If you are looking for the best sewing machine suitable for custom designs, you are in the right spot! Sewing machines are technical and specific types of machines, and therefore, this guide brings you all sorts of best sewing machines depending on your needs. We aim to provide helpful content whether you are considering starting an embroidery business or looking to grow one.

Let’s have a look at the basic requirements as well as the features to look for. These standout features will allow me to choose the appropriate design embroidery machine for my specific task. After that, we explore the age of computerized embroidery machines. As we move forward in the discussion, we focus on the advantages and the principles on which computerized machines work and, of course, the multiple benefits of using a threading embroidery fastening machine and a few selected models available in the market.

However, that is hardly the case! We shall narrow down our focus on the Brother PE800 Embroidery Machine since it is widely regarded as one of the best sewing machines. In this article, you will learn about its various cutting-edge features, how many inbuilt designs it has, and what makes it so popular among embroidery experts and users around the globe.

And to those interested in launching a commercial embroidery enterprise, don’t worry—we also have your back! We’ll assist you in selecting a suitable commercial embroidery machine and help you grasp the significant factor of speed in the embroidery business.

As you conclude this blog post, we aim to present you with an all-inclusive overview of the equipment and resources available in the world of embroidery so that you can understand them well enough for effective decision-making and confidently start your embroidery journey. So, let us explore your fears and find ways to satisfy your custom design creation wishes by using the best embroidery machine for your requirements!

What to Look for in an Embroidery Machine for Custom Designs?

To buy a machine that can sew your custom fabrics, you must weigh several factors first. Below are some important considerations you should not forget:

- Embroidery Hoop Size—The embroidery hoop size dictates the maximum area your machine can stitch. Remember the size requirements of your custom work and check whether the machine has the correct dimension hoops.

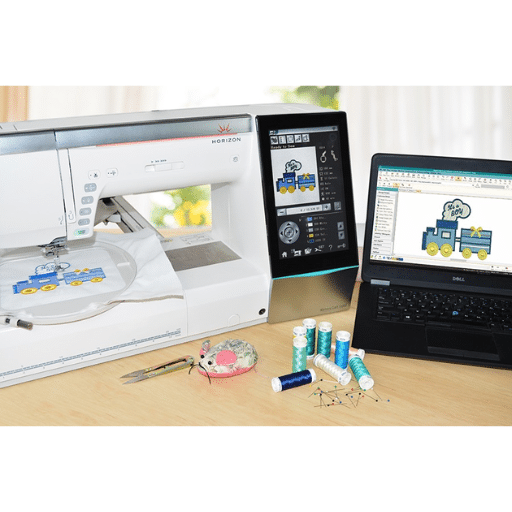

- Design Transfer Options—Choose a sewing machine with many design transfer methods. These can include USB, Wi-Fi, or cards, facilitating transferring designs directly from your computer or devices.

- Built-in Design Library—An underlying design library can be helpful if one has many pre-downloaded designs and seeks inspiration to change some or all of them or does not intend to create something new.

- Stitch Types and Styles—Provide a variety of stitch types and styles, such as embroidery machines. Consider your desired range when designing custom pieces and the required stitch options.

- User-Friendly Interface: A self-explanatory interface readily enhances the sewing experience. For optimal performance, the machine has a well-positioned LCD screen with products that do not require complex button manipulation.

- Embroidery Speed: The speed at which a machine operates dictates the period necessary to finish the project. Please contemplate the rate of production expected for your tailored designs and purchase a machine with matching embroidery speed.

If you note these points and select an embroidery device that satisfies your requirements, you can create your custom designs without fail. Let’s explore the possibilities and get you started with your creativity!

Essential Features of an Embroidery Machine

The custom embroidery machine has many features that your design requires. Some features are basic that we may look for; this difference helps us narrow down our selection. Here is the compiled list of features that will be of great help in making an educated decision:

- Embroidery Hoop Size: If your machine has a large embroidering space, it will come equipped with a standard-sized hoop or a tiny one otherwise. You must choose a hoop big enough for your envisioned project sizes.

- Speed of Stitches: Stitching tension conveys the speed at which the design is embroidered on the fabric. High speed will certainly cut the time, but remember that this is counterproductive at some levels as some designs may require finer stitches.

