Embroidery machine needles are a fundamental component in achieving optimal embroidery quality, yet selecting the right needle often poses challenges for both novices and seasoned embroiderers alike. This guide is designed to facilitate the decision-making process by providing an in-depth analysis of embroidery machine needle charts. We will explore various types of needles, focusing on their specific characteristics, such as size, point type, and material suitability. Our discussion will cover the functionality of different needle types—universal, ballpoint, and specialty needles—while highlighting their applications for diverse fabric types and embroidery techniques. By the end of this guide, readers will gain a thorough understanding of how to select the ideal needle for any embroidery project, ensuring superior results and enhancing their craft proficiency.

What is an Embroidery Machine Needle Chart?

An Embroidery Machine Needle chart is a detailed reference tool that encompasses crucial information about the various types and specifications of needles used in embroidery machines. This chart categorizes needles based on attributes such as size, which is indicated in numbers corresponding to the needle’s diameter; point type, which affects the manner in which the needle penetrates the fabric; and the appropriate material and thread compatibility. Furthermore, the chart outlines the optimal applications for each needle type, recommending specific needles for particular fabrics and embroidery techniques. By employing an embroidery machine needle chart, embroiderers can make informed decisions that ensure precision, reduce the risk of fabric damage, and promote the seamless execution of intricate designs.

Understanding the Parts of a Needle

An embroidery machine needle can be broken down into different parts, starting from the shank, which is the top part of the needle that connects to the machine and is often round or has a flat design for correct placement. The shank of the needle sits above the shaft, which has a varying thickness that determines what size the needle can be. The other critical part is the eyelet. Its size can affect the balance in the thread as well as the amount of tension present as a result of threading in the needle. The finest feature is the tip of the needle, as in every instance, it penetrates a piece of fabric. This part makes the needle either pointy, ballpoint, or of varied textures, enabling it to sync with a range of cloths and needles. The depression at the back of the needle’s eye is further located behind and is known as the scarf. The scarf helps engage the thread, therefore helping to form a stitch. The understanding of these features makes it easy to make a choice of the needle and, in turn, helps in achieving the desired quality level for different embroidery machines.”

How Needle Size Affects Your Embroidery Projects

While considering the embroidery machine needles in their working state, one can note the integral features within the design and performance capabilities of the needle. Firstly, the shank is the upper region of the needle that joins the machine, and its shape is mostly circular or has a flat side to allow for proper orientation. The shaft, which is below the shank and goes downwards, varies in circumference and hence forms the size classification of the needle. Seeing the needle in the broad aspect, the eye is another important part of a needle because it is the opening that the thread takes; however, the size of the eye might have an impact on the tension of the thread and stability during the stitching of fabric, too. Moving to the point, this part of the needle defines the sewing action once it is placed on the fabric; it can come in a variety of shapes like a sharp point, ballpoint, etc., depending on the fabric or sewing technique required. This is necessary as each needle will serve a purpose to the certain fabric. Finally, the scarf, which is found on the back of the needle eye, is a small indentation that aids in the making of the stitch and is used in assisting the formation of a thread loop. Being acquainted with these various components makes it easier to choose the right needle, and thereby, the output of the embroidery machine will satisfy the specified quality standards irrespective of the variety of works to be performed.

The Role of Needle Selection in Quality Embroidery

In my practice, I am able to state the correct selection of the needle determines the quality of the embroidery projects completed. The proper type of needle must be selected to ensure that the needle works harmoniously with the fabric and thread and the stitch formed is of high quality. Based on my review of the mainstream places on the internet, a needle’s size, point type, and accompanying materials must be taken into consideration most importantly. For example, if I select needles that are too large or too small for the fabric and the thread, I am likely to have problems such as puckering of fabric, thread breakage, and even missing stitches.

Some of the technical features to be looked at include the diameter of the needle, which is commonly referred to with a number; the suitable point type, which can be sharp, ballpoint, or universal; and the combination of the needle, fabric, and thread which should all be compatible for best results. I have found these recommendations enable me to safeguard the fabric and enhance the working of the embroidery machines. Therefore, as a result, I am able to achieve the desired quality image due to the appropriate technical approach and insights, together with the best practices in the industry.

