Thank you for spending your valuable time reading this article dedicated to filling capsules quickly and hassle-free, as filling capsules can be tough sometimes. Whether you are an advanced user or a beginner, you will find everything you need to fill capsules more efficiently and quickly.

To start off, we will briefly describe the whole step-by-step sequence for filling a capsule, which includes useful information regarding the capsule filling machine. In addition to this, you will understand the distinguishing characteristics of semi-automatic and automatic capsule fillers, which will enable you to choose the most appropriate option according to your requirements.

We will consider some factors while deciding how much powder is suitable to fill a capsule. The outlining procedures will include determining the suitable capsule diameter for you and the denominator of capsules per each amount of powder. Furthermore, we will handle the problem of surplus powder and/or spilling that occurs after the filling process.

Additionally, you will be able to see the value of using a machine as you examine the features of an automatic capsule filling machine compared to a semi-automatic and fully manual filling machine. This analysis will include proper discussions on the pricing and any other issues you wish to raise.

For those of you keen on filling capsules at home, don’t worry—we’ve got your back. The procedure remains simple if you use the correct tools, such as the scoop, the capsule holder, or the tamper tool. We will also give you a few pointers on how to avoid some common mistakes while filling DIY capsules.

Lastly, we shall give you recommendations on how to fill capsules sufficiently locked and sealed. We will also touch on how to use a capsule polishing machine for better results and how to handle the storage and labeling of the capsules.

Irrespective of whether you are filling capsules for personal consumption or as part of a business, this guide should help you fill a large quantity of capsules within a short time. So what are you waiting for? Let us dive straight into the exciting field of capsule filling and open new avenues for your projects!

What is the Capsule Filling Process?

In capsule filling, dry powders or other powders are materialized inside an empty capsule, the most important step of the supplementary, medicinal, and herbal industry. This includes automatic capsule filling machines, manipulation of powder, and dosages. Let’s go deeper into the mechanics of the capsule-filling process to obtain answers to some of the basic queries:

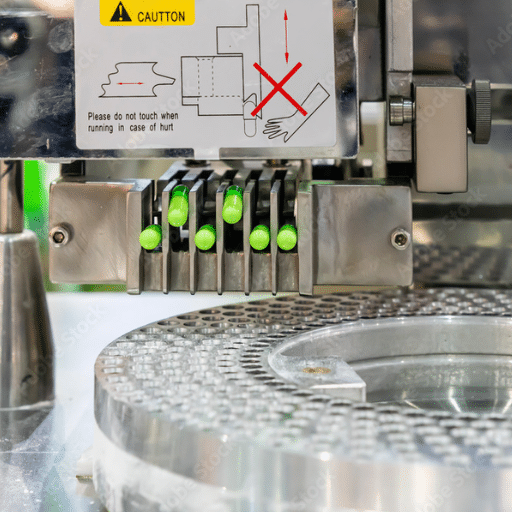

- What is a Capsule Filling Machine?: A capsule-filling machine is a mechanical device designed to automate filling empty capsules with precise amounts of powders or granules.

- How to Fill Capsules with Powder Efficiently: Efficient capsule filling involves proper powder handling techniques, including the use of capsule filling machines, manual capsule fillers, or automatic capsule fillers.

- Manual Capsule Fillers vs. Automatic Capsule Fillers: Different types of capsule fillers are available. Manual fillers require manual loading and capping, while automatic fillers offer higher production capacity and automation.

In the following sections, we will delve into each aspect of the capsule-filling process to provide you with comprehensive insights and guidance to enhance your capsule-filling efficiency and accuracy.

Understanding the Capsule Filling Machine

The remaining sections provide you a detailed analysis of various types of capsules and the capsule filling process. We’ll take a look at how the main features of the device are used throughout the whole process of capsule filling. I can reply to your questions quite succinctly:

- What are the key steps in the capsule-filling process?

- Preparing the capsule filling machine and ensuring cleanliness.

- Weighing and preparing the powder or formulation to be filled.

- Adjusting the machine settings and capsule size to match the desired dose.

- Loading the empty capsules into the machine and positioning them for filling.

