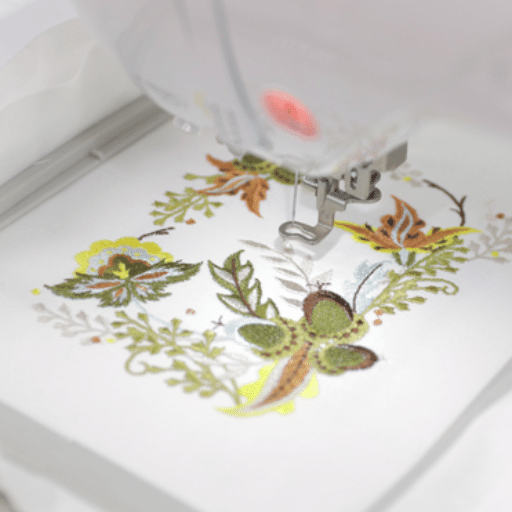

Due to technological advancements, embroidery machines have come a long way and are used in commercial circles and by involved ‘making’ fans. To cater to different embroidery needs, going from small decorated orders to high-volume purchases, it is essential to appreciate the embroidery machines market, particularly those with larger hoops. That is why this blog aims to take you through the details of selecting the ideal large embroidery machine, which focuses, among other things, on the hoop’s stitching capacity, the machine’s speed, the degree of versatility, and technological considerations. We will discuss various available choices and compare the features, specifications, and their effectiveness against the set embroidery requirements and standards. Whether you are a creative designer expanding your business or a meticulous craftsperson, this guide will be greatly helpful in making the choice.

What is the Importance of the Hoop in an Embroidery Machine?

Instrumental in the embroidery machine structure is the notion of the hoop, given the desirable stability of position throughout the embroidery. It prevents the fabric from shifting, which would lead to alterations in the design. Such tension is significant since even a small rotation is a shift in the design, which will lead to an error in the end product. Larger hoops allow for creating larger or several designs at once while avoiding moving the fabric, thereby increasing productivity and reducing lead time. Furthermore, the gauge and adjustment of the hoop will determine the machine’s range of applications for different fabrics and projects. Thus, a reasonable choice of the hoop size should maximize the embroidery machine’s performance and output quality.

How Does Hoop Size Affect Your Embroidery Design?

In embroidery, hoop size is considered to be an essential factor when it comes to the range of designs one can create. Bigger hoops allow the embroiderer to work on large patterns without regular rehooping, saving time and reducing the chances of alignment problems. On the other hand, frequent repositioning is a requirement when using smaller hoops, which can cause problems when stitching continuous designs. This is true for the size and the placement accuracy of small, detailed designs. In terms of construction, the hoop size should hold the fabric, but not too tightly, so excessive tension on the stitches is avoided and prevents puckering. Proper hoop size fits nicely with the ornamental and practical aspects of work as it would provide satisfactory results, whether a hobby or professional work.

What are the Different Types of Embroidery Hoops Available?

Based on research completed by professional sources, such as some of the best-ranked websites within the embroidery niche, I have noted some major embroidery hoops found in different domains. To begin with, there are ordinary hoops, usually made of plastic or wood, which would be appropriate for any basic embroidery work or project. Their simple structure renders them suitable for various fabrics since they are easy to use.

Then, we have spring tension hoops containing a spring that holds the fabric taut. These are quite helpful when working on smaller and more detailed designs since the tension is maintained, and there is no need for frequent adjustments.

Another significant improvement has been made with magnetic hoops, which provide an extra-quick solution for changing and repositioning the fabric. The magnet’s hold grips the fabric frame well, preventing the fabric from slipping during rehooping.

Lastly, there are form-fitted hoops used for different fabrics or designs. For instance, they are used for quilting or thick fabrics. Each hoop category has different advantages; hence, different embroidery problems can be dealt with differently. Understanding the functioning of each type of hoop allows me to select the best tool for the job, ensuring the best results in any embroidery project I undertake.

Why Choose a Large Hoop Embroidery for Your Projects?

