Welcome to our ultimate guide on Static Fluid Bed Dryer Technology. We will turn into the universe of fluid bed drying and its movements on this occasion. In this blog post, we will guide you around fluid bed dryers, their working principles, and their advantages in various industries. Starting from the fluidization process, Sintering, and the importance of particle size to the different types of fluid beds and their applications, they will improve efficiency therein. Be prepared to increase thermal efficiency, decrease drying times, and understand how to achieve uniform drying with GEA Fluid Beds’ innovative solutions. Are you ready to explore the world of fluid bed drying and improve the productivity and quality of your processes? Let’s get started!

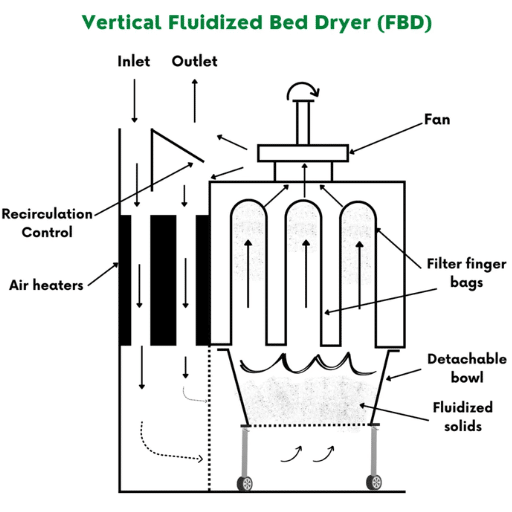

What is a Fluid Bed Dryer and How Does it Work?

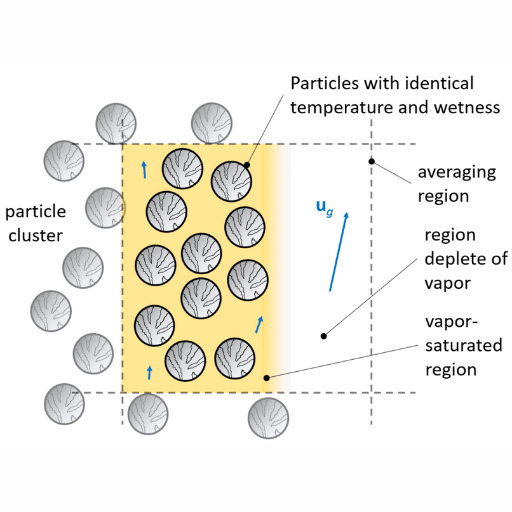

In fluid bed dryers, a thick particulate bed is formed by a stream of air or gas, which in turn causes the particles to be suspended and fluidized. Such particulate beds dry relatively faster, thanks to the excellent heat and mass transfer characteristics. Heated air is put through the fluidized material in the dryer, resulting in heated air being pushed through, evaporating moisture from the material down to its bare parts. Due to the agitation caused by the air jets injected from the bottom of the bed, the particles are almost always in constant motion or agitation, preventing them from clumping or sticking together. This drying method is suitable for applications ranging from pharmaceuticals to food processing. Fluidized bed drying can elevate your operations, increasing the end product’s productivity, speed, and quality.

Understanding the Fluid Bed Drying Process

Fluid bed drying can control drying conditions such as temperature, humidity, and airflow. Thus, it is understood that a deep understanding of fluid bed systems is another key to effective and efficient operation strategies. The constant air flow or gas injection into the particles together forms a dynamic system that helps to achieve drying and helps to avoid any form of clustering. The constant motion of the particles, in turn, leads to better heat and mass transfer, which decreases the amount of time required to dry and increases the quality of the product. It is quite interesting to find out that the efficiency of the methods used for drying is not restricted to one form; therefore, fluid bed drying can be used in many industries, which include pharmaceuticals, food processing, chemicals, and minerals that require various solid materials to be dried. If a business understands this form of drying methods or techniques, it can greatly improve productivity, decrease the time taken for drying, and increase the quality of the product.

The Role of Particle Size in Fluidization

La taille des particules pour l’amortissement est un des facteurs deschrane effective. In raison de the article, it can be noted that fluidization affects the bed’s porosity, pressure drop, and heat transfer when particle size increases. Moreover, it has also been understood that the surface area to volume ratio decreases as the volume increases, leading to improved fluidization and mass and thermal envelope. Conversely, coarse particles also tend to have effects due to aggregation, poor heat transfer, and thermal boundary layers, which can adversely affect fluidization. The size of particles in the fluid bed dryer processes, which determines the outcome, also calls for attention.