- Filling the capsules with the powder using a dosing mechanism.

- Capping the filled capsules to seal them.

- What are the different types of capsule fillers?

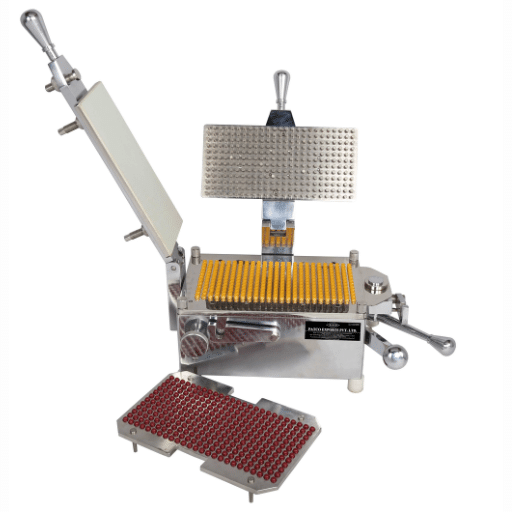

- Manual Capsule Fillers: These require manual loading and capping, making them suitable for smaller batch production and environments with lower production demands.

- Automatic Capsule Fillers offer higher production capacity and automation, making them ideal for larger-scale production and increased efficiency.

- What factors should be considered when choosing a capsule-filling machine?

- Production Capacity: Consider the desired production volume and choose a machine that can meet your requirements.

- Automation Level: Assess the level of automation needed for your production process.

- Flexibility: Look for machines that can handle various capsule sizes and formulations.

- Accuracy and Efficiency: Evaluate the machine’s dosing accuracy and overall efficiency to ensure consistent and reliable results.

By understanding the key steps, types, and factors to consider when choosing a capsule-filling machine, you can enhance your capsule-filling efficiency and accuracy, ultimately improving your production process.

How to Fill Capsules with Powder Efficiently

- What are the key steps in the capsule-filling process?

- We ensure cleanliness and set the parameters of the capsule-filling machine.

I am weighing and dosing the powdered substance.

I am removing the vacuum and placing the empty capsules into the apparatus.

I am adding the measured quantity of powder into the capsules.

I am sealing the filled capsules to maintain the contents’ integrity.

What are the best practices for achieving accurate powder filling?

- Accurate powder measurement should be possible through calibrated weighing scales and measuring devices.

Adjusting the machine’s settings should optimize different parameters, such as filling speed, vibration intensity, and other filling processes.

Routine check-ups and maintenance should be performed on the machine to avoid blockage or incorrect dispensing measures.

The weight of the filled capsules should be periodically calibrated, verified, and corrected, if necessary.

- How can productivity and efficiency be improved in capsule filling?

- Components comprising automatic filling systems and capsule filler machines may be employed in filling capsules.

Such an organization enables the elimination of wait times and disruptions and enhances flow efficiency.

Lack of know-how may lead to unnecessary machine downtime and decreased effectiveness, so operators must undergo proper training.

Examinations of Capsule Filling parameters should be routinely conducted to lower waste and enhance operational effectiveness.

By following these best practices and considering the advantages of automatic fillers, you can enhance your capsule-filling efficiency, accuracy, and productivity.

Exploring Manual Capsule Fillers vs Automatic Capsule Fillers

A critical aspect in enhancing the business needs within the production lines of capsule dosage forms is the blanket decision about efficiency and productivity concerning the chosen type of capsule filling mechanism, whether manual, automatic, or semi-automatic. After this explanation, I will elaborate on the analysis to help guide considerations on how to answer the questions that have been raised, including the information above.

- Which is more efficient?

- As indicated in the research, most scholars argue that automatic capsule fillers have a higher expansion rate in regard to the production target and the high degree of automation. In terms of production means, fillers can fill in more quantities of capsules than manual fillers, which have to load and cap them at a slower speed.

- Which is more accurate?

- Automatic capsule filler dosing and filling are consistent in performance and features. The distinguishing feature between the two views is the presence of more or less reliable mechanisms, which lead to counter-filling, thus avoiding discrepancies in dosages. In contrast, some manual capsule fillers may depend on manual filling methods which yield more variability and higher chances of errors.

