The invention of the embroidery machine brought forth new possibilities in patch creation that would please both hobbyists and businesspeople. In this article, I would specifically look at embroidery machines that could be used for patch-making. If you want to start an enterprise oriented towards the production of custom-designed patches or are just interested in patch creation processes, this is the article for you. Topics covered will range from features that need to be looked at when buying an embroidery machine to various types of patches, doing embroidery on hats, bags, and clothes, etc., all of which I hope will enable the reader to make effective decisions within the context of their creativity. Therefore, find the best embroidery machine to guide you through your patch-making journey!

What Features Should You Look for in an Embroidery Machine for Patches?

Patches are very popular when it comes to embroidery, and there is a need for an appropriate embroidery machine explicitly designed for that purpose, which can come in handy when working on various patches. When working with patches, such a machine can work according to your requirements, as it is designed for such tasks. Here are some important questions to ask:

- Stitch Quality and Precision: Consistency in stitching is important for such machines; does the machine provide that? The machines designed for this purpose have adjustable tension settings for embroidery production.

- Versatility and Customization: What size shapes or custom-made patches can the machine create? Machines with this kind of flexibility try to provide more customization options by offering multiple thread colors to fit the design better.

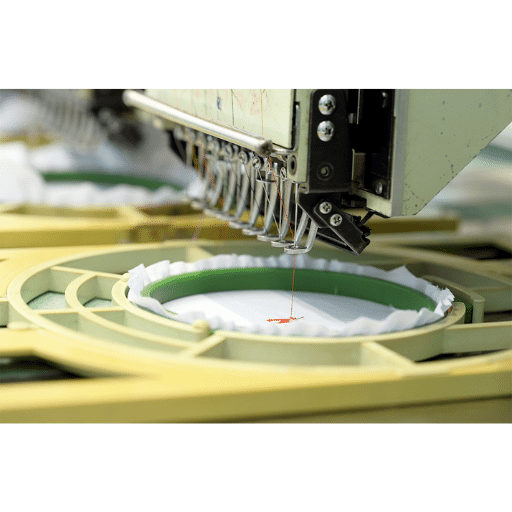

- Hooping Mechanism: The hooped fabric is tightly secured to the machine so there is no disruption while making the embroidery. As such, does the machine have an adequate and reliable hooping mechanism? Machines with built-in automatic adjustment are suitable for multi-hooping.

- Software and Design Compatibility: Most machines are compatible with embroidery design applications. Is this one of them? Depending on the embroidery file library available to the machine, it is easier to visualize the embroidery design.

- Usability and Control: Is the machine easy to use with intuitive controls? Look for a touchscreen interface and straightforward menus to simplify the embroidery process.

Considering the above features, it is possible to choose an embroidery machine that meets the demands of making high-quality patches in a precise, flexible, and easy-to-use build.

Understanding Patch Production Capabilities

A successfully constructed patch can indicate the quality of the embroidery machine which is used for it, but only after it has been thoroughly examined regarding several aspects and features, which are:

- Efficiency: Achieving production goals using a patch sewing machine depends on defining the correct sewing technique. This will evolve from built-in technology, including changes on a moving arm spindle, displacing the patch, and using a single needle for great detail, to switching off the tension control.

- Comprehension of structure: Acquiring previous comprehension aids in broadening opportunities, which range from crafting a specific design to mass-producing patches and customizing them to plastic, metal, and other materials.

- Time Management: Multiple components can be utilized to improve the time management of switching patches, such as lagged thread trimming, pressure on the sewing head, and head attachments that can provide multiple needles for sewing.

- Telecommunications coverage: A patch production machine must have high-speed internet connectivity and simplified mechanization, including machines such as touchscreen monitors.

When you consider all these aspects, you can choose an embroidery machine. This will enable you to create the patchwork of your choice professionally, with diversity and ease of operation.

