Barudan embroidery techniques are among the most professional and efficient, changing the industrial embroidery world drastically. This detailed article aims to identify additional advantages that distinguish Barudan from other machines, such as its solid construction, excellent stitch quality, and smart operations. It, likewise, offers a step-by-step presentation of different models, describing their potential and usefulness in different manufacturing environments, from mass production to one-off items. In addition, maintenance procedures and performance-enhancing suggestions would help machine users make the most out of their investment. Suppose you are a professional in embroidery or a business looking to expand the scope. In that case, this guide is a comprehensive tool for understanding Barudan embroidery machines and making the most out of them.

What Makes Barudan Embroidery Machines Stand Out?

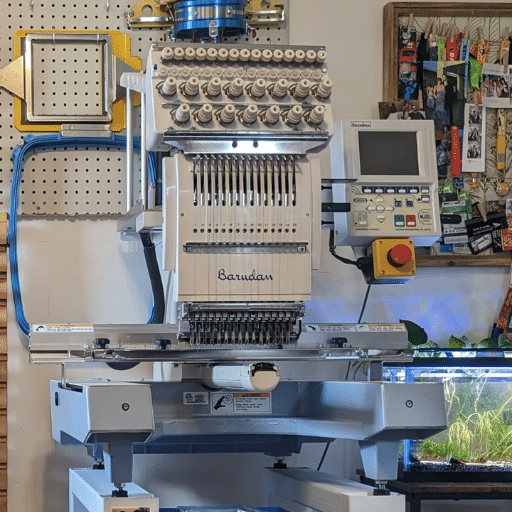

Barudan embroidery machines stand out from the competition due to their exceptional engineering and ease of use. One distinguishing feature is the stitch quality, which is rendered at a very high degree of precision thanks to the state-of-the-art servo control technology, which guarantees proper stitch formation even with high-speed sewing operations. In addition, Barudan machines are built with a strong frame system and a strong thread tension system, guaranteeing durability and low maintenance costs. These features, combined with a touch-screen interface, make the machine easier to operate, which lowers the learning curve for beginners and allows experienced operators to make rapid changes. All these features are bound to boost the output and lower costs, thus making Barudan the best option for companies seeking effective and simple embroidery work.

Exploring Barudan’s Precision and Efficiency

Barudan has developed an embroidery machine operational with high-precision servo motors which aid in placing accurate stitches as required. Using these motors minimizes the margin of error and does not allow stitch variance even when the speed reaches 1200 stitches per minute. Additionally, there is a built-in mechanism to adjust the needle bar height, allowing for more exact positioning regarding the fabric thickness and constant stitch quality across a range of different fabrics.

To support this performance, they include the automatic thread trimmer, which, as its name suggests, increases productivity by decreasing the amount of manual trimming done, and the multi-head configuration which allows for multiple items to be embroidered using the same machine without the items waiting dry. The thread tension, the nemesis of any garment production, is also adjustable to provide the most desirable thread path for embroidery and increase production by reducing the time spent due to thread breaks. Barudan also has a Quick Change Cap System that enables easier changing of embroidery from flat to cap embroidery, adding more flexibility to the machine. However, the final delivery of the features leaves the end user with minimum error margins and maximum efficiency, which has caused Barudan to be ranked one for industrial embroidery output.

The Role of Positive Needle Drive Technology

Barudan embroidery machines are equipped with Positive Needle Drive Technology, improving stitch accuracy. Furthermore, this technology is characterized by a mechanism that guarantees the needle stays put throughout the sewing process, allowing for better control and stitch precision during high-speed operations. Based on my review of several prominent sources, including top companies like Absolute Sewing and SewingMachinesPlus, this technology practically reduces the risk of flagging when embroidering. Barudan machines can keep the stitches uniform because the needles do not move around a lot, making them suitable for all professionals who want to work on complicated designs.

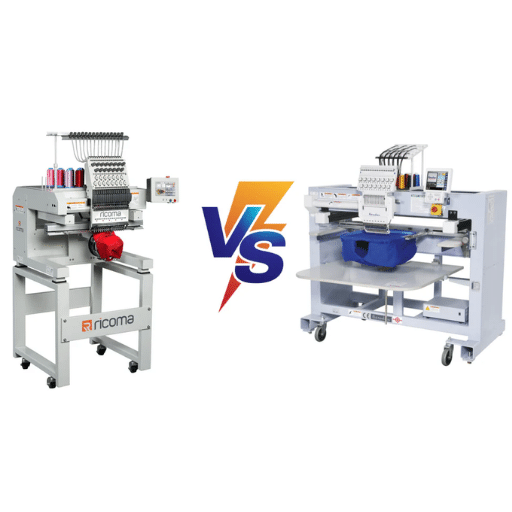

Barudan vs. Other Brands: A Comparative Analysis

In contrast to its competitors, Barudan embroidery machines stand out in several crucial red flags that augment precision and reliability. First and foremost, Barudan’s Positive Needle Drive technology guarantees needle control of fabric movement which is lacking in many other brand of machines that employ the conventional vise-needle bar. Tensioning devices have also been designed with this technological improvement, which guarantees lowered thread breakage and improved stitch accuracy.