- Number of Needles: Multi-needle sewing machines are great, as a single-needle sewing machine makes rather monotonous work, as you have to keep changing the thread for a different color.

- Built-in Designs and Fonts: These can greatly help you if you wish to use them rather than the conventional ones, as project creation takes time. They will leave you inspired, saving you a lot of time in your projects.

- Conectividad: Vea si la máquina tiene puertos o conectividad como USB, o se puede enchufar vía red inalámbrica. Eso le permite volcar sus propios diseños al ordenador, o acceder a bibliotecas de patrones de bordado online.

- Pantalla LCD y Edicion: The existence of an LCD that is simplicity-oriented and various editing features such as scaling down or turning the design adds more comfort and ease to design creation.

- Auto Thread Trimming & Thread Tensioning: These added characteristics help save time and, more importantly, ensure the quality of stitches is the same in all embroideries.

- Robustness and Customer Service: Please look for a sturdy machine that can withstand rough conditions. Reliable customer service is also important for effectively performing troubleshooting and maintenance tasks.

Assessing these primary features will enable one to gauge the type of embroidery machine that will meet their custom design fabric requirement, as it does not make sense to pick a random embroidery machine. Let us explore further details regarding computerized machines and expect more developments in the embroidery design process, including multi-needle machines, at this point.

How to Choose the Best Embroidery Machine for Your Needs

Choosing the best embroidery machine might be a daunting task. As someone who’s quite taken up with embroidery, I appreciate that everyone has their requirements for the machine they will use. So, to make your decision a bit easier, I have done my research and gathered quite a lot of information from the best sources available on the Internet. Now, here are some of the questions you should be pondering over:

- What is Your Level of Experience?

- Whether a novice or a seasoned embroidered, there’s a machine for everyone; the preferred level can determine that. For some beginner self-stitching units, some machines are quite simple and ready to use, while others have more extensive design customization capability for experienced users.

- What is Your Budget?

- The first step should be determining your budget, after which you can get an idea of the machines available in your price range. Considering the price range, there are low-range models and even high-class professional units. Still, determining your budget beforehand will make looking for one with the right features easier.

- What Are Some of the Embroidery Projects You Will Embark On?

- Remember the scope and dimensionality of the embroidery projects you will work on. Some machines can only do small and very detailed designs, while others are intended for bigger tasks like working on clothes or quilts. Establishing your project needs will help you choose a machine that corresponds to the specific hoop sizes and other requirements you have listed.

- What Are Some of the Features and Functions You Genuinely Require?

- Different machines provide various features, such as ready-made designs and the possibility to edit them. They also have an automatic thread trimmer, among other advanced features. Turn your attention to the features that matter most to the end purpose of your embroidery.

By answering these queries alongside the research done from different reliable platforms, you will be in a position that will enable you to select the most suited embroidery machine. It is essential to do a considerable amount of research and comparisons on the models you are interested in, check what people say about them, and even test the machines before the final decision. Good luck with the embroidery!

Understanding Built-in Designs and Their Benefits

In any embroidery machine, one of the features worth looking into is built-in designs. You can find these in-built designs stored in the device, enabling you to choose the particular design and stitch it on whatever item you wish to complete. Here are a few particular factors that can be evaluated about an embroidery machine’s built-in designs:

- Designs available for embroidery: Purchasing machines with many built-in templates is wise, as opposed to designing templates with around eight or nine. The more templates are available in the machine, the more chances you have of creativity in your embroidery.

- Design—Modifications: It is important to see that the machine you are purchasing can change its design. For instance, a built-in design can change size, rotation, or how two or more images are joined together.

- Design Accuracy: While purchasing the device, analyze the level of detail offered on the embroidered piece. Consider units that will provide nicely defined, crisp stitches, enabling each piece of embroidery done with the machine to look nice and clear.

- Design Features: Some developers launch mechanical machines in the market with software that can change the appearance of existing built-in designs and create new ones. Be sure to look out for such machines, as they only help widen your scope of creativity.

- Opciones de Transferencia de Diseño: Vea de qué manera es posible transferir al equipo más diseños. Algunos equipos tienen puertos USB o conexiones inalámbricas que permiten importar y bordar otros diseños creados por usted o adquiridos.

