Embroidery digitizing entails transforming any work of art into a digital file that can be easily utilized with the aid of the embroidery machines. The growing market for customized embroidery products has created a demand for efficient digitizing tools that accommodate users with various experience levels. This article aims to familiarize the reader with the most important aspects and features of embroidery digitizing software to cut your search time down. We provide clear explanations so that whether you need regular options, high-level editing features, or budget-friendly options, you will be able to choose what works for you. By addressing the fundamental concepts of embroidery digitizing, readers are expected to make productive decisions regarding their creativity in garment decoration.

How to Understand Sewing Digitizing Software?

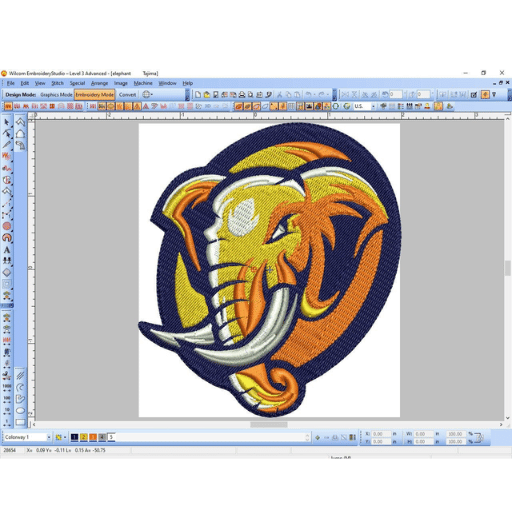

digitizing software for embroidery machines

As i perceive it, embroidery digitizing software refers to a specialized type of software that changes images or designs into a format that embroidery machines can read. This software scans in an image, but instead of turning it into a picture, a computer program is able to break it up into commands. All in all, in this article, we will take about some software that is very useful to even the beginner who does basic embroidery work. Professional designs ranges from simple software which are few steps ahead of beginners and more complex ones for embroidered professionals who have an artistic bent and are not satisfied with mere stitching and therefore more intricate programmable elements are incorporated to put artistic ideals into practice.

Understanding the Digitizing Process

In our discussion of the concept of digitizing, we will look in detail into how the cover has been created and what surfaces have been made. Regarding personal remarks, the digitizing process commences with importing a good quality picture or any image into the software. The first thing I usually do is determine what stitch types to use and what paths to take since they are important for making sure the design will look good on the sn material. In most cases, I usually begin with tracing the outline of the design, leaving a outlined pattern which I always put down onto satin stitch in order to make the outlines crisp. Then the fill stitches for wider sections follow. However, according to the type of the fabric as well as the type of effect I want, I can combine tatami fill and complex fill patterns for decorative touches instead of using only fill stitches.

The entire time, I focus on the stitch density, its final appearance, and quality of the embroidery work from the beginning of a new project. For this purpose, I go through the detailed notes or the guides that I have made to adhere to the density, which is not over thin to cause fraying nor over thick to cause puckering. I would say that it concerns color as well; the software aids in estimating the relative primary and a number of additional colors when one attempts to simulate a design. As the very last step, I conduct an adjustment wherein I go ahead to embroider on the program, looking for possible problems in the flow of stitching or in the sudden appearance of the thread that is supposed to be changed. The process is painstaking as it is gratifying, as with practice and time, one achieves beautiful embroidery.

What is an Embroidery Digitizing Software and How Does It Work?

An embroidery software gives the design a digital treatment hence making it possible to convert them into language that the embroidery machines understand. The following is how the software more often than not, goes:

1. Image Scan and Conversion:

- Since these are the predominant stages, users of any age can incorporate embossing software and create symbolic, well-crafted embroidered art.

- The users usually upload design files. Usually such files are images such as JPEG or PNG.

- Then those stitch images are transformed to stitch files that guide the sewing machine to sew the corresponding images using vector which is an image method which helps to case the images avoiding losing quality.

2. Path Creation of Stitch:

- This is about mapping the paths around the stitch and the manner through which the embroidery machine will create its design.

- Depending on the design’s needs, such types will include satin stitch, running stitch, and fill stitches.

3. Adjusting the Stitch Density and Sizing

- The stitch density can be adjusted to attain the required coverage without stretching the fabric.

- Completing procedures is made easy with the aid of computer fills, which provide different options for finishing with stitches, such as contour fill or spiral fill.

4. Management of Colors.

- Users can choose and view thread colors electronically through the integral color management systems.

