It is important to note that what began as simple needlework has, through the years, emerged into an advanced multidimensional art form assisted by sophisticated embroidery machines. An array of embroidery machines can be used whether one is a hobbyist or a professional practitioner. A good portion of their features enhances the ability to modify and customize gears to a large extent. Given the wide categorization of these varieties, we will examine the various machines based on their features, performance, ease of use, etc. We will direct you to all the details you require so that you will be able to procure a machine that will meet your personal or practical requirements. Even if you are interested in sewing machine models suitable for home use or commercial systems, we have it for you. Take a look at the most convenient sewing machines for making any project more creating.

What is an Embroidery Machine and How Does it Work?

Introduction to Embroidery Machines

An embroidery machine is a technological device that helps stitch beautiful designs on a piece of cloth. As with any device, it consists of both hardware and software parts. A needle, a bobbin and a hoop are some of the accessories, along with the sewing machine, which helps accurately design embroidery on the cloth surface. It is possible to convey data and designs to the machine through a medium which is then booted into reading the data and performing the specific stitching to the design. Other sophisticated models allow the user to use a computerized system that controls more design features, including stitch length, direction, and density. It, however, presents its main strength in general machine embroidery design productivity while retaining high-quality standards, thus making it useful to both beginners and expert makers.

Stepwise Procedure for Setting Up Embroidery Machine Tertiary

Begin by slowly and carefully removing the machine and its components and the packing material to set up the machine. However, ensure there is enough working space and that the surface where the machine is to be placed is flat and strong enough. After this, inset the embroidery hoop on the machine, ensuring it is fastened. Fill the bobbin case and insert the bobbin as per threading use the user manual. After that, insert thread into the needle as per the thread path designated, which normally requires passing thread through sorts of guides and tension disks and, finally, the needle itself. Once threading is done, the next thing you will do is plug the machine in and turn it on. Most embroidery machines have their own software interface, which takes in external files such as those in USB flash disks or directly connected to a computer. Choose the design you would like stitched out, then adjust the stitch parameters, length, and density. Finally position the embroidery fabric within the hoop and tighten it as much as possible to prevent movement during fabric stitching. With such arrangements in place, it is evident that you have completed all the preparations and are now ready to commence your embroidery project.

Important Specifications to Consider When Picking an Embroidery Machine

When purchasing an embroidery machine, there are some features that I feel are valuable and must be present, to get the best performance and worth. First of all, the buyer should settle for a machine with a relatively bigger embroidery area, which gives room for the flexibility of the projects in terms of size. Moreover, some machines may incorporate the design editing technology, which making such edits becomes less of a hassle since it can be done on the machine itself. The availability of a wide selection of inbuilt stitches and designs is another aspect that I found crucial in enhancing an embroidery machine’s creative aspects. The capability of high-speed stitching is also quite relevant since it tends to improve production efficiency, minimizing the wastage of time for each undertaking. In addition, an easy-to-operate interface, further enhanced by a touch screen of the machine, plays a significant role in the user enhancing the effectiveness of the functionality. Last but not least, being able to work with a good number of different file types as well as importing designs via USB or by attaching a computer are some of the functions that will help improve the equipment greatly.

How to Choose the Right Embroidery Machine for Your Needs?

Finding out the Differences: When to Use the Multi-Needle or Single-Needle Embroidery Machines

Several points are worth noting, especially when contrasting multi-needle with single-needle embroidery machines. The most important question is the requirements for your projects. From a practical standpoint, multi-needle machines can hold more than one thread color at a time, which reduces changeover duration, greatly increasing productivity. This makes them perfect for high capacity and complicated designs involving a lot of colors. Conversely, single-needle type machines need one to manually change the thread, which is a time-consuming exercise but may work well for hobbies or minor projects where the décor is not very busy. Concerning these, one would find that most low-cost multi-needle machines do not have extra features such as automatic threading, stitching speeds, etc., but are expensive. Single-needle devices remain most effective for beginners and simple embroidery endeavours. However, if you are looking forward to complex embroidery of large scale, it would be smart to invest in sophisticated multi-needle machines.