Recuerde también a cuántos, cuántos y cuántos de los diseños integrados a la máquina puede agregar, cuántos brindan opciones para la personalización al evaluar máquinas de bordar. Where possible, consider your specific goals in embroidery to find a machine with sufficient variety of designs that fit your needs.

How Does a Computerized Embroidery Machine Work?

The technological advancements that computer-controlled machines have brought to the modern universe of embroidery are remarkable. These machines accomplish the task of sewing together thousands of embroidery stitches with the help of the following steps: Fabrication of a multitasking design—a requirement that is achieved using embroidery design programs—and the fabrication of multitasking designs that are saved into convenient formats such as DST, WT, and PES.

- The Preparation Phase: Various methods are available to transfer the design to an embroidering machine, such as using a USB port or wireless connectivity. Other machines permit downloading designs through the device, designed to meet customers’ needs.

- Stretching: The fabric to be worked on is hooped firmly, ensuring it moves and shakes minimally while stitches are embroidered.

- Color hath Activated: Make a list of the threads’ colors needed and cross off the shades that have been cleared. If those few spools remain, the moving heads of computerized machines don’t need to be changed.

- Adjustment Phase: Attach the correct needle to the sewing machine again. The stitches must be adjusted during the final sewing of the required fabric.

- Embroidery Process: After everything is in place, the machine starts and does the embroidery according to the design’s framework. As stitches of different sizes emanate from now and then, the needle must be in different places, which will be done with the help of motor control.

- Finishing Touches: Once the embroidery is done, take the fabric off the hoop and cut any loose threads. Some machines provide these features as additional options, including automatic thread trimming.

Computerized embroidery machines offer a new dimension to your imagination and can do a mind-boggling range of turns, contours, and stitches. There is a wide range of scope, irrespective of whether you are a professional embroiderer or an amateur, as you can stitch with a lot of creativity through the provided machines.

Exploring the Embroidery Design Process

The embroidery design process, in the end, is a perfect combination of imagination, digitized designs, and layers of technology. As you begin this journey, you probably have concerns about the various stages of this embroidery design process. Below, we offer short clarifications to questions that are frequently posed while sourcing some material from reliable internet sites;

- How are embroidery designs made?

- Companies use several methods to produce embroidery designs. One is digitizing, where any design intended for stitching is first created as a machine-readable file. Designers use programs that ship with the software that provides a graphic interface with various embroidery design options, including editing, stitching, lettering, and many others.

- Can I bring my designs for embroidery?

- Yes, computerized embroidery machines have the feature of uploading their designs. A few machines accept .pes or .dst files, so you can put your designs in the mote. In addition, there are even machines capable of connecting with other devices through USB and Wi-Fi.

- What are the merits of using computerized embroidery machinery?

- With the help of computer embroidery machines, embroidering has become easier due to the variety of features and more straightforward settings that the devices possess. With the help of these machines, the cuts are made precisely, stitches are sewn dedicatedly, the thread is cut at the right moment and number, and many designs are built into the devices. They also have simplified navigation through user-friendly touch screens and allow changing, scaling, rotating, and flipping the designs.

Creating an embroidery design can appear daunting. Still, the inverted design sequence offered by computerized embroidery machines aligns many steps to help you accurately make detailed and individualized designs. These machines can give stunning results as they can sew designs imported by the user and any of the numerous sewed designs already available in the machine.

Advantages of a Computerized Embroidery Machine

While designing embroidery on a computerized machine, one gains autonomy that can help enhance the idea of embroidery and how it would look once it is complete. But to look at some highlights of designing embroidery on a computerized machine, let’s consider the following points.

- Unending Embroidery Designs: Uniquely, one can assemble a custom design. Since numerous embroidery machines have many already available options embedded into them, one can never have a shortage of embroidery designs and patterns. An intermediate and advanced-level embroidery machine can enable one to have flower-based patterns, American stitches, or even a hand-stitch font.

- Higher Stitching Accuracy: With embroidery creation becoming easier, it has also become imperative to maintain an outstanding level of professionalism to meet customer demands. Providing a higher grade of stitching requires the designer to employ advanced and computerized machines. Doing so ensures that every stitch is identical to the one before meeting every design’s predetermined complex outline.