Investing in a large embroidery machine is a plus for projects requiring intricate patterns and a fast turnaround time. Larger embroidery hoops allow for bigger or more complex designs to be stitched out in one go; this means that the repositioning of fabrics happens less and thereby improves the accuracy of alignment. This benefit enhances the flow of work considerably by reducing the time lost in between the designing parts of segments. In terms of specs, one has to look for larger hoops ranging from sizes of approximately 8×12 inches to more than 14×14 inches, as those significantly increase efficiency. Usually, these machine ranges lie in the stitches per minute of 800 to 1200 to keep up with the bigger projects’ higher focal points without losing the stitches’ quality. Furthermore, the software of the machine and its ability to work with numerous design formats add to its flexibility in solving an array of embroidery problems. This combination of characteristics makes large hoop embroidery machines suitable for detailed and large-scale embroidery jobs.

Which Embroidery Machines Offer the Largest Hoops?

All are thought out of the best embroidery machines with large hoops; several models can be pointed out based on huge hoop capacity and feature set. The Brother SE1900 has a multiskilling reputation and an embroidery area of 50×7”, allowing detailing and working on large projects. If larger dimensions are required, Janome Memory Craft 14000 can be used as it has a max embroidery area of 9.1×11.8 inches, which is ideal for larger designs. Another heavyweight in the industry is the USB Viking Designer Diamond 2, the embroidery area stretching one’s imagination up to a 14.5 x 14.5-inch hoop—providing vast areas to the embroiderer for complex and large-scale embroidery work. These machines are also fitted with several large stitching speed capabilities and modern technology that meet the demands of professionals and large-scale production. Users who intend to use these machines correctly and achieve project-specific goals must focus on hoop capacity and other attachments to these machines.

Top Innov-is Models with Extra Large Hoops

Taking a deep dive into the market of those embroidery machines with the most impressive hoop dimensions, we slowly but surely carve our niche into the Brother Innov-is series. From these, the Brother Innov-is NS2750D is hard not to notice due to its impressive embroidery capabilities and hoop that can take in a maximum design area of 6×10 inches. This model can work with complex designs, which is great for those who want to accurately execute medium- to large-scale projects.

The Brother Innov-is XV8500D, the real deal, the beast of the lot, is added to the catalog. With new technologies and features embedded in it, it can work with an extra-large hoop with an area of 8×12 inches. This enables the creation of new and sophisticated wide-ranging projects or even embroidery work, allowing passionate amateurs and professionals to use it.

The models suggest a trend: the Brother Innov-is V3 LE is a true nadir for large-scale embroidery, with a maximum hoop area of 9.5×14 inches. Seamlessly combining techniques and superior stitch quality, it is perfectly designed to take on even the most massive and ambitious projects. This triad of models from the Innov-is series offers a wide selection for every need, ranging from subtle to intricate or big designs, and, therefore, never failing to impress customers regarding compatibility and performance.

Exploring Brother Embroidery Machine Hoop Options

After reading the first three articles on Google.com, which dealt with Brother Embroidery Machine hoop sizes, I have integrated the information to help you understand the Hose Brothers washing machine better.

Choosing an embroidery machine from Brother can be tricky given the numerous options they provide regarding the hoop sizes for the embroidery machine, which is where the Brother Innov-is NS2750D shines, a versatile embroidery machine thanks to its 6×10 inch hoop. For those desiring more flexibility, the Innov-is XV8500D is noteworthy with an 8×12-inch hoop, offering ample space for intricate designs and larger projects. It is especially suitable for users advancing to more complex tasks. The Innov-is V3 LE provides the largest workspace for ambitious designs, having a robust 9.5×14-inch hoop. Each model delivers unique capabilities that cater to different project scales, ensuring I can select a machine based on my specific embroidery ambitions and preferred level of detail.

Comparing Husqvarna and Other Large Embroidery Machine Brands

Before comparing the Husqvarna brand to other key manufacturers of large embroidery machines, it is important to analyze their features. Stereotypically, models such as Husqvarna Designer Epic 2 have sufficient embroidery area covering hoop dimensions of 14.5×14.5 inches. This machine represents state-of-the-art technology, considering its maximum stitch out of 1,050 stitches in a 60-second interval and its stitching of multiple designs. All the intricate functions and this machine’s embroidery functions make the machine suitable for use on less daunting and complex projects.

At the lower end, however, Brother models like the Innov-is V3 LE are also efficient and effective for large projects as the hoop’s broad range reaches 9.5×14 inches. What is impressive about Brother is the mass attention focused on the unit’s ease of use, superior LCD touch panel displays, and even the capability of transferring designs through USB. The stitching speed of Brother’s V3 LE is on the same level as that of Husqvarna Designer Epic 2, which is up to 1050 stitches every minute.

