This blog post explains how to select the best Happy Embroidery Machine and that you should not be worried even if you are a novice. We will outline the specifications and characteristics that make Happy Embroidery Machines stand out. This tutorial also looks into the mechanics of ease of use, explainable durability, and after-sale services to provide a complete picture of why these machines are preferred in the market. Therefore, the readers of this article will be consumers with profound knowledge and experience, enabling them to make wise choices in the market and buy a machine that will improve their embroidery performance.

What is an Embroidery Machine and How Does it Work?

An embroidery machine is a sewing instrument that reproduces complex designs on fabrics. They embroider utilizing pre-designed images in a computerized form, which can be supplied in standard sets or uploaded by the user as required. Turning thread into an embroidering design in an embroidery machine is accomplished through a rapid up-and-down needle movement. There are also integrated hoop systems that hold the fabric in position and an assortment of pre-programmed needles and threads to write designs. Touchscreens and USB ports for design uploads are innovative aspects of modern embroidery machines that increase their effectiveness and speed. Multi-needle units allow designers to include more intricate and multicolored designs.

Understanding the Basics of Embroidery

Embroidering dates back centuries and is widely practiced as an art and a craft. It involves embellishing fabric with a needle and thread. Over the last one hundred years, the drive towards machined embroidery led to the image of a sewing ‘machine’ being vastly altered. The modern era introduced machines that started sewing, and soon, embroiderers could create more intricate and challenging stitches by pushing a button. The range of stitches can now be achieved smoothly without any delays as HID metal nuts are rotatable. Earthen designs and textures are now widely accepted in embroidery after engraving foundation stitches. Certain computerized items elevate the knitting to a new level, provide the designer with possibilities they could only dream of, and give the fabric designs a completely extraordinary quality. Designing computer embroidery is a global art and an effort worth the time as it greatly extends the options available for customizations to embroidering fans. Carrying out traditional design forms in a completely different world is possible.

The Role of Needle in Embroidery Machines

When examining needle usage in embroidery machines, I wish to note that it is an essential aspect of the process. It multiplies the working thread’s layer as it goes through several different layers of fabric, and its selection helps improve the quality of the finished product. Based on the fabric, the types of threads, and the design’s sophistication, I will choose the appropriate needle. Of note is that a combination of the point shape and thickness of the needle’s shaft and the type of eye also features prominently in the overall fitting of the needle. As I investigate the subject further, I have read from reputable resources that seem to agree that after some time, needles and thread should be brought for replacement so that the busy machine doesn’t have idle issues or side effects like breakage of threads and missing stitches. With this in mind, I pay attention to detail in these projects to not pollute the artwork standards created in any of the above projects.

Key Features of Happy Embroidery Machines

When considering Happy Embroidery machines, a few considered features enable them to excel in the competition. Their multi-needle system is compelling, with between 6 to 15 operational, allowing fast color changes in the rendering of intricate designs without changing threads. These machines employ powerful servo motors to execute the movement of the needles efficiently. This enables high-speed functioning up to as much as 1200 stitches per minute but with no loss of accuracy.

The highlight is a powerful and large touchscreen that allows users to swiftly move between various design libraries and the machine’s settings. Happy machines accept different designs through USB and network and are compatible with most common file types.DST and EXP are needed to make a quick change to the design.

The maternity systems, equipped with various hoop sizes for any project scope, from small patches to large-scale upholstery panels, also note technical accuracy. The automatic thread cutter and self-tension adjustment also complement their efficiency, as less manual help is required during embroidery.

Happy Embroidery Machines also stand the test of time, as they possess strong frames made to last and cause low vibration. This guarantees a stable stitch quality even in a high-workload environment. With adequate customer support and the availability of educational materials, these features make an industrial and personal embroidery solution an obvious choice.

Why Choose Happyjapan for Your Embroidery Needs?

The approach that has helped Happyjapan make its mark in the embroidery sector is its attention to innovation, quality of work, and customer satisfaction. The company’s machines are built with advanced technology, having sturdy multi-needle abilities that improve productivity and allow for the execution of complex designs. Moreover, the application of modern servo motors provides precise and rapid motion, which is necessary for both an efficient process and attaining quality results. In addition, their devices are easy to use and come with many connecting possibilities, making them easy to customize to fit various design needs. Happyjapan also stresses strength as its machines are designed and made to endure extreme use, and their functioning is reliable. Their commitment to after-sales and the development of training manuals ensure that after purchase, their machines are optimized, making Happyjapan a trustworthy partner for all embroidery lovers.

