Laser cutting of foam is an industry game changer. From custom packaging to detailed prototypes, foam can be cut with unmatched efficiency and precision. Because of the importance of the topic, this guide will examine the significant advantages of laser foam cutting and the most frequently used types of foam. It will also explain the underlying technology and practical advice for optimizing the effectiveness of the laser cutters. This guide will be helpful for professionals looking to advance their manufacturing processes and hobbyists looking to take their projects to the next level. From this guide’s information, readers can fully utilize foam laser-cutting technology.

What types of foam can be cut with a laser cutter?

Depending on the chemical composition and thickness of the foam, various foam materials can be laser cut. Some of the more common ones are Polyethylene (PE) Foam, Polyurethane (PU) Foam, Polystyrene (EPS) Foam, and Ethylene Vinyl Acetate (EVA) Foam. Each type has unique traits, including density and melting point, that determine the cutting parameters and results. PE is an example of closed-cell foam, ideal because it can burn but cleave to give clean cutting edges. Softer, open-cell foams, like PU, require more tolerance in the adjustment settings to prevent deformity. There is a need to properly test the compatibility of the foam material to ensure safety and precision.

Understanding the suitability of different foam materials for laser cutting

For efficient and precise results, some foam characteristics must be examined when laser cutting foam materials. Closed-cell foams such as Polyethylene (PE) are well-known for their high structural integrity derived from their finer microstructure. As a result, they produce clean edges that are free of burns or other forms of residue. PE is denser and has more rounded thermal properties, making cutting complex designs with a laser easier. In contrast, however, Soft open cell foams, such as Polyurethane (PU) and soft foams, are less dense and can be problematic due to low melting points and high deformation when dealing with heat. Fine-tuned laser power and speed settings are needed to protect the PU from deformation and for reduced surface contact.

The composition of the foam is another essential aspect to evaluate. Some foams, including PVC, can produce harmful gases or acidifying by-products when laser cut. Appropriate testing of the material’s compatibility and adequate safety measures for ventilation systems are required when dealing with these materials. Furthermore, checking whether the laser cutter can cut that particular foam is paramount since the machine’s power and focus may affect different materials differently. All these factors assist the users in selecting the best foam for their laser-cutting requirements.

Exploring EVA foam, polyurethane foam, and polyethylene foam for laser cutting

I discovered that EVA foam, polyurethane foam, and polyethylene foam contain characteristics unique to each type that would determine their usability in laser cutting. EVA foam is beneficial because of its smooth surface and rigid yet flexible structure, which allows for clean cuts and complex designs when adequately set. On the other hand, polyurethane foam is softer and less dense than polyethylene, which causes the edges to be less defined and produces lower machine power to avoid scorching. Lastly is polyethylene foam, which is lightweight and durable. Its dense composition, however, requires higher power settings to produce more significant amounts of fumes. When evaluating these materials, one considers aligning the properties of the materials to the required project outcomes while ensuring that proper ventilation and safety precautions are exercised during the operation.

Which foam types are laser-safe and produce the best results?

The more common laser-safe foam types are polyethylene (PE), ethylene vinyl acetate (EVA), or polyurethane (PU) foams. Polyethylene foam is firm and can be entirely laser cut with slight charring where the cuts are made, but it needs to be well-ventilated because of fumes. Another good option is EVA foam because it is easy to cut and can be smoothed but may also give off fumes. Polyurethane foam is laser-safe but burns more efficiently and must be laser-cut or engraved with a specific power and speed to get the best outcome. As with any materials, the proper laser settings should be used in combination with good ventilation to prevent inhalation of fumes and ensure good results with as little risk as possible.

How does a foam laser cutting machine work?