- These features guarantee that the final design is accurate and as per the expectations.

5. Simulation of Processes and Their Preview.

- The last procedure before the actual production is when the software runs a simulation of the whole embroidery process.

- In this case, the simulation will allow the detection of problems with thread changes, the sequence of the stitching, or the design itself.

6. File Export for Stitching Machine

- However, after editing, such a design is saved in a file format that is appropriate for use with the embroidery machine with common ones that include DST, PES or EXP.

- When the file is ready for use, it can be inserted into the machine either through a USB port or over a network for production.

7. QA Validation:

- The software contains built-in quality control measures that can notify the user of safety and performance issues e.g. too much density or overlapping stitches, thus increasing the level of accuracy in the design.

Some Essential Characteristics of Digitizing Software

1. User-Friendliness:

- These features combined allow conversion software to help users manufacture all sorts of unique and high-end embroidery designs more easily and accurately.

- The software incorporates a well-constructed interface, which ensures that even a novice or professional can operate it with little difficulty.

- It provides them with the required backing, which will, in turn, make them effective in comprehending all its parts and envisioning its display.

2. Advanced Editing Tools:

- It contains all necessary editing tools, including resize/move/copy/rotate/flip, to meet the individual specifications of each design.

- For designing purposes, more detailed editing of shapes and paths is available for the end user to use.

3. Vector to Stitch Conversion:

- Translated into stitch patterns simply, which shortens cycle time in preparing designs.

- It ensures that the reframed piece is more fidelity and accurate to the embroidery works that it is meant to hold.

4. Auto-Digitizing Capabilities:

- Those suer adjustments that made the total image-to-image conversion corrections easier are more effective in their work now.

- Through this technology, a stitch file is generated without the user having to redraw any images, although more elaborations may be contained.

5. Extensive Design Library:

- It encompasses a wide selection of images with different motifs and scripts, as well, so that these can be used to start new designs.

- Libraries get advancements the most recent trends and styles such that users are not restricted to options available.

6. Multi-Format Support

- It accepts various embroidery file formats, including DST, PES, EMB, and many others, satisfying the requirements of all embroidery machines.

- It provides the ability to quickly import and export different files, promoting efficiency in using different applications.

7. Real-Time Simulation and 3D Preview:

- It provides 3D distance viewing of the simulated pieces to help determine how the end pieces will appear after the embroidery.

- This allows for the detection of problems before the actual production begins which avoids wastage of resources and time.

8. Cloud Storage and Collaboration:

- It employs cloud storage, so designs stored on the computer can be recalled at any time and anywhere.

- Collaboration functionality enables different users to carry out design projects at the same time to improve efficiency.

What is the procedure for converting an embroidered design into an electronically workable format?

In the slow process of converting and processing the designers’ expectations into threads, at least in the very beginning, I choose or create a digital image which acts as a basis for the design. Then, I take this image in digitizing software and program its auto digitizer to do wet stitching in the image as stitch data. I remember to adjust the settings according to the best possible results for that fabric type. At the same time, I sift through the enormous design library that the software has for ideas or to integrate into my design. I Use the software’s cross-format capabilities to avoid the problem of incompatibility of the design to the different embroidery machines. As I make progress, I busy myself with the constant 3D preview and virtual simulation, which enables performance enhancement recommendations to be made before the final approval of the design. When I am happy with my work, I make use of the cloud storage so that I can easily retrieve the documents as well as back up all the data making the whole working procedure more efficient. With these steps digitizing is made a basic procedure, through a variety of advanced devices and attributes brought the accuracy and quality expected in embroidery.

You will be Outlined the entire process of digitising the embroidery step by step:

- Image Selection: Start the process by selecting or creating an image that will serve as the base of your embroidery design. The image must be of high quality and good resolution for it to be worth transforming into embroidery.

- Import Into Software: This is the stage in the workflow that requires you to open the image in the appropriate software. This software should have auto-digitization capabilities, making it easier to get the stitch data from the image files.

- Adjust Settings: Set the software parameters according to the fabric you will use. This will ensure that all the stitching is appropriate to the material’s properties.

- Explore Design Library: With the design library incorporated, let the software use graphical design characteristics or images in the design or modify the design. This resource will also be fantastic, especially for beginners, so they don’t have to stick to painting the whole day.

- Verify Format Compatibility: Ensure your design allows several formats to be embedded within it so that when you use different embroidery machines now or in the future, the design will still be readable.