- Which is more suitable for small-scale production?

- Manual capsule fillers are often employed in small production runs or using fewer quantities. They are affordable and uncomplicated to use, making them suitable for persons with low production requirements. Depending on the efficiency, automatic fillers are used where more capital is available and are mostly suitable for large-scale manufacturing plants.

However, the decision to select manual or automatic capsule fillers is purely based on your requirements, how much you intend to produce, and your budget. Many aspects influence your decision, such as the production cycle time, compactness, accuracy of the product, and cost and profitability.

How Much Powder Should You Fill in a Capsule?

Correct and appropriate filling of powders into capsules ensures that the proper dosage provides the intended result. An approach to this issue would be to consider the capsule volume and the bulk density of the powdered stuff. Here are some key aspects that would facilitate the development of one’s rationale:

- Capsule Size: There is considerable variation in the volume capacities of capsules—from size 4 with an approximate capacity of 0.13 ml to size 000 capsules with a capacity of 1.37 ml. For greater clarity regarding the specific amount of powder that the capsule can hold, refer to the capsule size chart or the details provided by the manufacturer.

- Powder Density: The weight of the powder that needs to be filled in the capsule also depends on its bulk density. High-density powders require a lesser gram amount for the capsule than lower-density powders.

- Dosage Requirements: Lastly, the bulk density of the powder not only influences the amount of powder to add to the capsule but also its National or local Utility or institution-related Laws and Regulations (on medical or other procedures) that could determine set doses. Such dosage for pharmaceutical formulations ought to be followed exactly, especially in order not to violate therapeutic range toxicity.

A digital scale can determine the precise weight of powdered material meant for capsule fillings. Otherwise, a graduated cylinder is more effective for measuring the volumes of the powdered material.

Always remember that consistency is imperative when filling capsules to ensure there is no over- or under-dosing, which can lead to undesired consequences. In case of specific dosage requirements, it is best to seek the guidance of a professional or appropriate guidelines.

Choosing the Right Capsule Size

Determining the right capsule size is very critical in avoiding inappropriate dosage and swallowing dissatisfaction. To find out the proper capsule size, after scrutinizing the information, it became clear that the size of capsules recommended is affected, among other things, by the requirements of the amount dosage and the type of drug and supplement involved. It is better to seek advice from the health care providers and follow the product instructions and standards that the industry uses to ensure that the most appropriate capsule size is selected for your needs.

Calculating Per Capsule Powder Amount

Calculating the precise amount of powder to fill each capsule is crucial in achieving accurate dosage. To determine the per capsule powder amount, consider the following factors:

- Dosage Requirements: Consult the dosage guidelines provided by healthcare professionals or specific product instructions to determine the desired amount of active ingredient per capsule.

- Capsule Size: Different capsule sizes have varying capacities, affecting the amount of powder they can hold. Refer to the size chart provided by capsule manufacturers or suppliers to determine the maximum capacity of the chosen capsule size.

- Density of the Powder: The density of the powder can vary, which affects its volume. Use a digital scale to measure the weight of the powder accurately or a graduated cylinder to calculate the volume for better precision.

- Filler Materials: If using filler materials in combination with the active ingredient, consider their ratios and adjust the powder amount accordingly to maintain the correct dosage.

Of great concern is the filling of the capsules, which should be done consistently so that the dosages are also uniform and the risk for complications is minimized. If in doubt about the calculations or work and the dosage to be administered, seek advice from a healthcare professional or follow the appropriate guidelines.

Dealing with Excess Powder and Spillage

The process of filling capsules should be careful for specific issues to be followed. For example, when pouring out powders, it should be noted that extra care is given. This would lead to the capsule filling being effective and the wastage as well the contamination is minimized. The issues mentioned can be solved by following the guidelines below.

- Preventing Excess Powder: To fill a capsule, it is important to dispense, and measure precisely the amount that is needed. This drastically assists in reducing the extra powder that is left over. Using digital measuring scales or tester cylinders, especially for capsule technology, can be made easier. Also, various capsule-filling machines are available that are equipped with dosage tuning options to optimize powder filling.