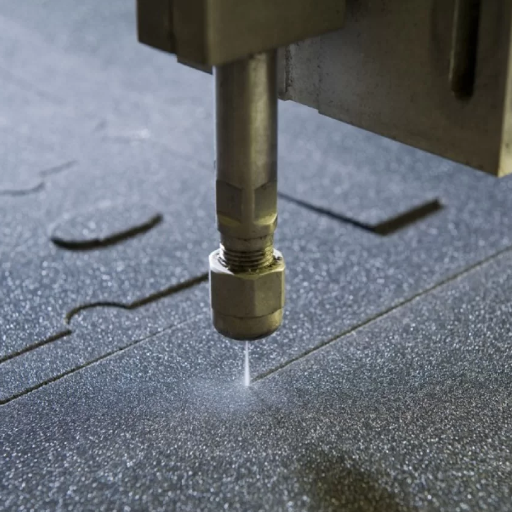

A foam laser cutting machine cuts foam materials with a focused laser beam. First, the laser directed at the focus point of the beam produces heat to either melt or vaporize the foam. To obtain clean and precise cuts, the laser’s power, speed, and focus are adjusted according to the density and thickness of the foam. Also, a built-in exhaust system for cutting fumes facilitates ventilation by removing fumes and debris. This mechanism achieves high accuracy while minimizing waste.

The basics of laser technology in foam cutting

Laser cutting is one of the best ways to execute high precision and deep cutting, particularly for foam materials. Intricate and complex designs require highly focused laser beams,s which is why the technique is ideal for custom usage. As opposed to traditional approaches, laser cutting involves low physical contact with the foam, decreasing the chances of damage or deformation. In addition, since the systems are automated, they produce more rubbers quickly while maintaining the same quality in different pieces.

With CAD software, users can set the cutting patterns to be repeatedly replicated with precision. This may not need as much hand-holding as other CAD designs, which makes work easier for engineers and cuts down costs. Also, laser technology works with all types of foam, including specialty, polyurethane, and polyethylene foams. Changing specific parameters, such as the power and speed of the laser, helps achieve desirable outcomes regardless of the material type.

Advanced filtration and extraction systems tackle environmental safety by limiting the emission of fumes and particles during the cutting method. This is helpful for the operator, but other people will remain protected, too, which increases environmental safety regulations. Foam processing can be done more efficiently and sustainably with laser cutting.

CO2 lasers vs. diode lasers: Which is better for cutting foam?

Whenever I need to cut foam, I think about using a CO2 or diode laser. I think a CO2 laser would be most effective for cutting foam. CO2 lasers help focus a beam with the correct wavelength suitable for cutting and engraving non-metal materials like foam. Also, the power and accuracy of CO2 lasers allow for clean edges without deforming the material, which is ideal for foam-related tasks. On the other hand, diode lasers are less powerful and more suitable for light engraving and cutting tasks. While diode lasers serve portability and cost savings, they struggle with cutting dense foam and thick materials where a CO2 laser would do just fine. CO2 lasers have proven to be more effective and resourceful in foam cutting.

Key components and features of a foam laser cutter

According to what is present, a well-performing foam laser cutter usually has some necessary parts. First, whether CO2 or diode, the laser source is essential and directly affects the cutting accuracy and power. The first part of this optical system is a set of mirrors and lenses: they ensure accurate direction and focus of the laser beam. Another essential element is the motion control system, which is active during the machine’s working process. It is in charge of the exact positioning of the laser head. It is usually provided by stepper or servo motors. In addition, an embedded cooling system prevents overheating and increases the machine’s life by sustaining optimal operating temperatures.

Furthermore, ventilation and air assist systems are essential: they remove smoke and rubbish from the cutting zone, ensuring smooth and precise machine operation. Last, software amenities are also necessary, allowing operators to easily set and adjust settings and design configurations. Each part serves a purpose in determining the machine’s performance, durability, and versatility.

What are the advantages of using a laser cutter for foam?

Laser cutters have multiple distinct benefits when working with foam. First, they excel in accurate cutting, ensuring that even the most detailed intricate designs and shapes are precisely cut. Since the laser cuts from a distance, there is less chance of material deformation, ensuring professional-grade edges and surfaces. Furthermore, the precision of the laser cutter allows it to cut through different types of foam, making it applicable for more than one purpose. Since their automation improves production speed, it also reduces time spent during the manufacturing process. Finally, with automated settings, accuracy is guaranteed with every cut, irrespective of the number of cuts needed. In addition, the digital nature of the machine means the process is easy to adapt, which means it can be customized to meet the specific requirements of a project without impertinent supplementary machinery.

