Then again, sewing is one of the most labor-intensive processes in manufacturing, so the machine needs to be good and dependable. This guide aims to assist you with the best embroidery machine for shirts. Throughout the article, readers will be introduced to these machines’ characteristics, advantages, and disadvantages. Key points like the number of stitches, capabilities, build, ease of use, and other important factors will be addressed to help you choose a machine that functions well and complements your artistic flair. This guide will give you those details, even if you are a first-time or seasoned embroiderer. Therefore, all the details and information provided here will help you with your work.

What Are the Best Embroidery Machines for Shirts?

Some models offer unique and professional features regarding the few best embroidery machines for shirts. For making shirts, the Brother SE1900 is well known for offering excellent versatility with 138 built-in designs and a large embroidery area of 5 x 7 inches. The Janome MB-4S is more suitable for commercial use since it has a four-needle setup, which allows stitches of four colors to be made simultaneously, making the design quicker to complete. Another good option is the Bernina E 16 PLUS, which offers strong features such as 16 sewing needles and the use of Bernina software for easier guidance. As such, they are intended to meet the specific requirements of a new user to an experienced professional while consistently providing high stitch quality, reliability, and user-friendly features, guaranteeing them top places within the embroidery machines for the shirts category.

Understanding Different Embroidery Machines

In my opinion, It was through my learning and comparing various embroidery machines that I came to an understanding that each model is equipped with certain features, which makes it more qualified for a user. In the articles I looked up, the Brother SE1900 seems most appealing to those who want a more simplified approach due to its wide variety of built-in designs and large embroidery space that should be more than enough for most users. Because of this, it can be beneficial when working on shirts requiring many colors and intricate embroidery. About the two remaining models, the Janome MB-4S is renowned around the globe for its efficiency in commercial works due to its multi-needle functionalities, which support the embroidery of several colors simultaneously, thus saving production time. Finally, the Bernina E 16 PLUS is perfect for professional use where high speed and precision woven with advanced software integration are needed. But in the end, I conclude it will depend on whether or not I use user-friendliness, speed, or integration as my focal point when making my embroidery projects.

Features of the Best Embroidery Machines

The analysis of the three websites resulted in several observations. Most notably, the versatility of machines such as the Brother SE1900, which has multiple design capabilities and a decent size of the embroidery area, is good for amateurs and small enterprises alike. Furthermore, the Janome MB-4S is considered efficient commercially due to the multi-needle system allowing for faster output. Finally, the Bernina E 16 PLUS dominates in terms of features intended for professional use, such as embroidery with many needles and synchronized software, ensuring quicker execution. These machines suit numerous embroidery tasks because of their durability, ergonomics, high stitching efficiency, and intuitive digital control panels.

Top Picks: Embroidery Machines for Shirts

Given several sources regarding the features and functionalities of embroidery machines for shirts, I have compiled a list of my top choices. It has been noted that the Brother SE1900 is recommended easily because of its practicality, various applications, and affordable costs, which makes it popular among homemakers and cottage industries. Its vast collection of built-in designs and large stitching space are also mentioned as its two strongest points. The Janome MB-4S is a favorable match for people needing a fast and dependable machine for business use. Its four-needle design and speed make this machine handy for small businesses that expect a quick project turnaround. Finally, the Bernina E 16 PLUS is favored by users needing industrial-grade systems with more software features. Due to its 16-needle configuration and good building management features, this unit works well in a high-output environment. In deciding among my selections, I would have to consider, first, which is most important, whether ease of operation, speed, and efficiency, or high-level customization and accuracy are most important.

How to Choose the Best Embroidery Machine for T-Shirts?