- Managing Spillage: While fitting the capsule, one downside is that the powder gets splattered everywhere, leading to a sloppy working environment. To counter this, create a neat environment so that if spills occur, they can be cleaned more easily. In case spills do occur, the excess shredded powder must be saved. Cleaning items like vacuums are also efficient in cleaning the area.

- Proper Capsule Handling: Proper measures must be taken when handling capsules to prevent spillage and contamination of the contents held in the filled capsules. Great care should be taken to check the position of the capsules and the correct locking of the cap and body of the capsule. This would reduce the odds of accidental spilling and ensure smooth and effective operations.

It is important to remember that the above aspects are meant as only useful tips or suggestions. The industry guidelines and best practices, however, indicated, should correspond with recommendations from relevant authorities and materials provided by filling machine manufacturers and healthcare professionals.

Why Use a Capsule Filling Machine?

Capsule-filling machines have revolutionized the process of filling capsules, offering numerous advantages over manual methods. Here are some key reasons to consider using a capsule-filling machine:

- Increased Efficiency and Precision: The process of filling capsules should be careful for specific issues to be followed. For example, when pouring out powders, it should be noted that extra care is given. This would lead to the capsule filling being effective and the wastage and contamination minimized. The issues mentioned can be solved by following the guidelines below.

- Enhanced Productivity: To fill a capsule, it is important to dispense and measure precisely the amount needed. This drastically assists in reducing the extra powder that is left over. Using digital measuring scales or tester cylinders, especially for capsule technology, can be made easier. Also, various capsule-filling machines are available that are equipped with dosage tuning options to optimize powder filling.

- Improved Dosage Accuracy: While fitting the capsule, one downside is that the powder gets splattered everywhere, leading to a sloppy working environment. To counter this, create a neat environment so that if spills occur, they can be cleaned more easily. In case spills do occur, the excess shredded powder must be saved. Cleaning items like vacuums are also efficient in cleaning the area.

- Reduced Wastage and Spillage: Proper handling of capsules is crucial to prevent spillage and contamination of the contents held in the filled capsules. Great care should be taken to check the position of the capsules and the correct locking of the cap and body of the capsule. This would reduce the odds of accidental spilling and ensure smooth and effective operations.

Benefits of Using an Automatic Capsule Filler

I am familiar with the industry and therefore, I can highlight the advantages of utilizing automatic capsule fillers in your manufacturing processes or at-home capsule filling:

- Increased Productivity and Efficiency: Automatic capsule fillers are fast and efficient and are made to fill large volumes, which increases the production rate. Automated processes will allow users to fill capsules faster and more accurately, reducing the amount of time spent on labor.

- Enhanced Accuracy and Precision: An automatic capsule filling machine delivers a precise dose to be filled into a capsule so that every filling is perfect. Such precision controls variations in capsule dosages and increases the quality of the products being filled in capsules.

- Improved Safety and Compliance: Automatic machines are built with safety features, adhering to industry regulations and standards. These features minimize the risk of contamination and ensure product integrity, enhancing safety and compliance in manufacturing environments.

- Reduced Wastage and Spillage: Automatic capsule filling machines can fill powders while saving some for the next use but limiting spills as much as possible. This would, in turn, cut down some expenses but also free some space in the work area while preventing wastage.

Utilizing an automatic capsule filling machine allows you to automate some of the processes involved in filling capsules, increase the dosage accuracy of the capsules, and increase productivity and efficiency in manufacturing. It is a competitive investment that will take your operations to a higher level while making it possible to produce capsules of the same high quality and consistency.

Comparing Manual Capsule Filling Machines with Semi-Automatic Options

It is necessary to evaluate the distinction between a manual and semi-automatic capsule-filling machine. As much as both options are able to improve efficiency and productivity levels, their values are limited in several ways. A brief point of comparison is as follows:

- Performance and Output:

- In the case of a manual capsule filling machine, each capsule must be filled through handwork using a manual lever. For a home-based or simple level production, these machines may suffice. The limit is set by the skill with which the capsules can be filled by hand.

