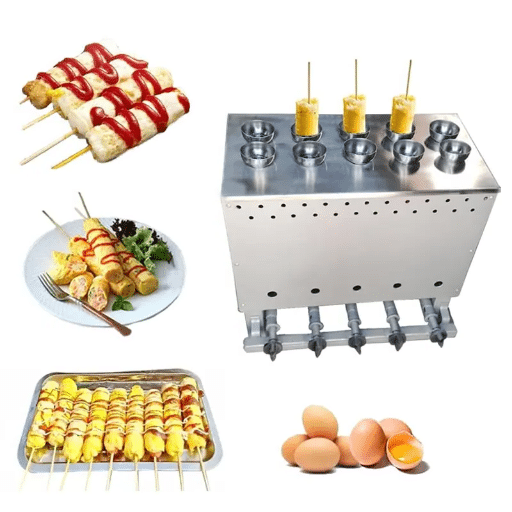

In today’s competitive culinary world, new devices and cooking methods that help to save time and inspire creativity in the kitchen are in great demand. This is how the Automatic Egg Roll Machine comes in play. This excellent appliance is built to facilitate the complicated and time-consuming procedure of preparing egg roll, hence enabling culinary practitioners to explore and reinvent traditional cooking methods. Apart from shortening the time required to prepare the meal this is a great piece of equipment that guarantees perfection in consistency every time the meal is made. Using the most advanced technology, the Automatic Egg Roll Machine overcomes the difficulties usually encountered by home and restaurant cooks, and offers a stress-free and reliable way of enhancing the cooking experience. This paper aims to engulf readers in the world of nutrition and the eatery industry through the devices of this kitchen appliance by revealing its features, advantages, and possible use in cooking.

What is an Egg Roll Machine and How Does It Work?

The Procedure of Making Egg Roll’s Step-by-Step Explanation

Making egg rolls is relatively easier with practice; however, it entails taking several structures of the whole egg roll and doing them accurately to get a perfect result in every making. Traditionally, this entails preparing the delicious filling of finely chopped vegetables, meats, or even seafood spiced with various seasonings to come up with mouth-watering tastes. The egg roll filling is then carefully placed onto a prepared egg roll wrapper, which is then rolled into a cylinder twenty-four. It is essential, therefore, to ensure that the edges of the wrapper do not remain open as spillage may be advisable during any cooking processes. once closed, the egg rolls are usually cooked by deep frying them till a golden brown crust is formed on the outside sealing the delicious filling within. The Automatic Egg Roll Machine lessens this multi-level activity such as filling distribution, wrapper folding, and sealing the egg roll by machine, lowering manual effort and enhancing optimal production of uniform and standard egg rolls every time.

Key Features of an Automatic Egg Roll Machine

Automatic Egg Roll Machines consist of various parts that have been constructed to prepare egg rolls effectively and uniformly. First, the filling hopper is an auxiliary device of the machine filled with the prepared filling. It is through it that filling, prepared for use is dispensed evenly on the wrapper in a suitable manner. After this, the filling flow is stopped and the wrapping device picks up and wraps the filling with the prepared fabric. This could imply that the unit may have adjustable arms or rollers in order to attend to different sizes of wrappers and to make sure that a perfect cylindrical wrapper is made. The other important part is the sealing device, which seals off the folded portions of the wrapper using a specific controlled force and temperature to ensure a leakproof envelope during the cooking process, which is heat-regulated. As some of the machines also have a frying section, it becomes possible for them to make the rolls with an even golden brown surface. All the components are systematically synchronized, facilitating the mass production of egg rolls, making them perfect and the standard quality.

Benefits Of Using Egg Roll Equipment In The Food Production Processes

One of the major operational advantages that come with the use of egg roll equipment in food production facilities are improved productivity, efficiency, and consistency. First, on the one hand, the automation of filling distribution, wrapping, and sealing, which were earlier more complex and handled by human labor, incurs a reduction in manpower costs by bringing down the manual intervention and dependence on skilled labor. This considerably reduces the time taken to produce the goods, and the output level is also high; hence,the manufacturers are strategic players in the market with lots of supplies. Apart from that, the use of machinery eliminates the chance of the product being of different sizes and shapes and even of various qualities, which is usually the case when human beings are dominating the production of the products. Also, egg roll equipment must consider hygiene requirements, hence ensuring that cleaning and other maintenance activities do not compromise the safety requirements of food products. Finally, the infusion of such machinery not only maximize the efficiency of the production line but also increases the scope of production as the producers can increase the capacity and variety of products with very little additional costs.

How to Choose the Right Egg Roll Maker for Your Needs?