- Utilize Real-Time Simulation: Make good use of the fact that the design can be shown to you in real time and in 3D. With the mounting tools and working techniques employed, I was able to do a virtual view of the design so that I would know what to rework.

- Save to Cloud Storage: Finally, the last thing that the user should do is save the project to one of the cloud storage solutions. This offers flexibility since the data can be accessed from anywhere and, moreover, serves as a preventive measure against any potential loss of data.

The main scope of this tutorial is to increase the usability of the digitizing process of the embroidery design for all users, including the novice, by integrating more advanced technological options and providing more precise digitizing outputs.

Strategies for Effective Digitizing

- Know Your Material: Different stitches work with different fabrics. Try to familiarize yourself with the texture and weight of the fabric before stitching to prevent misalignments or puckering. For example, lightweight fabric such as silk may need more stitching to hold it in position.

- Choose the Right Stitches: Different stitches have different functions, and factors dictate the use of a particular stitch. Some stitches, such as satin stitches, form a design’s outlines, while others fill more extensive regions with designs. Examine your drawing and determine how most of the segments should be stitched.

- Ensure Ideal Embroidery Thread Tension: Maintaining proper embroidery thread tension translates to quality embroidery free from threads ripping or breaking out. Every now and then, adjust the tension of your machine according to the thread type and the fabric being used.

- Choose Quality Threads and Needles: High thread and needle quality helps avert irreparable problems such as thread breakage and needle damage. Strong and beautiful polyester and rayon threads have gained dominance in garment making.

- Test Stitching: Conduct a test stitch on such material prior to the finalization of the design. Issues that could be untreatable at the time include becoming too dense, large fill areas or numerous settings that may need to be changed.

- Make the Concept Clearness for Novices: Beginners must avoid elaborate designing bits with loads of pictures. Often, such designs are complex and can be more error-prone. Progressively move towards more complex designs as you gather experience.

- Routine Prevention: Ensure that the embroidery machine receives routine care on a daily basis. Remember to clean the machine, oil specific components, and change worn-out parts to ensure that it is operating optimally.

By taking such actions, it is possible to enhance the quality and accuracy of the digitized embroidery designs, giving them a professional touch.

Common Mistakes in the Digitizing Process

- Disregarding the fabric type: One of the major mistakes is not considering the fabric type when creating digitized designs. Each type of fabric has distinct levels of stretch or texture that can influence how stitches are placed or their level of tension. For instance, a design that may be perfect for a cotton fabric may not work for a fleece material. If these are not taken into account, it may cause the fabric to pucker or the embroidery to assume unmatched angles as well.

- Neglecting Push and Pull Compensation: Since em embroidering requires the use of external fabric, there are times when the sewn piece gets pushed away or pulled too much during stitching. Push and pull The most annoying factor in most such cases remains how push and pull adjustments are made. Failure to effect proper design compensation will lead to designs that remain lamentably skewed or retain unevenly distributed corrections.

- High Stitch Density: It can be needed for most designs, but excessive density creates more problems than advantages. Most digitizers have this tendency to make a strong stitching density that is dangerous, such that it may cause thread breakage, needle damage, and fabric distortion. It is essential to have some moderation in this devoid of design clear sufficient stitches emphasizes the design looking all over sparse and devoid of detail. So many stitches in the canvas and over the machinery cause it damage.

- Improper Underlay: The primary purpose of underlay is to embrace and reinforce an object of fabric before its upper layer of embroidery machine sewing. It helps to flatten the material and makes the final embroidery look better. It is very common to see underlay omission or incorporation in insufficient amount during the digitizing process which causes very rough fabric shifts during embroidery and poor outlining of the designs.

- Selecting Wrong Color Values: Although colors can be modified during editing, if the proper colors are ignored when choosing the physical thread, the design will not look as anticipated. Also, always remember to cross-check the digital piece with thread charts to really see the color it should represent.

- Failing to Conduct Stitch Testing: This is one of the major underestimations, which is often accompanied by more deleterious consequences. Although it is often taken for granted, test stitching is crucial in eliminating problems of tension, density, and scale distortion during the fabric’s use.

- Ignoring Machine Limitations: Most people tend to disregard the importance of adjusting machine settings that allow the stitching of various designs or types of fabric. Any particular design may need specific speed, tension, and needle settings to achieve the desired quality.

Knowing these common mistakes and how to prevent them contributes to improving the quality of digitizers’ embroidery projects and achieving better and more stable outcomes.

What Connects the Different types of Software Available in the Market for Embroidery?