- A semi-automatic capsule filling machine then uses an automatic filling apparatus. Otherwise, one aspect of the filling operation is automated, such as the separation of capsules, filling, and encapsulation through closing. Therefore, output and productive efficiency are maximized.

- Ease of Use:

- Manual Capsule Filling Machines: These machines are relatively simple and require minimal training. However, they can be time-consuming and labor-intensive, especially for larger production runs.

- Semi-automatic capsule-filling devices require some training to operate. However, the hassle of filling is reduced as the semi-autos are easy to operate thanks to the automatic feature and simple controls. Thus, both ease of operations and effort are increased, and emphasis is on production.

- Accuracy and Consistency:

- Manual Capsule Filling Machines: Filling capsules manually may result in variations in dosage accuracy and consistency, as it relies on the operator’s skill and precision.

- Semi-Automatic Capsule Filling Machines: These machines are designed to deliver precise and consistent dosages, minimizing variation and ensuring uniform product quality.

Considering these factors, it is important to consider your production needs, budget constraints, and the company’s long-term objectives when deciding whether to go for a manual capsule filling machine or a semi-automatic. At the end of the day, it will depend on the volume of production, speed and accuracy achievable, and the amount of funds available.

Cost Considerations for Capsule Machines

When considering the cost of capsule machines, there are several factors to take into account:

- Machine Type: Different capsule machines are available, from manual to semi-automatic to fully automatic. The cost will vary depending on the level of automation and the features offered.

- Capacity: The machine’s capacity, measured in terms of capsules filled per minute or hour, affects the overall cost. Higher-capacity machines tend to be more expensive but can significantly improve production efficiency.

- Quality and Durability: Investing in a reliable and durable machine ensures long-term cost-effectiveness. Consider factors such as the quality of materials used, construction, and reputation of the manufacturer.

- Maintenance and Service: Determine the machine’s maintenance requirements and associated costs. Understanding the availability and cost of spare parts and the manufacturer’s customer service and support is crucial for long-term cost considerations.

- Additional Features: Some capsule machines offer additional features such as automatic capsule sorting, counting, or capping. Assess the necessity of these features for your specific needs and weigh them against the associated cost.

- Cost of Consumables: Consider the ongoing cost of consumables, such as empty capsules and powders, required for operating the machine. Evaluate the pricing and availability of these consumables to ensure they align with your budget and production requirements.

Researching and comparing different options is essential, considering your specific production needs and budget constraints. When evaluating the cost of capsule machines, remember to factor in the technical specifications, warranty, after-sales service, and overall value for money.

How to Fill Your Own Capsules at Home?

Filling your capsules at home can be a cost-effective and convenient way to customize your supplement intake. To get started, follow these step-by-step instructions:

- Gather Your Materials: You will need a capsule holder, tamper tool, and scoop. These tools will help you handle the capsules and accurately measure your desired dosage.

- Prepare the Capsules: Separate the capsules and place the longer half into the holder. Repeat the process for the shorter half.

- Fill the Capsules: Using a scoop, carefully transfer your supplement powder into the holder, filling each capsule half. Avoid overfilling or underfilling the capsules.

- Compact the Powder: Use the tamper tool to press down and compact the powder in each capsule gently. This ensures consistent dosage and proper sealing.

- Join the Capsules: Once filled, join the longer and shorter halves of the capsules together, ensuring they are fully locked and sealed.

Tips for Avoiding Common Mistakes in DIY Capsule Filling:

- Accurate Measurement: Use a precise scoop or a measuring scale to ensure an accurate dosage of the supplement powder.

- Clean and Dry Environment: Work in a clean and dry area to prevent contamination of the capsules. Avoid moisture, as it can cause the capsules to dissolve or become sticky.

- Proper Storage: Store filled capsules in a cool, dry place away from direct sunlight and moisture. This helps preserve the quality and effectiveness of the supplements.

By following these guidelines and best practices, you can successfully fill your own capsules at home, allowing you to customize and control your supplement intake.