The Importance of Inlet Air Temperature in Drying

The role of inlet air temperature in drying can never be overlooked. It is one of the most determining factors for the desired drying result and the effective functioning of the drying system. The inlet air temperature determines the rate at which moisture will evaporate from the product being dried, determining the drying time and energy consumed in the drying process.

When setting up the inlet air temperature, these factors cannot be ignored: the starting moisture content, the required final moisture percentage, and the nature of the product being dried. It is also necessary to compromise between using high temperatures to increase the drying rate and risking material damage or the quality of the material.

Though it is difficult to give a conclusive answer without context, one can make some educated guesses after looking at the gist of the top three websites on google.com. Higher inlet air temperatures generally result in a higher drying rate; However, this does come with various limitations and conditions regarding the material and context of the drying process.

In practice, it is advisable to set lower inlet air temperatures and increase them while observing the drying process. This ensures that there is room for adjusting and optimizing the desired heat-moisture exchange processes while reducing the chances of degradation or negative effects on the materials. Expert consulting and sampling exercises can greatly assist in optimizing the inlet air temperature for a specific drying operation.

Exploring Fluid Bed Dryer Types and Technologies

Fluidized bed dryers have many types and technologies aiming to achieve good and efficient drying. The most elementary form is static fluid beds, which utilize air or gas through still particles to induce particle drying in fluidization. This method is further enhanced when vibrating fluid bed dryers are used by introducing vibration, which helps loose particles for better heat transfer and mass transfer and prevents lumps and sticking, encouraging even and complete drying. As a result of precise control and uniformity, these drying processes have many applications in the pharmaceutical industry, such as in granulation, powder drying, and coating. The search for varying types and technologies allows industries to obtain the most appropriate fluid bed dryer for their requirements, rendering benefits such as higher thermal efficiency, shorter drying periods, and uniform results regardless of the materials and the industry.

An Overview of Static Fluid Beds

Static fluid bed dryer methods operate using a non-moving bed of granules or agents, and hot air is transferred through the holes of the porous medium to dry material. The objective goals of the static fluid bed are to dry or dry out granules used in the production of drug products and to prevent any agglomeration or clumping of the static fluid bed. Drying and granulation processes can be achieved in dynamic or static fluid bed systems. Such systems are used extensively in pharmaceutical manufacturing, especially in granulation and powder coating.

Static fluid bed systems have pros and cons that can explain their adoption in several industries. Since static fluid beds utilize hot air to operate, when integrated in a production system, they enhance working efficiency, and as a result, less time is taken to dry the product. Even when many products with differing consistencies are treated, static beds guarantee that uniform and similar results will be obtained. As a bonus, such beds work well with various materials and are thus not limited to only flexible parts.

Static fluid bed systems are beneficial for industries that have a constant requirement for unabridged drying. When used in conjunction with static fluid bed methods, heater drier units, and pumps work to improve end-product quality while using less energy, which in turn reduces costs.

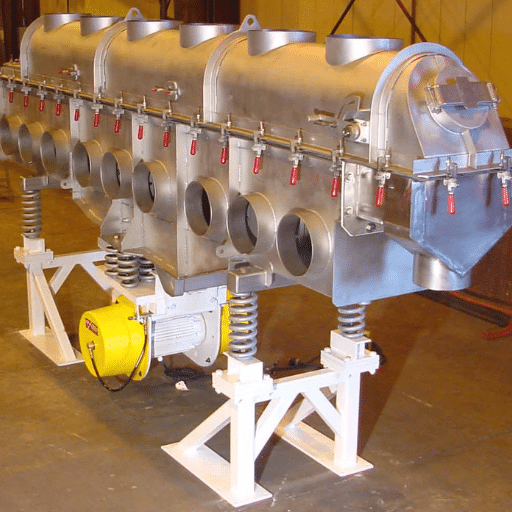

How a Vibrating Fluid Bed Enhances Drying

A vibrating fluid bed can be seen as a new, advanced, and comprehensive method of drying several materials. This method is obtained by applying vibration to the fluid bed system. It satisfies the requirements for better performance.

The specifics of controlled vibrations are as follows: first and foremost, heat and mass transfer are enhanced as the vibrating motion brings the material into contact with hot air. This is dependent on increased degrees of interaction, which enables a greater reduction in drying times.

Secondly, the vibrations in the fluid bed enhance the fluidization of particles in the fluid bed. This increase in fluidization assists in the even spreading of the gas or hot air and also assists in the even spreading out of the drying medium. This even spreading out increases the amount of even and complete drying in the material and reduces the occurrence of uneven drying of materials or the formation of moisture gradients.