Even more, Jimova’s Memory Craft 14000 enters the competition with a hoop dimension of 9.1×11.8 inches and features like built-in embroidery designs and automatic needle threading. It also focuses on creativity and accuracy; however, the interface is much simpler and makes it easy to grasp the extensive customizations of the product.

When considering some aspects, such as hoop size, stitching speed, technological integration, and features, aligning these technical parameters with the project’s requirements is necessary. Husqvarna excels in providing relatively large working space and technology-integrated solutions. Brother and Janome, however, offer competitive alternatives but with different technological advancements and equal operational speeds. The challenge, however, is these factors can be harmonized so that the user’s expectations concerning their embroidery project requirements are met.

How to Choose the Right Hoop Embroidery Machine?

Choosing a suitable hoop embroidery machine is influenced by a few technical and project-specific factors. First, gauge the size and value of your designs – A Brother Innov-is V3 LE or Husqvarna Designer Epic 2 has larger hoops ideal for extensive heavy-duty work’ however, it can also be more suitable for low-volume, low-value projects. Second, the required stitching speed must be determined; for high-volume production, some models may provide as many as 1,050 stitches per minute. The ease with which the machine can be operated, like an intuitive interface, design transfer through usb, and editing tools done on the machine, are critical for efficiency and should be appropriate for your skills and development goals. Third, the range of design file types that the machine can handle and the degree of its customization capabilities should be evaluated so that changing creative requirements can be met. Ultimately, these factors will direct you to the right embroidery machine based on what you seek to accomplish with the projects and the technical requirements.

What Features Should You Look for in a Large Hoop Machine?

My main interests, especially considering cost and return on investment, are accuracy, speed, and ease of use when choosing a large hoop embroidery machine. To begin with, I look for wide hoop sizes that may be available in some Husqvarna and Brother models to fit my design complexity and scale. Of course, stitching speed comes next in importance; the faster a machine works – up to 1,050 stitches a minute – the more productive and detailed the work done is. Smart technology is also integrated; finely designed interfaces make it possible to manage the machine effortlessly, and quick embroidery design uploading via USB saves time. Besides, the machine’s ability to work with various design files and allow for basic editing functions is necessary when imagining and designing future creative projects. If these parameters are considered, I could easily pick a machine with the right technical requirements and meet my ambitions.

How Does Hoop Size Fit Your Embroidery Projects?

While planning the size of the hoops for my embroidery work, I usually consider the size of the designs and the amount of detail required. Big hoops like those of Husqvarna or Brother let me do such dense designs in the least number of large re-hooping, which can interrupt the work’s flow and simplicity. In contrast, for the smaller fabric pieces, embroidery that requires more accuracy can be done without re-hooping and still exerts a certain amount of effort during the entire embroidery process. In contrast, smaller hoops are better suited for more frequent, less complex designs since they take less time to re-hoop. These require less time to re-hoop, thus allowing greater numbers of designs to be made in a shorter amount of time without losing quality. These distinct approaches enable me to adjust the embroidery sewing machine’s specifics to each project’s goals, giving me freedom and precision when crafting decisions.

Understanding the Needle and Stitch Capabilities

The needle penetration and stitches produced by the embroidery sewing machine are some of the basic techniques practiced to produce various and high-quality results across numerous projects to evaluate embroidery. Considering needle options, it is also important to determine the different sizes and types of needles required, as the machine may be compatible with different types of needles, affecting the stitch embroiderer and the fabrics worked on a machine. For instance, machines that Husqvarna, Brother, and Janome manufacture allow the user to use several needle positions and embroidery needles ranging from very fine ones suitable for light fabrics to heavy ones.

As to the stitch capabilities of the machine, look for machines with various stitch types and numerous patterns stored in the machine’s memory; this will increase your design opportunities. Enhanced models of embroidery machines available now allow you to create stitches in them, store them to alter them, and use them for different projects, for example, by increasing or reducing stitch density, length, etc. Moreover, the speed at which they perform embroidery may vary, with some high-speed ones performing up to 1,050 stitches a minute without losing quality. When people understand these capabilities, they’ll likely have a great level of accuracy and more flexibility, allowing them to work with various embroidery projects and materials effortlessly.

What Are the Innovative Features of Modern Hoop Embroidery Machines?