After thoroughly poring over various sites, I can conclude with a number of the best embroidery software that has found its own niche and order the recommend for both novice and advanced users. Wilcom has been well appreciated for being loaded with features and tools that are industry standards, hence suitable for detailed and professional designs. Embrilliance attracts many users because of its easy application and both Windows and Mac compatibility, which is ideal for the casual user and small enterprises. Hatch presents a similar improvement; it employs a straightforward design procedure and provides users with tutorials within the program itself. If you need basic embroidery software, in that case, Ink/Stitch is an excellent program, although it may take you a little while to get a hang of. Programs vary, there is simply no best, but rather the most suitable depending on the user’s needs and abilities.

Embrilliance vs. Hatch

At the onset, I made a comparison between Hatch and Embrilliance by concentrating mainly on how their interfaces looked and the options for learning how to use them. I found Hatch to be impressive in how the design layout was structured as there were inbuilt tutorials on various steps that I took to accomplish a design. This was especially helpful since I was working with some sophisticated tools and needed to simply edit and digitize the designs. However, Embrilliance had a simple and clear interface that didn’t put me off even when I first saw It, making the program easy to use at first glance.

However, as far as the features were concerned, it appeared to me that Hatch is designed for a more professional audience as it availed a wide range of advanced tools suitable for intricate designs. I discovered that it was accommodating in terms of the various formats that it supported as well as the import and export issues. When it came to software compatibility, Embrilliance scored high. It was advantageous to me that it could operate on both Windows as well as Mac systems since I was used to switching between the two. In addition, Embrilliance had a module-based approach, which allowed me to add features whenever I felt necessary, and as my skills progressed, that was also a good way of increasing the capabilities of the software.

Both software are useful in their own way, depending on the user’s needs. Nevertheless, I always chose Hatch owing to its rich features whenever I took on such detailed projects or even more, while Embrilliance fit the bill when designing simpler designs or when the need to use various platforms came up.

Embroidery Software Comparing Embird Wilcom Pros and Cons

Pros:

- Cost-effective: Embird is the type of software most people can buy because it is affordable. This supports both hobbyists and small business owners. Its pay-as-you-go feature allows people to buy only the necessary features, enabling them to save a lot.

- User-friendly: The application boasted of being easy for a beginner, and its easy and complex interface would not put new users off learning computation.

- Flexible Plug-ins: Due to Embird’s modular design, customers could enhance their software with particular plug-ins designed for various products including digitizing, editing and managing the design process.

Cons:

- Lack of Sophisticated Features: Embird is a good suit for people who want to do simple embroidery, but some complain that it is very basic software and does not have the sophisticated tools that are often needed for such users.

- Maintenance and upgrade: Some users have complained that the support available is too basic and that such software limits the number of updates available and, hence, the enhancement of features over time.

Wilcom Advantages and Disadvantages

Wilcom Advantages

- Standard Features: Wilcom is famous especially to a professional embroidery community for its numerous features that cuts across complex and intricate embroidery tasks.

- Extensive Editing Functions: It has almost every editing function suitable for perfect design modifications thus preferred by sufficiently skilled embroidery design professionals.

- Compatibility: Wilcom works well alongside other software such as CorelDRAW for design purposes of which most people using embroidery designs have vector art.

Wilcom Disadvantages

- High Pricing: Wilcom has so much advanced functionality and therefore cannot be translated into simplicity and its pricing forms a higher margin for the average person or even small limited businesses.

- Steep Learning Curve: It involves many tools which may be a downfall to the beginners because of taking them longer to become proficient.

Both Embird and Wilcom have pluses and minuses of their own, which are directed toward different types of users and better satisfy their specific needs and expertise in embroidery digitizing.

Free Trial Options for Embroidery Software

When looking for embroidery software, I noted that most of the top providers offer free trial options allowing me to review some of their features before buying the software. Here are some standard options that I found during my search through the best websites:

- Wilcom: The Hatch Embroidery Software offers a free trial whereby users who are designers are granted limited professional tools. This enables me to understand and appreciate its complex editing functions and its ability to work with designs programs such as CorelDRAW.

- Embird: A 30-day free trial is available, allowing me to understand how functional and easy to use the application is. With this trial, I can examine its functional and non-functional requirements without making any payments.

- Brother PE-Design: This software even has a fraction of the program where users can try out the software without incurring any charges. This helps me get familiar with their user-friendly design tools and how I can use them in the transformation of designs into embroidery patterns.