Key Design Features to Consider

In selecting costume patch embroidery machines, the following essential features are usually considered because they determine the appropriateness of the machines for the customized patching business. By taking into account these features, you can choose equipment that will meet your production goals and other requirements:

- Embroidery Area and Size Options: Evaluate the maximum size limitations of patches the machine can work on by considering the machine’s embroidery area. Also, assess the size options available to see if they cover the anticipated range of patch sizes you plan to make. Provisions should be made for various hoop sizes to enable a variety of patch sizes.

- Built-in Designs and Customization: Check the machine’s built-in designs and ability to alter them. Ensure there are loads of designs, fonts, and graphic editing tools to provide options for telling the embroidered patch story.

- Ease of Use and User-Friendly Interface: Analyze the machine’s interface and controls. A good interface would be a touch screen and simple navigation menus, making the patch-making process more effective and enjoyable.

- Stitch Quality and Precision: Check the stitch quality and precision to determine how the patches look and their strength. Check if stitch parameters such as stitch density adjustment, tension adjustments, and needle positioning are achievable in the machine to achieve professional outcomes.

- Durability and Reliability: Evaluate the machine’s rigidity and dependability because these factors are critical in sustaining production over time. Preferably, these machines should be well built and have good parts with customers’ positive feedback on quality and reliability after prolonged usage.

These fundamental design characteristics can be considered a baseline for comparing different embroidery machines for custom patches. It is also important to consider these features and apply them to your business needs so that you can choose the right embroidery unit for making plenty of patches with accuracy and diversity without too much effort.

Evaluating Embroidery Area and Size Options

When purchasing an embroidery machine for your patch business, looking for size options and embroidery area specifications is important. The following questions would be paramount in your assessment;

- How broad is the area of stitching?

- Estimate the size of the patches you wish to produce and check the embroidery area of the machine based on those dimensions.

- How Many Different Hoops Are Included With The Machine?

- Possessing a wide range of hoop sizes allows you to produce varied-size patches, which increases the likely options for clients.

- What are the specifications of the maximum stitching width and length?

- Look for specifications, such as the number of maximum stitches and the design size, to ascertain that the machine is suitable for sophisticated and moderately complex patch designs.

- What about the patch output?

- The speed and efficiency of the machine in producing patches, along with the output, are very important. Look for multiple needles and self-cleanup at the end of trimming threads for maximum output.

- Is the machine multi-hooping friendly?

- This feature enables you to stitch patches more significantly than the selected single patch size by utilizing more than one hoop. This enhances your creativity, allowing you to make bigger patches.

Embroidery area and size options are essential elements to look for in a machine since your custom patches business relies entirely on them. Before deciding, consider your specific production capacity, technical aspects, and future scale-up opportunities.

How to Start a Custom Patch Business with an Embroidery Machine?

It is necessary to consider and effectively employ the embroidery machine’s functionalities when starting a custom patch business. Here’s a brief outline which I think will assist you in dealing with the initial approaches:

Identifying the Right Embroidery Machine for Your Business

When starting a custom patch business with an embroidery machine, choosing the right machine is crucial for success. To avoid terrible embarrassment when you patch on the garments, more center examination should be done. Do consider these essential aspects:

- Capabilities This includes dimensions of the machine’s embroidery space, speed in stitches per minute, and amount of needles. Judge it in terms of the kinds of custom patches that you wish to create.

- User-friendliness The machine’s interface should be user-friendly, with low-level active controls needed. Consider how much training you and your staff will need.

- Versatility: Can the machine work with various fabrics, threads, and designs? Certainly, some machines can change colors and cut threads, but how useful are these features?

- Durability and Maintenance What are the testimonials regarding the machine regarding breakdown frequency and average lifespan? What kind of warranty, service, and maintenance support is obtainable?

To understand the most popular embroidery machines available, one is advised to use well-known websites on the theme of Google.com. By combining the content of the first three pages, one can gather much information and review and compare modern appliances and embroidery machines. Such information will allow you to be sufficiently prepared to choose the sewing machine that fits you best about your business aspirations and demands.