Factors Consideration When Choosing a Roll Making Machine

There are various factors that I must take into account when it comes to the selection of a roll-making machine, such as productivity requirements, operational features, and cost-effectiveness. First, one must know the production capacity to avoid purchasing a machine that cannot meet volume requirements in terms of speed or quality. Next, the other evaluation criterion is in regard to the machine’s operational features, which include the ease and compatibility with the present systems as well as product changes. Also, cost effectiveness is looking into the purchase price of the machine compared to approximate returns in the future such as very little to no labor cost and highly productive production. By considering the above factors in detail, I can be able to select a machine which suits my operational needs and financing.

Summary Of Pros And Cons Of Automatic Egg Roll Machines And Manual Egg Rolling Machines

Upon this evaluation, I lumped all automatic and manual egg roll machines and found some clear pros and cons related to each type of machine. The automatic machines are developed for mass production centers where maximum speed and uniformity of product output are observed, and very few employees are needed. Most of these types of machines are mmm, which normally produces how many rolls per hour? And this is way above the normal max efficient manual roll-making machine where an operator can only turn out at best 100 rolls per hour depending on the skill of the operator. The knowledge gained from this type of production capacity emphasizes the use of automatic means of production which lowers costs by some reasonable margin of around 30-40% in the long run.

But then, the hand machinery has its own merits in terms of flexibility and costs. Labor-intensive models provide a low entry point for smaller businesses or newer operations without the heavy initial outlay needed for fully automated systems. Such models also increase control over the customization during roll making, which helps the operators meet particular needs of the customers. In making decisions of this kind, I realized that choosing involves considering the tradeoffs and ‘what ifs’ against the production needs and affordability.

Assessment of Food Production Capacities and Performance

This process involves a detailed assessment of the quantitative aspects and performance measures for the food production aspects of both automatic and manual egg roll machines in operation. In this regard, I factored in the average production performance, power consumption and man-hours needed for each option. For example, with the use of now-utomatic egg roll machine, the rate of production is about 500 rolls per hour with 0.2 kWh of energy spent. This, compared to a manual operated machine by a qualified personnel, who made a case of 100 rolls per hour earlier such machine made a 100 rolls over depending on human energy for use, there are other blurs in power consumption.

I also did take into consideration the cost-benefit, noting that…which is the case since while the initial investments into the automated system are very high, there are less ongoing labor costs…perhaps because of its ability to operate more efficiently and depend less on human supervision, the operational costs are reduced by approximately 30-40%etc. In addition to this, automated systems also track quality parameters and help in manufacturing processes as well, which increases efficiency by eliminating much of the waste associated with defective products. However, manual operations still take longer intake and produce greater customization of individual batches, thus tapping on the extensive mass market without heavy capital money in infrastructure. Words like this. Looking at these factors, I can end up making a good decision in accordance to the production objectives I am aiming for and the available given economic circumstances.

What Are the Key Features of a Reliable Egg Roll Making Machine?

Review of the Features of an Automatic Egg Roll Machine

While investigating the critical aspects of an automatic egg roll machine, I cited information obtained from other websites performing well in the marketing to give a well-rounded evaluation. I discovered the following main features high production capacity with an average output of 400 to 600 rolls per hour, ease of use during productive operation and uniformity in the thickness and quality of the roll produced in different batches. Such machines incorporate sophisticated heating elements that evenly cook the product critical to the quality of the product.

The above features can be supported by the technical parameters related to the roll diameter adjustment limits from twenty mm to sixty mm and the temperature control limit of the machine which is precise within 80°C and 200°C. Most of the time, the machines have stainless steel parts that facilitate food safety and equipment durability. Automated systems are enhanced by the integration of intelligent sensors and PLCs improving the operating standard and reliability of the equipment making it in line with the expectations of the industry. Such analysis has facilitated educated choices on the appropriate automatic egg roll machine based on the operational and technical needs.

The Role of Stainless Steel in the Design of Machines

The egg roll-making machine contains stainless steel as one of its structural components, and this is most significant due to its qualities that promote hygiene and the ability to withstand wear and tear. According to the top three websites on Google, the use of stainless steel has many advantages, including those related to structural corrosion, sanitation, and structural integrity. These properties render it useful in equipment that undergoes frequent cleaning and comes in contact with various food items.

In relation to specific dimension standards, stainless steel materials help achieve a certain degree of thermodynamic and mechanical design of the equipment, which can handle harsh working conditions during extended operations without detrimental effects on performance. Thanks to the alloy’s superior tensile properties, it is possible to operate the machine at very high speeds while maintaining the physical integrity of the machine parts that come into contact with high temperatures while producing the egg roll within the allowable temperature threshold. Not to mention that materials such as stainless steel are non-oxidizing and are not reactive with foods, hence the finished product shall be free from contamination which is significant in meeting the safety requirements and quality of the rolls. Thus, in choosing a machine case made of stainless steel, these technical merits will help provide reasonable confidence for long term performance within the efficient parameters.