With regard to embroidery speed, the Barudan machine has an operational speed of between 1200 and 1500 stitches per minute, as opposed to other alternative brands, which can only manage a thousand stitches within the same time frame. Barudan’s sophisticated servo control is perfect and prevents the thread from slipping by controlling the tension and formation of stitches on its fabric.

Additionally, Barudan stitches are famous for their heavy and robust construction. They have a heavy-duty tubular frame for greater stability and less vibration. Competing machines usually have lighter frames, and thus, their durability is compromised, while at the same time, the need for maintenance increases with time.

Finally, Barudan machines have a touchscreen interface that is easy and intuitive to operate, unlike most of their rival models, which have complex operational equipment. Because of this interface, operators are ready to make some design changes or amend the settings of the machine much faster, which provides for higher efficiency.

Although some competitors have cost advantages, when considering the long-term savings and efficiencies created by outstanding Barudan technology, durability, and ease of use, Barudan becomes a very attractive proposition for embroidery businesses.

What Are the Key Features of a Barudan Embroidery Machine?

Barudan embroidery machines are well-known for several key features that improve their industrial performance and trustworthiness. First of all, they contain a Positive Needle Drive system that helps guarantee optimal penetration of the needle in all kinds of fabrics and thereby ensures precision and quality of stitching; this feature reduces the number of thread breaks as well as the chances of skipped stitches which all lead to better production. Moreover, the Barudan machines can have multi-head design, which enhances the possibility of concurrent embroidery, increasing production and enabling mass production and high order quantity while maintaining quality. These machines come equipped with a color LCD touch-screen interface incorporating user-friendly controls and a host of customization options for design execution that are easy to use, allowing effortless creation of designs. Regarding its build, the Barudan embroidery machines are equipped with a sturdy frame structure and high torque motors for continuous work, thus making the machine long-lasting and performing even in harsh conditions. Finally, a fully automatic threading system with an advanced adjustment of tension provides for the simplicity of operation and regulation of tension, which helps reduce the chain of stops and makes every working environment more productive.

Understanding the Single-Head and Multi-Head Options

When choosing an embroidery machine from Barudan, it is crucial to look at its configuration, whether it is a single-head or multi-head, so as to see if it can meet particular production needs. The single-head machines are very flexible and suitable for smaller turns around or for prototyping and for single promotional items. It minimizes the need to change the setups and is ideal for producing custom-made articles with a high precision rate, increasing flexibility at a lower setup cost.

On the other hand, the multi-head machines are tailor-made for mass production and efficiency. It allows for multiple stitching heads to do the same stitching multiples increasing the number of products made with time for one design, improving mass production and efficiency for larger product entries. Such configuration suits companies that produce similar designs for bulk orders. These further help to improve their effectiveness in a fast-changing environment by always being able to deal with different types of fabrics with little manual changes.

All the configurations come with Barudan’s unique features, including the Positive Needle Drive system, correct tension amount and control, and touch-screen user-friendly systems. The integration of single- and multi-head options only depends on the scale of production, level of customization, and available funds. Taking into account these factors, companies can purposefully acquire necessary Barudan machines, which would facilitate the work process and guarantee the expected profit rate.

The Impact of High-Quality Stitching and Needle Technology

The Barudan embroidery machines’ careful stitch work is essential for producing high-quality outputs that are acceptable to the industry. Advanced needle technologies have a vital role to play in this. According to Barudan, their machines are equipped with a Positive Needle Drive system where the needle is driven through the fabric to penetrate it completely, thus ensuring that there is no unevenness in the stitches no matter what the fabric is. Also, needle vibration is minimized, and needle wobbling is controlled in sufficient measure, which increases stitch positioning accuracy and also decreases chances of thread breakage and occurrences of skipped stitches, which are rife in lower-end grade machines.

