Being able to choose the right format for a project is crucial to its success in the world of machine embroidery. This blog post will serve as a how-to guide, specifically tailored to put you through the numerous varieties of this file format and how they are connected to different kinds of embroidery machines. The process of machine embroidery is most concentrated on the files, which are kept in digital instructions. The internal logic of this post will cover such pieces of information as some specifics of these formats, the problems of their interoperability, and the prospects of their conversion to such popular embroidery formats.PES, DST, and . EXP. You will also be able to understand the suitability of the formats in terms of the stitch precision, the closed design, and the machine requirements. By equipping yourself with this knowledge, you will be in a much better position to make the right decision on the most appropriate file, which will conform to the machine’s requirements and improve the quality of the embroidery.

What is an Embroidery File Format?

An embroidery file format can be best described as a digital template or plan that specifies how an embroidery would stitch a design. These embroidery files are specially modified for automatic stitching based on intricate graphics. This format includes stitch coordinates, thread color, stitches, and their order. Usually, each brand of embroidery machine has a proprietary standard file format. For instance, Brother stitching machines work in PES formats, whereas Tajima stitching machines work in DST formats. Knowing the specifics of these formats is crucial because they affect the parameters of sewing work done, such as the number of stitches made, the color of the thread used, and the final appearance of the embroidery. Accordingly, it is essential to choose the proper conversion to get effective results from the machine’s work.

Explaining Embroidery Digitizing and Its Importance

Embroidery digitizing converts artwork into a digital format intended for an embroidery machine, employing specific software programs for automatic stitching. The detailed process allows the design to be appropriately interpreted and stitched by the embroidery machine precisely as the digitizer intended. The focal part for digitizing includes, among others, defining the types of stitches, the density of the stitches, and the sewing order. The quality of the digitizing of the embroidery is directly proportionate to the degree of accuracy, which includes the distinctness of the stitches and color, as well as the overall design. Proper digitizing allows such intricate parts to be illustrated onto the material without losing essential details or causing thread snapping and misaligned designs. As with machine embroidery, all ideas turn into stitched pieces because digitalizing is one of the most essential aspects in achieving high-quality and professionally done embroidery works.

How Different Embroidery File Formats Work

I have used the top sources and my knowledge to consider how the various embroidery file formats are captured. These formats are crucial in “translating” the creative idea into the set of operations that the embroidery machine is programmed to perform. Every format, such as.PES, DST, and . EXP contain some data instructions regarding the types of stitches, the sequence in which these stitches are to be created, the use of threads, and marks for registration—for example, the.PES format is popular with users of Brother machines because of its good thread color and ease of use. On the other hand, DST is among the most used formats because of its ease of use. It contains limited instructions, mainly on stitching, with minimal color information. This makes it applicable to many devices but needs a different color coding process. The.EXP format is associated with Bernina machines as it contains details related to stitch points, ensuring good quality embroidery. Understanding these machine details makes it easier to select the best embroidery format compatible with my machine model and the embroidery design parameters required, ensuring the machine’s smooth performance and accurate design rendering.

The Role of Embroidery Software in File Conversion

Embroidery software is essential in accurately translating different types of embroidery files into digital design. This program enables the user to convert one file extension to another.PES to.DST or.EXP without omitting essential features of the design. The possible conversion of formats also allows the maximization of the use of different embroidery machines. Technical parameters such as stitch coordinates retention, thread color mappings, and retention of stitch types are critical in the transfer process. Adequately designed software checks that these parameters will not have a problem during the process, and the probability of the issues, such as a single stitch being out of place or color being lost, is relatively low. Besides that, advanced software packages allow batch conversion, easing the burden of dealing with several design files. This will increase the efficiency of operations since well-developed patterns will reduce the possibility of a design being produced that the embroidery machine is not suitable for or has a low quality.

How to Choose the Right Machine Embroidery File Format?

When choosing the machine embroidery file format for an embroidery file, it’s essential to understand the preferred working conditions with the embroidery machine to achieve maximum efficiency. Firstly, make sure you are clear about the embroidery machine’s format because different brands have their own formats; for example, Brother accepts.PES format, Tajima accepts .DST and Bernina accept.EXP. Further, the nature of the design plays a crucial role; more complicated designs may be of acceptable quality only in brands with formats for multi-color and intricate stitching. Understand if you need to use a software tool that would allow you to convert between these formats. This could make the whole workflow more flexible. Moreover, analyze the characteristics of the format and the software features, including, but not limited to, thread color libraries or any available design libraries, to improve your embroidery projects. The better articulation of these factors enables the selection of a format that mediates the intended level of precision, design quality, and ease of use, thus enhancing the quality of the embroidery work.