Trends in Production Equipment Development in Relation to Egg Roll Machinery Improvement

As a person who has followed developments in food machinery, I can say that the manufacturing of egg roll production machines is experiencing incredible transformation. There are more and more gee whiz applications of improved efficiency due to the incorporation of automation and smart technology to these particular machines. For example, the use of a Programmable Logic Controller (PLC) in a manufacturing process has made a great impact on the quality as well as the wastage minimization benefits. As reported in good research work done by the Institute of Food Technologists, the use of axis PLC systems improves productivity by 20 percent more than without them.

In addition, leveraging the power of AI and machine learning also enables predictive maintenance so that the machines have less unproductive time and longer service life. Other improvements include gathering and synthesizing information from different production runs to correct operational parameters on the fly. Modern egg roll machines are said to have thinned arrays of sensors that instantly relay information of the thickness and volume of the dough and filling, respectively, so that every roll made is of the right parameters, both size and weight is true.

Another advancement that deserves mention is the low-power heating elements that are incorporated in the cooking stage of the production process. According to the Food Equipment Manufacturers Association, such innovative machines achieve energy savings of as much as 30% percent while retaining maximum cooking conditions due to improved thermal analysis. Such improvements bring about cost efficiency as well as help meet the goals of reducing environmental degradation in the course of production without compromising on high food safety regulations. I am assured that there is a future in which food will be produced with the help of such technological automation and it will not have any backlashes.

How Can Egg Roll Production Line Enhance Your Business?

Creating a Productive Production Line

Creating an efficient egg roll production line is not easy; it encompasses adopting all modern technologies and the best practices available in the field. Including the necessary steps as per the considerations of other Bombay Pullens industry sources on production equipment efficiency, there is first optimizing workflow layout, use of PLCs and AI-based predictive maintenance, and compliance to food safety practice. Constructing of workspaces to fit equipment is critical in improving the output of workers since it reduces transition time between operations. Still, sensor arrays for constant feedback on critical parameters of each batch ensure that every product produced is of the required standards. Further, implementing these cost-saving measures helps reduce energy costs, which is a major operational cost for many industries. In this way, my business would boost its performance and adapt to the dynamic conditions in the market of food products.

Spring Roll Machine Adoption for Expanded Product Range

Adding a spring roll machine to my production line would be a great enhancement since it will increase the range of products outputted by my business and improve the required efficiency. Another benefit in the production line would arise from the use of advanced equipment from leading companies in the industry, which would enable me to accurately produce different kinds of spring rolls while maintaining low levels of manual labour cost. The feature of this machine includes several spring roll types that can be exported depending on the market need; this allows the maximization of the market. Similarly, the use of the newest technology including but not limited to computerized devices for rolling and cutting the dumplings also increases production where food safety is maintained. Such integration enhances operational throughput and is aligned with the contemporary ways companies operate, which ultimately leads to increased revenues and profits.

Advanced Technology Awaits Customers and More

Advanced technology helps to meet customer’s demands through advanced solutions which focuses on the consumer demands’ level of quality as well as speed. Since customers expect their products delivered on time, the use of new automation technologies helps me deliver my orders. Acquiring the service of data application enhances my perception of the customers and their needs which enables them to be more satisfied than before. Other than that, AI systems help generate models for maintenance scheduling and help in effectively deploying resources for maximum efficiency and minimum downtime. These innovations offer me the ability to be in the market and at the same time create value for my customers.

What to expect from modern egg roll making technology?

Developments in machinery for bulk production

When it comes to innovations on the automatic encrusting and forming machines, it is worth noting a firsthand perspective that provides an insight into the food production and its efficiency and precision. This evolution of ideas aimed at developing edible products in large quantities if suitable to adjust for batch production products’ shapes and sizes while maintaining their quality. In addition, the insights advanced by Young & Barbosa indicate that the incorporation of programmable logic controllers (PLC) in encrusting machines assisted in introducing high precision in the production process and this precision was guaranteed up to about 0.1mm in thick dough variations. This level of precision takes care of the aspect of desirable product uniformity as well as adherence to high quality and safety standards. Furthermore, regarding the speed of these devices, they usually increase the throughput of production processes by over 30 percent when compared to standard procedures. That has expanded my capacity to create many product categories through such technology while conserving materials for more sustainable business practices. Also, data collection systems incorporated in these machines also help monitor and evaluate production trends for improvement and decisions making.

