It is necessary to look at several aspects of packing machines such as the type of machine, its operational capacity, the materials used for construction, and the technology level for their overall pricing. Like most machines, which are pivotal for enhancing productivity in multiple industries, these also possess tangible and intangible aspects that affect their pricing. These factors will be discussed in detail in the following sections of this article to provide businesses with the necessary information to make educated purchasing choices. The article aims to assist companies in assessing their options about functionality and budget constraints by giving comprehensive frameworks.

What factors influence the cost of a packaging machine?

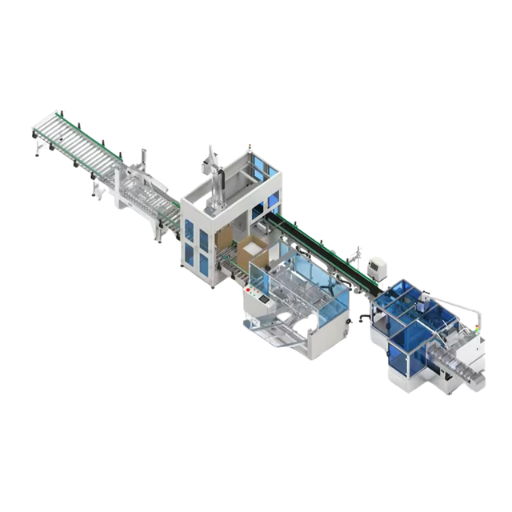

Several key factors influence the cost of a packaging machine. These include the type of machine (e.g., form-fill-seal, cartoning, or labeling), its level of automation (manual, semi-automatic, or fully automatic), and production capacity. Additionally, material compatibility, customizations, and the inclusion of advanced features such as IoT connectivity or vision systems can significantly impact pricing. Other considerations include the manufacturer’s reputation, support services, and the durability of components used. These factors collectively determine both the upfront investment and long-term operational costs.

How does the level of automation affect packaging machine prices

The level of automation indeed impacts the prices of packaging machines and, therefore, should be considered when deciding on a budget. Fully automatic machines are more costly than semi-automatic machines because they only need manual support instead of doing everything independently. Fully automatic machines utilize advanced systems and extremely cost-effective tools, including PLs, robotics, and sensors. These allow the machines to control the processes without any intervention. While highly automated processes are more efficient, it is clear that they are also more expensive.

How production capacity is important in cost measurement?

The cost of packaging machines is dictated by production capacity, which is one of the most critical factors in cost measurement because it affects the machine’s workings and operational scale. Machines made for substantial production capacity typically have higher cost requirements because they need more substantial parts, higher operating speeds, and better durability.

- Operating Speed: This is the most critical consideration. Higher speeds while operating a machine needs more sophisticated mechanical and electronic systems, especially when measured in units per minute.

- Load Handling Capability: Stronger or heavier packages often need to be embedded in more reinforced structures as well as have powerful motors.

- Cycle Time Efficiency: To reduce cycle times, precision engineering and high-performance materials are essential to short cycle times.

- Scalability Options: Flexible configurations to different production levels usually add to the cost of the machine.

What is the interplay between material unsuitability and pricing of a machine?

Material unsuitability factors differ in utmost importance because of the specialized parts and building materials involve different pricing ranges. Machines that handle materials that are corrosive or abrasive or at extremely high temperatures require a great deal of advanced alloys, coatings, and seals to maintain the machines and ensure functionality. These modifications escalate the cost and complexity of manufacturing, especially for systems that are designed to handle a wider range of materials. Dietary or drug industry-specific materials regulations and standards add unnecessary production costs.

How do different types of packaging machines vary in price?

Deployment costs for packaging machines are based on numerous factors. These include the type of machine, the level of integration of the machine, and the purpose for which it is intended. Machines that are entry-level like manual and semi-automatic machines are relatively cheap and are made for low production scale workflows. However, automated systems intended for high-speed and high-volume production are costly owing to the sophisticated technology and efficiency they embody. Specialized machines for uncommon packaging formats or materials almost always need custom engineering, making them even more expensive. Along with the factors above, build quality, brand name, and other features like data tracking or multipurpose functionalities can systematically alter the price of these machines.

What’s the price range for filling versus sealing machines?

The cost of filling machines will usually vary based on the degree of automation and use. Basic manual or semi-automatic filling machines are often sold at a starting price of $2,000, which is good for low volume businesses. For specialized products or complex liquids, high speed, fully automated systems for industrial use typically range from $25,000 to over $100,000. Sealing machines, however, tend to have a broader price range. Basic portable sealing equipment is obtainable within the $500-$2,000 price range, while automated industrial grade sealing systems tend to be between $10,000 – $50,000 depending on the materials, features, and size capabilities. The divergence in price is often tied to the machine’s capacity, precision, and customization options.