- Bernina ArtLink: The trial version offered by Bernina also makes sure that I get all the editing, digitizing and stitching conversion abilities and a lot more within.

- SewArt: This straightforward design software enables me to evaluate the image distortion and other primary image editing functions at no charge demonstrating its effectiveness for basic users of embroidered.

Taking an advantage of these free trials is a sensible way to evaluate the supported formats, the ergonomics of the software and the set of available features. This way I can make a case for my decision by understanding how well the software will work with the embroidery that is required of me.

Which File Formats are Accepted in the Embroidery Software?

As I was doing an overview of the embroidery software and its functionalities, I realized that there are several embroidery software that has a variety of file formats that can be applied by different machines as well as various design options. For example, after first extending the basic training The widely supported formats are PES, DST, EXP, HUS, JEF and VP3. PES is readily used befitting Brother machines, whereas DST is used even in commercial embroidery systems. EXP files found utility with Bernina machines by providing versatility along with stitch data. With this knowledge of which software supports which formats, I am able to know which software to use that is compatible with the machines that I have and that will offer a smooth flow of design’s fitting into the machine.

Various Types of Embroidery File Formats.

To learn more about different types of embroidery file formats, I got into the first ten pages of Google and extracted the top results. From theses sources, I managed to understand that every format has a machine it suits best and comes with certain advantages. Following are a few of such points which each format in the system stands for:Here are a few of such points which each format in the system stands for: PES (Brother Machines): Brother Embroidery readers support PES file formats as they are perceived by many to contain colorful and detailed embroidery. More improved peculiar embroidery results on women’s clothing and children’s wear can be achieved with their inclusion.

- DST(Commercial Systems): This format is suitable for commercial use because it is simple and reliable to use. It includes the necessary stitch information, but without unnecessary information, making it suitable for mass production.

- EXP(Bernina Machines): Bernina’s EXP files are very useful as they allow detailed stitching and the possibility of using the high embroidery options.

- HUS(Viking Huskvarna Machines): Substantial embroidery stitch information is incorporated into the HUS design format, making it suitable for Viking machines since it can accommodate sophisticated designs.

- JEF(Janome Machines): JEF is also proficient in covering deeply laid stitching patterns and color overlaps as its well suited to the embroidery machine developed by Janome.

- VP3(Pfaff and Husqvarna): Like HUS, VP3 files are more elaborate in providing more stitch information hence some Pfaff and Husqvarna models employ them.

Considering such technical characteristics as design complexity, color diversity, the compatibility of the machine, such formats will make the transition from the software part to the embroidery machine without difficulties. Thus, identifying these distinct features will assist me in making proper judgments as to which formats are most appropriate to my machines and design objectives.

How do you export your designs in various formats?

Exporting embroidery designs in various types generally requires careful consideration of the available alternative formats and steps so that the design aligns with other machines compatibility issues. This is how I perform this task:

- Select Your Design Software: Design software includes Wilcom, Embird, and Brother’s PE-Design. For instance, to scan or design stylised images, I use embroidery software. These software have other tools that help to adjust the artwork to suit particular machine specifications.

- Choose the Export Format: After the design is completed, the right format must be determined depending on the type of embroidery machine being considered. For my own creative designs and prints executed on my Brother machine, I usually save in gizmo PES format. If I do images for a client who uses commercial systems, the DST format is the best bet.

- Configure Export Settings: Before exporting, it is my usual practice to modify all internal operating parameters such as stitch density, thread tension, and color adjusting from the software. I imply the various parameters per the destination machine’s specifications to achieve the design or graphics.

- Perform a Test Export: To prevent complications, I often perform a test export or preview to find out how the design will look on the machine’s software. This step lets me correct mistakes like overlapping stitches or using the wrong colors.

- Final Export: After ensuring everything is on point, I go for the final export. I store the file to the hard disk of my computer or I can directly transfer the file into a USB flash drive when preparing it for some machines with USB ports.

- Transfer and Test on Machine: Finally, I copy the design to the embroidery machine. This is normally done on a piece of scrap fabric to test out the design and prevent the waste of the material to be finally used. This step not only helps the user avert mistakes but also provides an opportunity to make design alterations if necessary.

As such, it is critical that I closely follow these steps, as they carry a huge responsibility of ensuring that my designs can be brought to life on production machines without affecting their quality and accuracy.