Benefits of Happy Japan Products

Happy Japan products present some well-acknowledged features in the embroidery business. These machines boast an adequate multi-needle capacity of 6 to 15 without manual thread changes, significantly enhancing production efficiency. As a result of their precise design engineering, advanced servo motor technology also comes as a bonus, whereby speeds of up to 1,200 stitches per minute and the most precise stitching can be accomplished. The design is additionally user-centered, employing easy-to-use touchscreen interfaces that make embroidery patterns easy to navigate & modify. Most design programs are compatible with Happy Japan as there are no design limits, and various formats are supported. Other features that make these machines stand out include longevity, as they are constructed of solid materials that will withstand industrial and personal use. Finally, technical assistance and training aimed at resource delivery are essential customizing elements of Happy Japan’s marketing mix as they help customers thoroughly and efficiently exploit their machines.

Exploring the Voyager Series

Happy Embroidery Machines has made an exceptional shift in the embroidery industry by introducing the Voyager Series. This particular series is said to be ideal for anyone who wants to explore their creativity without necessarily compromising on the technical aspects. I also discovered that the Voyager Series is loved for its small size and great power since some users are constrained by space but don’t want to lose functionality. In this series, creativity meets practicality Anne wood, thanks to its stitching speed of up to 1,000 stitches per minute with a low noise level. The controls are so precise that even a person with minimal skills in embroidery can comfortably use the machine. Moreover, the Voyager Series allows you to work with various fabrics and the complexity of designs due to rotating hoops and an efficient thread control system. Hence, all these factors contribute to the fact that the series has become an excellent choice for home and commercial embroidery applications.

Customer Support and Distributor Network

Happy Embroidery Machines takes pride in its dedicated customer support and an abundant network of distributors, making it attractive in the embroidery segment. Their customer service support is commendable because they can promptly respond to technical consultation and operation problems. This is possible thanks to the helpdesk and an online knowledge base containing manuals, videos, and troubleshooting information. If needed, certified technicians can also provide on-site assistance for intricate technical needs, which helps to minimize machine “downtime” while maximizing productivity.

Happy Embroidery Machines’ distributor network is present in all parts of the world, increasing accessibility and local assistance. Authorized distributors receive training on the products and assist customers in choosing and using appropriate equipment. They also make it easier to obtain genuine spare parts and accessories, which helps preserve the normal working conditions of the machines. They are further reassured by a well-structured warranty scheme, which ensures loyalty to customers of Happy Embroidery Machines based on the need to protect their investment in perfect embroidery products.

How to Maintain Your Industrial Embroidery Machine

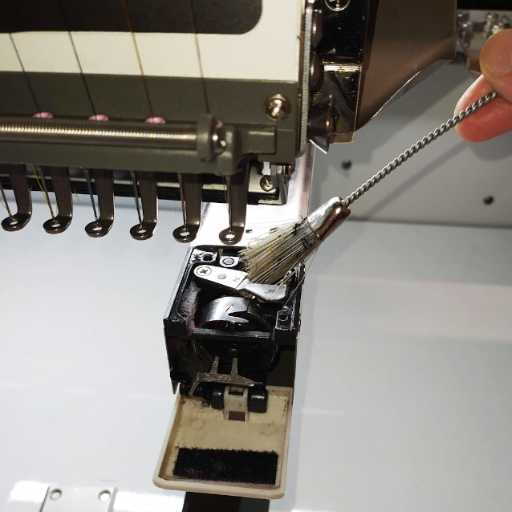

There are some specific checks that every owner of the industrial embroidery machine should keep in mind to boost and maintain the longevity of the machine. Maintenance also includes general upkeep and detailed checks. First and foremost, basic machine cleaning should be done using a damp cloth and detaching the lint or dust previously wiped off. A lens or air compressor can clean the needle plate and bobbin’s surrounding surfaces. The machine parts must be oiled according to the standard operating instructions, and a manual is available for these charts in areas of the machine where lubrication is required. The machine can become damaged if the manufacturer’s lubrication is not followed. You also need to check the wear and tear on the needles more often and replace them to avoid poor stitching. Ensure that you remember calibration strengths. Check the tension settings where necessary, and cross-check that they cut or pull edges according to the standard scale. Lastly, get a professional service hired every 12 months to allow internal parts to be inspected and checked for orientation. If you adhere to these recommendations, the machine’s life will increase, and the quality of the embroidery will even loom.