How to Select the Proper Needle Size for Your Embroidery Machine

It is important to mention that when working with an embroidery machine, the selection of the correct size of the needle correlates directly to the type of fabric as well as the thickness of the thread being used in the machine. The first aspect to gauge would definitely be the weight of the fabric being used; for needle sizes, it is generally 60/8 or 70/10 because light fabrics such as silk or organza have the tendency to cause more fabric damage. For medium fabrics, such as cotton or linen, a size 75/11 or 80/12 needle is more than enough in terms of balance in penetration and stability. However, with heavier fabrics such as denim or canvas, a needle’s size has to be larger in order to work with thicker threads, which are around 90/14 or 100/16 sizes to prevent any breakage. Do remember fabric alone is not the sole factor; use smaller-sized needles for finer threads, while larger-sized ones have to be cotton or metallic threads. Hence, for smooth embroidery, ensuring specific requirements of threads and fabric with the size of the needles helps avoid problems such as skipped stitches and even breakage threads in the machine and embroideries in general.

Factors Influencing Needle Choice

n choosing a needle to facilitate my embroidery projects, I have relied on well-regarded online content to make the process easier. The most important factors to consider while making a miss sewing needle selection are the type of fabric, the thread thickness, and the density of stitches. In the case of delicate fabrics, I use small needles to avoid damaging them, while larger needles, which fit thick threads perfectly, are used when sewing thicker fabrics. For example, the smaller the eye of the needle, the finer the thread used to stitch; however, when working with special threads such as metallic threads, the larger eye of the needle can be useful because these threads tend to break during sewing more often than not. I also evaluate the density of embroidery stitching because dense stitches may require stronger needles that can withstand repeated stabbing and not deform or break. By considering all these factors, I am able to ensure that the needle I choose corresponds to the threads I intend to use, allowing me to create high-quality embroidery works.

Commonly Used Needles for Various Fabric Types

As it evaluates needle samples for different fibers, for instance, for sykes or even chiffon materials, I prefer a fine needle of 60/8 or 70/10 size, which reduces the wearer’s distortion. For medium materials such as cotton or polyester, a needle size around 75/11 or 80/12 fits as it’s decent in how much it supports stitching and also how easy it is to sew things. For heavier materials, such as denim or upholstery, I depend on said 90/14 or 100/16 size needles. Overall, these standard guidelines allow me to improve the functionality as well as the appearance of my embroidery projects with relative ease.

Choosing Machine Embroidery Needles for Different Thread Types

When deciding on machine needles for embroidery, it is important to take into account the type of thread used; I utilize 60/8 to 75/11 range needles for finer threads such as silk or polyester fair. Because of their smaller eyes, the needles are able to effectively handle delicate threads. This diminishes the chances of the threat from fraying as well as excessive skipped stitches. The case is similar for standard cotton threads except that a needle size of 75/11 and 80/12 is enough for adequate stitch consistency while guiding the thread properly. Metallic threads and specialty threads, on the other hand, are different and thus need special consideration; for these reasons, I use metallic needles of 90/14 to 100/16 with larger eyes, which prevent the thread from breaking as it considerably aids in the threading. One has to keep an eye on those specifications as they determine the execution and quality of the embroidery, making sure that the needle and the threads used are compatible. Most importantly, by employing the right size and strength of the needle, I am able to meet the specific requirements of the selected embroidery thread.

Why is Needle Selection Crucial for Successful Embroidery?

Choosing the proper needle is extremely important for any embroidery project, as it greatly determines the stitch quality, layers of fabric, sewing performance throughout the project, and the overall efficiency rate. Using the right needle will make sure that the thread doesn’t get tangled or stuck within the fabric, which lowers the chances of threads snapping and stitches being missed. This way, the upper layer of fabric is not harmed due to the use of a different needle or size to the thread that may be deemed unnecessary; the embroidery work can, therefore, look quite professional. In addition, the correct needle size also facilitates better control over different threads and fabrics, and the composition and structure of the needle allow for more precise embroidery. When you understand and follow all these technical factors, you will increase the accuracy and the quality of the embroidery as well, and this will eventually lead to better quality and impressive works of art.