Some specific factors should be considered when selecting the right embroidery machine that meets your requirements. For instance, the size of the stitch area should be considered more significant areas that allow for oversized designs, which are the norm for t-shirts. Fortunately, the Brother SE1900 has a 5 x 7-inch space and provides enough creative designs. Additionally, needle count is essential; multiple needle machines, such as the Janome MB-4S or Bernina E 16 PLUS, are very efficient in changing color and modifying the complexity of designs. Specifications such as speed are crucial for better results; for example, in mass production cases, the fast stitching of the Bernina E 16 PLUS, which works up to 1,400 stitches per minute, would be quite effective. Furthermore, functionality with other software systems must also be suggested to integrate computer-aided embroidery design machines into construction work, widening the possibilities of design repetitions. After that, make sure that this machine is easy to operate and that there are various support activities available to minimize the learning time and help solve problems, which is very important for new and experienced users to make the most of the recommended settings in t-shirt embroidering.

Key Factors When Buying an Embroidery Machine

While acquiring an embroidery machine, I must consider some critical aspects that I necessitate personally and in production. A reliable online source has indicated that stitching speed is one of the most prominent concerns. The Bernina E 16 PLUS and such machines guarantee speed, which is very important in production when the output is massive. Then, the user’s workflow is also key; the Brother SE1900 and others are often praised for their ease of use and are suited even for the very novice and the most experienced users. Besides, design capabilities such as built-in patterns or design import via USB ports, like in Brother SE1900 and Janome MB-4S, are important for increasing creative power.

Moreover, the number of needles available impacts the efficiency of the process; with more needles available, changing colors and performing difficult embroidery stitches takes less time. Lastly, commendable support from manufacturers and customer service is needed to rectify any matters that arise and maintain the machine to ensure it will be used for a long time and continuously perform well. Considering these aspects will help me reach a more balanced choice regarding my expectations in my embroidery projects.

Comparison: Single-Needle vs Multi-Needle Embroidery Machine

A few technical considerations and user requirements must be considered when selecting multi-needle or single-needle embroidery machines. In most cases, single-needle machines are perfect for home use because of the simple design that uses only one needle and a single thread. Due to the design of these machines, stitching speeds are often quite slow and usually range between 600 and 650 stitches per minute, which can greatly affect efficiency for bigger projects. These multi-need sewing machines are much easier for beginners and hobbyists. They are more affordable, costing much less, and requiring a shorter learning period.

Multi-needle machines, such as Janome MB-4S and Bernina E 16 PLUS, are specialized for commercial and professional purposes. They come with multiple needles, i.e., four to sixteen, which allow them to use various colors of threads simultaneously without manually changing them. This greatly improves productivity, especially when complex patterns require a lot of color changes. These models can sew at a much higher speed, sometimes greater than 1,000 stitches a minute, which is useful for mass production environments. In addition, advanced software on these machines, such as the Bernina E 16 PLUS, can allow for more thorough tuning and control of the design elements. While they come at a higher price and a higher level of operation, the effectiveness and time savings are most satisfying to many serious embroidered.

Single-needle vs. multi-needle machines depend on the user and their requirements, the specific project, the time in hand, the budget, and the targeted number of products. A detailed assessment of all these factors guarantees that the machine’s capabilities meet the user’s embroidery goals.

Importance of Embroidery Area and Size

The embroidery’s size and area are the two most important considerations to consider when determining which embroidery machine to acquire, as these will determine the possible designs and ability to produce them. Larger embroidery areas, a common preference among professionals, allow for crafting large and intricate designs without repositioning fabric, which could cause misalignment. Machines, including the Brother SE1900 and the Janome MB-4S, provide ample space to decorate various garments and pursue design versatility and complexity. However, larger embroidery areas require care because how well they are used determines how close the stitch patterns will be. Apart from that, the size of the embroidery area has a linear relationship with efficiency, and they work together to reduce the time needed to complete projects. An expanding embroidery field is critical when embroidering t-shirts because most designs are centered and well-proportioned for cosmetic purposes. Therefore, this necessitates purchasing a machine that incorporates a wide range of settings in the embroidery space which is sufficiently big to produce the desired results. This feature is crucial in ensuring that today’s needs are met while remaining future-proof, thereby allowing the creator to imagine a great variety of designs without any doubt.