Essential Maintenance Tips for Needle & Bobbin

When using special industrial embroidery machines or equipment, focus on properly maintaining and caring for needles and bobbins, as it will ensure adequate stitching without excessive downtimes. It is proper for starts to check the needles for bluntness or burr formations which may fracture the threads or damage the fabrics; it is advisable to start replacing the needles after about eight operating hours and rest change them as per specific material’s requirement. Also, when inserting the new ones, ensure they are correctly inserted and secured tightly so they do not produce unnecessary vibrations. Regarding the bobbins, it is essential to explain the needed consistent tension to achieve the desired outcome of even stitch formations. The work should be done using a very soft brush or compressed air to occasionally blow the bobbin case, its surroundings, and the area. Do not fill bobbins to the beaks, as this creates tension-related problems. Bobbins must be rewound with one rotation to achieve the goal of creating uniform stitch placement. This shouldn’t be a complicated endeavor because we have constantly supplied the information to you. You should inspect the spools regularly for damage and replace any worn ones to prevent poor performance. Such established rules positively influence the quality of manufacture and the service life of workpieces of the embroidery machine or equipment, which is common wisdom among the best professionals in the industry.

Extending the Life of Your Single-Head Embroidery Machine

As I am trying to prolong the duration of use of my single-head embroidery machine, I have developed a practice of using a planned maintenance program. I clean the machine every week so that lint and dust do not interfere with its working. As the minerals build up, I also routinely lubricate the moving parts per the manufacturer’s instructions. It has been necessary to monitor the tension settings and replace the needles after every 8 hours of operation to maintain the stitching. I also schedule annual professional servicing, which helps me detect problems statistically and ensures that I work ideally and prolong the machine’s lifetime. Considering these practices, I use my embroidery machine without fear of losing quality.

Troubleshooting Common Issues with Multi-Head Machines

In the case of multi-head embroidery machines, several typical malfunctions can be solved relatively straightforwardly. I would initiate multi-head machine troubleshooting with tension settings, crucial to avoiding thread breaks and inconsistent stitch quality. My routine includes cleaning the tension discs and threading all threads through the machine. In the second place, wired or needle breaks are also caused by improper needle position, and wear and tear prevails over the standards, requiring replacement or correction. Additionally, I verify if the fabric is correctly hooped so it does not move during embroidery. So, fixing the head synchronization issue is vital if the registration or design errors occur due to offset heads on embroidery machines. I often need to align embroidery frames and verify that the software parameters correspond to the parameters of the machine. The scope of these corrective measures ensures that the number of problems experienced and the efficiency of machines are both intact.

What Makes Factory Direct Purchases Beneficial?

For those in the hunt for quality products at lower costs, factory direct purchases offer a lot of goodies. First, most exporters and retailers add a percentage to their cost to mark consumer prices. This is usually eliminated when the goods are purchased straight from the manufacturers. Furthermore, direct purchase means that the quality and authenticity of the product are maintained as there are no alterations to the products. Also, direct factories can offer customers customized products that suit their preferences. Additionally, direct contact with manufacturers allows customers to receive and understand information concerning a product’s point of purchase and how it is supposed to be used or even cared for. All these factors make the buying process more accessible, so direct purchases from the factory should be a priority for any careful shopper.

Advantages of Buying Directly from Manufacturers

Cost Efficiency: It is economically wise to buy from the manufacturer directly and save a lot of money. Without dealing with wholesalers or retailers, buyers can purchase at lower prices without extra costs.

Enhanced Product Quality: Buying from the source guarantees a better quality product. Since the products come directly off shelves, there is minimal chance of counterfeit or tampered goods reaching consumers.