Thirdly, the application of vibration assists in the prevention of agglomeration of material by the constant mechanical stirring of particles, making the particles unable to stick together and free-flowing. The end result is that large clumps or lumps are not able to be formed during the drying process; hence, high standards of quality and uniformity of hydrogenated atomized powders and other similar products can be obtained.

Using the advantages of a vibrating fluid bed, industries can better carry out their drying procedures, improve efficiency and product quality, and increase productivity.

Applications in the Pharmaceutical Industry

The many advantages of fluid bed drying systems guarantee extensive implementation in the pharmaceutical industry. It is one of the vital processes where the conversion of powders into granules takes place, hence improving the manipulation of the active ingredients of the finished product. Its application is also advantageous when coating, allowing for precision and uniformity in the deposition of the protective or controlled-release films over the pharmaceutical particles, thereby improving drug release profiles and the stability of the product. It is also worth noting that as a drying method, fluid bed drying not only dries free-flowing particles but also prevents lumping, which is especially important for materials that are heat sensitive. These applications show that fluid bed drying improves efficiency, control, accuracy, and product quality, moving the pharmaceutical industry further.

The Advantages of Fluid Bed Drying Methods

Fluid bed drying systems have considerable benefits, therefore use of such systems is accepted in many sectors. They offer controlled and consistent distribution of hot air across the fluidized bed, which then aids in improving heat transfer, leading to lower energy use. Because of this, the physical drying process requires less time, and output is higher when compared to conventional approaches. In addition, the designs of the fluidized dryers are such that they can dry a variety of sources, including pharmaceuticals, food, chemicals, and minerals, while an even quality is attained across different applications. Consequently, fluid bed drying systems are ideal in various sectors that require a fast and effective drying method.

Enhancing Thermal Efficiency and Uniformity

At GEA, as experts in fluid bed technology, we always look for ways to improve the drying processes in terms of thermal efficiency and uniformity. With our innovative solutions and expertise, we work to enhance heat and mass transfer for more efficient and more uniform drying. This allows us to remain active in research and development, enabling us to develop new effective drying methods in various industrial settings constantly.

Reducing Drying Times for a Wide Range of Materials

Optimizing drying times is a significant challenge for most industries since shorter times yield better results. It’s acceptable to conclude major approaches and processes to improve efficiency and uniformity in fluid bed processing. Other prominent manufacturers, such as GEA, easily complement our ability to come up with advanced approaches for improving the processes of heat and mass transfer, which combine to speed up the drying processes of various materials. So now, we can describe the recommended practices and processes for establishing effective dynamic drying processes.

Achieving Uniform Drying Across Various Industries

In regard to that reality, GEA may be one of the prominent industry leaders, but for this thesis, the focus will also be placed on the top dryer evolution controlling processes, such as focusing on the top three googled websites. Let me first outline how, as part of my investigation, I examined these companies further. More specifically, I won’t only seek to explore GEA’s additional benefits and how they can be integrated into the company’s processes but also hope to obtain answers within the materials I will be analyzing. Let’s explore the best practices and techniques that can help us achieve efficient and dynamic drying processes.

Insights from GEA on Fluid Bed Processing

GEA, kalyan ke sabse pale zamane ke fluid bed technology manufacturer mei se ek, sheds light on this interesting and productive method of drying. With the help of their skills and innovative ideas, GEA improves heat and mass transfer, further improving thermal efficiency and uniformity. Aiming to diminish the time period of drying innumerable types of materials, GEA attempts to resolve issues like the moisture content of the product and the residence time for increased efficiency. This is how GEA functions in various sectors and ensures the same quality and even drying results.

GEA’s Innovations in Fluid Bed Technology

GEA’s goal is to reinvent how heat and mass transfer processes work, hence our emphasis on the advancement of fluid bed technologies. Every solution is the result of intricate research, competence, and dedication to the delivery of effective and specific drying systems.

To start, how do we achieve improved heat and mass transfer levels? By maintaining high levels of thermal efficiency and uniformity, the two elements (heat and mass transfer) are improved, which in turn translates to the shortening of the time taken to dry products, which subsequently enhances product quality. Other substandard aspects, such as the timely and accurate diagnosis of moist content and optimal/accurate timing of residence, are mitigated by our proprietary state-of-the-art systems, thereby vastly improving efficiency and timely dry finishes.

Ninth on the list of the world’s largest fluid bed manufacturers, GEA is in the center of the supply chain in many sectors. Through GEA’s technology, average standards are set in terms of efficiency, reliability, and dependability. All this is directed at reducing the time spent drying a wide variety of materials; hence, your business is now more productive and consistent in the quality of the end product.