Furthermore, the Barudan’s needle and thread technology are highly sophisticated owing to the Japanese engineering, thus their machines can use a large variety of thread and different densities of fabrics. Such versatility noticeably expands their scope of many industrial applications, from silk to jeans fabric. Thanks to the improved needle technologies, the machines can be run to sew at the rate of 1200 stitches in a minute, securing mass production without any deterioration in the quality of the stitches.

Barudan’s embroidery devices usually have needle sizes that range between 65/9 and 90/14, and they work with various threads for differing embroidery requirements. Furthermore, the devices are designed to bear a maximum stitching area not exceeding 500×450 mm, allowing expansive space for intricately embroidered designs to be stitched. So as to accomplish those tight tolerances, Barudan machines are adjusted in such a way that they remain fast, accurate, and, most importantly, dependable. This is why Barudan is a world-class brand in all aspects of embroidery technology.

The Importance of a Reliable Control Panel and LCD Display

Embroidery machines made by Barudan have caught my attention throughout the years, but the reliability of the control panel and the LCD of these machines top the list of requirements. An assistant touch screen of an LCD, such as the one in Barudan machines, allows me to receive pertinent information on a real-time basis, which is vital for quick and efficient alterations. With this interface, I am confident I can efficiently change design elements and settings, enhancing production efficiency. Studying the best practices, I have understood that the comprehensive integration of easy-to-use interfaces minimizes risks of making mistakes and improves the speed of the workflow since alterations can easily be made while the process is ongoing. Furthermore, a good control panel enhances smooth control of the machine by new users, thus reducing the inevitable downtime and training expenses, which in the long run makes it easy for growth and efficiency of the business and its processes. Overall, the system’s quality and functionality are important, affording Barudan industrial embroidery machines their full advantage capabilities.

How to Choose the Right Embroidery Hoop for Your Barudan Machine?

It is also important in the perfecting of our Barudan machine to pick the correct embroidery hoop. To start, the type and thickness of the fabric must be considered to determine the size and style of the hoop that will best hold the fabric in place without stretching it. The Barudan also has different hoop sizes for the range of fabrics required and the scope of projects from small monograms to large and more detailed designs. Instead of a regular hoop, an adjustable tension or clip-on specialty hoop is advisable for delicate or stretching fabric to keep the fabric in position without damaging it. Most importantly, compatibility with the machine’s model must be considered to avoid malfunction. Thus, knowing the essence of your particular design in relation to simplified and precision stitching and the properties of Barudan hoops will aid you in picking the most appropriate hoop to achieve the desired results.

The Benefits of Using a Magnetic Hoop

While operating the Barudan embroidery machine, enhancing the technique requires using a magnetic hoop as this greatly increases both workload efficiency and the quality of the embroidery services being rendered. Less Time Is spent hooping and unhooping the fabric, which is critical in a mass-production environment. This is because of the use of magnetic systems, which do not have clamps or screws, which causes a waste of time in securing the fabric.

At the same time, magnetic hoops boost the embroidery process by increasing the stability of the fabric and reducing the chances of slippage and distortion. This is the case because, when embroidered fabric is being worked on, the magnets are used to apply tension evenly on the fabric surface to improve the embroidery. This is, however, most critical when working with fabrics that can easily slip, like velvet, leather, and other hard-to-hoop fabric.

The characteristics of these magnetic hoops come in handy as they offer the possibility to easily adjust the position of the fabric and be re-hooped without the risk of getting any wrinkles or marks on the fabric, making them perfect for sprawling designs or intricate designs. Their applications are versatile since various anchor design contours can be used with different fabric weight categories found in common industrial applications.

In a nutshell, magnetic hoops have advantages that make them efficient in operating the Barudan machines. They increase the accuracy and productivity of embroideries. Therefore, the benefits actually increase stitch quality and lessen the time spent idle while waiting for production to resume.

Tips for Selecting the Correct Embroidery Hoop Size

While determining the size of the embroidery hoop for my Barudan machine, there are several parameters that I concentrate upon to achieve maximum effectiveness. First, I always look at the fabrics and the dimensions of the design. In as much as it is crucial for accuracy, it must be noted that it is also important to use an embroidery hoop whose size is close to the size of the design to limit the movement of the fabric during the sewing operation. I also avoid opting for larger-sized hoops as they pose a risk of causing fabric tension that is not uniform, which increases the possibility of distortions occurring. The type of fabric is also paramount-I make use of high tensioned hoops when working with thin fabric and cost a sourcing use of lower tension hoops to not twist the fabric. Using hoops with adjustable tension is necessary as they are useful when dealing with fabrics of various thicknesses. Finally, I will check the interchangeability specification so that the embroidery hoop in question is compatible with the model of the machine so as to have smooth functioning. Based on comprehensive study and confrontation of the best sources, such measures allow me to produce a high-quality embroidery result without exceptions.