Impact of Needle Type on Embroidery and Decorative Stitching

The quality of the stitch that would be required alongside the final look of the material being used depends on the formation- the design, size, and substance of the needle. For instance, using a needle that is sharp is essential when dealing with closely woven fabrics where accuracy is key, while with knit balls, ballpoint needles are suitable as they make their way between the fibers without puncturing the fabric. Furthermore, there are needles that are specialized, such as titanium ones which are more durable and would be able to withstand the thorough use of them during high-density stitching. Depending on the fabric properties and the project types I seek to undertake, employing the right type of needle will not only ensure high stitch uniformity but also increase the longevity of both the needle and the fabric. Thus, considering my needle selection process, this attention to detail makes my embroidery better as this ensures the originality and the aesthetic charm of every piece of work.

Avoiding Stitch Issues with the Right Needle

In order to enhance the quality of my embroidery and make it look more professional, I ensure I do adequate research to pick the needle depending on the type of thread or fabric I’m using, and this, in turn, helps me avoid stitch problems. This particular methodology guarantees that there is smooth stitching, which increases the quality of my embroidery. Sharp and small needles are especially best for thin fabric, while I switch to bigger ones made from ballpoint for knitting. For a smooth stitching experience, I also have titanium needles for heavier stitching. In conjunction with the needles and the fabric or the thread that I needed to work with, I tried to match them as well; for example, thread thickness and fabric weight are matched to the needles in order to prevent stitch skipping or breaking of threads. All in all, with thoughtful planning and a keen eye for needle selection, I am able to avoid major drama and issues in stitching.

Enhancing Embroidery Projects with the Right Needle

To improve my embroidery projects, using the best needles that insist on tailoring the type of needles to the fabric and thread requirements. I use a needle that is proportional in size to the fabric and thread I am using for my sewing, for I want to be very accurate. While working with fine silk and chiffon fabrics, I prefer to use a 60/8 fine needle as it will easily sew these lightweight fabrics without causing damage. As for medium fabrics, I believe that a properly sized 75/11 needle will be able to achieve good penetration while providing decent stitching. Heavyweight denim fabrics require a really good 90/14 needle since it is quite large and stronger, will minimize thread breakages, and ensure that the stitches remain consistent. Relying on the technical specifications offered by these sources, I am able to effectively adjust needle selection and thereby increase the visual and structural performance of my embroidery, achieving the professional quality of work.

How to Use a Sewing Machine Needle Chart Effectively?

A sewing machine needle chart can be used efficiently by first analyzing the parameters of your embroidery project, such as fabric and thread thickness. This chart is extremely useful where the appropriate needle size and type are related to the specific fabric composition. For example, the use of fine needle sizes is recommended on lightweight fabrics, while larger needles should be used on heavier ones, which help in needle penetration as well as stitch quality. Watch out for the type of needles, ballpoint for knits or sharp for wovens, and such that are required for specific types of stitches. Be wary of not having the size of the eye of the needle out of the range of the thread type, as it can lead to fraying and bring on the need for spooning. Making it a practice to check this chart after every project, for instance, before starting any new project, will make sure that your embroidery work bears a touch of professionalism and quality by ensuring that all the elements are considered and put into proper use for quality outcomes.

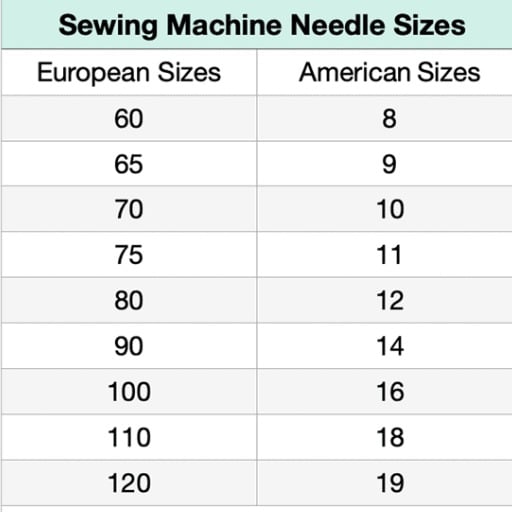

Interpreting the Size Guide in Needle Charts

In order to set the working conditions of the needle types in combination with various models of embroidery machines, I first try to cross-reference each model with existing suppliers to ensure compatibility. After familiarizing myself with the details of my embroidery model, I am able to pick out the most appropriate needle types that affect stitch quality and effectiveness, especially in terms of the number of stitches that can be made. For example, the machine may highlight certain needle numbers or brands that allow it to achieve its best under particular circumstances. The size of the needle is not the only issue I am concerned with because there are a number of other factors that come into play, such as the type of thread used and the tension settings of the needle. With these researched principles, it is also feasible to use the needles on the appropriate model of an embroidery machine, thus enabling one to achieve great accuracy in stitching while minimizing the wear and tear of the machine.