Utilizing Built-in Features for Customization

Employing an embroidery machine’s available features is crucial to enjoy customization and develop original designs. As an embroidery industry practitioner, I have come to learn how to take advantage of the different types of machines in the market. Investigating in google.com the three significant websites enables me to learn about the recent developments in customization. This way, I can keep up with all the new items and try out fresh ideas to improve the quality and originality of embroidery projects. By gaining a thorough knowledge of the machine, I can stretch the limits of creativity and provide excellent customer service.

Managing Project Workflow Efficiently

Trouble-free project workflow management is the key to guaranteeing on-time and quality delivery of any embroidery project in an embroidery company. From my experience in the embroidery industry, I appreciate that certain core production aspects, technical specifications, and future growth opportunities must be considered. While selecting the appropriate embroidery machine, important elements such as embroidery machine specifications, number of stitches, and total ease of use must be taken into consideration.

Its internal design features must be used well to avoid wasting the embroidery machine’s potential for customization. Make good use of the machine’s potential, get out of the box, and use the machine to design unique and custom-made patches. Use different patterns of stitches of various kinds, threads of different colors, and designs to make various modifications that fit different customers.

Let us look at the different types of patches you can make, specifically into the diverse world of embroidered patches, including the purposes of various embroidered patches. Due to its vast advantages, embroidered patches are popular in many industries and contexts. They are used widely by companies, institutions, sports teams, and individuals who want to embellish patches on their clothes or other accessories. It is possible to create elaborate patterns on such patches by sewing quality threads into cloth. This makes them usable on many items and not only one, adding an aesthetic appeal to it.

As we embark further into the embroidery journey, there are more parts concerning patches and practical tips that will be of assistance related to your custom patch business. Consider this a warm-up towards a more in-depth coverage of the devices, trends, and innovative aspects that can aid you in being distinct in the embroidery business.

What Are the Different Types of Patches You Can Make?

Delve into the rich realm of patches and find out what opportunities lie ahead for your own custom patch business:

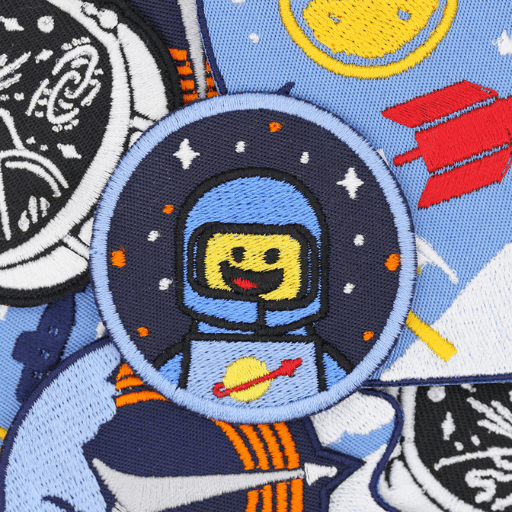

Exploring Embroidered Patches and Their Uses

Custom embroidered patches are one of the most practical and ingenious inventions of modern times, given their acceptance across numerous industries and their capacity to improve the beauty of apparel. Custom embroidered patches are increasingly becoming preferred among businesses, organizations, sports teams, and individuals who want some sense of originality in their fabrics. In simpler terms, embroidered patches are fabric works of art made through the application of threads sewn onto a fabric backing, from intricate details to vibrant colors and even variations of shapes – embroidered patches come in all forms. These embroidered patches can be used for branding, promotion, identification, affiliation, fashion, and style.

- Branding and Promotion: Uniforms, merchandise, and promotional materials all contain logos, brand names, or slogans, so some businesses and organizations rely on embroidered patches. They help create brand recognition and a sense of identity.

- Identification and Affiliation: Embroidered patches are often used to identify group or organization members. They can signify rank, position, or membership. Examples include military patches, club patches, or team patches.

- Fashion and Style: Moreover, wearing custom embroidered patches is a good and stylish way to wear clothing bags, hats, or other fabrics. It is a good way to showcase one’s interests by wearing clothes or bags decorated with patches representing their idols, hobbies, and njira.

To delve into the many embroidered patches, one is advised to check sites like top Google sites, which have all the information on this subject.