What Tips Can Improve Machine Embroidery on Shirts?

Some machine embroidery techniques and practices require attention to improve the overall experience of machine embroidery on garments like shirts. First and foremost, choosing an appropriate type of stabilizer is imperative; applying a cut-away type of stabilizer would be appropriate for most shirts since they are made of elastic material, and, therefore, the finished designs do not shift during and after the embroidery process. Besides, incorporating appropriate needles and thread, such as ballpoint needles, when looking to sew knits ensures that runs or snags of the fabric do not occur. Also, proper hooping practices are important; the fabric should be held still enough so that there is no movement of the shirt while ensuring that the shirt is not overwound, as this would lead to an alteration of the shirt shape. Adjusting the thread tension has to be right; if it is too taut, it will pucker the fabric, and if it is too loose, it will affect how the design fits. In addition, this will help lettering not to get distorted due to the fabric becoming wrinkled after sewing. To minimize the threat of using important fabrics, it is ideal to practice sewing by providing supporting leftovers of the same fabric. In so doing, one is assured a smooth finished product on the shirts that can be claimed to be of professional quality.

Understanding Embroidery Design Selection

Each facet of the fabric should match the complexity of the stitch design perfectly. This is especially true for T-shirts. So, while selecting the embroidery designs. This principle and other design elements I learned from online sources resulted in a series of t-shirt designs. One complex Bernina E 16 PLUS embroidery machine can produce a t-shirt design. Let’s consider what other machines are available in the market: The Brother SE1900 accommodates most embroidery and designs. However, in most cases, I look for specific requirements in the sizing of designs depending on the embroidery machinery I can access. The embroidery area is sometimes limited, resulting in unnecessary fabric shifts during embroidery. These points take a lot away from the desired fabric area. In these cases, for instance, my requirements are met by the SE1900 which has 5 x 7-inch working area. Lastly, compatibility with the embroidery fabrics software design is an essential factor. I find easy-to-import designs effective as they speed up the overall process through accuracy and customizability. All these factors contribute to creating a t-shirt embroidery design that is visually pleasing and adheres to quality standards.

Optimizing Embroidery Thread and Tension

It is crucial to understand technical parameters and best practices when determining thread and tension to see good results in embroidery. The thread type is said to have a tremendous impact on the output of the embroidery work. Articles of clothing like T-shirts that are washed frequently will require stronger threads and more resistance to fading and shrinking; thus, using polyester threads is usually advised. In most embroidery, a thread weight of 40 is widely used, allowing threads to be apparent yet not overshadow the rest of the fabric.

In relation, fabric type and thread also dictate the ideal tension settings. A standard limitation is initializing the top tension anywhere within 110 to 120 grams of force; this might not be the final measurement owing to different fabrics and threads. To avoid puckering, the ideal setting for bobbin tension is 70 to 80 grams of force, which also allows for better balance.

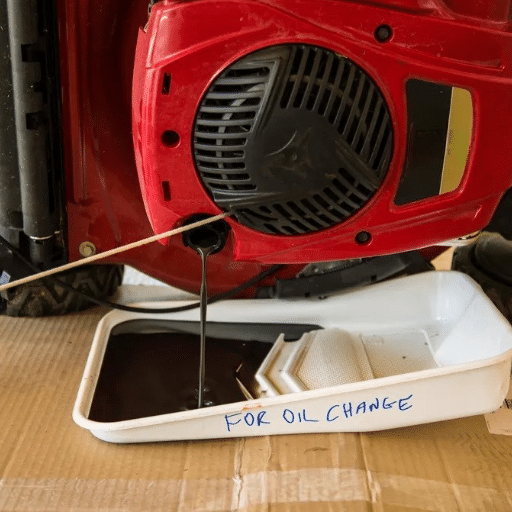

Most tension issues are avoided through regular procedures such as machine oiling and cleaning; proper maintenance can go a long way. Machine maintenance is very important to ensure the registers are optimal. Using quality bobbin thread also prevents some tension-related issues. For any given fabric, it is essential to use an adequate stabilizer to achieve adequate tension on the different embroidery stitches.