How much do multi-function packaging machines typically cost?

The costs of multi-function packaging machines differ based on the level of detail in their arrangements and their usefulness. Basic models for small businesses are priced between $10,000 and $30,000. Industrial models with automation, multi-function packaging abilities, and sophistication generally go for $50,000 – $200,000. As a rule of thumb, machines with customized features that enhance speed, level of efficiency, and precision come at a higher price.

What’s the cost difference between pouch packaging and sachet packing machines?

Pouch machines cost more than sachet machines due to their improved capacity and increased ease of complex formatting. The price difference serves industrial, large-scale pouch machines over $100,000, while mid-range models fall within $15,000 and $30,000. Sachet machines start at $5,000 to $10,000 for beginner versions and go as high as $50,000 for more complex configurations. As expected, the large sachet machines are considerably cheaper since they rely on basic features like low operational scale and lack of complex multi-format capability.

Are there hidden costs associated with purchasing a packaging machine?

There are always costs that may arise when buying a packaging machine, which may not be immediately evident. Examples of these costs include installation, ongoing training for the operators, maintenance, and repairs. Spare parts, consumables like films or packaging, and even software updates may be incurred over time. Electricity costs will also be incurred, and any custom adjustments that are necessary for certain production requirements will have to be made. All these aforementioned expenses make up the cost of ownership and must be considered in their totality.

What maintenance expenses should you anticipate for packaging equipment?

In correlation to other equipment, maintenance costs for packaging equipment could be slightly variable concerning its type, complexity, and how frequently it is used. As a rule, routine maintenance means having consumable components replaced, including wear and tears like cut blades and seals. Mechanical parts also need lubrication, and sensors and controls have to be recalibrated occasionally to reduce downtime and maintain accuracy. Furthermore, operators must consider the expenses incurred in technical support, which involves routine preventive maintenance and some emergency repair servicing. In some instances, especially where added features and functionalities are involved, there may be charges associated with software updates and modifications. Charges related to energy consumption during normal operations and even idle modes also need consideration due to operational budgets in the long term. In addition to everything mentioned above, one crucial point to remember is that the equipment needs to be maintained optimally to prolong its life span.

What is the effect of training and installation costs on the overall price?

The final price integrates all components such as installation and training, which are necessities for the smooth employment and functioning of the system assigned to them. Installation includes the processes of configuring the machinery to site-specific conditions, including installation and initial calibration. Induction covers onboarding new operators and staff and enables them to operate the system adequately and safely. Such investments are critical during the initial phases because they lead to enhanced efficacy over the long term by significantly reducing initial downtime and operational errors and increasing overall productivity.

What about parts and upgrades economically?

These expenses highlight the importance of spare components and upgrades because these factors will define the operational system reliability and performance over time. These components include elements subject to normal wear and tear and need to be replaced periodically to prevent unexpected breakdowns. The costs of these replacements highly depend on the machine’s complexity, the availability of parts, and the frequency of scheduled maintenance. Upgrades, on the other hand, are changes made primarily for increased efficiency, improved compatibility, or greater functionality, which usually results in long-term savings in operating costs and extends the useful life of the equipment. Budgeting properly will alleviate operational disruptions while aiding the system’s changing needs, demonstrating why upgrades and spare parts are monetary requirements.

How does customization affect packaging machine costs?

Improvements in productivity and ease of operations are possible when designing new or modifying existing packaging machines. However, such measures come with cost associated with novel engineering processes alongside making unique components. Developing these custom solutions takes much longer than traditional ones due to more excellent performance and compatibility requirements, and the resultant investment is also much larger. These customized machines are, however, capable of saving costs over an extensive period due to better operational efficiency, increased productivity, and being able to meet precise product specifications. It is essential to consider and analyze the objectives of the custom requirements against the spending regarding production needs to ensure maximum return on investment.

How does the incorporation of distinct elements dimention the cost of food packaging machines?

The cost dimension of food packaging machines can be altered without much effort due to factors such as variety of use, multi-functionality, and precision machinery. While the cost remains constant for the machinery parts, novel features like MAP, vacuum sealing, or systems for rapid labeling do demand sophisticated parts at an entirely new price point. A simple example is the addition of oxygen sensors and gas-flush mechanisms that ensure prolonged shelf life and thus minimize supper market sell-by dates. This invariably adds to the initial equipment cost. The cost downside does not stop here. These custom stand-alone conveyors, along with powered vision sorting technology, do tremendously support machines for delicate food processing, cabling more excellent pessimistic addition to expenditure.

How much extra do pharmaceutical-grade packaging machines cost?