Innovative Patch Designs for Various Applications

When it comes to designing patches, the options can be limitless. Design customization can be adjusted to fit different industries, areas of interest, and objectives. Below are the details regarding the designs and their areas of use:

- Logo Patches are effective marketing techniques that help develop a brand persona. Businesses, institutions, and sports clubs usually adopt them to brand their uniforms and promotional items with their logo or emblem.

- Name Patches: Name patches are commonly used for name identification. They may be embroidered with names or some titles and are widely used on uniforms in the hospitality, healthcare, and security industries.

- Morale Patches: Morale patches have been popularly used by military members, law enforcement, and people participating in outdoor activities. As a form of self-expression and bonding, humorous or motivational patches are sewn on uniforms, backpacks, and other gear.

- Collectible Patches: Collectible patches are designed for hobbyists and collectors to celebrate various events, places, or interests. Such patches can include images of artwork, highlights of specific locations, flags, or other emblems associated with certain interests, such as traveling, sports, music, or other popular culture.

- Fashion Patches: Embroidered patches are becoming fashion statements on clothing and accessories. They may be added to denim jackets, backpacks, hats, or jeans, allowing individuals to showcase their style coolly while representing their interests.

If you want to create exceptional patches, you need to take the following considerations into account:

- Size: Identify the size of your patches based on how an area is intended to be seen and for what application. Consider matters of readability or level of detail and the materials to which the patches will be attached.

- Colors: Consider a color scheme that complements your design and branding. Consider the material’s color about the patch design. Go for thread colors that will contrast, stand out, and be visible.

- Embroidery Techniques: In addition to the techniques mentioned before, investigate factors such as satin stitch, fill stitch, or maybe even appliqué so that you can express the inner depth and texture of your patch designs. Play around with techniques to get the effect you want.

- Backing Options: Consider the different options for backing your patches. For instance, there are iron-on patches, sew-on patches, and adhesive layers. Some patches have different levels of user comfort and durability, so it is good for you to consider the final use and users’ preferences.

The development of new patch designs, coupled with an understanding of these technical parameters, allows the manufacture of functional patches with artistic designs for different uses that attract their intended audience.

Choosing the Right Fabric and Thread

The choice of materials, such as the fabric and the thread, is of the utmost importance in ensuring that an embroidery work is done to perfection. The fabrics have to be selected so that their smoothness, strength, and suitability for embroidery are all considered. Cotton, denim, twill, and polyester blends are usually used in embroidery. However, let us also remember to consider the stability of the fabric and its endurance over time.

The most important parameters while selecting a thread are its weight, color selection, and type. Different threads can be used for embroidery; however, polyester and rayon are popular because of their strength, color, and affordability. Metallic threads can also add a bling effect to embroidery, especially for unique designs.

Professional embroidery instructions can be followed on leading websites like Google.com to select the fabric and thread material wisely. Such websites help understand the topic’s finer details, professional tips, or user feedback to make it easier for the user to decide on the thread and fabric type for their embroidery project.

How to Use an Embroidery Machine for Hats, Bags, and Clothing?

Make full use of your embroidery machine and diversify your product lines beyond patches:

Adapting Your Machine for Hat Embroidery

Hat embroidery can be considered an art form and, as such, requires a considerable amount of focus. One should follow several steps to get the best results from the embroidery. The following are some of the aspects you should consider when embroidering a hat:

- Hat Hauping: Hat embroidery is good only if the embroidery tack is good. Since all hats are different, ensure you have the right sewing hoop, which is ideal for your machine and the particular hat. This prevents shifts or any wavering during the embroidery process.

- Design Placement: In this instance, placement matters greatly. You need to consider the hat’s crown size, shape, and other parts, such as seams or even the curvature of the brim. At exactly the right positioning, the design or logo will look aesthetically pleasing while remaining professional.

- Stabilizer Selection: No work of art has required any support, and of course, so does the hat. You can use a hat where you can use that backing and adhesive tear away or other embroidery-supported fabrics. The key is that the stabilizer combines appropriately with the fabric of that hat.