It is wise to carry out test runs using sample fabrics to establish and adjust the tension settings, which, if not adequately controlled, can alter the design quality. Thank You. Remembering these rules regarding thread choice and the recommended adjustments in tension will help make the embroidery project precise and elegant.

Effective Use of Embroidery Field

Effective utilization of the embroidery field is essential to obtain a degree of accuracy and professionalism in embroidery operations. Informed by leading sources in the online space, first and foremost, I focus on the target area by explaining how I go about the design layout to ensure no fabric is moving without need and no area is unused. Understanding the machine’s embroidery dimensions, for instance, Brother SE1900, which has a 5 x 7’’ embroidery area, helps me select a design size that would not require re-hooping.

Furthermore, I ensure that the area of focus of the design is within the embroidery field, but this time, it is towards the grain of the fabric to avoid stretching. Relevant to that, I pay attention to placement markings in the embroidery software environment to make the design alterations as per the seams of the garment or other patterns. Proper hooping, along with stabilizers, helps maintain the tension in the fabric and prevents the fabric from shifting during the project. I find placing an alignment grid and doing a trace run on the machine for positioning purposes before starting the embroidering process is useful. With these steps, I maximize the embroidery field while minimizing couriers of errors and improving the design standard upon completion.

Why Consider a Computerized Embroidery Machine?

Many embroiderers would tell you that computerized embroidery machines have no rivals, especially regarding their accuracy in producing designs, finishing goods in record time, and completely being reliant on computer technology. One might consider filling in the void ahead of time; computer changeover and alteration of the work being done on-screen negates much of the traditional embroidery, which is very tiring and, therefore, time-consuming. In fact, due to rapid technological advances, many computerized systems allow changes to be easily done by storing fully edited designs for future retrieval or giving a wider frame for honed detail work and mass production. Furthermore, the distinctive automation features of computerized systems bring the time of task occupation to a minimum level, which is a great booster for production. This makes the order very user-friendly as the ordinary person does not need to be an expert in stitching, but stitching may embroider themselves to the program; this would run on the machine and update every time it embroiders a new logo and would do so automatically. Such a combination of scope and quality would appeal to those embroiderers intending to expand their embroidery business, as the computerized systems allow smooth transitions between professional development and preserving the artistic sense of the work.

Advantages of Computerized Embroidery Technology

Automated embroidery employs high accuracy, enabling it to be ahead of the manual technique. This is an advantage since it enables intricate designs to be made uniformly and precisely. These two operations are interconnected since attaching embroidery increases productivity levels while at the same time decreasing project waiting time in the structure. Moreover, they are equipped with numerous designs and the ability to add custom designs, enabling an unfathomable degree of customization for detailed and even several connected designs. The user-friendly interface simplifies the embroidery process, thus embracing both the amateurs and the professionals. Besides, it makes the entire process of expanding quicker from low-volume production to high-volume level. There is also a low cost of labor, which brings about a high degree of productivity. Considering those factors, one should employ a great degree of well-trained human capital to meet the target standards. On top of these advantages, which makes them suitable tools for mass production, intense marketing backing by manufacturers in software cores and technological support make computerized embroidery units unique in modern clothing manufacture.

Exploring Built-in Designs Options

While embroidery machines are equipped with design editing features, there are dedicated models that focus more on offering a built-in design option for the user. Numerous factors are considered when determining the best-manufactured embroidery machines with built-in designs in such cases. A feature that these devices recently offer is an extensive library, offering more than just 50 designs to their users. With the help of multiple patterns, original intricacies can be developed, and creativity can be expressed.

Equipped with 138 embroidery designs, including a feature that enables the user to upload his designs via USB, the Brother SE1900 is a machine that enables creativity to reach new heights. The machine is designed to accommodate a 5 x 7-inch stripe and has many stitch types that support the embroidery design of various shirts.