Traditional embroidery techniques have evolved due to various factors, including changing requirements, new technologies, and globalization. Globalization has transformed embroidery, and the world is becoming an embroidery market due to its easy accessibility. Embroidery has always been centered on moving the needle and the hoop woven with cloth, but modern hoop embroidery machines have revolutionized the sector with their unique features. Embroidery machines are multi-purpose devices with a unique integrated drilling machine shaped like a console. The time or period saved using modern embroidery machines is the timeline for the designer to translate a design onto a shirt that ultimately fits. Computers can also correct unintended errors and even erase functions. With the continued mechanization of embroidery, women have been progressively replacing male dominance in needlework, especially in Pakistan, China, and India – Singh N. As the consumer perception of mass-produced embroidery has changed, designers have incorporated more eccentric styles and utilized sophisticated mechanical technologies. Different techniques enhance the quality of embroidery, which can boost its volume. However, it is essential not to overlook the dense cultural representation of embroidery charged with symbolism. Embroidery integrated into clothing allows its wearer to manifest their adaptation in a new environment as an inscriber.

Exploring Built-in Embroidery Designs and Digitize Capabilities

Modern embroidery machines have an array of built-in designs and digitizing features to meet the needs of both beginners and professionals. According to reputable sources in the market, such as Brother, Janome, and Bernina, such machines include millions of stitches and a variety of thematic decor that can be found and retrieved with a single press of a button. For instance, a Brother machine has hundreds of designs that allow the user to change the look without breaking a sweat.

Modern machines are digitizing so much that people can now upload images and use them as templates to stitch. It lets them take an image and create stitch data out of it. Consequently, this allows the user to take the stitch details and manage other factors, such as the length of the stitch and its density. Many of them can work with CAD software and accept merged formats, e.g., PES and JEF, EXP, giving them a wide range of options. Allowing computer connection, USB ports, or simply using Wi-Fi makes it easier for machines to upload custom images to them. These technologies allow the users to change the embroidery and have it fit their unique style without complicating the process, and the final result is still a quality stitch.

The Role of Speed and Lock in Embroidery Efficiency

When thinking about speed and lock-in embroidery efficiency, I realize those aspects are important for productivity and quality. For me, the detail aspect is important especially in marketing activities and big projects, quite a lot of large and commercial embroidery machines operate at high speeds, often up to 1000 stitches per minute. But, locking in itself is not enough if speed doesn’t suffice. It’s a good lock if that mechanism performs so that the thread does not loosen nor break; hence, all the sewn fits would not shift. Furthermore, critical specifications such as stitching gradation in speed, stability in prone voltage adjustment, and other integrated automatic functions raise my operations. These equipped machines produce high output and quality, enabling embroidery to be done faster and come out neat and perfect. I believe that to achieve the desired embroidery results, speed and a good lock mechanism must be there so that impressive designs can be easily and quickly created.

How Does a Multi-Needle Machine Enhance Embroidery Projects?

Introducing multi-need embroidery machines into the industrial landscape has tremendously transformed the speed and design capabilities of embroidery projects. Most of these machines are built with several needles, 4 to 10, depending on the machine, which can be adjusted to several threads during the stitching process without changing any setup. This feature reduces the time wasted between changing colors and speeds up the embroidery process, especially for complex designs.

Multipoint or multi-needle machines can be differentiated based on certain technological factors that enhance performance.

- Automatic Thread Tensioning Devices: Automatically adapts the tension to fabrics and threads during sewing.

- High Performance: Most multi-need sewing machines can achieve between four hundred and one thousand stitches in a single minute, making the machine more productive and retaining the desired detail in the sewing process.

- Independent Needle Adjustment: This feature enables switching between the two-color threads, enhancing the rate at which the patterned sewing is done.

- Large Embroidery Area: Hases a significant amount of real estate, for example, 12×8 inches or more, for embroidery large designs without necessitating changing environments and any designs within a single setting.

- Edit functions: Various software packages and machines allow for modifying designs on the machine.

These machines registered multi-functional capabilities, and while enhancing speed and precision for embroidery, they became suitable for commercial and mass usage.

Why Invest in an Embroidery Machine with a Large Hoop?

Purchasing an embroidery machine with a big hoop is beneficial for multiple reasons, mainly concerning flexibility, effectiveness, and creativity. An added advantage of a large hoop sewing machine is the increased area coverage, which permits users to sew large and detailed designs without having to retighten the fabric often, thus saving a lot of time. This is quite helpful for detailed works and mass production since it allows multiple portions of the design to be sewed in one go, wherein the sewing is done along the same patterned area. Furthermore, larger hoops can accommodate heavy and several layers of fabric, making the machine ideal to handle various projects. This investment enables users to engage in various projects, thus increasing their creativity and efficiency in production, which is essential for business entities looking for ways to expand their embroidering services.