- Maximized Time to Profit margins: Automation has helped save manpower due to technology in this industry. Simple tasks such as changing the color of the thread have now been automated with the introduction of advanced sewing machines. By completing tasks more efficiently, one could save time and reduce the overall cost of production.

- Routine-Friendly Features: Modern computerized sewing machines are easy to use for everyone, whether you are a novice or an expert. They come with many user-friendly features, like rotating and mirroring patterns or resizing them, which are all simple to use.

- Versatility and Adaptability: You can use computerized embroidery machines on any material or fabric, whether it is clothes, accessories, or home décor items, because the machines allow such freedom. They facilitate the placement of designs and embroider complex components that come out in clear detail.

In the computerized embroidery machine, weigh the embroidery area size, the stitching speed, the number of embroidery needles, and the type of supported design files. These specifications will define the embroidery operation for the fabric and ensure perfection and creativity in the end product.

Importing and Creating Custom Designs

Working with and making custom designs is an integral part of computerized embroidery. It allows you to customize and get creative in your projects. Whether you want to embroider a custom logo, a monogram, or a work of art, the possibility of importing and making custom designs makes this achievable. Here are some tips to get you started.

- Design File Formats: Check your embroidery machine’s specifications to see which design files it is compatible with, such as .pes, .dst, .exp, .jef, .vp3, and others. This will help you since you will find loads of design files available for download online or made using a design program that will be usable on your machine.

- Design Software: Look for embroidery design software that will allow you to work with the required file formats. These software programs are useful in making, modifying, and customizing designs that suit your preferences as you work with them. Seek interfaces that are easy to navigate, sophisticated editing tools, and machines compatible with your embroidery.

- Digitizing: If you want it your way, it will help you understand the digitizing process, as this will help you design the custom embroidery you want. Images and artwork can be turned into digitized files tailored specifically for embroidery by determining the type of stitches, colors, and other key attributes, all of which fall under digitizing. This task is not easy; it requires a lot of dedication and understanding of the relevant design software or focused digitizing software.

- Design Libraries: Explore and download ready-made embroidery artwork from various online marketplaces and design libraries. Such online stores carry designs for specific purposes, styles, and themes. One thing to consider is whether the designs are in file formats compatible with your embroidery machine.

This immediately means that when engaging in the importing and designing processes, one can express themselves in ways that are unique to them and may not have been possible with such embroidery projects. Seek out stores, materials, and methods to enlarge the possibilities for showcasing creativity.

Why Choose a Multi-Needle Embroidery Machine?

A multi-need embroidery machine is far better than embroidery machines with a single needle due to its countless advantages. Listed below are some of the reasons you should consider investing in a multi-needle machine, which is an upgrade:

- Efficiency and Time-saving: Multi-thread embroidery machines make embroidery complicated or multi-color designs easy. You can thread all colors simultaneously, reducing the need for constant thread changing, which is quite time and effort-savvy.

- Versatility: Multi-needle machines can make intricate designs by holding multiple strands of thread together, which helps create professional results without constantly re-threading the machine.

- Expanded Design Options: Many multi-need machines are already equipped with several shapes, and they can also take custom shapes to expand the range of designs you can create. You can play around with exploiting many styles, themes, and techniques.

- Suitable for Commercial Use: For owners who plan to run a commercial embroidery business, getting a multi-need machine is not just recommended but essential. It boasts incredible speed and versatility, which are useful for bulk operations, producing large quantities to please a large customer base.

- Ease of Use: Although advanced features allow for more creativity, multi-needle machines are designed with the average beginner in mind and are user-friendly for all embroidering fans. Built-in tutorials and direct contacts help all embroiderers achieve smooth stitching without interruptions.

Purchasing a multi-need embroidery machine will possibly enhance your work in terms of creativity and efficiency, and you will enjoy a host of possibilities. For enthusiasts or anyone looking to own a successful embroidery venture, it is useful to have a multi-need machine, which will help broaden the scope of one’s embroidery art skills.

Benefits of a Multi-Needle Machine

If you enjoy embroidery and have contemplated investing in a multi-needle machine, let me say that it might be one of the best decisions for your embroidery projects. There are a host of advantages that multi-needle machines give you, and here they are:

- Increased Efficiency and Speed: One of the great things about such a machine is that it has numerous needles, which means it can have different colors set up simultaneously, and therefore, you don’t have to change the thread as much. This makes your stitching faster, and your projects can be finished much quicker, saving time and effort.

