When the aim is to keep the foods for longer periods, intensify the flavors or include healthy options, then businesses within the food processing sectors find industrial food dehydrators as indispensable tools. This blog is intended to educate you about the many properties as well as the advantages of industrial food dehydrators so that you can make the right selection based on what your business requires. For food dehydrators, large scale food production do’s not matter whether you are a small start up, there are various capabilities and numerous varieties that once understood will increase your efficiency and improve the quality of products. Allow us to show you the different categories of dehydrators, trends in technology and other relevant aspects that need to be considered when buying dehydrators for your business.

What is an industrial dehydrator and how does it function?

Apprehending the economic significance of industrial dehydrators

Industrial dehydrators are equipment providing food drying by evaporation of moisture under controlled drying process. Thanks to heat and air movement, these devices keep the foodstuff by drying water content of the food in order to prevent the food from bacteria propagation and decay. An industrial dehydrator is designed specifically for the purpose of providing an increased period for storage of foodstuffs without tampering the taste and nutrients or even increasing the same. These are operated using different techniques of food drying such as air drying, freeze drying and vacuum drying which are meant for various forms of food and business requirements.

Explain the relationship between airflow and drying in abnormally shaped objects.

In the processes of drying by means of industrial dehydrators, the removal of moisture is made more effective because there is flow of air which promotes evaporation. Air always aids the drying of foods since warm or hot air is moved around the food directly enhancing the evaporation rate. Carefully controlled airflow is critical for ensuring that the best possible drying rates and energy efficiencies are generated and this has direct implications on the success of the dehydration process.

Important characteristics of a commercial dehydrator

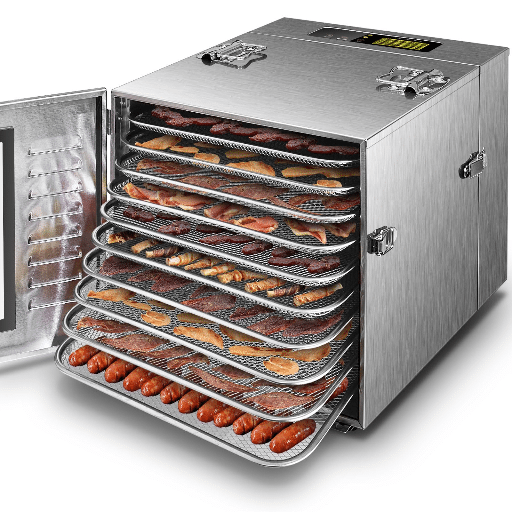

The commercial dehydraters come with several features that are crucial in improving the efficiency. Adjustable temperature controls which allow for specific regulation according to the food type for instance. High-capacity trays make it possible to dry a lot of your food at once which is very productive. The high level of research based on theoretical simulation concepts helps in evenly drying food and further avoids conditions that promote moisture formation that would cause spoilage. There are also designs that are energy efficient which are cheaper to operate but still have strong construction that allows them to last very long in harsh industrial use.

How to choose the right commercial food dehydrator for your needs?

Factors to consider before purchase

The following considerations will be critical in determining the commercial food dehydrator that is best for your particular needs: First is the production capacity of the machine so that it matches your production volume expectations Second consider the Temperature Range so that there is versatility with different foods Third is the Airflow System for effective drying to avoid wastage Fourth: Energy Conservation to reduce running costs Fifth is the Build Quality for resistance over time in rugged conditions. Further appraisal may include programmable settings and ease of maintenance to bolster these useful characteristics even further.

The importance of temperature control

In a commercial food dehydrator, it is essential to control temperature so that the drying process is done precisely. Different foods need specific temperatures to be dehydrated in an efficient yet safe manner. Keeping food at the right temperature helps to maintain the food’s taste, nutrition and structure, it also lessens chances of microorganisms developing, as well as preventing excess evaporation, which would spoil it. Therefore, a dehydrator which possesses an adjustable temperature control system will improve greatly the quality and uniformity of the final dried products.

Evaluation of industrial mesh trays in comparison to stainless steel trays

In evaluating both stainless steel or industrial mesh tray options for a commercial food dehydrator, the following may be helpful: Stainless steel trays are strong, lightweight, and have good corrosion resistance, thus making them suitable for long-term use even in harsh working conditions. However, industrial mesh trays do provide good ventilation which in turn promotes even drying and quicker dehydration rates but might be a little harder to clean properly so as to maintain hygiene standards. Make your selection considering the factors of durability as well as drying speed efficiency.

What are the benefits of using commercial dehydrators in food production?

Advantages of food preservation using the dehydration process.

Food dehydration is of great importance for the preservation of food. It is one of the classic preservation techniques that extends the shelf life of products by moisture elimination that prevents the reproductive processes of bacteria, yeast, and mold organisms as well as insects. This approach allows for the retention of most of the nutrients of the food in addition to the fact that the weight and the volume of the food is reduced, thus reducing storage and transportation expenses. Foods that have undergone dehydration usually have good taste, and during cooking, they can be hydrated again. Therefore, the application of commercial food dehydrators makes it possible to improve the food production processes efficiency and sustainability. There is less waste of products which translates to cost reduction.