Understanding Machine File Compatibility

Analyzing some embroidery file formats chosen for the machine and the design is essential to understanding machine file compatibility. The most critical aspects to consider in the file format are the embedded systems and routers, such as Brother machines.PES files, while Tajima machines are used.DST file formats. Another factor to consider is how complex the designs will be and which format will achieve better detail and color. Another dimension of flexibility is provided by your software’s ability to convert formats, making integration and procedures smoother. Besides, there are threads libraries and other features; threads and design customizations are other aspects that should be considered to improve the quality of your production work. This context about machine file compatibility helps explain how precision and the quality of work in paintings like embroidery are upheld and maintained, which aligns with the information from the major sources.

Factors Influencing Your Choice of Embroidery Files

Several elements must be considered when selecting the appropriate embroidery file format to ensure quality and compatibility. To begin with, your embroidery machine understands the embroidery format, for example.PES, DST, and EXP have to be taken into consideration. Each format has a different folding capability depending on the machine and the design’s complexity level.PES files have advanced color management capabilities, while DST files focus on stitch-specific commands.

Another consideration pertains to the detail and complexity of your design—formats such as PES are more suited for multi-layered designs because they carry more color details. On the other hand, if you are looking for ease in sharing files that do not contain complex color details across different embroidery machines, then DST seems ideal.

Further, technical parameters are equally important. Consider the types of stitches, pathing, and registration marks contained in these files; these are crucial elements and will impact the quality of your designs. Moreover, you must ensure that you support and control embroidery-conducive software that can convert and engrave technical functions without reducing the quality during file conversion.

In short, it is crucial to comprehend the characteristics of your machines, the degree of complexity of the design, and the capacity of your system that should address these factors when selecting the appropriate embroidery file types. This guarantees accuracy in the reproduction of designs, and the production process operates efficiently so that high-quality embroidery outputs are obtained.

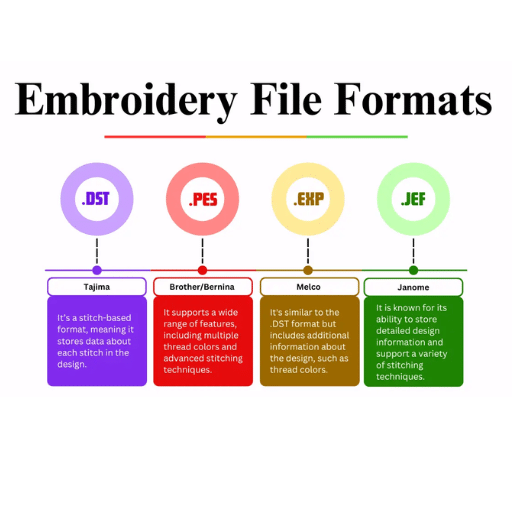

Standard Embroidery File Formats Explained

Embroidery file formats are essential for working with embroidery devices and computers. Here are a few stamps collected from the top three deemed experts that can facilitate a brief understanding of the most frequently used embroidery file formats and some unique technical specifics about specific file formats.

- Format PES (Brother)

The PES file format is the most common and used format among Brother brand embroidery machines. This format emphasizes color and complex stitching patterns, making it suitable for many intricate designs. Technical specifications encompass color stop commands, thread color codes, and stitch sequences, guaranteeing that designs can be reproduced precisely as intended.

- Format DST (Tajima)

The DST format is universally accepted by a range of different brands, which makes it quite flexible. However, it is more suitable for Tajima machines. This file format is ideal because it focuses on stitch instructions. However, stitch color instructions are adjusted manually. Important parameters include stitch length, jump stitches, and trim commands, comfortably holding an industrial embroidery environment.

- Bernina .exp format

EXP files are meant to be used with Bernina and some commercial equipment. They focus on stitch data without much color encoding. Their ease of understanding and modification in a commercial setting is a strong reason for their preference. They encode information that includes basic stitch coordinates and trim commands, making the design presentation uncomplicated.

Embroidery file format selection requires insight into the machine type and the format features each can work with. This way, all the processes will be incorporated, ultimately allowing the ideal reproduction of the design, leading to improved embroidery quality.

What Are the Main Types of Embroidery File Formats?

