Reliable and efficient packaging processes are essential in the food production industry and even more so in cookie manufacturing where productivity and quality are priorities. Industrial packaging machines are sophisticated systems that help to optimize operations, reduce material loss, and protect the product’s quality during transport and storage. With modern technology, manufacturers strive towards improved accuracy, increased scale of production, and cost effective solutions to satisfy heightened consumer needs. This essay analyzes the impact industrial packaging machines impose on cookie manufacturing processes, emphasizing their features, advantages, and the novel technologies that enable such transformations.

What are industrial cookie packaging machines and how do they work?

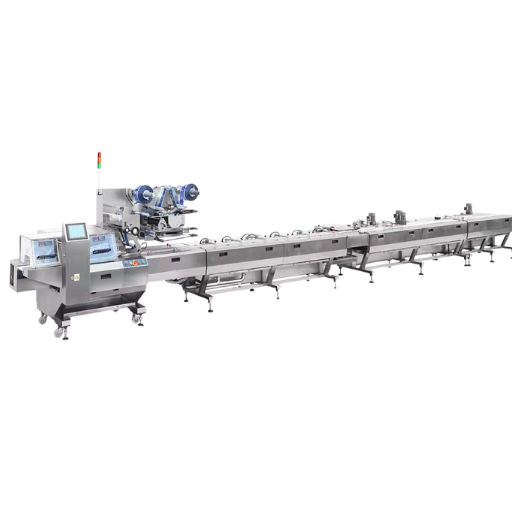

Machinery for industrial cookie packaging is classified as specialized equipment for automating wrapping, sealing, and cartoning the cookies for distribution. These machines are set up and run by combining a mechanical apparatus with a programmable package to achieve precision in packaging. Normally, cookies are moved on conveyors to the packaging unit, which aligns, doses, and packages the cookies in plastic or foil. More advanced machines may have vacuum packaging, labeling, and even weight checking for quality assurance as well as maintaining product standards. This level of packaging automation allows companies to reduce production time and manual labor while maximizing efficiency.

The Different Cookie Packaging Systems

The packaging systems for cookies work through a combination of multiple mechanisms that work together in a system to enhance precision and speed during packing. Such systems usually have conveyors for cookie transfer, alignment and spacing sensors, and sealing units for wrapping the cookies with protective material. Depending on the level of automation and control of the machine, additional labeling, weighing, or even vacuum sealing can be done for better product quality. The bottom line is that cookies must retain their specific design and quality while making the whole packaging process seamless and less labor intensive.

Key component of industrial cookie packaging machines

Conveyor System

The conveyor system mechanically narrows, moving cookies across different stages of the packing process. It also takes care of the spacing and alignment, which is done by servo motors that regulate speed. For most systems, conveyors are constructed with food-grade materials and ensure FDA and ISO3100 standards are met.

Feeding Mechanism

The system organizes the cookies in single or multiple lanes in the feeding mechanism for optimal movement flow. Automatic feeders mostly have sensors and pneumatic systems that can identify, sort, and place the cookies without damaging them.

Film Roll and Wrapping Unit

This component contains the film roll that initiates the wrapping process. It usually utilizes a rotary sealing method that works with heat-sealable films made of polypropylene or polyethylene. The sealing temperature is adjustable between 120 degrees Celsius and 180 degrees Celsius, and the sealing rate is adjustable according to the material and packaging.

Sealing Station

The sealing station guarantees that the seal is tight to the point of being air-free. Attainment of freshness is easily achieved with the integration of heat-sealing jaws or ultrasonic sealing technology with optimum speeds. Machines are built to deal with seal strengths of 15-20N for effective packing.

Labeling and Printing System

Labelers place preset branded information or barcodes, whereas printers print the date codes, batch numbers, and QR codes. Standards such as print quality and other measureable conditions, such as DPI being over 300 or higher, ensure traceability compliance and readability.

Weight Verification Scale

Every package is automatically verified through integrated electronic checkweighers to ensure that the specified weight range is met. Modern systems can deliver accuracy within ±0.01 grams, which increases quality compliance and reduces overfill.

Control Panel and Software

Machine operation is precise thanks to the advanced control panels, which include a PLC (Programmable Logic Controller) interface. The intuitive HMI (Human-Machine Interface) enables operators to track and change parameters such as speed, temperature, and even alignment.

Each component ensures that cookies are packaged within industry requirements for speed and accuracy.