- Enhanced Options for Design: These machines have better features, such as bigger areas for massive and complex embroideries, and they also allow you to get creative and embroider more than before while using the bigger area. You’re no longer constrained and can take your needlework to the next level.

- Results that are of Professional Quality: Because each needle works separately on the project, the machines can produce embroidery that is on a professional level every single time while maintaining consistent quality throughout the design. The result is that your embroidered projects look incredibly professional and exude sophistication.

- Easy to Use: Even less experienced embroiderers should have no trouble getting the hang of multi-needle machines equipped with built-in tutorials and simple controls. Focus on your embroidery designs and let the machines do the work, as they are specially made to provide a pleasant experience for users.

Thanks to using a multi-needle machine, regardless of whether you’re a hobbyist or want to start a professional embroidery business, you can enhance your embroidery projects, save time, and broaden your scope of creativity. It is an investment you won’t regret, and it will take your skills in embroidery to the next level.

Comparing Needle Embroidery Machines

Selecting the appropriate needle painting machine for your operations requires evaluating multiple factors. Let’s discuss the features you should look for when you are trying to make a comparison of different machines:

- Number of Needles:

- The first aspect is the number of needles in the machine, which determines how many different thread colors the machine can use simultaneously.

- Make sure to get machines with a suitable number of needles depending on the count and variety of embroidery projects you might have in the future.

- Embroidery Area:

- The embroidery area indicates the maximum physical space that can be designed or embroidered to create embroidery designs.

- Check the size of the designs you usually create and look for a machine that provides an adequate embroidery area for them.

- Built-in Designs and Fonts:

- Review the available designs and fonts built into the machine and check the center’s range and variety.

- The machine should contain enough designs related to what you want to create.

- Stitching Speed:

- Another factor to consider during this evaluation is stitching speed, which measures how fast an embroidery design can be worked on.

- Evaluate the speed demand of your projects and ensure the machine has a desirable stitching speed for efficient production.

- Ease of Use:

- Lastly, consider how user-friendly the machine is by looking at its interface, buttons, and navigation system functions.

- Find the intuitive controls and instructions so your embroidery experience is pleasant and easy.

- Connectivity and Software Compatibility:

- Look at the machine. Can it be connected to external devices like USB flash drives or Wi-Fi networks to import and share designs?

- It is advisable to check border-to-border compatibility with any embroidery software you currently use or plan to use later.

Considering these factors and pointing to the various needle embroidery machines based on their relevant technical specifications, features, and ease of use, you can decide to align with your cut embroidery targets and ambitious dreams. They do remember every machine has its advantages and disadvantages, so I am considering a set of priorities based on your needs, which will aid in evaluating the wide range of solutions available in the market.

What Makes the Brother PE800 Embroidery Machine Stand Out?

The Brother PE800 Embroidery Machine stands out because it has some interesting features and functions. Below are some major reasons this machine is so popular among embroidery lovers.

- Wide scope for embroidery: The generous size of the PE800 enables the user to extend their creativity by allowing monogram embroidery, quilting, and large designs and decorations. This wider working area gives the users relative comfort as they can visualize and sketch the designs without straining.

- Simple to use: The PE800’s intuitive and easy-to-use interface simplifies the embroidery process. The machine has been designed with controls and functions that are very easy to use, allowing users to set the machine up and switch between settings and options with relative ease.

- More design: The Brother PE800 application has a variety of built-in designs and fonts, giving users an array of creative options. Furthermore, it has a USB port, which allows users to upload their designs and work on projects in their style.

- Other editing features: This embroidery machine includes altering the size, rotating, and bending the design forward or backward. Embroidering can always ensure that whatever they design can be changed to fit their design, which makes every single embroidery unique.

The PE800 embroidery machine offers reliable performance consistency. Its reliable structure allows it to withstand heavy use and deliver consistent results. This is achieved with the help of high-quality stitching machines, which help control thread tension for professional embroidery.

In conclusion of our review, the Brother PE800 Embroidery Machine is also distinguished by its comprehensive sewing field, intuitive navigation panel, wide graphics base, flexible editing features, and consistent performance characteristics. So, whether you are an embroidery veteran or a novice, this has all the tools and capabilities you would need for great embroidery.