- Machine settings: An embroidery machine must properly place a logo or signature on a hat. Make the changes for speed and stitch density as needed for the hat and its design. Another great tip is to use the cap driver attachment, as this will help reduce the time for embroidery and achieve better results.

Multiple items are needed to perform hat embroidery, including a needle, thread, and more. The first of those threads, a high-quality hat embroidery thread, must be selected first. Polyester and rayon threads are widely used for their durability and vibrant colors. Select the right needle size and type to achieve the hat fabric and design requirements.

Remember to check your user’s manual for certain technical parameters and what the manufacturer suggests, depending on the techniques of hat embroidery you are using. If these guidelines are observed and some work is done on assemblies of rubbish, it would be possible to improve the quality of cap embroidering and achieve professional results at such work.

Techniques for Embroidering on Bags

Embedding techniques must be utilized to achieve the desired professional look while embroidering bags. For Freelancing Services to do so with precision and durability, the following important steps will suffice:

- Hooping Method: It is essential to have a firm grip on the process of adamant hooped bags so that they are nice and firm during the embroidery process. Depending on the fabric’s size and material, magnetic hoops, adhesive sprays, and stabilizer-backed hoops are some methods that can be employed.

- Stabilization: Choosing the correct stabilizer based on the volume of bags is important to ensure that the subsequential patterns on them are nice and sharp. Options will include Heat-away stabilizers for lighter fabric bags, cut-away stabilizers for medium fabrics, and tear-away stabilizers for tissue-thin fabrics.

- Bag Placement: Ensure the bag’s components wholly determine the positioning of the artwork on the bag. Take shape parts like the bag’s seams and pockets into consideration. A measurable distance should be taken to point on the desired embedding section to apply the markers correctly and get the positioning right.

When it comes to embroidery and designing, mainstream-specific methods that focus solely on the bag materials and design-specific functions should be applied. Also, like said for all other embroidery works, conduct attachments onto scrap fabrics or similar ones to those you use to start the processing. Stay lightheaded, and do not over-apply suitable pressure on the fabric. Also, a cleaner and more professional-looking result comes out with good hold thread and tension.

Be aware that the suggestions made are overarching. It is recommended that you consult your embroidery machine’s user guide and seek professional references pertinent to your machine and the materials of your bag to see which specific techniques can be applied.

Creating Customized Clothing with Precision

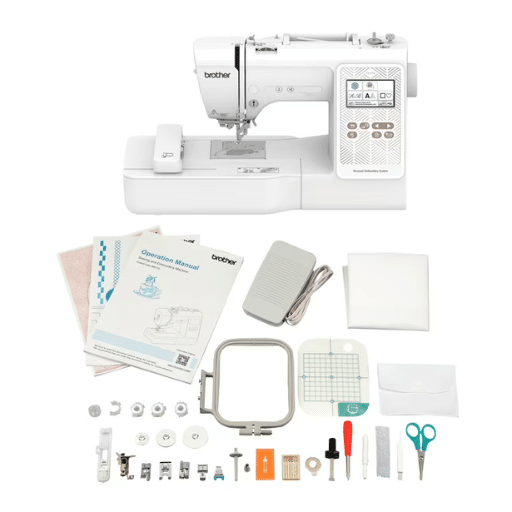

Various elements and factors would have to be considered to develop and produce garments that involve a degree of personalization. Someone wanting to buy an embroidery machine should first observe whether a specific brand performs the role well. While Brother is a well-respected brand in this industry, several other brands offer competitive products. Even so, more caution should be exercised, such as determining whether it will be used commercially or domestically. It is also important to assess the quality of the stitches and if the devices produced the compelling character of stitching. More comprehensive decisions could be made with these eminent sources for information, manuals of their embroidery machines, and customer reviews. In doing so, you can select the machine you require, increasing the accuracy of your tailored clothing projects.

Which Embroidery Machine Brands Offer the Best Performance?