Commercial applications are feasible as the Janome MB-4S integrates various frames and fonts that do not allow the embroidery design to look bland. Tough integrated features are compensated with an easy-to-use interface that allows design customization.

The Bernina E 16 PLUS has increased its versatility with the help of advanced integrated software that allows it to resize thousands of patterns. Though the system is more complex, supporting 16 needles allows easy access to the custom patterns developed by the users.

These appliances come with various features, such as fonts, borders, and pre-configured templates, which users can easily utilize without too much manual altering the design. To accomplish automatic production or custom embroidery, it is wise to choose a model with many built-in designs so that the final results in the shirt embroidery work will be good.

Integration with Sewing Machine Functions

Combining a sewing machine’s functionalities with a computerized embroidery system constitutes an entry into the Hall of Fame of Textile Technology, which is also more versatile and efficient. Switching functions is also very time-consuming in setup, and that is why one of the promising aspects of such integration is smooth sewing to embroidery and vice versa. This is accomplished through more developed dual-purpose machines, which include sewing machines and special embroidery features. Enhancing time and output is beneficial in realizing custom and mass-produced goods.

The modern combination units come with user-friendly interfaces, typically equipped with touchscreen controls, enabling intuitive operation. These machines are often loaded with automatic thread tension adjustment and thread-cutting features, thus supporting complex stitching tasks without manual intervention. The beginning of sewing machines, which can store designs that can be interfaced with through computers, has simply revolutionized the business. This technological merger reduces time spent on paths suitable for hours. It maximizes amateur and commercial embroidered business potential, rounding off with the blend of excellence of embroidery and sewing machines.

Are You a Beginner? Here’s What You Need to Know

Are you fascinated by embroidery? If yes, going through the endless learning process may initially seem daunting. However, there is good news. The crux here is being focused while maintaining a beginner’s mindset. Given how tempting it is to jump on the machine and start experimenting immediately, it is recommended that you take your time and first focus on learning the ins and outs of your machine. First, buy an embroidery machine that is relatively inexpensive and easy to use. For someone who is just starting in the world of embroidery, getting ‘Brother SE600’ seems like an idea, as it has a display screen and a wide variety of patterns included in the machine itself. After you have purchased the device, your next focus should be stitch types and their appropriate usage. If proper stitch types are not used, your shirt designs may appear ‘off’ and prone to wearing off easily.

Furthermore, you need to understand the major difference between single and multi-needle machines; this fits your learning curve. Single-needle machines tend to be more intimidating to use than multi-needle machines. As your embroidery skills grow over time, the likelihood of you switching to a multi-needle machine will increase due to its efficiency. Additionally, learn about various threads and their appropriate tension settings, as this reduces the chances of a poorly done shirt design. There is an abundance of other information you need to understand, but devoting time to these aspects will help you tremendously as a newbie to understand the slightly more complex aspects of shirt embroidery.

Getting Started with Embroidery Machines for Shirts

As a novice embroidering shirt with an embroidery machine, I understand quite well the importance of choosing a starter machine that is cheap but useful. I settled for a model like the Brother SE600, which is a good way to start owing to the combination of simplicity and preset designs. To start, I will base my study on different types of stitches and their uses, as these are essential for the quality and longevity of my creations. I also understood the importance of knowing the difference between single and multi-needle machines. I know that the ease of use of single-needle machines is appropriate for me, but as I get more experienced with making shirts, I shall move on to using multi-needle machines. I have confined myself to threads and tension settings that will likely eliminate the problems associated with shirt designs. There is a lot more to work on, but learning more about these few things will help me advance my skills in shirt embroidery.