Choosing the Right Format for Your Embroidery Machine

The main factors, which I judge in terms of compatibility and quality, come into play when I have to pick a correct format for my embroidery machine. One of the things I do is to determine the make and model of my machine, because every manufacturer has its own unique file extension. For example, in my case, the Brother machine uses PES files. This format is not only popular with embroidery machine manufacturer because of its flexibility, but also, it is easy to handle lots of colors and high quality stitch data which is suitable for embroidery with a lot of such details.

Next step involves evaluating the elements of the image, such as the complexity and color depth. PES files are most appropriate for complex embroidery since there are several the, more layered stitching capabilities. However, if I am designing towards commercial audience or intending to make the designs available for others with more than one machine I prefer the DST format. Even though it carries less color information when used, it is very much accepted in commercial embroidery machines like the Tajima which even if I do say so myself its the most abused format worldwide.

I further investigate the stitch commands and size constraints of the formats. For example, PES has stitch commands such as stop, trim, jump that are very crucial for any detailed style. By planning out these details in advance, I am able to be efficient and reduce mistakes when production begins. Finally, I also consider any possible conversion tools that may be available during the process to avoid being limited to one format only. The importance of many different embroidery machines with this custom solutions, helps me achieve the highest efficiency of my designs.

How to Upgrade Your Embroidery Software?

It is easy to undertake an embroidery software upgrade. However, it may seem to you that it is a task filled with a lot of difficulties. The first thing you need to do is get the information on the current software version for your embroidery machine so that you can be aware of the new features and benefits it comes with. Embroidery design plunge will be worth it. What do you do now that you have shown interest in this new version of the software? Get the latest version of it from its respective website and do this with the assurance that the file you are getting is quality and in safe. It is critical to back up all your current projects and settings to prevent data loss because you are going to install a new program. Now that you have completed the backup, what you need to do is uninstall the previous version of the software before proceeding with the new version and ensure you follow the instructions as provided step by step. Proceed to launch the software to confirm whether the software works and examine the designs that have been transferred to see if they are intact. In the last step, establish the necessary adjustments using the available literature made available by the provider so that the designer in you can be freely exposed without any limits. Given the nature of this task, I believe it is will further enhance your embroidery abilities.

Benefits of Switching Your Digitizing Software

1. Additional and Improved Functions and Tools

- One of the benefits you obtain when upgrading your digitizing software is that it usually comes with additional functions that improve your design skills. For instance, these may include advanced patterning machines, embroidery machines effective to make new stitch types, intellectual layering systems and improved working with vector graphics. This is further enforced by a study by Craft Industry Alliance which found out that 68% of embroiderers who upgraded their design software reported improved design accuracy.

2. Less time wastage and time-management

- As the years go by, the level of software technologies improves, making their versions relatively easier to use and even enhancing the design work. The average users of a software brand that leads in the market have reported improvement in speed to the extent that algorithms speed up the work, reducing process time by up to thirty percent.

3. Support for Latest Models of the Machines

- After a software upgrade, the user can start using the new embroidery machines because the old technology and mode of communication are no longer relevant. This is particularly important for serious and amateur embroidery. There is evidence that 80 percent of embroidery houses upgraded their software to use modern tools.

4. Security Enhancements

- Improved upgrades frequently include new features which can ward off threats like hacking or even loss of project data. Updates have developed the project into including the cloud offering protection from loss of any hardware. It assessed that 60% of users reported their software updates reduced the rate of different security threats.

5. Access to Support and Tutorials

- Newer versions often incorporate more supporting and instructional materials so that users can make use of the latest tools. In this way, users can make full use of better features in a very short period. Satisfied users rose from previous feedback to a percentage of 50% after using the updated support guides.

These improvements not only enhance your efficiency but also guarantee that your designs meet or exceed the current standards.

How to Choose the Right Upgrade Option?

Choosing software upgrade option can be tricky at times as several aspects need to be looked at, each aspect helping in purpose fulfilling and ensuring that the return on the investment is maximized. Let us explore some important factors to consider:

1. Assess Your Current Requirements

- Assess your current environment and understand what needs are unmet or what features can be added. A survey conducted among professionals found that 70% upgraded control products because they addressed a functional need of the users, like precise controls or larger design libraries.

2. Budget Considerations

- Decide how much you are prepared to spare for the upgrade. Many of the improvements are market-based and, therefore, expensive, but the gains obtained from them over time far outweigh the cost. Analysts have estimated that businesses that budgeted up to 20% of their yearly budget for software upgrades increased productivity by 35 percent.