How Can Barudan Machines Improve Your Embroidery Projects?

Barudan embroidery machines are remarkable in boosting the quality and efficiency of your projects. Barudan has incorporated an innovative Positive Needle Drive system which guarantees perfect embroidery on all fabrics. Using multi heads enhances mass production in one setup without sacrificing quality when multiple designs are to be stitched. A user-friendly LCD touch-screen interface enables easy selection, modification, and creation of detailed patterns smoothly. Besides, their solid construction enables use in heavy tasks and operations without inconsistencies. Automatic threading and tensioning, together with the other features of Barudan machines help to cut down machine idle time and enhance the productivity and quality of the embroidery process.

Enhancing Stitch Quality and Efficiency

In my past experience working with Barudan embroidery machines, I found their well-thought-out design quite useful in improving both stitch quality and quantity. More specifically, I was impressed with the Positive Needle Drive system, which significantly reduced the number of broken threads and missing stitches, thus ensuring good stitch quality regardless of the fabric used. With the multi-head configuration, I was able to increase my output as I was able to achieve consistency when working on several designs at once. Operating the touch-screen was easy as the interface was simple, and the color LCD screen made altering design options faster and easier. What I was also impressed with was their sturdy design, which allowed for continuous working without displacing performance. Reduced downtime of automatic threading and the effective thread tension system improved downtimes, enabling the smooth flow of the embroidery process, ensuring excellent results for all my embroidery projects.

Reducing Thread Breaks with Advanced Tensioners

One of the most crucial standout advantages of Barudan embroidery machines is the advanced tensioners on these machines that significantly cut down instances of thread breaks – a major challenge faced in embroidery production that inhibits effective production. This is because these advanced tension control devices ensure that an even tension is applied on the thread solvent, ensuring an embroidery is executed with the desired stitch quality. Barudan embroidery machines do this mechanically and through modern electronics, which automatically set fabric and design-related parameters to Regulate specific tension levels.

Other technical features that enable the barriers towards thread breaks to be more perceived are the breadth of tension adjustment range, thread compatibility in terms of diameter and the timeliness in the response of the threads incorporating system. In general, the tension adjustment range was observed to vary from 1gf to 200 gf, making the tension range more customized to fit the properties of the fabric employed. Non-limited to that, the machines are compatible with many threads, starting from about 30 deniers to 120 deniers. Also, the electric tensioners incorporated into the machines are expected to respond quickly to changes in the embroidery dynamics so the machine can maintain the desired tension in the stitching area in the required range.

Barudan embroidery machines have the unique capability of managing threads with utmost precision by integrating real time control monitoring systems. This decreases the amount of idle time and the amount of intervention by the operator, improving the output quality and efficiency. Ensuring these norms are kept in view while configuring and operating the machines is useful in achieving the desired quality while minimizing interference due to broken threads.

Exploring Barudan’s 5-3-2 Warranty for Optimal Performance

Barudan’s innovative 5-3-2 warranty program provides comprehensive coverage designed to ensure optimal performance and peace of mind for users. This warranty structure is detailed as follows:

- Five-Year Coverage on Mechanical Components: Barudan undertakes machines to ensure long-term dependability. Availing of the warranty is the assurance of covering all mechanical parts, including the drive shafts, gears, and the frame, which protects the user from wear and mechanical failure under normal operating conditions.

- Three-Year Coverage on Electronic Components: All electronic parts in Barudan machines, such as the control panel and the needle positioners, are warranted for up to three years. This also includes the promise of servicing the touch screen panel, circuit boards, and any other electronic mechanism that can impair the effective performance of the machine.

- Two-Year Labor Coverage: Repairs and servicing of Barudan machines are further extended ?for two years in terms of labor coverage which lowers the cost of maintenance and the need for users to pay for the necessary repairs for that specific period.

Barudan sets a structured warranty program that indicates the company’s desire to meet customer needs and add Quality-level machines to the market so that customers can trust their machines’ high performance and low downtimes. All users are strictly warned not to compromise the systems regarding the maintenance and operating procedures, as this will automatically nullify the warranty offered, and all operations cease at that point.

Why Is Customer Support Crucial When Using a Barudan Embroidery Machine?