Solutions for different packaging machines for cookies

Broadly, cookies are packaged using horizontal flow wrapping machines that operate at high speeds by wrapping plastic film around single items or groups of cookies. Such machines employ continuous motion technology that guarantees wrapping accuracy. Cookies that need pouch-style packaging are best suited for being packaged in vertical form-fill-seal machines. Cookies are filled in bags made from a roll of film as the edges of the bag are sealed and the bag shows a high level of sealing tightness. Cookies filled in rigid trays or containers need tray sealing machines, which increase the quality of storage and transport of the cookies. Each type of machine fulfils the particular packaging requirement according to the product’s format, speed, and shelf life.

How can automated cookie packaging machines improve production efficiency?

Incorporating automated cookie packaging machines increases production levels by reducing the amount of physical work and mistakes that need to be done for the manual packaging of cookies. Such machines operate at high speeds with elevated accuracy, enabling them to package more products quickly. Automated packaging machines use resources efficiently while minimizing wastage and lowering cost. The latest computerized solutions permit remote supervision of processes and swift modifications to achieve uninterrupted productivity with reduced inactivity periods. They also allow the business to quickly respond to higher production needs while maintaining the quality of the products. This feature ensures that the machines remain dependable for high-volume manufacturing processes.

Improving packaging efficiency and speed

Automated cookie packaging machines that operate at high packaging speeds and output levels rely on modern technologies like servo-driven machines and robotics. Such systems avoid dropping and skewing parts, thus increasing the quality of the work, and achieving desired results. Depending on product type and packaging format, the configuration of the machines can achieve speeds of up to 100 to 600 packages per minute. This is made possible by motion control that is cognizant of the factors above and enhances workflows by stopping all obstacles that hinder workflows.

Another important aspect is the added use of control panels and sensors, which allows for measuring and monitoring throughput, material usage, and error rate, among other factors, in real-time. Such systems help to minimize uptime by identifying and correcting faults in real time. Also, machines that have modular architecture and can perform tool-less changeovers can accommodate multiple packages, thereby improving efficiency and accuracy. With these factors combined, automated processes result in significant enhancements in both speed and output to adjust for the needs of production.

Minimizing Costs of Operations and Human Risk

Automated packaging systems have lowered operational expenditures of companies because of lower human effort needed for them to function. These systems are set up to operate repetitive processes that are prone to human error. Using fatigue and inattention as a basis, machines with advanced technologies, such as vision systems, AI checkpoints, and others, can minimize those risks with precision in detecting faults and deviations from set standards. Moreover, the enhanced productivity and reduced cost of operating systems gives rise to increased performance when automated systems operate while staffing requirements are kept at a minimum.

Achieving uniformity in packaging standards

Consistent quality control is observed in automated packaging system through the uniformity and accuracy of the packages produced. These systems follow strict protocols for the measurements, seals, labels, and materials that are used. State-of-the-art sensors alongside constant scans can identify discrepancies and correct them on the spot. In addition, accurate monitoring through the use of data ensures that each unit produced are of the set standard requirements. Such uniformity helps strengthen a brand’s reputation and aids in regulatory compliance, which varies across industries.

What are the key features to look for in a cookie packaging machine?

When choosing a cookie packaging machine, several essential aspects must be carefully analyzed to achieve optimal productivity and dependability. The first important element is the machine’s ability to accept several different packaging styles and fit different shapes and sizes of cookies. Second, the packaging machine should have easy-to-operate controls and programmable functions that allow for rapid adjustment of settings to make the process more efficient. Third, to achieve superior quality at higher production levels, these machines need to have high-speed capabilities. Besides, built-in advanced inspection systems with sophisticated sensors for effective product or packaged good rejection help to ensure the system’s overall quality. Furthermore, for the long-term effective performance of the machine and regulation compliance, factors such as maintenance requires, prevention of machine wear, and food safety must be considered.

VFFS : Vertical Form, Fill and Seal Unit’s functional details.

VFFS machines are widely used in packaging cookies and other food products because of their automated processes. It entails forming a pouch with a flat sheet of film, inserting the desired product into it, and sealing it off, all in one flowing operation. There are several technical parameters that one needs to analyze for VFFS machines, such as speed, which is between 60 to 120 bags per minute depending on the complexity of the machine, as well as the film width support, which spans between 300mm and 600mm for different sizes of products. Most importantly, accuracy in the filling stage compensates for variations in weight, which is essential in maintaining the desired product quality.