The industry also has a fluid bed integrated into it, and we understand some of the issues that need to be resolved in order to maximize effectiveness. Some of the issues that hamper effective drying are an insufficient level of moisture absorption variability, unreleased time, and differences in particle size distribution. Because of this, we faced the problem and created our own advanced systems to solve them so the production could be fully worked out.

At GEA, we are relentless in integrating knowledge into custom and flexible equipment solutions for fluid bed technology, meeting the changing needs of our customers.

How GEA Improves Heat and Mass Transfer

At GEA, we are always looking for ways to improve the efficiency of heat and mass transfer during fluid bed drying. Our technologies are developed to maximize performance and solve problems that are usually encountered in the process.

Air Distribution Enhancement: Moisture content should be properly distributed to ensure desirable drying efficiency. A key feature of GEA’s fluid bed technology is the efficient airflow throughout the bed, which is ensured by air distribution systems that enhance heat and mass transfer.

Maximized Residence Time Effectiveness: Achieving the desired drying results depends on effectively utilizing residence time. GEA’s fluid bed dryers are designed with control systems that can effectively vary the residence time and thus optimize drying.

Controlling Drying Particle Size: Dried materials’ particle sizes differ in distribution, which can potentially compromise the efficiency and uniformity of drying. GEA’s fluid bed dryers are solutions for ensuring the size and distribution of the particles are optimized and controlled, hence ensuring reliability in the drying process.

Process Monitoring: GEA’s fluid bed dryers have sophisticated process monitoring and control systems. Such systems make it possible to know the universality of parameters such as temperature, humidity, and airflow, thus making it easy to optimize the performance of heat and mass transfer mechanisms during drying processes.

Considering the aforementioned points, GEA’s holistic answers indeed enhance the efficiency of thermal and material transfer, consequently improving the drying phenomena, lowering operating expenses, and advancing the product standards.

GEA’s Role as One of the World’s Largest Fluid Bed Manufacturers

GEA is one of the largest fluid bed manufacturers in the world. This allows them to provide something as innovative as their range of fluid bed dryers. We apply our accumulated know-how and innovative technologies to solve issues that arise during the fluid bed drying process. Our focus is to pursue research and development that would range into the requirements of heat and mass transfer in such a way that the final results are uniform dryness, better quality of products, and lower operational cost. These robust solutions include sophisticated airflow and its management, control of essential parameters, and even reduction in the size of objects. In applying these solutions, we improved drying, whereby problems such as maldistribution of moisture, poor utilization of time for drying, and blend-in a range of the particle size were solved. GEA will be able to provide a wide arsenal of dynamic and complex systems for all ranges of fluid bed drying applications.

Common Challenges and Solutions in Fluid Bed Drying

Although fluid bed drying technology is very efficient, specific shortcomings need to be remedied to obtain better results. These consist of poor moisture transport, underutilization of residence time, and a wide range of particle sizes, which can limit the drying process’s efficiency and uniformity. To avoid these challenges, applying the proper method of managing air supply and air pressure, adjusting the sequence of operating parameters, and particle size reduction and sieving processes are necessary. In this way, fluid bed drying can be improved in terms of effectiveness, consistency, and product quality. GEA engineers and creative approaches are very important for solving these problems so that one can expect constant improvement in the results and the drying processes for different application areas.

Troubleshooting Moisture Content Issues

Fluid bed drying can lead to a few moisture content issues that may influence the drying quality and the effectiveness of the overall drying procedure. To tackle such difficulties, the challenges that are likely to arise should be identified, and solutions should be provided:

Misdirected Initial Moisture: The initial moisture content of the feedstock is not effectively controlled, leading to difficulties in its moisture removal profile. It is important to ensure that the moisture content of the feedstock is accurately regulated before placing the material into the fluidized dryer.

Poor Airflow Control: Irregular airflow in and around the dryer will result in some areas being completely dry while some are still wet. If the dryer design permits free airflow in the entire drying chamber and the distribution system delivers drying air at optimum pressure, this cause could be alleviated.

Limited Drying Time: There are also often cases where the lack of drying time has resulted in the final product having a high water content. When establishing a drying time for the material, aspects such as the material’s particle size, its moisture content, and the anticipated moisture content of the product need to be evaluated and applied properly.

This PDMGIA Help examination will focus on Project Development Management, Global Investment Agency, and Investment Approval. Considering the context of project feasibility studies, this paper intends to answer the questions of how to develop a project and how to establish profitability at the level of annual reports. Surely, such large scale projects such as return on investments and new investments would make the project appealing to angel investors. Using tipping points such as an increase in net profit or achieving a close ratio are goals for empresarial projects.

