When expanding an embroidery business, investing in equipment that allows for versatility and increased production is suggested. Equipment selection includes specific criteria such as technical specifications like number of heads, speed, and range of stitches. For example, having a more significant number of heads implies having a four-head embroidery machine that can simultaneously carry out identical designs, thus making the output more efficient. The machines should also be able to have a speed of between 750-1200 stitches per minute, which is a practical compromise of quality and amount of time taken. In addition, machines with a wide stitch range should be purchased, allowing for complex and diverse designs such as thin lines and filling up dense areas. Such diversity would enhance the range of creativity you offer your customers.

The most significant advantage of tying in the purchase of embroidery machines with the said features is that they intensely focus on the said features, overall streamlining operations and reducing risks of errors. This allows for the reduction of manual input and maximum workflow efficiency. Having the correct type of machines enables a business to manage more oversized orders and factors such as quality, which is a significant component for any customer and must be consistently met. As you expand, consider the appropriateness of the machines you use and update or replace them if the situation dictates. The embroidery business is very competitive as the industry is dynamic, so raising the level of competition is easy. The strategic selection of versatile embroidery equipment is foundational to sustaining growth and expanding your business reach.

How to Operate a 4-Head Embroidery Machine?

The operation of a four-head embroidery machine is somewhat complex and needs to be done in sequence. First, the machine is placed in a stable position to avoid vibration while working. Then, the design file is loaded through a built-in software interface, or an external device is connected to upload the pattern. Each embroidery head is carefully threaded with the right colored threads, while each tension setting is checked against the fabric and design so that the stitching is of the highest quality. Position the fabric in the embroidery hoop while the fabric is aligned in a manner that avoids the fabric being distorted in the final product. Before starting the embroidery work, it is essential to test the design layout, thread tension, and machine settings to confirm that they have been appropriately configured. However, to move the load fully, the design can now be embroidered, and each head for the design should be evenly stitched. Finally, the product should be inspected before cleaning and maintaining the machine for its following uses to enhance its life span and performance.

Getting Started with the Control Panel and Software

Once you learn the significant control features and the software embedded in the 4-head embroidery machine, you can get the most out of it. For many machines, the computer’s screen contains a touch panel required for navigation, as it is usually the primary part of the machine that a user interacts with. One of the most significant advantages of this machine is that files can be loaded into the machine’s software through a control panel’s sub-feature – design import and export. So-called “default” software options should be used. These can include the basic settings in the mechanical parameters like stitch count, order of color stitches, and zones of fabric types.

One of the critical tasks in the software module should include developing and modifying the designs and appropriate stitch patterns for the specific project. However, before the commencement of the embroidery process, it is essential to check and ensure that all the calibration settings are suitable to maintain quality. This guideline and similar comprehensive guides from these leading resources highlight the need for design verification, which can be found on most recent interfaces and help avoid errors during the actual execution stage. In addition, elaborating on the conduct of the file management makes it possible to save and access all the design files, ensuring efficient operations. Users can implement the knowledge gained from these authoritative sources in a manner that enables them to effectively control the diverse features of their embroidery machines to ensure maximum productivity.

Ensuring Precision and Consistency in Finished Projects

Embroidery projects can be completed successfully and consistently with minimal wows by tackling the projects in a stepwise manner. I have seen good results using EmbroideryWare, Textile Tech Source, and Embroidery Machine Reviews, which all recommend preparation and planning that is meticulous and very detailed. In my case, I ensure that each job begins with placing the right threads on the machine and adjusting the tension depending on the material used. Careful calibration has always been my guiding principle, so I try to perform a dry run to check the alignment, stitch, and color.

Another critical step takes us through the second stage: constant supervision during embroidery. I deal with each stage so that, when there are inconsistencies, I act in real-time to make adjustments to resolve the differences before the final product suffers. After the final production has been done, I always take the time to look for the embroidered parts of the item and examine their discrepancies from a design and quality perspective, making sure that everything goes according to plan. By using these techniques, coupled with the advanced automation of my equipment, I can produce timely projects without compromising the quality of work.

Tips for Working with Different Materials and Garments

Adaptability and Precision are paramount when working with diverse materials and garments. My training and experience-driven knowledge from top places such as EmbroideryWare, Textile Tech Source, Embroidery Machine Reviews, and others leads me to suggest first determining the type of needle and thread for the fabric that will be used. I usually have thoughts about employing thinner needles and threads when dealing with silk to avoid damaging the fabric. In contrast, using more potent and thicker threads on denim fabrics is imperative as it guarantees strong stitching. Stabilizers are equally important; the right stabilizer will avoid fabric distortion for stretchy materials. I do a test stitch on a piece of fabric before any embroidery process to set the correct tension and make adjustments. The quality of the garment is of great focus, and my knowledge of the properties of each fabric reflects that no two garments are the same.

References

Frequently Asked Questions (FAQ)

Q: What should I consider when choosing a four-head embroidery machine?

A: When selecting a four-head embroidery machine, consider factors such as the types of garments you plan to embroider, whether you need capabilities for flat embroidery or tubular items, the brand reputation, and whether the machine is equipped for your specific needs, such as varying stitch types or a wide variety of thread colors.

Q: How does a four-head embroidery machine differ from a single-head machine?

A: A four-head embroidery machine can embroider multiple identical designs simultaneously, increasing production efficiency, while a single-head machine is typically used for smaller batches or more customized projects.

Q: Can a four-head embroidery machine handle embroidery on finished garments?

A: Yes, a four-head embroidery machine can handle finished garment embroidery, allowing you to sew designs onto already constructed items such as shirts, jackets, and other apparel.

Q: Is it essential for the machine to be equipped with a particular type of software?

A: A machine equipped with advanced embroidery software can significantly enhance design capabilities, ease of use, and integration with other digital tools, making it easier to manage and execute complex embroidery projects.

Q: What are some reputable brands for four-head embroidery machines?

A: Some reputable brands include Ricoma, known for its user-friendly machines and robust support, and other manufacturers based in countries such as China that offer high-quality machines suitable for various embroidery needs.

Q: How do I maintain my four-head embroidery machine?

A: Regular maintenance involves cleaning, oiling the moving parts, checking tension settings, and ensuring the wheels and other components are in good condition to avoid breakdowns and ensure smooth operation.

Q: Can these machines handle a wide variety of fabrics?

A: Yes, most four-head embroidery machines are designed to handle various fabrics, from delicate silks to more rigid materials, making them versatile for different embroidery projects.

Q: Are there specific policies I should know when purchasing a machine?

A: When purchasing a four-head embroidery machine, review the manufacturer’s privacy policy and return policy to understand how your data is handled and your options if the machine does not meet your expectations.

Q: Is it possible to embroider shoes with a four-head embroidery machine?

A: While typically used for garments, some advanced four-head embroidery machines can be adapted to embroider shoes, especially if they have attachments for handling more complex shapes.

Q: What is the advantage of using tubular embroidery over flat embroidery?

A: Tubular embroidery allows for embroidering around cylindrical items like sleeves and pant legs without deconstructing the garment, whereas flat embroidery is ideal for flat surfaces like patches or unassembled fabric pieces.