Best Beginner Embroidery Machines

I believe everybody benefits most from owning an embroidery machine and for that reason, the Brother PE800 is the best embroidery machine for beginners. It includes a 5×7 aperture for embroidery which makes it easy to create bigger designs. The colour touch is quite simple and allows the user to scroll through the available designs or editing options, thanks to the built-in design feature. The Janome Memory Craft 400E is an equally great option, known for its consistent performance and accuracy. It has 160 designs pre-installed and the area available for embroidery is large as well for people who want to be more adventurous as they gain more experience. Last in this category is the Singer Quantum Stylist EM200, which also gets a favorable rating for its price and functional capabilities, which include an automatic needle threader and built-in designs of 200. Every one of these machines combines easy-to-use capabilities and extra specifications that any individual beginning to attend to embroidery should highly consider.

Top-Rated and Best Embroidery Machines for Business Use

It has become quite rampant to find several overwhelming reviews of the best embroidery machines for commercial use. Among the best embroidery machines for commercial use, three most popular models emerge from the extensive reviews made by leading online sources. Firstly, the Brother PR1055X is solitarily highlighted because of the several productive features that most people consider quite helpful. The machine has a 10-needle system, automatic needle threading, and a large area for embroideries, increasing productivity and reducing nonproductive time. Another great alternative is the Janome MB-7, designed for businesses that need embroidery. This touch-screen seven needle embroidery machine has a large amount of memory, editing capabilities, and the ability to connect with other devices to download necessary embroidery designs, making it easy to work on large and complicated designs. Last but not least, the Melco Amaya Bravo is one machine that is appreciated for its efficiencies in speed and step-up expansion capabilities. Programmable and intelligent machines with an automatic bobbin thread adjustments as well as automated thread breakage are used to maintain high consistency and high production levels. All these machines have been properly constructed, appropriately designed, and easy to use, making them the best and most recommended embroidery machines for commercial use.

How to Create Stunning Designs with Your Embroidery Machine?

Tips for Choosing the Right Designs

More than I care to admit, I’ve become familiar with the top industry websites when looking for the right designs to use in embroidery projects. The following are key points that one should take in mind.

- Know Your Machine’s Specifications: Every embroidery machine has a technical specification defining what design works with which particular machine model. Take, for example, what the Brother PR1055X can do, which is more elaborate patterns due to having ten needles and extensive embroidery area. Checking on the stitch per minute (SPM) rate, how many needles the machine has, and what design area is the maximum can help in ensuring design selection that is appropriate for within the capabilities of a machine.

- Choose Suitable Design Complexity: It is very important for comprehension’s sake to relate the machine and the design thereof with the project undertaken. For example, Janome MB-7 is a seven-needle system that offers good embroidery on middle-range designs that involve a few colors and limited thread changes. Try not to fill your machine’s built in design memory beyond its limits plus the design area measurement ought to be well within the mechanical restrictions of the embroidery machine.

- Change The Design File Format Otherwise It Will Affect The Designs: If a certain design is not compatible with a machine, there will usually be an unacceptable file format (PES for Brother, JEF for Janome, etc.). Ensure that the designs are taken in an appropriate machine-compatible format. Many commercial embroidery machines like Melco Amaya Bravo accept common formats and have ports to import designs easily.

- Test Designs on Similar Fabrics: A trial-suitable design should be used on a fabric similar to the material being used in the project. It is important to adjust parameters like the needle size and thread tension, especially on the Melco Amaya Bravo, which has automatic tensioning devices.

- Review Design Density: Excessive threads may cause problems with fabric stability and even the fabric with the threads performance. The Brother PR1055X and Janome MB-7 machines allows maximum use of the varying densities due editing processes. However, ensure that your fabric type supports the density so that it does not pucker or distort.

Domestic embroidery machines may handle all aspects of sewing, but stress must be placed on the above lest the selections made proceed without due concerns with the probing machine technical parameters, rendering it highly ineffective.

How to Use Built-in Embroidery Designs

Acquiring a machine with several built-in embroidery designs requires understanding several steps before using this unique feature. To begin with, explore the functionalities present in the machine as well as moving around the menu. For example, on the Janome MB-7 or Brother PR1055X, there is a built-in design library accessed from the touchscreen menu. Choose the appropriate design and note that it should be within the defined dimensions of the embroidery hoop. Effort should now be geared towards threading the device, and this has to be the order of the design being modelled. The Janome MB-7, for example, will give you a prompt to change the thread color when using other machine designs. Lastly, examine the installed embroidery unit’s monitor to look at the design before proceeding to its actual embroidery to check it’s complete. You must also sew a test piece of fabric that uses the same color and density of the threads in your final project. An orderly approach like this one avoids the costs of the quality of embroidery.