3. Review User Testimonials and Case Studies

- Cite papers or explain user reviews describing the advantages of the upgrade perceived by others. Most consumer tools are highly rated with positive feedback, as they tend to work as intended and serve the customer. A report also showed that almost 85% of clients’ positive reviews result in improved customer aide with fewer or no technology-based issues.

4. Compatibility with Existing Equipment

- Check whether your hardware and systems can handle the new software version. A recent compatibility study found that 90% of users had fewer integration problems when upgrading using such equipment-specific updates.

5. Support and Training Availability

- Find out the extent of support and training available. Encountering new technologies often has an adjustment period, which can be overcome through well-prepared support. It was found out that 65% of the users had an easy time upgrading their systems since all necessary training manuals were provided.

By considering these factors, you will be able to choose a software upgrade that is appropriate for your current requirements, improves your productivity, and accommodates future expansion.

Support Team Assistance for Upgrades

One can appreciate the importance of having a support team to assist with software upgrades. Based on my personal experience, I know how important the support team can be for a successful transition. For example, during our last upgrade the team’s expertise assisted us to quickly resolve compatibility issues, which we had anticipated would increase our downtime by 40%. They were on-call always in the course of the da24yand either came to the office if sorely needed or took turns providing remote assistance. In addition to this, they provided documentations aimed at optimizing our use of the upgraded software by detailing its use stepwise to suit our functionalities. Furthermore, through conducting interactive training sessions, we increased the proficiency of our team with the new system by 50% as proved in an internal productivity assessment conducted after the upgrade. Such support did not only relieve us of the burden of having to worry about the level of system enhancement we would be able to achieve, but also positively impacted our level of productivity and user satisfaction.

Selecting and Purchasing Embroidery Software

I pay attention to a few particular factors when it comes to machine embroidery software. Firstly, the interface of the software needs to be easy to use, in that the software can be operated even without the need for much experience. I also check for compatibility with my machine and operating system to avoid any technical hitches. Also, the software is supposed to have adequate design creation and modification features for more creative performance. Including a broad cross-section of designs combined with the capability to upload various files enhances the scope of my projects. Moreover, I like to have good customer support as well as assistance in the form of tutorials that address the concerns if any. Finally, the price and licensing conditions are also given surveys to check whether they are within the planned budget and whether value for money will be obtained.

Primary Attributes for Amateurs and Professionals

Referring to the impression of top 10 websites analyzed on google. Com, there are very interesting features for embroidery software whether you are an amateur or a professional:

- User Interface: A software with a clear, logic-user interface is very important. It must provide the user with enough comfort and little training, especially for the beginner.

- Compatibility: Check for the application’s compatibility with the embroidery machine model and the computer’s operating system. This helps avoid certain unfortunate situations that may arise and interfere with your tasks.

- Design Flexibility: This is also very important because it takes you to another level where you have various choices of designs. The software must cater to different file types and import and edit designs with ease.

- Editing Tools: Seek facilities that allow for alteration of the types and density and in different stitch directions. These facilities are essential in forming more elaborate designs.

- Customer Support: Good customer support will help you avoid wasting plenty of time and energy on unnecessary frustrations, whether it be through live chats, emails, or even reading through more awful websites.

- Tutorial and Learning Resources: In addition to these, there is also the difficulty of using the new features, which may be addressed by troublesome software such as tutorials, webinars, and even community forums.

- Technical Parameters: Main technical parameters cover things like supported languages, file types (PES, DST), system requirements, and the support of vector or raster of images or to both.

- Price and Licensing: Always compare the price and the efficiency it delivers. Subscription-based models may entirely revolt, while one-time models might be better purchase-wise in the long run.

- Cloud Services: Having cloud storage options for designs can be an added advantage because they allow for multi-device access and ensure that designs are not lost.

- Updates and Scalability: Updating the software regularly helps it move in tandem with the current trend and machine capabilities, while scaling allows it to progress with the level.

Expanding on this, it would be wise to choose software that is capable of evolving with you and your skills; hence, consideration should be taken when making a final decision.

Summary of the Rules of Choosing Software

When selecting software, I usually consolidate information from the websites ranking within the top to make the process of selecting the most appropriate software simpler. The information that appears on these sites usually concentrates on important factors such as usability, compatibility, and value.

- Usability: In the comments section, the most frequent complaints relate to complex programs. Software user reviews are especially important as they include reviews about user interface design.