Features of the Brother PE800

In this regard, Brotherhood’s PE800 Embroidery Machine has been the industry favorite for such embroidery segments because it gives embroidery enthusiasts and layerers like me control almost every usage aspect. Let me highlight some of its important specs.

- Huge Embroidery Space: PE800 accommodates monogramming, quilting, and creating large-scale divergent, if not larger, designs and embellishments in the form of a robust embroidery space. Such large-scale embroidery items may be garments or home decor items.

- 138 Built-in Designs: The floral, seasonal, and decorative designs embroidered and layered in the PE800 are innumerable and readily editable on the panel or screen. These designs have been featured in numerous incorporated designs because they will give the user an unending edifying experience and flexibility that seemingly combines imbalance with harmony.

- Compatible with Different Materials: The PE800 can be used with many fabrics, such as silk, lace, denim, and linen. By pushing and breaking boundaries, the user will be able to have a variety of textures while creating unparalleled creativity.

To summarize, the Brother PE800 Embroidery Machine is easy to use, has a large working area for embroidery, has a wide selection of designs built into its memory, and can be used on various materials. The PE800 is a perfect machine for hobbyists or ardent embroidery buffs looking to develop their creative ideas.

Exploring the 138 Built-in Designs

The Brother PE800 Embroidery Machine has a perfect combination of built-in designs up to 138. These designs include floral embroidery patterns and those of animals, which can be used for different embroidery works. So, whether you’re stitching clothes, creating custom-made products, or updating your decorative items, the built-in features help you choose the perfect elements. Let’s go through some additional elements along with those mentioned above:

- Design Types: The built-in embroidery designs include nature, holidays, monograms, etc. This makes selecting an ideal embroidery design easier because it puts most of your choices in one place.

- Adjustment & Scalability: The designs can be made smaller or larger depending on the requirements, which attracts those looking for more precision and adaptability. Different items will need custom dimensions, and these designs provide just that.

- Stitch Density and Complexity: Due to their varying density, stitch features can also be bulky or smaller. This allows for greater customization in the stitching of the design, helping you achieve your desired outcome.

- Design Editing and Customization: Its built-in designs can be edited using options such as resizing, rotating, and mirroring as components of the customization process. This means custom designs can be created according to your specifications or imagination.

You only need the Brother PE800 and a ready-made design to get going on your embroidery projects because this machine has many built-in designs and allows you to adapt them. These designs can be part of your occupation whether as a professional or as a hobby, they are an excellent place to start for your creativity.

Why It’s a Top Choice for Embroidery Enthusiasts

The Brother PE800 has emerged as one of the best choices for those into embroidery owing to its impressive features and flexibility. Here’s why it is well-rated among the embroidery users of the PE800.

- Plenty of Built-in Embroidery Designs: The Brother PE800 introduces a series of built-in designs that allow you to push your creative limits with plenty of options. The designs offered include artistic monograms and many more creative patterns, and the built-in ones enable you to start your embroidery creation immediately.

- Possibilities of Modification: The Brother PE800 lets you modify and personalize the built-in designs, ensuring you create something special for all designs. This means you can resize, move, or rearrange the designs you include, making sure you have custom embroidery pieces.

- Quality Impressive Results: The Brother PE800 allows accurate embroidery stitches for the best results. The pE800 has top-of-the-line tech and top-shelf components that allow users to create beautiful, detailed images through embroidery. This means there is attention to detail where the embroidery is done, translating to detailed and amazing work on various fabrics and clothing.

- Intuitive Control Panel: An easy-to-use control panel makes all the designs and machine settings easy to choose and use. You wouldn’t need to waste time figuring out how to use the PE800 as the interface is very user-friendly; having an LCD touch screen helps you go through all the designs, embroidery settings, and options to preview the designs before finalization.

- Custom Speed for Embroidery Efficiency—The Brother PE800 has an adjustable embroidery speed that you can set based on your needs for the particular project. Whether you desire a controlled speed or get the work done in a limited time, this machine gives you the flexibility to serve your needs.

- Looking for a trusted brand? Brother has been able to establish itself as a force in the embroidery market owing to its quality when it comes to reliability for Brother. With history written in stone and reliable faith in the future, the Brother PE800 is surrounded by orders, good reviews, and customer service.