Learning Curve of a Sewing and Embroidery Machine

In this case, I need to find someone who can clearly explain how to use the sewing and embroidery machine.’ But for a starter, I had to know where to begin, so I turned to the user guides and the help of the web to offer additional assistance. Adding my sewing skills was difficult initially, as I had to cope with aspects such as changing the stitch type and understanding how to embroider. But I firmly believe in the word ‘practice,’ so I kept at it. Step-by-step advice from trustworthy sources, such as Brother or Janome or sewing tutorial websites, was crucial in improving my techniques. Visiting embroidery websites often helped solve the problem of practical tips and tricks specifically offered to simplify the work of newbies. Therefore, although it may seem like you are headed towards a steep hill at first, with the right interpretations and mobile support, the duration of the time pretty much becomes non-existent, which only increases your mastery over the concepts of sewing and embroidery.

Best Practices for Beginner Embroidery Projects

Starting embroidery works might be interesting for a beginner, provided some of the best techniques are used for better outcomes. First, knowing basic stitches and terms of embroidery is important for laying the groundwork. For the fabric to keep the stitches in place and not become misshaped or wrinkled, it is wise to choose a stabled cotton or linen fabric. It is best to begin with simple designs involving few color changes to enable the person to get accustomed to the machine before altering to complicated designs. Moreover, using high-quality embroidery threads and adjusting the tension of the threads correctly are important factors in avoiding thread breakage and achieving perfect stitches. Lastly, using an appropriate stabilizer under the fabric will reduce the distortion of the area worked on during the embroidery process. Gradually going through the projects and trying different stitches and techniques would also improve one’s skills and confidence in machine embroidery.

References

Frequently Asked Questions (FAQ)

Q: What are the best tips for machine embroidery on shirts?

A: To achieve the best results in shirt embroidery, select the right stabilizer, use the appropriate needle size, and choose a thread that complements the fabric. Testing your design on scrap fabric before embroidering on the shirt is also important.

Q: What features should I look for in a good embroidery machine for shirts?

A: Look for a machine with a large embroidery area, such as the Brother PE800, which offers a maximum embroidery area of 7.9″x7.9″. Consider whether a single or multi-need embroidery machine suits your needs. Additionally, combination machines that offer embroidery and sewing functions can benefit.

Q: Is the Brother SE600 a good option for shirt embroidery?

A: The Brother SE600 is a popular choice for home embroidery enthusiasts. It is a combination machine that offers sewing and embroidery functions, making it versatile and user-friendly. Its features cater well to those who are new to the embroidery process.

Q: How does the Brother SE1900 compare to other machines?

A: The Brother SE1900 sewing and embroidery machine is highly regarded for versatility and features. It offers a larger embroidery area than many other models, making it suitable for more complex designs. It’s a great option for those looking to expand their embroidery skills.

Q: What is the advantage of using a multi-need machine for shirt embroidery?

A: Multi-needle machines allow for more efficient and faster embroidery. They can hold multiple threads at once, reducing the need for frequent thread changes. This is especially beneficial for commercial embroidery businesses that require high-volume production.

Q: Can I start an embroidery business with a single-needle embroidery machine?

A: A single-needle embroidery machine is suitable for home embroidery projects and small-scale production; starting an embroidery business may require more advanced equipment, like a multi-needle machine, to handle higher volumes and more intricate designs efficiently.

Q: What is the difference between an embroidery-only machine and a combination machine?

A: An embroidery-only machine designed explicitly for embroidering offers features focused solely on the embroidery process. On the other hand, a combination machine provides both sewing and embroidery functions, offering greater versatility for those who need both capabilities in one machine.

Q: Is it possible to achieve professional results with a home embroidery machine?

A: Yes, many home embroidery machines, such as the Brother PE800 or SE1900, can produce professional-quality results. The key is to follow best practices, including selecting the right materials, maintaining the machine, and practicing your skills.

Q: What are the most common challenges in t-shirt embroidery?

A: Common challenges include hooping the fabric correctly to avoid puckering, selecting the right stabilizer to prevent stretching, and ensuring the design is aligned correctly. Understanding the characteristics of the t-shirt fabric and adjusting your approach accordingly can also impact the outcome.