Embroidery file formats can be broadly categorized into PES, DST, and EXP, each based on machine brands and design complexity. Brother machines use the.PES format, which is useful in retaining detailed color information as well as complex stitching patterns. The.DST format, which has a wide application on Tajima machines and many others, is focused on stitch data and not so much on color, making it suitable for industrial purposes.

On the other hand, Bernina embroidery machines and software are used. The EXP format’s main goal is stitch count optimization, making stitch changes easier in business environments. For quality embroidery projects, it is essential to appreciate the particular requirements of the embroidery machine and the characteristics of the different formats.

An Overview of DST, PES, and EXP Formats

Knowing the differences and uses of the DST, PES, and EXP formats helps to enhance the quality and processes of embroidery. According to some experts, these embroidery file formats have certain features that define their usage on particular machines or for specified projects.

DST Format: The DST format is widely used with Tajima machines and in most brands. It’s stitch-oriented, focusing on the exact commands that create stitches instead of the colors that need to be sewn. Because of this capability, it is best used in situations where the embroidery machine is not fully automated and has to be operated manually, as is the case in garment factories.

PES Format: The PES format is preferred for Brother embroidery machines. It is known for its precision in reproducing colors in embroidery designs. It can also be used to reproduce fancier stitches and designs that are hard to replicate. It also supports color stop features and thread color codes, thus increasing the detail of the design produced.

The EXP format is targeted at Bernina and some industrial machines. It emphasizes efficiency and ease of editing through primary stitch data. Concerning PES colors, this format does not include as much color. Still, due to its compact representation of stitch coordinates and trimming instructions, it is helpful in commercial settings where CAD designs are often modified.

Through authoritative documentation on features and technical specifications, users know what format best meets their machines’ requirements and the intricacies of their filename projects, assuring effectiveness and quality in the embroidery processes.

Comparing Expanded File Formats vs. Native File Formats

When comparing the various aspects of expanded formats like DST, EXP, or PES with native formats, there are noticeable differences regarding how they function and are applied in embroidery. Wide compatibility and increased user-friendliness are the significant reasons expanded file formats have gained popularity despite not containing elaborate design items like thread colors or layers. Besides that, they do not get complicated easily; expanded file formats can store primary stitch data, which is crucial.

On the other hand, native file formats are more complicated since they are specific to one machine. However, they offer a significant advantage: the ease of embedding various embroidery systems in that single machine. Thus, all levels of integrated design data, such as layers, palettes, objects, and even multiple types of stitches, are present within the native file format. Because these formats adequately use and take advantage of a machine’s capabilities, they guarantee a high level of design reproduction without needing adjustments.

The key takeaway is the following:

- Stitch Data: The relationship between expanded file formats and native file formats relies heavily on the arrangements of stitch lengths, stitch types, and even stitch sequences.

- Color Information: Expanded formats require global adjustments when dealing with thread colors; in contrast, the native formats have specific acceptable color threads.

- Design Complexity: The expanded formats through which the design outcome is realized are fairly uncomplicated. They use the simplistic approach of retaining the bare minimum, such as layers in addition to the text.

- Compatibility: The major drawback of expanded formats is that they require particular systems, whereas expanded formats can be deployed with any machine.

By considering these parameters along with the use case requirements, the users can select the best embroidery format concerning compatibility and the level of detail design retention.

Choosing the Right Format for Different Embroidery Machine Brands

Selecting the appropriate format according to the different brands of embroidery machines is a crucial factor in obtaining quality results. From what I have seen and based on several reviews of top resources, I know how important it is to pay special attention to the correspondence between a file format and the particular embroidery machine’s capabilities. For Brother machines, my preference is usually with the PES format since it correctly supports high color accuracy and complicated stitch designs. I prefer to use DST files to operate Tajima machines because they work perfectly with the machine’s stitch information. As for the Bernina machines I use, I find the EXP format best suited as it is easy to create or edit and is a more direct method of encoding stitch data. In conclusion, finalizing the right format is an issue that balances the machine attributes and the detail of the design to avoid defective production and spoiling the design.

How Do Different Embroidery Machines Interpret Embroidery Files?

An embroidery machine uses specific files to digitally record all instructions on stitching out the pattern by controlling the needle and the fabric with programmed commands. All the available models and brands seem to have their requirements, and how they manage files is quite different. Most embroidery units working with major file formats such as DST or EXP embroider the data without additional coding, meaning the color must be set manually. However, embroidery machines with PES formats stitched directly onto the fabric can adjust the design’s depth and colors automatically. This distortion in translation is occasioned by the machine’s internal microcomputer, which translates the coded stitches and colors into various movements. Knowing how these processes differ makes choosing a file type that will work with specific software programs to achieve the desired design and an accurate stitch outcome easier.