Customization Options: Customers appreciate being given the option to alter products. Most direct manufacturers can implement custom orders, changing design, dimensions, and functions according to clients’ requirements.

Improved Communication and Support: When buyers purchase directly, they can communicate more effectively with the company about the intended product. This level of contact enables precise product details, issue resolution, and complete customer management after the sale, thus improving the customers’ overall experience.

Sustainability and Speed: Manufacturing directly promotes efficient supply chain management, diminishing the logistics-related carbon footprint and waste. In addition, it fastens delivery, as there is no longer a time lag between production and the consumer.

How Happyjapan USA Ensures Quality and Value

As we expand our Happyjapan brand in the United States, we must adhere to strict quality management procedures. I conduct testing at several levels based on best practices to ensure our machines’ performance, endurance, and implementation. For instance, those producers who provide materials for us procure high-grade materials, which allows us to ensure the quality of the structure of all elements. In addition, we also show commitment to value in our pricing strategies, as we sell directly from the factory and do not have unnecessary markups overhead. Besides, we always put our customers first by providing them with bespoke assistance and having a full warranty on all our products. Working hand in hand with our clients, we get to improve our services and create new ones as per customer requirements. These initiatives enable us to deliver consistently and often surpass customer expectations, contributing to the company’s excellent reputation in the embroidery sector.

Understanding Warranty Options and After-Sales Service

Upon scrutiny of warranty options and any after-sales service-related issues, it is apparent that it starts with evaluating the coverage. In the context of an informed warranty selection, most well-known producers advise that in case of significant repairs, they should cover both parts and labor costs and extend beyond the usual time frame. I am keen on selecting any product with three comprehensive protection features, warranty plans, and no out-of-pocket expenses in case of faults. Other customer-related factors, such as after-service, also come into play, and therefore, I ensure that the manufacturers have adequate technical assistance and customer service personnel. Detailed manuals and Internet resources allow me, in some cases, to deal with minor problems on my own. Individual approaches to selecting warranty plans and service options will also enable me to utilize the equipment more efficiently and for a longer time.

How to Choose the Right 12-Needle Embroidery Machine?

It is essential to focus on key features to ensure that the 12-needle embroidery machine meets your needs and helps achieve your production goals. First, examine the machine’s construction and quality, checking whether it comprises solid materials capable of sustaining heavy use. Second, the machine’s features must be assessed; it must be able to embroider various fabrics and execute complex designs. Third, analyze the stitch speed and efficiency of the machine, which are crucial in determining productivity and quick turnaround. Furthermore, consider the machine’s interface and software integration, as these features make the machine more straightforward to use and work with design programs. It would also be prudent to check for the availability of technical assistance and training that would help optimize the machine’s performance. Once you have these features, selecting a 12-needle embroidery machine that will serve you efficiently becomes easy.

Factors to Consider for Commercial Embroidery

In the review of commercial embroidery devices, some essential elements have to be assessed to maximize productivity and ensure output quality. Start by looking into how the machine works with various fabrics and its ability to work on intricate patterns, which is essential for commercial flexibility. The output of the embroidery process also has to be evaluated in terms of quality, with particular attention paid to the stitches’ accuracy and uniformity in all diverse orders without losing the set quality. Also, one more critical parameter is the speed of the machine; the faster the machines, the more production and less lead time, which provides an edge in a competitive market.

Also less relevant are the technical support and the options for ongoing maintenance. Be on the lookout for manufacturers who provide proper training and also have good customer relations in the case of queries, as well as reasonable warranty provisions to ensure minimal downtime and prolonged use of the machine. It is also ideal to purchase a machine where the software and its interface are simple for more effortless operation and easy connection with design software to enhance the workflow.

Finally, consider the machine’s scalability as well. If the business faces increased demands, having a machine that is easily upgradeable or modified to deal with an immense workload is an advantage. When such factors are critically evaluated, businesses make choices that are appropriate to the purpose of their production and their market strategy, resulting in positive growth in the fortunes of the companies dealing with embroidery.