To facilitate maintenance and user-friendliness, modern VFFS machines are equipped with easy to use touchscreen interfaces that allow programming and adjustments. For cookies, in particular, multi-pillow and gusseted bag types offer important versatility. The ability to precisely set sealing temperature and pressure guarantees strong seals, protecting products from spoilage. In addition, sensors and inspection systems are integrated into the machine to monitor and enhance reliability by spotting abnormalities in the packaging process. Adherence to food grade material standards like FDA and EU regulations guarantees the machine can be used with food products.

Adjustable packaging formats and sizes

Flexible adjustable packaging formats and sizes are crucial for varying requirements within different industries. Fitted modern VFFS machines enable multiple bag styles, such as pillow, gusseted, and block-bottom bags, to be used. These formats and sizes can be fitted using a simple interface that changes preset configurations. Efficiency is increased as there is no need for constant reconfiguration and helps aid a wide range of packaging needing materials while improving product presentation.

Integration with existing production lines

Integrating new VFFS machines is effortless because they were created to be incorporated into various manufacturing setups and environments. These equipments can be connected to other pieces of machinery, like filling equipment, conveyors, and labeling devices. The integration allows workflows to be automated, reduces idle periods and enables the product to be treated similarly throughout the entire production cycle. Moreover, the modular design enable easy VFFS system integration into pre-existing systems without extensive modifications or infrastructure expenditures. Overall, these systems can streamline operations and maximize effciency, and allow the organization to enhance throughput.

How do industrial cookie packaging machines ensure food safety and product freshness?

To maintain food safety and product quality, industrial cookie packing machines utilize advanced sealing technologies, machine designs, and controlled packaging environments. Cookies are sealed within a protected environment that prevents moisture, air, and other contaminants from entering. The food-grade materials and design of the machines also help protect the cookie from outside contaminants. Even oxygen is removed and substituted with an inert gas to enhance freshness using modified atmosphere packaging (MAP). Food safety standards such as FDA and HACCP regulations are followed to enhance safety further. The machines can also be easily cleaned and serviced, reducing the chances of cross contamination in the production facilities.

Materials and hygienic design of the machines

Hygienic design and appropriate materials are essential for packaged cookies to ensure freshness and safety. When building these machines, stainless steel and other highly polished food-grade metals are used to inhibit bacterial growth and corrosion. When the machines are built with non-corrosive materials, they can easily be cleaned and sanitized, reducing contamination chances. These new materials used also prevent the collection of debris due to smooth edges, rounded corners, and no open spaces. The new design not only improves the safety of the product, but also allows manufacturers to comply with regulations from different countries.

Airtight sealing technologies

Technologies for sealing airtight are crucial in boosting freshness and shelf life of a given product by avoiding the entry of oxygen and moisture. Modern approaches targeting the optimal seal include heat, ultrasonic, and vacuum sealing. In heat sealing, the combination of pressure and temperature is applied to the packaging material to bond them together thus forming an effective barrier. In ultrasonic sealing, high-frequency vibrations join materials together to achieve accuracy and dependability even with complex packaging structures. In vacuum sealing, air is removed from the package before sealing it, which is best for delicate products that are prone to oxidation. These systems are designed to achieve and maintain constant, leakproof seals with high-speed production lines where both efficiency and product integrity are critical.

Options Available for Preserving Shelf Life

My emphasis shifts to materials and designs that reduce exposure to oxygen, moisture, and light for packaging methods that have an extended shelf life. Multi-layer laminates containing aluminum or EVOH (ethylene vinyl alcohol) layers work well as barrier films for perishable goods. Modified Atmosphere Packaging (MAP) is important as well. This involves substituting the air in the package with a gas mixture to reduce oxidation and microbial growth. Moreover, active packaging solutions, which use oxygen scavengers and moisture absorbers, can enhance preservation further while also ensuring quality and safety of the product.

What are the latest innovations in cookie packaging technology?

The modern advancements made in cookie packaging are primarily centered on maximizing Eco-friendliness, freshness, and consumer convenience. One of the most impactful innovations is the addition of biodegradable and compostable materials that are protective yet diminish environmental impact. Additionally, high-performance resealable closures are gaining popularity as they enable consumers to securely store opened cookies- an effective way to preserve freshness while reducing waste. Furthermore, the use of smart packaging technologies, such as freshness indicators and QR Codes for product information and traceability, are on the rise, allowing producers to enhance consumer experience while ensuring greater transparency in the supply chain. All these developments combine industrial Eco-friendliness and modern packaging’s functional requirements.