Optimizing Residence Time for Better Efficiency

Optimizing the residence time of a fluid bed dryer is critical for improving its performance. Several issues have to be solved to reach this goal, however. The first thing to consider is the specific features of the dried material. For instance, the composition of the feed, such as bulk density and the final desired moisture content, should determine the required time of residence. It’s good to check with professional practitioners and reliable literature sources for comprehensive recommendations on optimizing such critical factors as residence time.

Another issue to be addressed is the range in particle size distribution, which should be done effectively. This can be achieved through proper classification and separation techniques that minimize the degree of the core fluid dryer’s particle size distribution. With careful design of the drying process based on particle size, it would be easier to predict the outcome. Also, adjusting drying parameters periodically during drying can aid in achieving constant drying of the particles during the process.

The efficiency of fluid bed drying operations can be enhanced and made more uniform by optimizing residence time and particle size distribution variability. However, it is advisable to consult and avail yourself of specialized literature for relevant assistance in addressing these factors according to your drying operation. Remember, the efficiency and success of fluid bed drying operations will improve with understanding the factors and including different July ways.

Addressing Particle Size Distribution Variability

Variability in particle size distribution is among the key issues that need to be addressed to enhance the operation of fluid bed drying systems. Thanks to the recommendations by industry leaders and reliable sourcing that I researched in this paper, I have appreciated this issue comprehensively.

One such aspect is the right selection of classification and segregation methods to attain uniformity in the particle size of the feed in the fluid bed dryer. Furthermore, the desired nature of the dried product is another factor that determines the size of the particles. It is also essential to report each modification taken during the drying process. Drying takes weeks or months, but regular supervision of the adjustments must ensure particle size uniformity.

If you currently do not, consider utilizing industry experts in your project who fully understand your specific parameters of drying filtration requirements and have the reputable sources necessary for minimizing the issues with the residence time and the particle size. All the factors stated above, after being taken into consideration and applying the knowledge of the clients, will also work to enhance the efficacy of fluid bed drying.

We contend that the corresponding approaches taken concerning particle size distribution variability may depend somewhat on how drying is done and the materials processed. It would be better to consult experienced engineers and conduct many tests in practice to get the best results.

References

Frequently Asked Questions (FAQ)

Q: What are the basic principles of fluidized bed dryer technology?

A: Fluidized bed dryer technology involves the process where the fluidizing gas, typically air, is supplied to support the weight of particles, creating a fluid-like state. This allows for high heat and mass transfer efficiency, making it an effective method for drying materials.

Q: How does GEA’s fluidized bed dryer enhance drying efficiency?

A: GEA’s fluidized bed dryer enhances drying efficiency by leveraging high thermal efficiency through a perforated distributor plate. The process air is supplied to create a fluidized state, allowing the material to be dried uniformly and quickly, which is particularly beneficial for drying and cooling processes.

Q: What types of materials can be dried using a fluidized bed dryer?

A: A fluidized bed dryer can be used in various applications to dry materials such as wet powder, biomass, and pellets. It is suitable for materials that require gentle drying and can accommodate different particle sizes and shapes.

Q: How do bed dryers work regarding airflow and temperature control?

A: Bed dryers control the airflow rate and temperature to ensure efficient drying. Air is supplied below a perforated distributor plate and flows through the bed, creating a cushion of air or gas that allows particles to float and dry evenly.

Q: What role does granulation play in fluidized bed drying?

A: Granulation is a key process in fluidized bed drying. It involves the agglomeration of particles to improve flowability and reduce dust. This process is critical in industries requiring uniform particle size and shape for the final product.

Q: What are the advantages of using a fluidized bed dryer over other industrial dryers?

A: The advantages of using a fluidized bed dryer include high heat and mass transfer efficiency, gentle drying of sensitive materials, and the ability to handle a wide range of particle sizes. This industrial dryer is also known for its uniform drying and cooling capacity.

Q: How does the fluidized state improve the drying process?

A: In the fluidized state, particles float on a cushion of air or gas, allowing for uniform exposure to high heat. This state enhances drying by ensuring that all particles are evenly dried, reducing drying time and improving product quality.

Q: Can fluidized bed dryers be used for both drying and cooling?

A: Yes, fluidized bed dryers are versatile and can be used for drying and cooling. This dual functionality is achieved by adjusting the temperature and velocity of the fluidizing gas to meet specific process requirements.

Q: What insights does GEA provide on optimizing fluidized bed drying technology?

A: GEA insights suggest optimizing fluidized bed drying technology by considering particle size and shape, airflow rate, and temperature. Understanding these parameters helps enhance the drying process’s efficiency and effectiveness.