When choosing an embroidery machine, it is critical to evaluate aspects like available patterns and designs, embroidery swivel capability, the machine’s accuracy, usability, and the brand itself. These features make the Brother PE800 the right machine for embroidery lovers who are at the beginning of their creative path and want to ensure the highest possible results with the least effort.

How to Start a Commercial Embroidery Business with the Right Machine?

Starting a commercial embroidery enterprise requires calm and sober consideration and thought. The choice of the machine is perhaps the most important step to take. Here are some short replies to frequently asked questions when deciding on the best embroidery machine for custom designs:

- Q: How do I select the best embroidery machine for custom designs?

- A: When buying an embroidery machine for custom designs, consider the machine’s configuration: sections of different stitches, designs, estimations and requirements, fluency, and brand image. Ensure that the machine addresses your business needs concerning speed, strength, and versatility with fabric and thread types.

- Q: How can I improve productivity in my commercial embroidery business?

- A: Enhancing productivity in a commercial embroidery business starts with acquiring a fast embroidery machine. Thus, machines that can stitch much more quickly without losing concentration and quality would be ideal. Moreover, improving the business’s general efficiency can be achieved by optimizing processes, arranging the designs and threads, and applying efficient project management.

- Q: What are some pointers for nailing embroidery projects effectively?

- A: Effective project management is crucial for a successful embroidery business. Define the scope clearly, set appropriate expectations about due dates, and report on progress so that the client’s needs are known. Employ the appropriate project management tools and techniques to gain control over the order, inventory, and production flow. Assess and control your processes so that efficiency and customer feedback are increased.

With the right commercial embroidery machine and project management skills, one can easily build a solid base for their embroidery company and design attractive tailor-made engravings to satisfy their customers.

Choosing the Right Commercial Embroidery Machine

To choose the best embroidery machine for custom designs, good research should be conducted, and several factors should be evaluated, including the assessment of specific business orientation, production capacity, the purpose of making the articles, etc. Evaluate the various models and the equipment manufacturers to settle for one that meets your price range, requirements, and production capabilities. Moreover, the device’s construction strength and operation complexity should be considered to optimize productivity in the long run. Additionally, take note of customer ratings on the machines, recommendations from the industry, and discussions with experts in Machines for Embroidery. As a business operator, you should be on the lookout for directional and feasible machines that will, in turn, meet the customers’ expectations. A well-designed, efficient machine will meet the desired maximum production output.

Understanding Embroidery Speed for Business Efficiency

The speed of embroidery machines is one of the major determinants of the efficiency and productivity of your embroidery firm since the speed with which an embroidery machine can carry out stitching directly reflects the time taken to complete an order to the client’s specifications. When selecting an embroidery machine for custom projects, various considerations concerning embroidery speed should be put in mind:

- Stitch Per Minute (SPM): An SPM is a scaling measure called stitches per minute. SPM is simply the number of stitches an embroidery machine processes in a single minute within its working cycle. The greater the SPM, the quicker the production processes are completed within a given time, hence greater efficacy in completing orders. Although this may be noted, it is paramount to allow for a reduction in embroidery speed when the complexity of embroidery increases to maintain fine detail in the finished product.

- Finer Speed Control: Many embroidery machines are fitted with a finer speed control mechanism thanks to modern technology. This mechanism allows these machines to alter their sewing or stitching speeds depending on the stitch sequence or even the type of fabric being used. This capability is important for every project regarding flexibility and uniformity in quality standards.

- Time Estimation: While researching the most suitable embroidery machines for your business, many manufacturers will estimate how long it will take to produce certain designs or stitches. These estimates inform you of the time and resources required to execute certain projects regardless of scope or size.

When settling on an embroidery machine, consider customer reviews and suggestions from other embroidery professionals and experts in this industry. Also, consider your business requirements, possible embroidered designs, and expected output rates. Ensuring that embroidery speeds, quality, and ease of use are reasonably well integrated is a key consideration in maximizing the efficiency and productivity of operations.

Also, remember that the embroidery machine speed may differ slightly between different brands and models. Therefore, it’s best to check the manufacturer’s guidelines for the embroidery speed and relevant technical parameters.