The Importance of Machine Brand and Machine File Format

Selecting a suitable machine for industrial and commercial purposes requires looking at the brand because it dramatically influences performance, reliability, and growth ventilation. Such reputed brands might possess the most advanced technological inventions, enforce high-quality standards, and provide solid after-sales services, which reduce downtime to a very significant level and enhance performance. Moreover, machines of good brand manufacturers usually come with many manuals and help, easing the struggle of integrating them into work practices.

A file format of a machine also holds considerable importance since it enables a machine to use or work with operating systems and applications. If specific file formats are used, the risk of misstated information is minimized as well, and such information is processed without any problems. The utilization of computer-aided engineering is unquestionable since the file formats ensure that interfacing hardware can communicate with all machines and software as intended. In an ecosystem of operational resources, choosing the right machine brand and file format is vital for cutting downtime and increasing effectiveness.

How Embroidery Design Influences Format Choice

For an embroidery design to be created depicting a specific format, it is fundamental to consider the technology-related conditions and integration requirements that are very important in the selection. My research from the pinnacle of available resources indicates that the intricacy of an embroidery design determines the file formats to be used. Specific standards, such as DST and PES, are preferred because they are compatible with most industry embroidery machines, which will help to ensure that the workflows are smooth and relatively easy to introduce into the existing ones. Furthermore, the choice of format may influence the accuracy and the overall quality of the embroidered output; different formats may allow the design to include diverse details and specifics of color. Hence, it’s correct to say that proper format selection targeted at a particular design requirement helps to achieve necessary production results while optimizing the whole process of production.

Ensuring Embroidery Machine File Compatibility

Remembering many essential technical requirements to preserve the compatibility of file reading with embroidery machines is critical. Remember to start by inspecting the formats supported by the machine. Some formats used by most embroidery machines include DST, PES, JEF, and EXP. Each format has its characteristics, such as DST being a stitch-based type, which makes it ideal for more accessible designs; PES, on the other hand, is more flexible and can handle more complex designs and color layers. The next item to consider is the design’s embroidery stitch count since machines also have a maximum limit that has to be adhered to, such as 50000 or 100000 stitches; violence in such limits can foster errors during the embroidering phase. In addition, most of the machines have memory limits, so the size of your file must fit these limitations for optimal results.

Last but not least, check the thread color code. You should not change the color map, which will alter the end embroidery rendering. So long as these parameters are observed, compatibility concerns are reduced, and as such, it promotes impeccable works and exceptional embroideries.

What Are the Most Common Types of Embroidery File Formats?

Commonly used embroidery format files include DST, PES, and EXP. Each format serves different machine compatibility and design specifications, which are key for efficient embroidery operation as indicated below:

- DST (Data Stitched Tajima): Most internationally recognized, DST is widely used in different machines, especially Toshiba’s, since no embroidery quality issues arise. It only deals with stitch data, making it suitable for plain designs without colors.

- PES (Brother Embroidery Format): Narrowly acceptable for Brother Machines, the PES format maintains the details of stitched and colored data. This format can design many complexities, enhancing the reproduction of the design.

- EXP (Bernina Embroidery Format): EXP is mainly used in Bernina machines and appeals because it simply conveys the necessary stitches to the machine. It does not have an elaborate color code, but its simplicity allows for alterations in a business environment.

Format choice is determined by compatibility with a machine brand and the degree of complexity of the design, which ensures the quality of the results and minimizes stitching time.

Exploring the DST Format and Its Uses

Considering its strength and compatibility with numerous machine brands, but more importantly, those from Tajima, the DST (Data Stitch Tajima) format is viral in the embroidery industry. The square peg fits most commercial embroidery machines and caters to designs targeting stitch data. While it is pretty good at numerically coding the basic stitching features such as length, sequence, and type, it does not, as a rule, contain color information, which can be disadvantageous to designs that require strict color reproduction.

Key Technical Parameters of DST Format:

- Stitch Encoding: The DST format can record stitch length, type, and sequence, and this information guarantees that stitches will be formed similarly on all compatible machines.

- Color Information: The lack of embedded color data within the machine means that the machines will require manual color assignments when configuring the machine.