Improving preparation and the use of primary resources in the process

The employment of commercial dehydrators in food production improves efficiency by speeding up the preservation process, making it possible to pack the processing and achieve standardization of the finished product. Dried foods thus render great economy by lessening waste, extending the useful life of foods and maximizing nutrients. These advantages make the use of dehydrators significant in improving food production’s overall efficiency.

Uses of pet food or other products

The use of any commercial dehydrators has very great advantages for pet food and other commodities because these devices for dehydration are very easily used and power the process on a large scale. This saves nutrients and increases shelf life and the quality of the products. In regards to dehydrated pet food, it is more effective and retains its taste. In addition, its volume has been lowered, which makes it easy to store and transport. Also, the dehydrated pet food is not easily spoiled and does not allow the growth of microbes which makes it a much better alternative in sustaining the health of the animals.

How to maximize the efficiency of your food dehydrators?

Tips on drying and monitoring temperature steady state conditions

Effective operations of food dehydrators requires that drying and temperature conditions are managed and are consistent. To begin with, the dehydrator should be pre warmed for the range that is suited for that specific food product. Place food pieces flat on a tray ensuring adequate separation for proper air flow. The temperature should also be changed and constant monitoring is required for uniform drying because too much fluctuation might spoil the products. These procedures are effective and variate should seek instructions from the manufacturers as variate rotates trays in the time intervals helps to achieve uniform dehydration of the product.

Importance of Prospective Tray Locations for Airflow

With respect to Dehydration, proper tray arrangement will increase airflow efficiency which will speed up the drying process. Air should be able to reach each and every food piece by arranging the trays appropriately. Avoiding too much concentration and leaving space are parts of this strategy. In doing so, you assist the dehydrator in drying the food product in the most effective and uniform manner, allowing for consistency and high quality. In this case, it is advisable to change the position of the trays from time to time while the food is drying in order to enhance airflow.

Setting the timer for a maximal duration of a full 24hours even for some foodstuff with difficulty in drying deserves the respect

Keeping the timer on is very crucial and important considering you can schedule the entire drying process for 24 hours without having the need to constantly check on the dehydrator. Every type of food item has specific drying times recommended for it. With the use of a timer, you can dry foods within the recommended drying times with little chances of over-drying. Different types of foods require different amounts of time for them to be dehydrated and this timer helps in maintaining that time or time range which allows the individual to perform other tasks too. Another point is, the timer is an important element in a dehydrator which helps in achieving the desired outcome without causing any wastage.

Reference sources

Frequently Asked Questions (FAQs)

Q: What features should I look for in a food dehydrator aimed at the commercial sector?

A: The food dehydrator must have a large capacity and an industrial-grade stainless steel body, and a 99-hour timer is also a feature worth having if there is something that needs to be dehydrated. Besides, an integrated food slicer can also speed up the process.

Q: What about the warranty of the industrial food dehydrator?

A: Yes, our industrial food dehydrators have a comprehensive 5-year warranty which covers any defects that might arise, as well as guarantees megaservice from the original date of purchase.

Q: How do I use an industrial food dehydrator without compromising food safety?

A: For vital food security, it is essential to comply with manufacture instructions, clean parts of the unit in a regular basis and use controls when wearing food safety gloves. This will assist in avoiding potential contamination.

Q: What is the size of a commercial food dehydrator designed to meet large drying demands?

A: For instance, many large commercial food dehydrators can be stacked to 10 trays, and with multiple trays some amount of food can be processed all at once. Ideal for industrial usage, this large capacity ensures efficient drying requirements.

Q: Do commercial applications require a stainless steel dehydrator?

A: Yes, a commercial grade stainless steel dehydrator is important for strength and hygiene in commercial use. It does get a lot of use, and remains hygienic.

Q: Is it possible to make jerky using the dehydrator?

A: Certainly, our dehydrators are ideal for juices. They do have focused temperature and airflow, which enables the safe production of dried meat products.

Q: What are the advantages of using an industrial cart when combining a food dehydrator?

A: An industrial cart is useful for mobility and space, as it helps to move and arrange trays in the busy kitchen of a commercial establishment.

Q: What does it cost to buy industrial food dehydrators?

A: The price of industrial unit may differ depending on the specification and capacity, however for commercial use, it is wise to choose a reliable unit with a comprehensive warranty, since the initial cost may preserve greater value in the long run.

Q: Do you have any extra equipment which can assist in the efficient operation of the food dehydrator?

A: Yes, the use of an all-in-one food slicer will improve the preparation stage, and hence, one would achieve the best slices and the best dehydration possible in your industrial applications.