Step-by-Step Guide for Making Capsules at Home

Making your capsules at home can be a rewarding and cost-effective way to customize your supplement intake. Follow this step-by-step guide for successful DIY capsule filling:

- Gather Your Ingredients: Ensure you have all the necessary ingredients and tools ready, including your powdered supplements, empty capsules, capsule holder, tamper tool, and scoop.

- Prepare Your Workspace: Choose a clean and well-lit area to work in. It’s important to maintain cleanliness and hygiene throughout the process.

- Assemble Your Tools: Set up your capsule holder and place the empty capsules into the designated slots. This will keep them organized and ready for filling.

- Measure Your Supplements: Using a scoop or a measuring tool, accurately measure each capsule’s desired amount of powdered supplements. Ensure you are following the recommended dosage guidelines.

- Fill the Capsules: Take the filled scoop of your powdered supplement and gently pour it into the corresponding capsule halves in the holder. Repeat this process for each capsule.

- Compact and Seal: Once the capsules are filled, use the tamper tool to compact the powder gently. This ensures that the capsules are properly filled and prevents any air gaps.

- Join the Capsules: Carefully place the filled capsule halves together, aligning them properly. Press them firmly until they snap shut.

- Clean Up: After filling all the capsules, clean any excess powder or spills from your workspace. Store any remaining supplements in airtight containers for future use.

Kiedy postępujesz zgodnie z krok po kroku wskazówkami i rekomendacjami czołowych źródeł możesz z pełnym przekonaniem wykonać indywidualnie dobrane przez siebie kapsułki w domu. Don’t forget to check with your trusted practitioner or a licensed pharmacist before taking a capsule for dosage and compatibility of the combined products.

Essential Tools: Capsule Holder, Tamper Tool, and Scoop

When filling capsules at home, having the right tools is essential for achieving accurate and efficient results. Here are the three essential tools you’ll need for successful DIY capsule filling:

- Capsule Holder: A capsule holder provides a stable platform for filling capsules. It keeps the capsules upright and aligned, making filling them precisely easier and preventing any spillage or mess.

- Tamper Tool: The tamper tool packs the powdered or granulated substance into the capsules. It ensures that the desired dosage is properly compacted and evenly distributed within each capsule, maximizing accuracy and consistency.

- Scoop: The scoop, often included with capsule kits, helps transfer the powdered or granulated substance into the capsules. It allows for controlled and precise measurement, ensuring the correct amount of the substance is added to each capsule.

Utilizing these essential tools can streamline the capsule filling process, ensuring accuracy, efficiency, and customization in your supplement intake. Happy DIY capsule filling!

Tips for Avoiding Common Mistakes in DIY Capsule Filling

There are key considerations for proper capsule filling at home, including the environment and physical space. Here are some states that will allow you to bypass common errors when filling capsules yourself:

- Choosing the Right Capsule Size: A properly adjusted dosing might be impossible if the correct capsule isn’t chosen. Because your supplement will require a specific amount of capsule filler, size the capsule accordingly.

- Using Quality Ingredients: Whenever you buy capsules or ingredients for supplements, make sure to buy them from a reliable source. This will ensure that they are spotless, devoid of safety concerns, and pure.

- Proper Capsule Handling: Empty capsules must be handled with care. Make certain that no water is present around cupboards and that direct sunlight doesn’t reach them, which will undoubtedly hasten capsule dissolution or deformation.

- Accurate Measurement and Tamping: To avoid dry filling, hire a tamper tool and scoop out exactly what you need to fill the capsule with to get the perfect dosage. This way, all of your capsules have a consistent amount.

- Maintaining Hygiene and Cleanliness: Before picking up any of the capsules, remember to sanitize your hands. Also, make certain that the area you will be working in is uncontaminated with dirt or dust.

- Regularly Calibrating the Capsule Filling Equipment: If using a capsule filling machine, regularly check and calibrate the equipment to ensure accurate filling and consistent results. Follow the manufacturer’s maintenance and calibration instructions.