Precision and versatility in creating intricate designs

Laser cutters are efficient tools that do not compromise on multi-layered or intricately detailed cuts. Their unparalleled precision allows the user to cut high-level, complex patterns without shifting focus or heavy concern. Furthermore, even smooth cuts can be made using CAD software, ensuring maximum accuracy with every edge. This added computer software is especially helpful with foam as it makes the chance of material distortion and uneven cuts virtually non-existent. In addition, lasers can work through all densities and types of foam, from soft and light foams to stiff and high-density ones. Because of their multi-purpose use, CAD software benefits users by making design customizable and intricately detailed while ensuring repeatability regardless of project scope.

Efficiency and speed compared to other foam-cutting methods

When evaluating the efficiency of a laser cutter compared to other traditional foam-cutting methods like hot wire cutters or blade cutters, it becomes evident that foam-cutting laser cutters cannot be matched. Unlike conventional methods, which involve much manual work, laser-cutting machines work without human assistance. This means that cutters don’t have to do any precision work, which would have required much time. Moreover, by removing the manual control processes, laser cutting ensures consistent quality, optimizes production, and reduces material wastage. The best part is that foam laser cutters can quickly alternate between complicated designs, so all projects’ lead times are significantly shorter. For these reasons, laser cutters have become the preferred machines for all businesses, big or small.

Clean cuts and reduced material waste

Laser cutters are proficient in making precise and sharp cuts to the materials. This is one of their significant advantages over traditional methods, which result in rough edges and distorted shapes of the materials being cut. The concentrated laser beam cuts smoothly without tears, burns, or frayed edges, so the foam is not damaged. This high level of detail improves the quality of the cuts and decreases the amount of material wasted during the cutting process. Also, laser cutting systems are built to enhance the efficiency of cutting material using cutting pattern nesting algorithms, which calculate the placement of the cut patterns on the foam sheet. Such techniques increase the savings from laser cutting and reduce waste, making it more environmentally friendly. Overall, these characteristics help achieve higher accuracy and waste reduction in highly detailed designs on delicate types of foam.

How do you choose the best laser cutter for foam projects?

It is essential to consider certain factors when choosing a laser cutter for foam projects to maximize productivity and efficiency. Start with evaluating the power rating of the laser, as greater power output is usually needed for cutting through thicker or denser foam materials. Next, assess the machine’s bed size, as the volume of sheet foam you have and the scope of the project you are working on will dictate the bed size you need. Cutting accuracy is another important consideration, so choosing a cutter with high resolution and constant power output for clean cuts and intricate designs is advisable. Also, determine if the machine is adjustable for various foam types and thicknesses to meet your custom application needs. Lastly, I prefer models with sophisticated safety features, robust ventilation systems, and dependable after-sales service to ensure sustainable and professional-grade operations.

Factors to consider when selecting a foam laser cutting machine

When choosing a foam laser cutting machine, I always consider essential features that will satisfy the requirements of my project. To begin with, I analyze the machine’s laser power because high wattage is critical for cutting through thicker or denser foams. After that, I checked the bed dimensions to verify that they accommodated the size of the foam sheets I planned to work with. Lastly, precision is vital, so I look at the machine’s resolution and power consistency that guarantees clean, accurate cuts for professional-looking end products. These things help me with my machine selection, so it satisfies both my technical requirements and my project objectives.

Comparing laser power, work area, and focal length for optimal results

Balance is essential to contemplate while gauging laser power, work area, and focal length. The efficiencies and depths of a laser-cut foam directly correlate to the power, so while lower wattage lasers may do the job of detailed engraving, 100W devices make foam cutting effortless. One must also consider the foam sheet size the machine’s work area can fit. A machine with a 600 x 900 mm work area is more flexible for detailed large-scale projects. Moreover, the cut’s accuracy and precision depend on the lens’s radius; shorter focal lengths are ideal for precision detailed cuts, and longer focus lengths shine when cutting thicker multi-layered materials. Together, they grant your machine the ability to perform with optimum precision to fulfill your application requirements.