Compared to business-standard equipment, pharmaceutical-grade packaging machines are notably more expensive. This results from having to comply with various international regulations like GMP (Good Manufacturing Practice) and FDA regulations. These machines usually have incorporated advanced EMU and water sterilization systems, HEPA filtration, and strict environmental controls to guarantee the products integrity. Additional sterile traceability, software validation hosting, and material compatibility assessment are all extra steps that raise the price, sometimes exorbitantly. Depending on customization needs and production capacities, pharmaceutical-grade machines can cost anywhere from 50 to 200 percent more than their non-pharmaceutical-standard counterparts.

What’s the cost difference between standard and high-speed packaging machines?

The gap between the prices of standard and high-speed machines is that high-speed packaging machines are advanced models that tend to be the most expensive because of the technology built into them. The output, production speed, degree of automation, and production technologies characterize the price difference. Unlike standard machines, high-speed models are built to handle significantly larger outputs. A standard machine works at a speed of 50 to 150 units per minute, while high-speed models operate at a rate of over 300 units per minute. Other necessary specifications are servo-driven systems, automated feeding systems, and high-speed sensors for quality control. Besides, these machines enable incorporation of special diagnostic software to enhance their capability which is another reason for the increased cost. Cost differential greatly varies from 50% to more than 150% in terms of the specifications needed and other operational requirements.

How do supplier choices influence packaging machine prices?

The location of the supplier does affect pricing since it correlates to the specific manufacturing quality, range of services offered, and even the geographic location of the supplier. Maintenance and training also add an expense to the cost but enhance the machine’s value and reliability, which is why premium suppliers tend to charge higher prices. On the other end of the spectrum, suppliers situated in lower production cost regions might offer more budget-friendly options. Suppliers capable of customization and the integration of technologies will also impact the overall pricing depending on the complexity of the clientele’s needs.

What is the cost difference for local suppliers and others in the region or other countries?

Multiple factors affect the cost difference for local suppliers and others in the region or other countries. Local suppliers are usually more expensive due to the high costs associated with production and labor. However, the assistance offered, such as effective communication, lower shipping costs, and expedient delivery, can offset this expense. Suppliers in remote areas with lower manufacturing expenses can provide competitive pricing. When considering international suppliers, it is crucial to recognize that tariffs, extended deadlines, customs duty, and other expenses might complicate the evaluation.

How does a supplier’s reputation affect machine costs?

A supplier’s reputation greatly impacts machine costs due to the provider’s perceived quality, reliability, and service provided after sales. Quality suppliers usually have high prices for their commodities, because their name is linked with good quality machines, sophisticated technology, and renowned sturdiness. Furthermore, established suppliers provide support in the shape of warranties, technical assistance, and routine maintenance, which is more than expected at a simple purchase. They tend to be very cheap, believing that such things place lesser risks. Still, lower prices might lead businesses to pursue simpler supports that could cost more in the long run.

What role does after sales support play in pricing?

Those who buy machines often cite a need for after-sales assistance, such as installation, teaching, maintenance and repair. These are crucial for the pricing of the machine. Higher purchase prices are often demanded from products that have high aftermarket supports after from machines of suppliers that have installed them. The support offered ensures there are fewer cases of downtime equipment, disruptions to operations, and longer working hours for machines, which helps justify the cost. On the other hand, minimal aftermarket support can lead to increased spending over a longer period because the cost of repairs, inefficiencies, and operational ineffectiveness detracts from the machine’s benefits significantly.

Is investing in expensive packaging machinery worth it for small businesses?

Long-term benefits should be viewed as more important than the costs that small businesses must pay upfront when purchasing expensive packaging machinery. Opting for high-quality machinery normally ensures increased efficiency, fast production, and uniform packaging, which enhances brand image while minimizing labor costs. Also, sophisticated machines can prompt the adaptation of various product lines and types of packages, thus enhancing expandability and business growth. However, before making any investment, small firms must first determine their production volumes as well as operational requirements to ensure that the machines will not only suit their financial strengths but also fit into their long-term goals.

What are the cost-benefit considerations for small-scale operations?

The cost-benefit considerations for small scale businesses lie on efficiency improvement or scalability or return on investments. Typically, high-quality packaging machinery contains automated features such as programmable logic controllers and durable constructions to ensure reliable performance over time. For instance, advanced automation combined with operational flexibility has made PLC-based packing systems less dependent on manual labor, thereby reducing labor-related expenses significantly.

Furthermore, I look at the possibility of production and compatibility. Machines that can either adjust their speed or are designed as modular are the best for small-scale operations that expect to grow or have different products. For example, equipment capable of packing 20-50 units per minute with no downtime for adjustments is an actual benefit in small-scale settings. Furthermore, power efficiency, such as machines using little power but having high outputs, impacts operational costs positively.