Ways of Customizing Your Embroidery Works

Embroidery is not merely a decorative art but a thoughtful piece of work that emphasizes understanding human emotions and creativity. Here, feedback from the wearers or owners was key, and I urge you to enhance your results by including theirs, too, through monograms. Some machines, such as Brother PR1055X, include text editing features that allow making names, initials, and other letters on any embroidery work, while some machines are programmed to print them by g. For example, to match the degree and fabric of the embroidery product that the design is created for, try mixing different colors and types of threads. Appropriate software like the Janome MB-7 has built-in programs which enable you to take and modify a design be it yours or one that you found commercially available. These changes can be made by applying bead work to the embroidery or using other unique fabric backgrounds. This offered different art with different meanings, which in the end made these several kinds of art pieces work as a product but enthusiastically off from the crafters’ perspectives.

What Accessories are Essential for Embroidery Machines?

Essential Enhancements for Your Embroidery Machine

While we talk about the embroidery machine and the basics associated with it, there are a few accessories which are of utmost importance. The first and the foremost among them are stabilizers. These provide the required assistance to fabrics, J-VereK, regarding the stitches being made on them. They include cut-away stabilizers, tear-away stabilizers, and water-soluble stabilizers, among others, and they are applicable to specific designs and fabric types. To make seam and embroidery sewn pieces last longer, there is a range of embroidery threads which include polyester and rayon. To maintain proper tension in the fabric and reduce the risk of puckering, hoops of different sizes are very effective in holding the fabric firmly under the embroidery head. Needle sets for embroideries use specific-purpose needles which enhance neatness in stitches even in places with minimal space where stitching a pattern requires more finesse. In addition, there is also a thread called the bobbin thread, which is lighter and thinner than the top one, thus creates a smooth and balanced embroidery design. With a proper storage case you are able to load necessary materials such as threads and needles, and other little valuables where it will not disrupt your work. Last but not least, you might want to buy some embroidery software that will further increase your designing potential by allowing you to make your designs and import ready patterns. Each of these accessories has its list of significance, which returns improved efficiency from the machine and quality of works.

Hoes of Choice for Any given Project

In order to achieve the best possible embroidery outcome, selecting the appropriate hoop for the projects is of great importance. From my experience and top industry field nodes research, it is evident that the size and kind of the hoop one chooses differs due to the nature of the undertaking. Smaller hoops help in working on small and complex designs, which are more delicate and require certain levels of control. In contrast, the larger hoops are most effective when using many designs on one fabric or when a vast design is to be made. Tensioning and adjustable hoops are helpful as they can accommodate any width if the fabric and the measurement of the artwork inserted in them differs. Likewise, it is not a big secret that the correct model of the hooper has also to be chosen, along with the necessary instruments. Through careful selection of the suitable hoop, one is able to hold the fabric in place, eliminating and preventing wrinkles while evenly spacing the stitches, leading to proper and neat embroidery.

Apprehending the Significance of a Quality Bobbin

Based on my analysis of the best-known online information resource, it is reasonable to conclude that top bobbins and good-quality end products are all essential for executing successful embroidery projects. In an embroidery machine, the bobbin is meant to hold the underneath thread, which is in the same importance as the top thread in creating balance stitches. Important factors to consider when choosing a good bobbin are the followings:

- Material: Bobbins are made of plastic or metal. Metal bobbins are quite heavy and can create the most tension, while plastic bobbins are much lighter and less prone to corrosion.

- Size and Compatibility: The embroidery bobbins within the case should more than fit the embroidery bobbin case to resolve the problems of unruly tension and the entire logistics hassle. Some of the common sizes are class 15, L, and M, although you must read your machine’s manual to determine what size is recommended.

- Winding Quality: Proper bobbin winding helps clients because it balances tension and suction as well as feeding. Tighten up the bobbin threads, and the winding should be made more symmetrical so that there are no loose fragments or too tight areas to obstruct the sewing thread in the bobbin case.

By paying particular attention to these specifics—material, size and compatibility, and quality of winding—it is possible to eliminate the most frequent hammer embroidery problems, like shifted stitches or cut threads, thus raising the productivity and quality of the embroidery process.

How to Maintain and Troubleshoot Your Embroidery Machine?

Basic Procedures for Handling Embroidery Machines

If you want your embroidery machine at work and doing quality results, these are some of the maintenance tips that you should acquire in the routine activities:

- Cleaning: Periodic cleaning is performed on the machine to avoid accumulation of lint and dust that would affect how well the machine performs. This step involves the use of a tiny brush or a vacuum cleaner to suck dust from the needle plate, bobbin area and the area around the thread path. It should be done after every project or, if you do a lot of embroidering, once each week.