Top foam laser cutters for different project scales and budgets

While looking for the best foam laser cutters, I’ve realized that the Glowforge Plus is most suitable for small to medium-sized endeavors because of its ease of use and accuracy. The Thunder Nova 51 provides an even more robust solution with a larger work area and more advanced features for detailed tasks, making it ideal for more extensive or industrial projects. Finally, the OMTech 60W provides a balanced option for professional-grade performance on a mid-tier budget. Each feature has different power and reliability ranges for varying foam-cutting needs. With each of these laser cutters, there are other project scopes and budgets, making it essential to tailor your choice to your application needs.

What safety precautions should be taken when laser cutting foam?

From a safety standpoint, personal safety and proper equipment operation are a must when laser-cutting foam. Working in a well-ventilated space or wearing a fume extraction mask is essential because some foams emit harmful gasses when heated. Make sure the type of foam you use is laser-safe because some foams melt or ignite. Additionally, safety goggles with laser protection must be worn to protect your eyes from laser reflections. To prevent malfunction, the laser cutter should be routinely maintained, and to manage any unintentional fires, a fire extinguisher should be accessible. Lastly, the equipment must be utilized according to instructions and recommendations when working with specific materials.

Understanding potential hazards and fume generation

Some risks associated with laser cutting of foam need to be managed for safe practice. The most crucial issue is the emission of fumes and gases, which, depending on the type of foam, could also contain poisonous materials such as hydrogen cyanide, formaldehyde, or other VOCs. These fumes, vapors, and substances are dangerous to inhale without the appropriate ventilation and access to proper extraction systems. Some foams are very combustible and can pose fire risks when laser power is excessive or if the material is non-laserable. There are also health risks or damage to machinery from residual particulates from cutting lapses if there is no efficient guarding.

To control these factors, a laser-cutting-friendly material has to be chosen along with all other industry best practices. This ensures that the environment is safe for the operators while remaining efficient with the machines.

Proper ventilation and protective equipment for safe operation

I assure you that proper ventilation cannot be compromised when dealing with the fumes and gases emitted when cutting foam using lasers. An industrial fume extractor or exhaust ventilation system is needed to capture and remove VOCs. It also provides a reasonable assurance that air quality regulations are being met. Furthermore, adequate chemical PPE, such as respirators with vapor filters and safety goggles, must be worn to protect oneself. Maintenance and inspection of ventilation systems must also be done regularly because their performance during operations needs to be ensured. These measures ultimately protect both the operator and the surrounding work environment.

Best practices for handling different foam types during the cutting process

Knowing the properties of specific foam types is critical for precision and safety during the cutting process. As for open cell foam, use lower laser power, slower cutting speeds, and more focused attention to detail to minimize burning or charring owing to the bounding box’s open nature. Closed, denser cell foam requires more laser power and multiple passes for cleaner, consistent cuts without melting. Always confirm the composition of the material to avoid hazardous fumes, mainly when working with polyurethane or polystyrene foams, due to their dangerous emission of chemicals when heated. Always perform test cuts on material samples to adjust the laser parameters and settings for the best results while limiting material waste. Finally, ensure that the foam is firmly fixed while cutting to avoid warping, misaligning, or yielding uneven cuts, thereby ensuring quality performance and operational efficiency.

How do you optimize laser settings for cutting various types of foam?

As we set precise laser configurations for different foam types, the first step is determining the foam type and its makeup. When cutting open-cell foam, use lower power settings, less cutting speed, and set the laser not to burn the foam. Use higher power settings while cutting closed-cell foam, and consider multiple passes for tougher cuts. Accomplishing test cuts on scrap materials is vital to further setting refinements to achieve the desired quality. Ensure adequate exhaust for polyurethane and polystyrene foams to reduce harmful gas emissions. Secure the foam material firmly before cutting to avoid distortion or undesirable results.

Adjusting laser power, speed, and focal length according to the foam’s properties

The specific attributes of the foam must be considered while setting the laser power, speed, and focal length for foam cutting. When working with lower-density open-cell foams, do not exceed higher power settings if the cutting speeds have to remain high. Likewise, cut at lower speeds to ensure minimal burning or melting. On the other hand, closed-cell foams or higher-density materials would require an increase in the power level for adequate penetration. A slight increase in cutting speed may also be beneficial in ensuring the cuts are clean without charring. The optimal focal length should be modified to ensure the laser beam is sharply focused at the cutting surface. Ensuring precision guarantees improves edge quality and ensures there is no uneven cutting. Remember to perform test cuts on scrap material to validate these adjustments and make sure the entire project remains consistent without any overlap.