Comparing Multi-Needle vs. Single-Head Machines

In selecting either a multi-needle machine or a single-head embroidery machine, I must say that I paid a lot of attention to the opinions of leading sources. The multi-needle machines are handy because they can efficiently operate various colors all at once without manual changes of threads, which is time-saving during busy times. However, these machines are usually adaptable and can work with different materials and complicated patterns appropriate for professional embroidery businesses. Single-head machines are ideal for low-volume users or self-employed persons as these machines are primary and cheaper. These are ideal for a short production run with a high demand for change for custom orders. Each option has its merits; hence, my preference for the needle machine is more efficient and extended, coupled with the need to improve concentration at the workplace while meeting various customer requirements.

Best Practices for Optimizing Sewing Field and Hoop Usage

It is conclusive that optimizing your sewing field and embodying the hoop interjection on the garments is essential for efficiency and accuracy in embroidery work. If you are beginning to design, choose the correct size of the hoop. Make sure it has dimensions as close as possible to the actual size of the sewing field. The guidelines provided assist in maximizing the tension and stability of the fabric, thereby reducing the chances of the fabric being puckered and the stitch being accurate.

The machine’s characteristics should be considered while sizing the maximum sewing field of the appropriate shape for embroidery. These parameters depend on the device’s model but tend to follow a set range of maximum field size, which is 200 mm200 mm and 400 mm450 mm. These technical limitations, therefore, dictate the dimensions of the most significant designs that can be executed on the embroidery machines without repositioning the hoop, which saves time and enhances work process efficiency.

To minimize fabric movement when embroidering, correct hoop tension should be observed. To stretch the fabric securely, the screw mechanism of the hoop is fixed. The same should be indicated when backing or stabilizers are used as needed for the type of fabric to improve support and stitch quality to the most optimal level possible.

Regularly checking and maintaining the hooping and tensioning systems is of utmost importance. Examine the parts for any deformation or damage and replace them whenever necessary. In addition, a test run with similar fabric samples with the exact design dimensions may also help prevent some problems from occurring when beginning the production run.

Following these practices and ensuring that all technical parameters are followed will yield the same high quality throughout and increase efficiency and satisfaction in embroidery processes.

References

Frequently Asked Questions (FAQ)

Q: What makes Happy Embroidery Machines stand out in the market?

A: Happy Embroidery Machines are renowned for their multi-need embroidery capabilities, making them ideal for commercial and personal use. They are easy to learn and operate, featuring advanced touchscreen controls and a 10-year warranty for peace of mind.

Q: Are Happy Embroidery Machines suitable for heavy-duty projects?

A: Happy Embroidery Machines are designed to handle heavy-duty embroidery projects efficiently. Their robust build and reliable performance make them perfect for continuous, high-volume production.

Q: Can I personalize logos using Happy Embroidery Machines?

A: Absolutely! Happy Embroidery Machines are perfect for customizing and personalizing logos on various garments such as shirts, hats, and caps. Their precise stitching ensures high-quality outcomes.

Q: Do Happy Embroidery Machines offer financing options?

A: Yes, many distributors, including Texas and other nationwide distributors, offer financing options to help you acquire Happy Embroidery Machines without straining your budget.

Q: What types of embroidery machines does HappyJapan offer?

A: HappyJapan offers a range of commercial embroidery machines, including single-head and multi-needle embroidery machines. These machines are designed for different scales of operation, from entry-level to advanced commercial use.

Q: How can I get support or learn more about using Happy Embroidery Machines?

A: Happy Embroidery Machines are easy to learn, but if you need assistance, call us for support. Our team is ready to help you understand and make the most of your embroidery machine.

Q: What is the difference between the hcd3 and hcr3 models?

A: The hcd3 is a versatile model suitable for various embroidery tasks, while the hcr3 is designed for heavy-duty and high-production environments. Both models feature easy-to-use touchscreen controls and are part of Happy’s world-class lineup.

Q: Are there any US distributors for Happy Embroidery Machines?

A: Yes, several US distributors, including Texas, can provide you with Happy Embroidery Machines. These distributors offer support and can help with any questions you might have.

Q: What is the warranty period for Happy Embroidery Machines?

A: Happy Embroidery Machines come with a 10-year warranty, ensuring long-term reliability and support for your investment.

Q: How can I protect my privacy when purchasing Happy Embroidery Machines online?

A: Always review the privacy policy of the website you are purchasing from to ensure your personal information is protected. Reputable distributors will have clear privacy policies.