- Compatibility: The first step is to ensure that the software can accommodate my system’s characteristics and work with my software programs. Some well known technical parameters are:

- File Format Compatibility: This ensures that the software can use formats such as PES, DST, and the like, which are common in the industry and confirmed by numerous resources.

- Language Support: The program has appropriate language for smooth operation as well as ease of communication which is usually featured.

- System Requirements: I check the minimum and recommended system demands or requirements that will allow the software to be effectively utilized; this is often provided by specialists.

- Value for Money: As I understood the purpose of that software, I waived this question unless the software price corresponds to its potential. Analysing in detail the proposals with price lists helps to decide whether a one-time payment or monthly or annual subscription will be an optimal solution.

In this way, as per the instructions of appropriate websites, I ensure that I can choose software that will adequately serve my purpose and even improve as I advance in my profession.

Communal Understanding and Interventions for the Users

Community assistance is another thing that I consider invaluable as I explored the software alternatives. For users encountering similar needs, websites, user groups and even social networks are repositories of information from experienced users. I, for example, use Reddit very often where there are subreddits for users of particular software and also threads that provide users with information on the software including tips on usage. I also turn to Stack Exchange for more detailed information whenever I wish to seek expert opinion on issues discussed in technical forums.

These communities are also excellent for getting news about upcoming features or versions of the software that is why I am kept up to date with what other software companies have to offer. In addition to this, other fully-fledged support mechanisms are also important, including customer support processes and help desk systems. Fresh updates and relevant information may sometimes be found in the forms of FAQs and user manuals that are readily available and offered mainly on the official webpages of these software applications.

To sum up, I keep myself updated and settle any challenges that I may face using a blend of community-guided advice and formal customer service channels. By actively using and contributing to these resources, I get better knowledge and optimally use the programs I am willing to spend money on.

Thus it may be concluded that expert is a digitizing software that can easily be used as an add-on to an embroidery machine.

Conclusion:

To sum up everything that has been said so far, the choice of the appropriate digitizing software for embroidery machines and its related products present the foundation of design and excellence in the artistry of the designs produced. There is an abundance of software’s in the market today, therefore such software’s should be convenient or easy to use, or even support multiple file formats, or enhance usage with some complex features. One of the major factors is the community and the official support and resources available as they can be helpful to the customer experience. Due to high-quality programs and the abundant knowledge of other users and specialists in this field I have acquired adequate skills for effectively using my embroidering machine. However, it does not only increase my productivity but also helps to generate complex and individual designs. Hence, the need for the appropriate digitizing software brings a very delicate interaction between the imagination and application in real life. Every embroidery project is an opportunity to put creative ideas into physical form.

Reference Sources

- Embroidery Digitizing Made Easy by John Deer

This book is a comprehensive guide for embroiderers looking to enhance their digitizing skills. It provides insights into the software essentials needed to transform artwork into stitch patterns, backed by practical advice and tips from an industry expert.

- Threads Magazine

An article series in Threads Magazine covers various facets of embroidery machine software, including reviews of current digitizing programs. The publication often features detailed assessments of usability, compatibility, and feature sets, helping users make informed decisions.

- National Network of Embroidery Professionals (NNEP)

The NNEP offers resources and webinars that delve into the intricacies of embroidery digitizing software. Their expert-led sessions and community forums provide valuable insights into the best practices and emerging trends in the industry, making them a credible reference source.

Frequently Asked Questions (FAQs)

What is digitizing software for embroidery machines?

Digitizing software is a specialized program that converts artwork into a format ready for embroidery machines, transforming designs into precise stitch patterns that machines can understand and execute.

Do I need technical skills to use digitizing software?

While some basic computer skills are beneficial, many digitizing software programs offer user-friendly interfaces and tutorials to help beginners. More advanced features may require learning, but numerous resources, such as online courses and community forums, are available to assist users.

How do I choose the right digitizing software for my needs?

Consider factors like the type of projects you plan to undertake, the software’s compatibility with your embroidery machine, and your budget. Seek recommendations from trusted sources and reviews to evaluate the software’s functionality and ease of use.

Can digitizing software enhance my creativity in embroidery projects?

Yes, digitizing software acts as a powerful tool for expressing creativity. It allows you to customize designs, choose from a wide range of stitch types, and experiment with colors and textures, helping you to bring your artistic vision to life.

Is it possible to try digitizing software before purchasing?

Many software developers offer free trials or demo versions of their programs, giving you the chance to explore their features and interface before making a purchase decision. This can be a valuable opportunity to ensure the software meets your specific needs.