The future of food making with food machinery

In the way as I understand it, in the future it will be possible to utilize even more food machines which, if deployed correctly, will definitely alter the way how food is produced. With machines becoming more advanced and machine learning developing, future generations of food machines will likely be more intelligent and flexible. In my opinion, artificial intelligence, as well as analytics that are applied during the operation of machines for food processing, will substantially improve production processes. The predictive maintenance feature will for example reduce downtime by about 40 percent because a sensor will detect when a machine is about to fail so that immediate action can be taken to prevent that breakdown.

By providing communication through IoT certificates, such workflows will give rise to enhanced and more agile modes of food production amongst users. These will serve monitoring purposes that, among others, facilitate the collection and storage of the data that helps make informed decisions, such as environmental conditions in processing areas. I expect such expectations of personalization will also have an additional effect on food manufacturing and allow the production of food separately for each consumer, perhaps even targeting every nutrient and allergen in the composition, resulting in optimal health benefits with maximum availability of foods.

In addition, in view of the changes in the industry structure, Robert says it is only a matter of time before robots will be developed that will be able to copy manual culinary work so that artwork in cooking is not lost as well as industrial facilitation. As more and more energy-saving devices, as well as ordering and delivery systems optimized for a target market, are adopted, savings on production may be achieved perhaps by 25%. If I address these developments, I can stretch the limits of food-wearing creativity and serve products that fully satisfy all the quality and ecological requests of modern society.

Multipurpose filling and forming machine to keep up with the trends

In order to meet the new trends arising in the food processing sector, I have sought to add a multipurpose filling and forming machine in the production line. Such innovative technology has been developed to respond to the flexibility of consumers’ cravings for varied and personalized food offerings. With its advanced features, it is possible to more than fill pastries and dumplings by producing plant-based protein products with great quality and speed. Its modular structure ensures ease of part swapping, thus limiting downtimes on changes and improving the general efficiency of the output by about 30%.

The filling and forming system does come with the required control technology as the portions will be of the right size as well as product uniformity, which is essential in ensuring consumer faith in us is maintained. Further, the machine is fitted with smart sensors that perform actual quality control during production to ensure that the quality of all products is within acceptable thresholds. With the adoption of this technology, I expect a reduction, by a third of raw material waste content, which will help us meet our ecological management objective. This strategy provides an opportunity for me to expand into the contemporary arena and unlock quality, efficiency, and environmentally viable approaches in the industry.

Reference sources

-

Junyu – Egg Roll Machine

-

ANKO Food Machine Solutions – ER-24 Egg Roll Machine

Frequently Asked Questions (FAQs)

Q: What is an egg roll making machine?

A: An egg roll making machine is unique equipment helpful in egg roll manufacture. These machines save time by enabling the preparation of a large number of egg rolls in the shortest duration, and such technology is useful in the food sector.

Q: How does the egg roll machine manufacturer ensure quality?

A: In order to perform these activities, egg roll machine manufacturers ensure that they use materials such as stainless steel and modern techniques in their construction. Testing is also a major part of it in order to conform to an industry-set standard.

Q: Can the machine make various flavors of egg rolls?

A: Certainly, the machine is very flexible and can be modified to produce different types of egg rolls by adding additional desired ingredients.

Q: How does a waffle cone maker relate to egg roll machines?

A: Although all these machines are found in the food machine industry, a waffle cone maker is an ice cream cone maker, and an egg roll machine is a specialist egg roll producer. Both, however, involve controlling the dough and cooking.

Q: What is the advantage of deploying an automatic egg roll production line?

A: An automatic egg roll production line simplifies the production considerably, so less manual work is employed, and the production level rises. This is a good production option for companies that want to increase their production level.

Q: What if I want to know how to operate my egg roll-making machine because I encountered a problem?

A: If you need assistance, please feel free to contact us. Most machine manufacturers have customer service that answers questions on maintenance, fault finding, and spare parts.

Q: Do machines for making egg rolls also contain the dough belt production feature?

A: Yes, certain machinery configured for producing egg rolls is also capable of producing a dough belt, thereby facilitating the manufacture of the dough sheets utilized during egg roll production.

Q: What other food items besides egg rolls can be made using these machines?

A: Although they are predominantly used for the production of egg rolls, an array of food machines can be easily modified to produce similar items like spring rolls, dumplings, samosas, and many others.

Q: Why do most people choose a stainless steel egg roll machine over other types?

A: Stainless steels are the materials that most people prefer in the production of food machines because they are longer-lasting, corrosion-resistant, and easy to clean, which is key in most food machines.