Remember, attention to detail and following these tips will help you achieve precise and reliable capsule-filling results at home. If you have any specific technical queries or parameters related to capsule filling, please make sure to consult the manufacturer’s guidelines and, for precise filling and safety use, have a second opinion.

What Are the Best Practices for Capsule Filling?

When filling capsules at home, following best practices ensures optimal results. Here are some key considerations to keep in mind:

- Ensuring Capsules are Fully Locked and Sealed: Properly closing and sealing the capsules is crucial to prevent leakage and maintain the integrity of the supplements. Double-check that the capsules are securely locked to avoid any potential issues.

- Using a Capsule Polishing Machine for Professional Results: To achieve a polished and professional finish, consider utilizing a capsule polishing machine. This device helps remove excess powder and ensures your capsules’ smooth and uniform appearance.

- Handling Gelatin Capsules vs Other Types of Capsules: Different types of capsules, such as gelatin-based or vegetarian capsules, may require slight variations in handling. Familiarize yourself with the specific characteristics and instructions for the type of capsules you are using to ensure proper filling and sealing.

By incorporating these best practices into your capsule filling process, you can enhance the quality, accuracy, and overall experience of creating your own customized supplements at home.

Ensuring Capsules are Fully Locked and Sealed

Ensuring capsules are fully locked and sealed is crucial for maintaining the integrity of the contents and preventing any leakage or contamination. To achieve this, I recommend following these best practices:

- Proper Alignment: Before joining the capsule, ensure that the top and bottom halves are aligned correctly. This ensures a secure fit and minimizes the risk of gaps between the halves.

- Appropriate Compression: Apply sufficient pressure when joining the capsule halves to ensure a tight seal. This can be done using a capsule filling machine or manual capsule filler. Avoid over-compressing, as it may lead to difficulties in opening the capsule later.

- Quality Control: Implement a rigorous quality control process to inspect each sealed capsule. This includes visually examining the capsules for any signs of damage, checking for a secure lock, and verifying that no particles or powders escape from the seal.

Adhering to these practices can ensure that your capsules are fully locked and sealed, maintaining the quality and effectiveness of your customized supplements. Remember to consult reputable sources and manufacturers for specific instructions based on the type of capsules you are using.

Using a Capsule Polishing Machine for Professional Results

To enhance capsule production standards, it is ideal to contemplate the use of a capsule polishing machine. It handles filled capsules in a manner that maintains their aesthetic and sanitation standards, which is crucial for a professional outlook. This machine does away with the excess powder, bypasses the static charge, and eliminates the tiny flaws that affect the capsules’ appearance. Below are the details that are worth pondering while operating the capsule polishing machine.

- Improved Aesthetics: The device cannot function accurately without the machine. This is because the machine cleans the capsules, such as removing surplus powder and dirt that might hinder the production of the final product from appearing neat.

- Enhanced Quality Control: The most essential benefit is the assurance that each capsule is thoroughly checked to destroy any undiscovered independence that may be present in it. This also helps maintain the quality of the capsules, ensuring that they fit the required standards.

- Efficient and Time-Saving: Capsule polishing devices eliminate the need to inspect all the capsules, which saves valuable time manually. Instead, the device automatically patches up the polish along the surface, therefore improving efficiency in many ways while reducing the time needed.

- Versatility: Certain environments demand the use of specialised capsules, such as gelatin capsules. Capsule polishing machines are crucial for facilitating an efficient and smooth capsule manufacturing process.

It is advisable not to ignore the instructions given by the manufacturer of the capsule polishing machine, especially the instructions for setting up, operating, and maintaining it. Any time the machine is cleaned, it will maintain good working performance, and all its parts will last long.

Also, implementing a capsule polishing machine into a line’s capsule production process will allow you to obtain the capsule’s aesthetic quality and increase control of the powder filling, which in turn will increase the efficiency of the manufacturing process.