Tips for achieving clean cuts and preventing melting or burning

I take on several strategic approaches to ensure I achieve clean cuts without burning or melting the foam during the laser cutting. First, I have the laser settings adjusted to match the type of foam. For softer foams, I keep the power low and adjust the speed to prevent overheating. Proper ventilation is essential to remove heat and cut debris properly. I use constant air assistance that reduces the likelihood of burns while ensuring the edges are cleaner. I can also confirm the parameters for the test cuts on scrap pieces to verify the setting before doing the actual project. And I often clean the lens and the mirrors of the laser to maintain efficient precision and consistent results.

Creating test grids to determine ideal settings for different foam materials

An equally important step to the aforementioned parameters of the method, but never addressed by other critics, is making grids to seek the appropriate parameters for the foams. Start by building a grid with different power and speed sets for every box. On one side, constantly add power increments, for example, 10, 20, 30%, and on the other, speed 50, 60, 70%. This approach can be passive but great for setting parameters. The foam being tested should represent the materials utilized for the ultimate project.

While performing these tests, labeling every section of the grid is essential so that results can be easily referenced later. While assessing, pay attention to edge quality, cut depth, and burning or melting signs (if any). Remember, the workspace needs to be adequately ventilated, and there should be air assistance during the entire procedure, or else heat will concentrate. Besides, precision at the focal point needs to be taken care of; cutting height can, and should, be adjusted slightly to enhance the cutting on varying foam densities. This method saves time and limits material waste by allowing specific settings to be used before production.

What are some creative applications for laser-cut foam?

Laser-cut foam is an instrumental material for various industries and other activities. It is employed in custom packaging, where foam sections are accurately cut to fit particular shapes to pack sensitive or awkwardly shaped items for shipment. Due to its detail-cutting capabilities, artists and designers use laser-cut foam to make large stencils, decorative pieces, and dioramas. It is also used in the theater and film industry to create detailed props and other set pieces. The automotive and aerospace sectors utilize laser-cut foam to manufacture components of seats and parts for thermal insulation. The combination of precision cutting and foam’s adaptability makes it a helpful tool for creativity and practicality in every field.

Designing custom foam inserts for packaging and organization

Developing custom foam inserts starts by knowing what items need to be stored or placed inside a box and their dimensions. This procedure requires selecting the most suitable type of foam, considering its density, durability, and shock-absorbency. PE, PU, and XLPE are among the most popular types of foam used, and each one carries different benefits that are suited for the task.

The next step is carefully measuring the material to ensure a perfect fit. CAD software is often used to develop the item into a detailed model with the appropriate cutouts. The designs are then sent to a laser cutter or CNC machine to guarantee the product’s quality control. The final product could also be enhanced through color coding or layered inserts for better organization.

Custom foam inserts are manufactured and used in tools management, aerospace, industry e-commerce, and electronics. They provide improved organization, impact, vibration, and environmental stress protection. Combined with design software, precision manufacturing makes it easier for engineers and designers to develop appealing and functional custom designs.

Creating intricate foam board projects and decorative elements

While designing advanced foam board projects and decorative pieces, I try to sculpt the distinct properties of this material to relish its fullness. I initiate the process by sketching it out in CAD software, enabling me to visualize it in detail before making it. After completing the design, I manually cut the foam board using a precision blade or CNC Router while more elaborate shapes are carved using automation. I add layers, color highlights, and other texture details to enhance the decorative elements’ beauty further. The lightweight and robust feature of foam board serves its purpose well in architectural models, signage, creative displays, and other things that emphasize functionality and aesthetics.

Exploring foam laser cutting in prototyping and product development

The advent of foam laser cutting has profoundly impacted prototype and product development by offering an effective, quick, and flexible way to create shapes in foam. This technique uses a high-powered laser to make precise, delicate cuts with little risk of damaging the material due to excessive heat. The capability of cutting foam sheets with tight tolerances makes it invaluable for creating prototypes, foam packaging inserts, and lightweight structural components. Furthermore, laser cutting guarantees the same outcome for many cuts, which is essential during the iterative processes of designing and crafting on small scales.