Tips for Managing Embroidery Projects Effectively

Over the years, I have developed a deep understanding of embroidery projects and how essential it is to be well organized. The following are some steps that will aid in managing embroidery projects:

- Compile Policies: Before commencing any embroidery project, write down the project’s conception by explaining the design, supervised thread colors, and stitches. Thumbnails of supplies that include needles, threads, and stabilizers should be handy by making ready a workstation.

- Automation and Efficiency: Automation and workflow efficiency can help minimize time. Start by preparing the material for threads of the right size and hoop threads, then the requisite design files. Before the preparation, a test should be done to ensure all designs are high-quality with a sample fabric.

- Project Management: Multiembroidery projects justify the requirement of realistic set time frames and deadlines. Time management is vital, dividing time into segments that accommodate design digitizations, machine setups, and stitching.

- Serviceable Condition: Regularly care for the embroidery machine by performing scheduled stitches to ensure minimal disruption and optimal performance. Per the manufacturer, instructions on oiling and changing devices should be simplified.

- Assurance: An examined embroidered part should be scrutinized for flaws or wrongs. For a professional presentation, loose ends should be properly addressed, and additional support of embeds or any other needed fix-ups should be provided.

- Communication and Collaboration: if you are doing embroidery tasks for clients or collaborating in a team setting, it is advisable to communicate with them to understand their needs and expectations. Engage clients or team members seeking a change or participating in any feedback on the designs.

When answering the question of the best embroidery machine for custom designs, several considerations must be resolved, including the available stitching area, ease of operation, the size of the hoop, and the number of preset designs. Further, technical features such as the speed of embroidery, measured in stitches per minute (SPM), differ from one machine to another within the same brand and model. In such circumstances, it is wise to use manufacturers’ data for up-to-date and accurate information on these technical features.

References

Frequently Asked Questions (FAQ)

Q: What should I consider when choosing the best embroidery machine for custom designs?

A: When choosing the best embroidery machine for custom designs, consider the embroidery area, ease of use, hoop size, and the variety of built-in designs. Also, look for features like automatic thread cutting and embroidery digitizing capabilities to bring custom designs to life.

Q: How does a sewing and embroidery machine differ from a regular one?

A: A sewing and embroidery machine combines the functions of a regular sewing machine with machine embroidery capabilities. It allows users to create intricate embroidery designs and complete sewing projects using a single device, often featuring various built-in designs and fonts.

Q: What are the top 10 embroidery machines for custom design enthusiasts?

A: The top 10 embroidery machines for custom design enthusiasts typically include models offering spacious embroidery areas, a selection of built-in designs, and high-quality embroidery results. Specific models may vary based on personal preferences and budget.

Q: Can I import my designs into an embroidery machine?

A: Many modern embroidery machines allow you to import your designs. This feature is often supported through USB connections or embroidery software, enabling you to create custom embroidery projects.

Q: What is the importance of maximum embroidery size in a machine?

A: The maximum embroidery size determines the most significant design you can create in a single hooping. A larger embroidery area allows for more complex and spacious designs, which are crucial for custom embroidery projects.

Q: Are there beginner-friendly sewing and embroidery combination machines?

A: Many sewing and embroidery combination machines are designed with beginners in mind. These machines often feature user-friendly interfaces, automatic thread functions, and built-in tutorials to help new embroidery users get started.

Q: How do I find the best embroidery machine for my needs?

A: To find the best embroidery machine for your needs, consider what features are most important for your projects, such as the embroidery field size, the variety of designs and fonts available, and the machine’s ease of use. Reading reviews and comparing top models can also help make an informed decision.

Q: What is machine embroidery, and why is it popular among crafters?

A: Machine embroidery is the process of using a sewing and embroidery machine to create designs on fabric. It is popular among crafters because it allows intricate, high-quality embroidery work to be easily replicated, making it ideal for custom designs and larger projects.

Q: How do automatic thread features enhance the embroidery process?

A: Automatic thread features enhance the embroidery process by reducing manual thread handling, ensuring precise cutting, and minimizing thread breakage. This leads to smoother operation, less downtime, and better overall stitching results.

Q: Where can I find designs online for my embroidery projects?

A: You can find designs online for your embroidery projects on various websites that offer embroidery patterns and files. Many platforms allow you to purchase or download free designs to import into your embroidery machine.