- Design Information: It is pretty essential, with no multi-layered or congested text complexity, but it sticks out for a couple of layers, i.e., purposively for stitch data, for an uncomplicated design to be realized.

- Machine Compatibility: Most commercial embroidery machines, especially Tajima models, readily accept the product, making it useful for ordinary embroidery works.

These parameters indicate the DST format’s advantages and disadvantages, especially its intended use for primary and uncomplicated embroidery work where the need for multicolored or complex patterns is not emphasized. However, it implies that when this format is selected, a compromise must be ensured between the simplicity of use and the amount of detail in the design, making it most suited for the nature of the embroidery task.

The Significance of the PES File in Machine Embroidery

The PES file format is an essential element in machine embroidery as it has broad applicability across different machines. Since it is one of the most popular formats, PES files are often used in Brother and Babylock machines, making transferring the designs accessible. This format incorporates features like unique stitch patterns, various thread colors, and design layering, which are pretty advanced, thus making it easy to use in complicated embroidery jobs. In essence, PES files contain digital representations of embroidery stitches together with essential details like the stitch type and its order, the color to be used, and other commands to the machine, which is enough for effective embroidery reproduction of the design. Besides, PES files can hold big design files, but not above 100,000 stitches and most of them have a good number of colors as per the thread color library that has been preset. When going for this format, it is common for users to enjoy integration with designing software that allows easy alteration in the stitching pattern and formats, hence leading to the improvement of the embroidery process and the quality of the end product.

Understanding Common Embroidery File Types and Their Applications

While my perspective concerning the most widely used embroidery file formats and their emergence is unique, I base it on some well-known and respected online sources. In my study, I concluded that DST and PES formats are the most popular because they are compatible with numerous machines and facilitate the transfer of designs without distortion. DST is an increasingly standard, stitch-based format for rather simplistic designs in commercial settings that demand quick turnarounds. PES is more popular because it is more versatile and can handle a combination of stitch patterns of many colors for personalized or elaborate embroidery designs. Other formats cater to specific manufacturers, such as JEF, which is applied to Janome machines and focuses on accessible design applications. The selection of the desired file type is predicated on stitching frequency and machine size requirements meant for production so that the embroidered product is functionally and aesthetically suitable for many uses.

References

Frequently Asked Questions (FAQ)

Q: What is the embroidery file format you need for your machine?

A: The embroidery file format you need depends on your machine’s brand and model. Each manufacturer may support different formats, such as PES, DST, and EXP. It’s crucial to know the specific machine format your machine can read.

Q: Why are there different machine formats for embroidery files?

A: Machine brands have developed proprietary formats to optimize performance and capabilities. As a result, each brand may have its native format, like the PES format for Brother machines or the JEF format for Janome machines.

Q: Can my embroidery machine read multiple embroidery file formats?

A: Some machines can read multiple embroidery file formats, but many are designed to work with a specific format. To determine compatible formats, consult your machine’s manual or manufacturer.

Q: What is a DST file, and is it widely used?

A: A DST file is a stitch file used in commercial embroidery. It is one of the major embroidery file formats and is read by most embroidery machines, making it a popular choice for professional embroidery projects.

Q: How do I choose the proper embroidery file format for my machine?

A: Choosing the proper embroidery file format involves understanding the required file format for your specific machine. Consult your machine’s documentation or the embroidery machine manufacturer to determine the correct format.

Q: Are there file formats that support detailed embroidery designs?

A: Some file formats are better suited for detailed embroidery designs. Formats like ART or EMB may offer more advanced features for intricate designs and are available in the embroidery industry for specific machines that support them.

Q: What happens if I use an incompatible file format?

A: If you use an incompatible file format, your machine may not be able to read the file, resulting in errors or inability to stitch the design. It’s essential to use the correct file extension and format for your machine to ensure proper functionality.

Q: Can I convert artwork into an embroidery file format?

A: Digitizing embroidery converts artwork into an embroidery file format. This involves using software to transform vector graphics or raster images into a stitch file your machine can read.

Q: Are there universal file formats that work on every embroidery machine?

A: While no universal file format works on every machine, most embroidery machines read some formats, like DST and PES. However, it’s always best to verify compatibility with your specific machine.

Q: What is the significance of file names and extensions in embroidery files?

A: The file name and extension are crucial in identifying the file type and ensuring it is read correctly by your machine. The file extension indicates the embroidery format, such as .pes or .dst, which tells the machine how to interpret the data.