Matching Needle Types with Embroidery Machine Models

In order to set the working conditions of the needle types in combination with various models of embroidery machines, I first try to cross-reference each model with existing suppliers to ensure compatibility. After familiarizing myself with the details of my embroidery model, I am able to pick out the most appropriate needle types that affect stitch quality and effectiveness, especially in terms of the number of stitches that can be made. For example, the machine may highlight certain needle numbers or brands that allow it to achieve its best under particular circumstances. The size of the needle is not the only issue I am concerned with because there are a number of other factors that come into play, such as the type of thread used and the tension settings of the needle. With these researched principles, it is also feasible to use the needles on the appropriate model of an embroidery machine, thus enabling one to achieve great accuracy in stitching while minimizing the wear and tear of the machine.

The Basics of Needle Knowledge for Beginners

For those new to embroidery, the development of needle knowledge is critical. Firstly, it includes searching for information about needles and their use with different types and weights of fabrics. Here, I was taught that the size of the fabric dictates the size of the needle, which is used — 60/8 for light fabrics, 75/11 for medium-weight ones, and 90/14 for heavy ones. Moreover, the size of the eye of the needle has to correspond with the size of the thread so that no fraying or tension mishaps happen. It was equally important to pay attention to the kind of needle and its intended use; for instance, ballpoint needles are generally more appropriate for knits, whereas sharp needles are for woven fabrics as they determine the penetration of the needle through the fabric material and the quality of stitches produced. These technical specifications are a guide in choosing the right needle, which I needed to improve the quality of my embroidery and the end result of each project.

Related Articles: Expanding Your Knowledge on Machine Embroidery Needles

To address the above inquiries concisely, consider the following points derived from a range of specialized articles on machine embroidery needles:

- Selecting the Right Needle for Fabric and Thread: Articles emphasize matching the needle size to the fabric’s weight, with needles like 60/8 recommended for lighter fabrics, while 90/14 is suited for heavier materials. These ensure precision and avoid fabric damage.

- Using a Needle Chart: Guides suggest always consulting a needle chart to choose the appropriate needle size and type, factoring in fabric and thread requirements. This practice promotes even stitches and reduces thread breakage.

- Needle and Machine Compatibility: Research highlights the importance of consulting your machine’s manual and compatible needle types to maintain performance. Choosing the correct needle brand or type can enhance stitch quality.

- Beginner Tips: Beginners should start by understanding the basics of needle sizes and types (ballpoint vs. sharp) to suit different fabrics, which improves sewing outcomes and prevents machine issues.

These focal points serve as a reliable foundation for enhancing knowledge about machine embroidery needles, ensuring that your projects achieve a professional finish with minimal complication.

Exploring Different Types of Needles for Embroidery

In order to investigate various categories of embroidery needles, I started researching the needle online sources and then summarizing their findings for subsequent application. To start with, I recognized the significance of the right type of needle, bearing in mind the fabric and thread type that was to be used. Since ballpoint needles are used for knits, they accommodate well between fibers without snagging, whereas a woven fabric requires the use of sharp needles for easy penetration for a smooth stitch. The size of the needle matters as well, with a 60/8 size being appropriate for thin fabrics and a 90/14 being more acceptable for heavily textured fabrics. While looking out for the needle and the machine combination, I read through the manual of my machine so as to choose the brand and type of needles that would work well with the settings of my machine’s tension. As a novice, I have been able to grasp the differences in the several types of needles, and this has enhanced my embroidery technique such that every embroidery I make of various designs has neat stitches; this strengthens my confidence and satisfaction in the work.