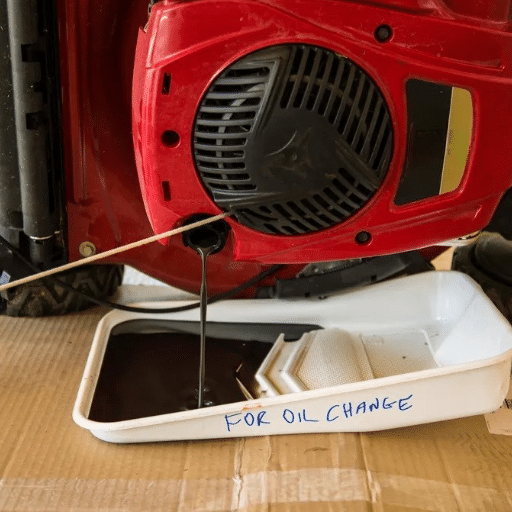

- Oiling: Oiling minimizes risk of wear and tear due to friction. Follow your machine’s manual and find out where to craft oils are needed and what craft oils are recommended. In general practice, a few drops of machine oil should be smeared on the moving parts and not mainly in the bobbin case and hook area, every 40-50 times of use.

- Needle Change: Stitching quality is likely to degrade without changing the needles from time to time. Skipping stitches and breaking threads are common challenges experienced from sewing with the same bi/fabric needle for too long, especially if it is worn or bent. The needle should be changed after every 8-10 hours of embroidery or every new project initiated.

- Bobbin Case Adjustment: Take great care of the bobbin case so it is clean and free from lint. With everything as it should be, apply a drop test to check the bobbin tension as is spelt out in your manual. Tension is ventilated when the bobbin is able to fall but rotating does not occur so fast.

- Software Updates: It is advisable to load the current updates since there may be more to enhance the system’s functionality. Please go to the manufacturer’s homepage for firmware updates and installation instructions.

- Professional Servicing: Annual maintenance is necessary through certification by a specialist, during which the machine undergoes internal cleaning, timing adjustment, and calibration.

People should not abandon this preventive process maintenance for the time being. Factors that extend the operability of an embroidery machine are cleaning, lubricating, changing the needle, adjusting the bobbin case, installing and updating the software, and professionally servicing the machine.

Common Problems and How to Fix Them

Thread frequently breakage

Out of all the problems I have encountered, frequent thread breaks seem to be the most prevalent. Several factors, such as incorrect thread tension, damaged needle, or type of thread used can cause this.

Solution

- Check Thread Tension: The first thing I do is to correct the developed thread tension. For most projects of this nature I would have it set at about 4 to 5. But I usually check my manual for nomogram.

- Needle Replacement: I have in mind the type of cloth I am working on and, chop chop, the needle has to be changed if bent or worn for some reasons.

- Quality of Thread: When bursting higher-quality threads, I avoid using every type of embroidery thread, as the low-quality ones tend to break off easily.

Fabric Puckering

Another problem that requires attention is fabric puckering, which is very unpleasurable for any embroidery and often occurs due to improper hooping, wrong stabilizer or constraining too much thread.

Solution

- Hooping Technique: I make sure the fabric is painful enough but not rigging in the hoop.

- Stabilizer: The proper stabiliser for the fabric is chosen. Cut-away stabilisers are particularly suitable for knit fabric.

- Adjust Thread Tension: I release the thread tension and make a test run when the results are unsatisfactory.

Stitches that have been omitted

A skipped stitch occurs when a needle is dull, not placed properly, or has problems with the bobbin.

Solution:

- Needle Condition and Installation: I changed the needle as it was due and also turned it to the right position.

- Bobbin Case Inspection: I clean the bobbin case well to remove all the accumulated lint over time. Next, I check the bobbin thread tension, as we did above.

- Thread Quality: I try to avoid this problem by using much more expensive needles and threads.

Stitches not in Line

Uneven stitches may stem from improper tension, a poor bobbin case or it may have to do with the fabric.

Solution:

- Tension Settings: I check and fine-tune the tensions of both the upper and bobbin threads once again.

- Bobbin Case: I visually inspect the bobbin case for wear and tear and make sure it has neither scratches nor other damage.