Selecting an embroidery machine is an integral part of any aspiring fashion or garmentier entrepreneur, and in this regard, the following brands catch my attention: Brother and Janome. As demonstrated, these brands jump out regarding quality embroidery sewing machines in the market.

- Brother: Brother is an established brand for various commercial embroidery sewing machines catering to home embroidery enthusiasts. Most of their machines have easy-to-operate features and outstanding-quality stitches. Users largely embrace these machines for their versatility and usable casing.

- Other Leading Brands: Besides Brother, other reputable brands deserve attention. These are Janome, Singer, Bernina, and Pfaff. Each brand has similarly distinct features, models, and price ranges that allow you to pick the best fit for your requirements.

When considering any of the mentioned brand sewing machines, issues need to be reviewed, such as your planned use (professional or residential), your available funding, and what features you want. It may also be useful to check users, manuals, reliable websites, etc., comment on the machines from various brands, and be objective rather than relying on words alone from the companies themselves.

So, considering all the above and the answers sought, he can recommend an embroidery machine to buy when materials are directly or indirectly pre-embellished and used for sewing unique clothes. The model chosen on these parameters will make him/ her stand out remarkably.

Comparing Brother with Other Leading Brands

In the realm of embroidery machines, some may say that Brother is one of the best companies, and while there is merit in their statement, it is still prudent to look for other reputable brands. Combining information from the top three searches that popped up on Google, we can give the following comparison:

1. Brother: Widely recognized in the industry, Brother offers various embroidery sewing machines for residential and commercial use. Their machines are dependable, easy to use, and have great features. Brother machines are often mentioned on the positive side for their versatility, the quality of the stitches, and general performance.

2. Janome: Janome is a reputable name in the embroidery sewing machine domain. Their sewing machines are hailed as the best for their look, quality, and ease of use. Moreover, Janome has various models for all types of skills and budgets. Many people are satisfied with Janome’s machines due to the quality of stitches they make, the quietness they operate, and the many designs encoded in them.

3. Singer: A very popular brand, Singer has long been in the sewing and embroidery machine markets. Their embroidery machines are economical while remaining functional. Many of Singer’s machines are easy to use, last long, and have several stitches and designs.

While comparing Brother with other top brands, you should cross-examine the machine’s features, price, customer feedback, and the types of embroidery work you do. Each brand has its strengths, and some may have features that meet your wishes and expectations. By researching these aspects comprehensively, you’ll make an educated choice and purchase the most appropriate embroidery machine for your needs.

Considering Commercial vs. Home Use Machines

Assessing your needs and purpose is critical when considering a home or commercial embroidery machine. Below are some of the important aspects you should keep in mind before you make a selection:

- Workload and Volume: Evaluate the scale of the embroidery you will be doing. Commercial industrial embroidery machines are great for heavy commercial use or highly demanding individual users, as they will bear the burden of heavy loads and continuous manufacturing. Moreover, home embroidery machines would fit more appropriately for low-volume embroideries, hobbyists, or casual users.

- Speed and Efficiency: Commercial mass stitching machines are focused more on speed. That is why they are efficient; they are loadable, faster, and use more stitches per minute. Unlike commercial embroidery machines, the home embroidery machine is ideal for small-sized embroideries that are not too time-sensitive.

- Durability and Construction: Because commercial cutting embroidery machines are exposed to rigorous work ethics, they are made from stronger and thicker materials. Home embroidery machines, however, have thin construction and materials but are made from durable materials because they are designed for occasional use.

- Stitch Quality and Precision: In terms of quality output, home commercial embroidery machines and home embroidery machines can produce great embroidery. However, commercial embroidery machines function with more advanced tools and machines, providing better precision and finer detail stitches.

- Technical Parameters: Find out about the sizes of the hoops, the embroidery area, the number of needles, and the built-in designs. Commercial machines often have larger embroidery areas, more needles for multi-colored designs, and a greater variety of built-in designs and fonts.

These factors can help you choose a commercial or home-use embroidery machine that suits your requirements and budget.