Lastly, I evaluate maintenance and longevity. Machines made from corrosion-resistant materials and fitted with self-diagnosing technologies minimize repair costs and increase their lifespan. Besides this, prioritizing machinery with good technical support will also minimize interruptions, guaranteeing excellent performance and making it investment-worthy.

Are there any low-priced options for start-ups who want to operate in packaging industry?

Yes. There are cost-effective packaging equipment options available for startups; emphasizing price consciousness while ensuring better functionalities. To mention a few examples, semi-automatic stretch wrappers or tabletop vacuum sealers offer optimum results at a fraction of fully automated systems’ prices. Additionally, by reducing initial investments through scaling operations over time through modular machinery, new firms can adopt more flexible approaches to attaining economies of scale in their processes. Another option is leasing/renting which allows one’s business to use high-quality equipment without incurring significant upfront charges. Having energy-efficient and long-lasting equipment would save them money in the long run since they would not need so much maintenance, and operation expenditures would be reduced significantly.

How does leasing compare to buying packaging materials for a small business?

Compared to purchasing, leasing packaging materials gives small businesses more flexibility and lower costs in advance. In this case, leasing gives entrepreneurs access to the latest technology without becoming owners. It is ideal for companies that cannot raise sufficient capital or whose operational requirements change frequently. However, despite all this, leasing can lead to higher overall expenses than outright purchase over time. For companies with stable packaging needs and funds available, there is no better option than buying equipment which ensures long-term savings on costs and complete ownership. Therefore, it becomes necessary to look at all the financial implications of each choice so as to choose a decision that aligns well with both the organizational goals and objectives as stipulated by its policies.

Reference sources

Frequently Asked Questions (FAQs)

Q: What factors influence the cost of a bag packing machine?

A: Several factors influence the cost of a bag packing machine, including the level of automation (semi-automatic vs. full automatic), production capacity, materials it can handle (e.g., powder, granule, liquid), additional features like vacuum packing or heat sealing, and the overall quality and brand reputation of the manufacturer. The complexity of the packaging system and whether it’s part of a complete production line also affect the price.

Q: How does the type of product being packaged affect the cost of a packing machine?

A: The type of product being packaged significantly impacts the cost of a packing machine. For instance, a powder packing machine may be priced differently from a machine designed for packaging liquids or solid items. Machines for food and beverage products often require special features to meet hygiene standards, while pharmaceutical packaging machines may need additional precision and regulatory compliance features, all of which can increase costs.

Q: Are automatic packaging machines more expensive than manual or semi-automatic options?

A: Yes, fully automatic packaging machines are generally more expensive than manual or semi-automatic options. This is because automatic machines offer higher production speeds, require less human intervention, and often include advanced features like integrated filling, sealing, and labeling capabilities. However, they can be more cost-effective in the long run for high-volume production needs.

Q: How do additional features like vacuum packing or filling capabilities affect the machine’s cost?

A: Additional features like vacuum packing, filling capabilities, or integrated cutting machines can significantly increase the cost of a packaging machine. These features add complexity to the machine’s design and functionality, requiring more sophisticated components and engineering. For example, a vacuum packing machine or a fill and seal system will typically be more expensive than a basic sealing machine.

Q: Does the size of the packaging machine impact its price?

A: Yes, the size of the packaging machine does impact its price. Larger machines capable of handling bigger volumes or larger items (like a machine for plastic bags or a carton packaging system) are generally more expensive. This is due to the increased materials, more powerful components, and larger production capacity they offer. However, a machine big enough for your specific packaging needs is crucial for operational efficiency.

Q: How do different packaging materials affect the cost of packing machines?

A: Different packaging materials require specific machine capabilities, which can affect the cost. For instance, a film wrapping machine may be priced differently from a paper bag packaging machine. Machines designed to handle multiple types of materials (e.g., plastic, paper, foil) or those with the ability to work with pre-cut or premade bags might be more expensive due to their versatility.

Q: What role does automation technology play in the cost of packaging machines?

A: Automation technology plays a significant role in determining the cost of packaging machines. Advanced features like servo motors, programmable logic controllers (PLCs), and integrated software for production monitoring can increase the price. However, these technologies often lead to higher efficiency, reduced labor costs, and improved consistency in packaging, which can justify the higher initial investment for many packaging companies.

Q: How do secondary packaging capabilities influence machine costs?

A: Secondary packaging capabilities, such as case packing machines or machines that can handle both primary and secondary packaging, tend to be more expensive. These machines often include additional components for collating, grouping, and packing products into larger units or cartons. The ability to perform multiple packaging functions in one system can increase the overall cost but may provide better value for businesses needing comprehensive packaging solutions.