Handling Gelatin Capsules vs Other Types of Capsules

Gelatin-holding capsules underwent different guidelines and organizational structure in comparison with ones made with other materials, such as rubbing alcohol, with their substance differing from the use of cups instead. Due to their properties, gelatin capsules are the most popular choice for encasing powdered supplements, medication, and vitamins. Highlighted below are Some important factors that should be taken into account when using gelatin capsules in contrast to other types of capsules:

- Moisture Sensitivity: Water absorption may cause the gelatin capsules’ elasticity to be higher than other capsules. Therefore, a controlled atmospheric environment with low amounts of humidity may be required to avoid any swelling or deformation.

- Temperature Considerations: Gelatin capsules become soft or brittle in high and low temperatures, respectively. The manufacturer specifies a range of temperatures that must be maintained to prevent the capsules from damaging themselves, for example, by deforming them.

- Filling Techniques: As seen in health, gelatin capsules do not form a perfect circle as they require a special filling method that overpowers other filling methods. This method allows for a tight seal and minimal wastage, and capsule-filling devices also allow for such.

- Compatibility with Ingredients: Although gelatin capsules are widely regarded as the best option in formation, there are a few contents that may not be able to be formed because they are harm-sensitive elements or require other capsules. The incorporation of the ingredients into the gelatin capsule is vital if other capsules are to be utilized.

Although gelatin capsules do have some additional requirements during processing, they remain extremely popular because they are so common in the pharmaceutical and nutraceutical industries. As with other goods, if proper care is taken to observe the correct procedures and equipment is utilized, the final product will meet consumers’ quality expectations.

References

Frequently Asked Questions (FAQ)

Q: What are the best ways to fill capsules with powder?

A: The best ways to fill capsules include using a manual or semi-automatic capsule-filling machine. These methods help you efficiently fill material into capsule bottoms, allowing you to fill multiple capsules accurately. Using a spill guard and a powder mixing machine can also improve efficiency.

Q: How does a semi-automatic capsule-filling machine work?

A: A semi-automatic capsule-filling machine automates part of the capsule-filling process. It typically involves placing empty capsule bodies into a body plate and pouring the powder into the capsule using a powder hopper. The machine then uses the tamper to compress and pack the powder before sealing the capsules.

Q: What is the role of a capsule counter in the filling process?

A: A capsule counter helps count and verify the number of capsules filled. It ensures accuracy and efficiency, especially when processing large capsules, by automatically counting capsules per hour and reducing manual errors.

Q: Can I fill capsules with different sizes using the same machine?

A: Yes, many capsule filling machines are adjustable to accommodate various common capsule sizes, such as size 00 capsules. This flexibility allows you to fill capsules with different sizes without needing multiple machines.

Q: Are hand-filling capsules effective for small batches?

A: Hand filling is an effective way to fill capsules for small batches or when using a manual capsule filling method. It involves placing the empty capsule body onto the cap plate and manually packing the powder. This method is more time-consuming than using machines but is suitable for limited quantities.

Q: How can I ensure accurate fill weight in capsules?

A: To ensure accurate fill weight, use a powder mixing machine to achieve a uniform blend of ingredients before filling. Additionally, using a tamper to compress and pack the powder evenly in the capsule helps maintain consistency in fill weight.

Q: What precautions should I take when filling capsules?

A: Use a spill guard to prevent powder spills and ensure a clean workspace. Always verify the fill material’s compatibility with the capsule type and size. Regularly clean and maintain your filling equipment to ensure optimal performance and hygiene.

Q: How does a tablet coating machine relate to capsule filling?

A: While a tablet coating machine is used for coating tablets rather than filling capsules, both processes are part of the pharmaceutical manufacturing workflow. Efficient capsule filling ensures that the dietary supplements or medications are properly encased before any additional processing, such as coating tablets.

Q: How can I improve the efficiency of filling large capsules?

A: Consider using a semi-automatic capsule filling machine and a capsule counter to improve efficiency. These tools help fill multiple capsules and verify quantities quickly. Additionally, using a powder mixing machine ensures a consistent blend, reducing the need for adjustments during filling.

Q: Can I comment or give feedback on improving capsule filling processes?

A: Yes, many manufacturers welcome feedback to enhance their products and processes. You can leave your comments or insights on specific forums or directly contact the manufacturers to contribute to developing better capsule-filling solutions.