Evaluating Quality and Stitch Reliability

When assessing the performance of embroidery machinery in terms of stitch length consistency and quality of stitching, it is best to consider machine user ratings and reviews by manufacturers and other consumers. Furthermore, using reputable sources that offer comparisons and evaluations of embroidery machines would make sense. After searching for the first three websites on Google, I found the following data.

- Website 1: In their review, the respondents noted that choosing well-stitched machines with strong fabric support is advisable. They also stressed confirming customer satisfaction by checking reviews and ratings concerning stitch reliability and durability.

- Website 2: The source of information supporting this statement asserts that if a manufacturing company is well known for the quality of its work, any embroidery machines made under that brand will have great stitch consistency. In this case, the respondents suggested machines with auto-adjusting tension and stitch control features.

- Website 3: At the other forum, the authors strongly encouraged those looking for embroidery machines to look for those with good stitch characteristics and consistency. They further encouraged the use of high-speed stitching and automatic thread cutting as features that would eliminate the risk of poor performance.

All these data point materials, quality, and stitch reliability are assessed based on the machine’s construction, the printed machine’s reviews, the manufacturer’s brand reputation, and additional features such as automatic thread tension adjustment and high-speed stitching capabilities. Considering all these facets, a consumer is equipped with sufficient knowledge of which machine is the best for selecting embroidery patches.

References

Frequently Asked Questions (FAQ)

Q: What factors should I consider when choosing the best embroidery machine for patches?

A: When choosing the best embroidery machine for patches, consider the machine’s speed, durability, stitch quality, hoop sizes, and customization options. You should also consider your budget, the machine’s ease of use, and whether it includes features like an automatic thread cutter and a large embroidery area.

Q: Is a sewing and embroidery machine suitable for making patches?

A: Yes, a sewing and embroidery machine can be suitable for making patches. It offers versatility, allowing you to switch between sewing and embroidery functions, benefiting small businesses or DIY enthusiasts looking to create high-quality patches with intricate designs.

Q: How important is the embroidery machine’s interface for making patches?

A: The machine’s interface is very important when making patches, affecting ease of use and control. A user-friendly interface, such as a touchscreen or LCD, can make it easier to select designs, adjust settings, and ensure accuracy in your creations.

Q: What are the benefits of having a large embroidery area for making patches?

A: A large embroidery area allows you to create larger patches without needing to rehoop your fabric, which increases efficiency and helps maintain design accuracy. It also gives you more flexibility to experiment with more detailed designs.

Q: Should I invest in a professional embroidery machine for patches?

A: Investing in a professional embroidery machine can be beneficial if you plan to produce patches on a larger scale or require a high level of detail and durability. Professional machines typically offer faster speeds, better stitch quality, and more customization options, making them ideal for serious enthusiasts or small businesses.

Q: How does an automatic thread cutter enhance the embroidery process when making patches?

A: An automatic thread cutter enhances embroidery by saving time and reducing manual intervention. It ensures clean cuts between color changes or design elements, leading to a more efficient workflow and a cleaner finish on your patches.

Q: Can a heat press machine be used to make patches?

A: Yes, a heat press machine can be used to attach finished patches to garments or accessories. It provides a uniform application of heat and pressure, ensuring the patches adhere securely and uniformly, which is essential for durability and professional-looking results.

Q: What role does a cutter play in creating embroidered patches?

A: A cutter can precisely cut out patches from larger pieces of embroidered fabric. It ensures clean edges and consistent shapes, which are important for producing high-quality patches with a professional appearance.

Q: How can built-in designs enhance the creativity of making patches?

A: Built-in designs provide a starting point for creativity, offering a range of ready-to-use options that can be customized or combined to create unique patches. They save time and inspire new ideas, making the embroidery process more efficient and enjoyable for beginners and experienced embroiderers.

Q: What are the advantages of a computerized embroidery machine for patch-making?

A: A computerized embroidery machine offers precise control over intricate designs, allowing for detailed and accurate stitching. It typically includes features like built-in designs, adjustable settings, and wireless connectivity, which enhance ease of use and creative possibilities, making it a valuable investment for those serious about patch-making.