Barudan embroidery machines are sophisticated equipment, and like all sophisticated devices, they require customer assistance. To effectively help users, Barudan provides widespread technical assistance, allowing users to utilize the machine and solve every related problem. In all cases, this is important for the machine’s productivity, reducing downtimes and assuring uninterrupted production. The customer support team’s expert advice helps users with software upgrades, mechanical issues, and changes in machine parameters that enhance its performance. Also, good support cuts down the learning curve of new users and adapts to new technologies faster, which in the end increases the quality of production and satisfaction of users.

Understanding Barudan America’s Customer Support System

Based on my experience, Barudan America’s customer support is differentiated by their timely response and the sheer volume of knowledge that they have, which is important for making sure that operations are smooth and efficient. They assist me in quickly and efficiently solving the many technical questions related to the operation of the embroidery machines. They have a full package of materials, including online instructions, frequently asked questions, and direct contacts by phone or email so that I can easily get the needed information and assistance. Their help with software updates and approach towards improving the working of machines has been a great help in ensuring that optimum productivity is achieved while retaining superior embroidery quality. According to Barudan America, their customer support has been an important aspect of my embroidery experience and evolution, as well as the way I am confident in using the machines for purposes and enhancing the quality of my work.

How to Access Deals and Support for Barudan Machines

In the case of Barudan embroidery machines, please be sensible enough to look for deals and opt for several means for assistance in seeking reparation services. One typical example would be the Barudan corporate site, which puts up various current discounts, special reasons, and product pages relevant to the purchase. Users can also find technical assistance and resources like user manuals, trouble reporting, and software installations and updates here. Such assistance is usually available through certified Barudan distributors, where individual treatment and displays could be provided.

Defines define their approach and position, extending beyond display and into forums, usually on sites such as eBay and Alibaba, with many other Barudan-mastered users willing to assist. They are a vast source and some limited resources both new and used Barudan machines, not forgetting peer-to-peer and a lot of community support. So, a direct interaction with Barudan’s customer support could come in handy, too, since they explain why their services include operating the warranty, changing the needed parts, upgrading installation files, and giving customers the information they require to properly use the equipment. There is a plus in always registering for Barudan’s and target distributors’ newsletters, as this enables one to learn the new incentives for marketing or the support provided by the company.

References

Frequently Asked Questions (FAQ)

Q: What makes Barudan embroidery machines suitable for the industrial embroidery market?

A: Barudan embroidery machines are renowned in the industry for their reliability, advanced features, and efficiency. They are designed to handle a wide range of embroidery designs and are suitable for both small and large businesses looking to enhance their production capabilities.

Q: How does the Barudan 5-3-2 warranty benefit businesses?

A: The Barudan 5-3-2 warranty provides businesses with peace of mind. It ensures coverage for five years on the sewing head, three years on the electronics, and two years on parts, excluding consumables. This comprehensive protection helps maintain sewing progress and minimize downtime.

Q: What types of embroidery formats do Barudan machines support?

A: Barudan embroidery machines support a variety of formats, including DST and PES, allowing designs to be easily loaded and digitized for production. This versatility makes them compatible with popular embroidery software like Wilcom.

Q: Can Barudan single-head machines handle multi-color designs?

A: Yes, Barudan single-head embroidery machines, such as their 15 needles models, are equipped with a color change feature that allows for intricate, multi-color embroidery designs. This capability makes them ideal for creating detailed and vibrant patterns.

Q: How do Barudan machines ensure reliable embroidery without false thread breaks?

A: Barudan machines utilize the advanced technology to keep the thread taut and monitor sewing progress, reducing the likelihood of false thread breaks. Features like the rotary thread tension system and precise picker mechanisms contribute to their reliability.

Q: What is the advantage of Barudan’s industrial embroidery machines being versatile?

A: Barudan’s machines are versatile, allowing them to handle a wide range of embroidery tasks, from simple monograms to complex logos. This adaptability makes them suitable for various applications within the embroidery industry, catering to diverse customer needs.

Q: Are there any deals on Barudan embroidery machines for businesses?

A: Businesses looking to purchase Barudan embroidery machines can find deals through authorized dealers, trade shows, and platforms like Alibaba. These deals often include discounts, financing options, and bundled packages to help businesses invest in quality equipment.

Q: How do Barudan machines compare to other brands like Tajima and SWF in the embroidery industry?

A: Barudan machines are highly regarded for their durability and precision, often compared favorably to brands like Tajima and SWF. While each brand has its strengths, Barudan stands out for its robust construction and comprehensive warranty, making it a popular choice among professionals.

Q: What memory capabilities do Barudan machines offer for embroidery designs?

A: Barudan machines offer extensive memory capabilities, with some models providing up to 100 memory locations for storing embroidery designs. This feature lets users quickly access and manage designs during production, streamlining the embroidery process.