- Proper Stabilization: I make sure that the fabric and the stabilizer are properly and tightly hooped to eliminate any chances of movement during the stitching of the embroideries.

Through this process of looking for such problems, checking, and making more adjustments to eliminate them, I can achieve constant and high-quality embroidery output.

When to Explain About the Embroidery Machine Troubles to Experts

Although I usually enjoy troubleshooting and cleaning my embroidery machine, there comes a point where I have to call for help from experts to ensure the machine is durable and accurate. For instance, in some cases, even if I have a proper setup, the machine does not work, and in some cases, it breaks; this might mean that some parts are malfunctioning and need the help of a specialist. In routine use and with minimal worries, any embroidery machine could last for approximately 500 hours of usage after which it would call for a professional checkup, however such problems can constrain this duration.

However, when insulations of mechanical parts or any other preventative measures have been taken with no success and one experiences excess noise such as grinding or clicking, there is a need for a doctor. These are signs of mechanical failures in a sewing machine touch screen or other parts of the sewing machine that cannot be penetrated during regular user maintenance. Electrical concerns like powering failures and involuntary turns further mandate the need for third-party assistance mainly because any internal damage could affect the circuitry.

Finally, having completed the working description of requirements and identified gaps in it, I realize that there are probably situations when such intervention is needed. Such modern machines sometimes have software that may need updating or reinstalling, without which the problem will likely worsen. For this reason, engaging professionals is quite inevitable.

Engaging a professional in any service activities certainly takes care of some of these intricate problems. It also enables the machine to operate efficiently for a long time, making it a worthy investment while also improving the standard of my embroidery work.

Reference sources

-

Wikipedia – Embroidery Machines

-

HindustanMetro – HSW Embroidery machine has won the Excellence in Embroidery Machine award in Dubai from Radio City

-

fibre2fashion – India enforces BIS certification for weaving & embroidery machines

Frequently Asked Questions (FAQs)

Q: A sewing machine is different from an embroidery machine in terms of its features and the purpose it serves. Just why is this so?

A: A sewing machine is used primarily to sew pieces of cloth together, while an embroidery machine is used to purposefully embroider patterns, designs, or any appealing element, especially on cloth. Some high-end units can work both ways, referred to as sewing and embroidery machines.

Q: I would like to know what the essential attributes of a Brother embroidery machine are.

A: Primary functions to be included comprise a touchscreen liquid crystal display for ease of use, the size of the embroidery area, the number of font types, and the number of designs incorporated in the machine. Conversely, model Brother NQ1700E has quite a number of these features suitable for either novice or advanced users.

Q: Can I add embroidery on hats with my embroidery machine?

A: Yes, many embroidery machines come with accessories or hoops that can help make hats. A multi-needle embroidery machine is often the better option for commercial embroidery or frequent hat projects.

Q: What is the benefit of using a multi-needle embroidery machine?

A: Multi-needles on embroidery machines can embroider using more than one color of thread at a time without replacing them. This is especially important for more complex and larger projects. High-quality multi-need embroidery machines are available from manufacturers such as Ricoma and Baby Lock.

Q: How pricipal is the sizing of the embroidery area?

A: The embroidery area size determines the size of the design that the user will be able to create. A bigger embroidery area is ideal for bigger embroidery, such as furniture upholstery or sweatshirts.

Q: Which types of fonts can be used on embroidery machines?

A: Children and adults use a variety of artistic embroidery machine templates with font styles built in for different usages. Some sophisticated models permit the user to upload, in addition to the built-in remains of the fonts, any subsets of ‘working’ fonts, and even whole new fonts. The Brother SE1900 allows such multiple font usage for personalization.

Q: Can I do my designs on an embroidery machine?

A: Certainly, most embroidery sewing machines are equipped with softwares that help create and import designs. Chroma or similar software will allow you to create complex designs and will help you in digitizing the designs so that you can start embroidery more easily.

Q: Which machine is the best to be used to commence the embroidery journey?

A: As a beginner, it is fitting to opt for a sewing and embroidery machine, such as a Brother SE1900 or Janome Memory Craft 550e. These machines ensure that users do not experience any difficulties since they are equipped with amazing features and functions suitable for a variety of jobs.

Q: How do I take care of my embroidery machine?

A: As a rule of thumb, maintenance entails cleaning the needle area, lubricating the machine according to the instructions, and threading in the right threads and bobbins. You can also increase your machine’s useful life by occasionally taking it to a professional for servicing.