Understanding the Use of Ballpoint and Sharp Point Needles

The information I gained from mastering the use of ballpoint and sharp point needles has been very important in the improvement of my embroidery skills. Surprisingly, I came to understand that each needle type is unique and has its application based on the type of fabric by the ruling online resources. For instance, ballpoint needles are designed for knit fabrics; owing to their round tips, they can pass through the fabric without cutting or tearing the fibers; hence, snagging is reduced and covering stitches smooth. Sharp point needles cater to woven fabrics. Sharp pointed needle tips easily penetrate woven fabrics to allow for the formation of increases. Stitches that do not distort the structure of the fabric. I can, with assurance, choose a needle type that suits each project, greatly improving the quality and durability of my embroidery work.

Tips for Maintaining Your Embroidery Machine Needle

I want to discuss one of the factors that can improve the performance of your embroidery machine as well as the needle, which is the maintenance of your embroidery machine needle. After spending hours researching the best sources on this aspect, I was able to distill the crucial maintenance practices. For starters, regularly inspect the needle and replace it every 8 – 10 hours to prevent it from becoming too blunt, as this may result in broken threads and fabrics. To get rid of the dirty adhesive or residue build-up that can upset the stitch, the needle can be cleaned by wiping it gently with a soft cloth dampened with oil or lint-free cloth. Also, respect the size and type of the needle as indicated by the operational manual of your sewing machine, as using the wrong type will only create extra stress on the motor of your machine. In relation to the selected needle size and thread, proper tension settings, for instance, one that is not too high or too low relative to the other components of the sewing machine, are of paramount importance for the quality of the stitches produced. These technological parameters reinforce the needle and, in turn, increase the quality of my work as an embroiderer.

References

-

Madeira USA Needle Guide – A comprehensive guide to choosing the correct needles for machine embroidery.

-

AllStitch Embroidery & Sewing Machine Needle Selection Guide – Offers tips and hints on needle selection and the impact of needle size on thread tension.

-

Needle ‘n Thread: Best Sources for Good Embroidery Needles – Discusses various sources and considerations for selecting quality embroidery needles.

Frequently Asked Questions (FAQ)

Q: What is the importance of choosing the right sewing needle for embroidery machines?

A: Choosing the right sewing needle is crucial for achieving optimal results in embroidery. The correct needle can make a big difference in the quality of your stitches and the final appearance of your design. It helps in preventing thread breakage, needle damage, and fabric distortion.

Q: What are some common needle sizes used for home sewing machines?

A: Common needle sizes for home sewing machines range from 60/8 to 110/18. The larger the needle number, the thicker the needle, which is suitable for sewing fabric that is dense or tough materials.

Q: How does a ball point needle differ from a standard needle?

A: A ballpoint needle has a slightly rounded tip that pushes aside fabric fibers rather than cutting through them. This makes it ideal for sewing elastic or knit fabrics, whereas a standard needle is best for woven fabrics.

Q: What types of needles are made specifically for commercial embroidery machines?

A: Needles made specifically for commercial embroidery machines include types like the 15×1 and hax1. These needles are designed to withstand the high-speed operations of commercial machines and maintain their original shape and dimensions for longer periods.

Q: Can hand-sewing needles also be used in embroidery machines?

A: No, hand-sewing needles cannot be used in embroidery machines. Machine needles have a specific design, including a shank and groove, that is compatible with the machine’s mechanics, unlike hand sewing needles.

Q: What is the role of a stabilizer when using embroidery machine needles?

A: A stabilizer is used to provide support to the fabric during embroidery. It helps maintain the fabric’s tension and prevents distortion, ensuring that the needle can create clean, precise stitches.

Q: What is the best advice for choosing needles for tough materials like vinyl or quilt fabrics?

A: For tough materials like vinyl or quilt fabrics, it is advisable to use a size 90/14 or larger needle. These needles can handle dense or tough materials better and ensure smooth stitching.

Q: How do schmaltz needles cater to different sewing needs?

A: Schmetz needles are also available in a variety of types and sizes to cater to different sewing needs. They offer specialized needles for different fabrics and threads, making them a versatile choice for sewers.

Q: Why is it important to keep a variety of needles on hand?

A: Keeping a variety of needles on hand allows you to quickly adapt to different sewing projects and materials. Since different fabrics and threads require specific needle types and sizes, having a selection ensures that you always have the right tool for the job.