For optimal materials usage, lasers are used for cutting instead of traditional methods because they allow for speed and less waste. Specialized laser systems can be used for different foam density and thickness types, meaning that any requirement can be catered for. This flexibility helps industries like aerospace, automotive, and consumer goods manufacturing, which need specific material properties. Engineers and designers achieve precision and eliminate the hassle by incorporating foam laser cutting during product development. This technology is an effective tool for providing innovative and quality solutions to remain competitive in the market.

References

Frequently Asked Questions (FAQ)

Q: What types of foam are suitable for laser cutting?

A: Several types of foam are suitable for laser cutting, including EVA foam, polyethylene foam, and certain types of PVC foam. These materials respond well to laser beams, allowing for clean and precise cuts. However, it’s important to note that not all foams are laser-safe, so always check the material specifications before processing.

Q: Can I use a fiber laser to cut foam?

A: Fiber lasers are powerful cutting tools but are generally not the best choice for cutting foam. CO2 lasers are more commonly used for foam cutting due to their ability to cut at lower temperatures, which is ideal for foam materials. Fiber lasers are typically used for cutting metals and other hard materials.

Q: What are the advantages of laser-cut foam inserts?

A: Laser-cut foam inserts offer several advantages. They provide precise, custom-fit protection for delicate items, ensuring a snug fit in cases or packaging. The laser-cutting process allows for intricate designs and clean edges, which are difficult to achieve manually. Additionally, laser cutting is efficient for producing multiple identical inserts quickly.

Q: Is EVA foam laser cuttable?

A: Yes, EVA foam is suitable for laser cutting. Due to its flexibility and durability, it’s a popular choice for many foam products. You can achieve clean, precise cuts and even engrave intricate designs when cutting EVA foam with a laser. However, appropriate laser settings are essential to avoid melting or burning the foam.

Q: What should I consider when choosing a laser machine for cutting foam?

A: When choosing a laser machine for cutting foam, consider the power output, cutting speed, and bed size. CO2 lasers are typically the best choice for foam cutting. Look for machines with adjustable power settings to accommodate different foam thicknesses. Also, ensure the machine has proper ventilation to handle fumes generated by the laser processing of foam.

Q: Can I laser-cut polystyrene foam?

A: While it is possible to laser-cut polystyrene foam, it’s generally not recommended. Polystyrene foam can melt and release toxic fumes when exposed to laser beams. If you need to cut polystyrene foam, it’s better to use alternative cutting methods like hot wire cutting or CNC routing. Always prioritize safety when working with foam materials.

Q: What are some standard foam-cutting techniques besides laser cutting?

A: Besides laser cutting, standard foam cutting techniques include CNC routing, waterjet cutting, hot wire cutting, and die cutting. Each method has its advantages depending on the type of foam, desired accuracy, and production volume. For example, CNC routing is excellent for thick foam sheets, while hot wire cutting is ideal for straight cuts in polystyrene foam.

Q: How does laser cutting foam compare to CNC cutting?

A: Laser and CNC cutting are both effective for foam processing but have different strengths. Laser cutting excels at producing intricate designs and clean edges and is faster for thin materials. CNC cutting, on the other hand, is better for thicker foams and can handle a wider variety of materials. Laser cutting is generally more precise, while CNC offers more versatility in cutting depths and foam types.

Q: What safety precautions should I take when laser-cutting foam foam?

A: When cutting foam with a laser, ensure proper ventilation to remove fumes generated by the laser. Wear appropriate safety gear, including laser safety glasses. Use a laser machine with a proper filtration system. Never leave the machine unattended during operation, and always follow the manufacturer’s guidelines for your specific laser cutter. Lastly, ensure the foam you’re cutting is laser-safe to avoid potentially hazardous reactions.

Q: Can laser cutting be used to make soundproof foam?

A: Yes, laser cutting can be used effectively for soundproofing foam. It allows for precisely cutting acoustic foam panels into specific shapes and sizes, which is crucial for proper installation and maximum sound absorption. Laser cutting can create intricate patterns that enhance the foam’s sound-dampening properties. However, ensure the specific type of soundproofing foam you use is suitable for laser cutting to avoid any adverse reactions.