Benefits of Larger Embroidery Fields for Your Quilt and Apparel

Integrating larger embroidery fields into your machine is revolutionary for quilting and garment projects as it simplifies steps in creativity and production. To begin with, a wider sewing area tackles the issue of redesigning a pattern now and then, as it can be done in a single go and at the same position on the cloth. It is wise in time and helps ● maintain perfection with little or no chances of any mistakes. Websites like Brother, Janome, and Sewing Mastery state that using larger hoops helps manage broader patterns essential for quilting, as perfection is needed while crafting large fabric surfaces. In addition, when dealing with garments larger than the embroidered area of the clothing, it allows for sewing more parts with fine detailing. Another advantage is support for thicker and multiple-layer fabrics, increasing the types of materials you can more effectively apply to your projects. Therefore, having a machine with wider embroidery dimensions encourages innovation, increases efficiency, and allows more work to be done, thus contributing more towards individual and business purposes.

Maximizing Creativity with Larger Hoops and Extra Large Designs

In my journey optimizing creativity around larger hoops and extra-large designs, I’ve realized that embroidery machines with large embroidery fields greatly change my workflow and allow new possibilities and ideas to flow. As can be seen from such resources as Brother, Janome, and Sewing Mastery, larger embroidered hoops reduce the number of times an item needs to be re-hooped, which assists in the continuity of design and fewer chances of misalignment. About my fabric quilting projects, I can easily quilt a great portion of fabric using many accurate and consistent patterns in all my work. Then, when looking at something like apparel, I, for instance, do not have to re-hoop a silk skirt with a lot of embroidery as I have ample opportunity to use big hoops. Also, working with thicker and layered fabric broadens the project’s scope regarding the types of fabric that can be used. Thus, acquiring an embroidery machine with a big hoop, besides giving me amazing opportunities to boost my productivity, greatly inspires me creatively and helps in personal and commercial activities.

References

Frequently Asked Questions (FAQ)

Q: What should I consider when choosing a sewing machine with one of the largest embroidery hoops?

A: When selecting a sewing machine with one of the largest embroidery hoops, consider the size of the projects you plan to work on, the type of fabric you will use, and whether you need features like a large color LCD or a high-end embroidery machine for intricate embroidery designs.

Q: How does a giant hoop help in creating larger designs?

A: A giant hoop allows you to create larger designs without re-hooping the fabric multiple times. This helps reduce errors and ensure the precise placement of intricate embroidery designs. It also expands your workspace and lets you complete projects more quickly.

Q: What are the benefits of using a cap frame in embroidery?

A: A cap frame is a tool that securely holds caps in place while embroidering. It ensures accurate placement of designs on curved surfaces and helps embroiderers achieve professional results, especially for commercial projects.

Q: Why might a designer want to use a large embroidery hoop?

A: A designer might prefer a large embroidery hoop to accommodate extensive and intricate designs, allowing for more creative freedom and fewer interruptions in the embroidery process. It also enables the creation of larger projects with ease.

Q: Can a high-end embroidery machine with a large hoop preview designs before stitching?

A: Yes, many high-end embroidery machines with large hoops come equipped with a large color LCD that allows users to preview designs before stitching. This feature is invaluable for ensuring proper placement and making any necessary adjustments before starting the embroidery.

Q: What role does a sensor play in a sewing machine with a large hoop?

A: A sensor in a sewing machine with a large hoop helps detect fabric positioning and hoop placement, ensuring that the embroidery design is aligned correctly. It assists in preventing errors and enhancing the overall embroidery quality.

Q: How can embroiderers reduce thread changes when using large hoops?

A: Embroiderers can reduce thread changes by planning their design color sequence efficiently and using machines with multiple needle capabilities. This reduces interruptions and speeds up the embroidery process, especially on larger projects.

Q: What is the advantage of having an extra-large workspace in embroidery machines?

A: An extra-large workspace in embroidery machines provides more room to maneuver large pieces of fabric and work on extensive designs. It enhances the ease of handling larger projects and allows for better management of intricate embroidery work.

Q: Why is bobbin work important in large embroidery projects?

A: Bobbin work is important in large embroidery projects because it ensures smooth and consistent stitching, which is crucial for maintaining the quality of intricate designs. Proper bobbin tension and capacity can significantly impact the outcome of the embroidery.