High-speed packaging solutions

The industry has witnessed a change by introducing an efficient and precise modern food packaging solution. Robotic arms as well as modular design automation systems have made it possible for mid-tier and high-tier businesses to enjoy high throughput speeds without compromising their mid-tier or high-tier packaging standards. These solutions are equipped with intelligent sensors and software controls which monitor each stage of the packaging process so that downtime and quality issues are avoided during the packaging process. Moreover, many of the new high-speed systems operate with integration of environmentally friendly packaging materials without compromising performance. The solutions offer rapid adoption of cost-efficient models for large-scale business operations while pivoting to meet the ever-evolving consumer demand and regulatory restrictions.

Smart packaging systems with IoT integration

The use of Internet of Things technology has enabled ground-breaking developments in supply chain management and consumer engagement through Smart packing Systems. These systems facilitate embedding sensors, RFID tags, and cloud computing, which can be used for tracking, monitoring, and communicating timely information on the status and geographical location of the products. Smart packing makes it possible to monitor the temperature of perishables and set up tamper and usage alerts through IoT technology. As a result, the safety and quality of the products is enhanced, while waste is minimized. In addition, these solutions improve inventory management and enable tracking and operational efficiency. For consumers, smart packaging includes QR codes which provide the user with an enhanced experience by facilitating greater access to product information and improved trust and transparency.

Sustainable packaging options

Sustainable packaging options use renewable, biodegradable, or recyclable materials to minimize environmental footprint. These innovations include plant-based bioplastics, molded fiber containers, and reusable packaging solutions. Furthermore, the design of lighter-weight products assists in reducing carbon emissions during transportation while conserving materials. Many companies also prefer paperboard or compostable films over traditional plastic packaging. Including closed-loop recycling ensures materials are reused, significantly decreasing waste in landfills and promoting circular economy practices.

How to choose the right cookie packaging machine?

The production capability, the types of cookies the machine can package, and the level of automation are some of the criteria to check when determining which cookie packaging machine to purchase. The machine’s output must be proportional to the company’s production requirements for optimal usage. Similarly, the machine’s packing materials and sizes must be compatible with the dimensions of the cookies being produced. An organization’s efficiency, operational costs, and expenditure in machinery are all impacted by the level of automation. Having a packaging machine that is fully automated will ensure faster and more reliable packaging, making it easier for a company to increase their productivity. However, these machines are usually far more expensive than semi automated or manual machines. Moreover, consider how difficult the machine is to operate and maintain, and whether it has modern features, like modified atmosphere packaging, which extends the shelf life of food products. The ideal machine offers an appropriate balance between cost and functionality and is suitable for long-term use.

Evaluating your production capacity requirements

When determining your production requirements, assess how many cookies are produced in a day or week. This will help you understand the speed and power required from the machine. Operations on a smaller scale would require around 30-80 packages to be made per minute, while larger-scale operations could require 100-300 packages per minute. Always consider whether the machine in question can perform continuously for long periods of time without overheating or burning out, along with the amount of downtime needed.

Furthermore, the variability of cookies in shape and size should be considered. The machines need to have the capacity to handle range in proportions such as widths between 40 and 180mm and thickness between 5 and 50mm, as well as weight, so that the differing assembly lines can be produced without a hassle. This also minimizes overly complex structures when changes in production periods are made.

The level of automation needed depends on the amount of labor supplied and efficiency desired. Features such as auto feeding, sealing, and error detection are implemented in fully automated systems allowing for high production, but the initial investment is significantly substantial. In contrast, semi-automated machines are more affordable for consumers of moderate output and enable more manual work to be incorporated more efficiently.

Some parameters such as type of sealing mechanisms, package materials, and innovative features like nitrogen flushing need to be tailored to the product requirements to preserve it freshly and with the desired quality. Miscalibrating or ignoring these can lead to unwanted results. By focusing on these guidelines, a product can be crafted that meets existing specific needs and goals flexible for change.

Comparing different packaging machine models

In addition to the price, speed, and size of packaging machine models, the selection process also considers several other impactful aspects. Manual models are best for new small-scale operations or startups, as they serve more straightforward requirements with low maintenance. Semi-automated models are affordable while allowing for some extent of programmable settings to fit the needs of a wide scope of business requirements. These models are ideal for mid-scale production. Lastly, fully automated models are built for high precision and large-scale production and come equipped with advanced touch-screen interfaces and integrated quality control systems. These models, while expensive, increase long-term productivity and accuracy. Regardless of the model, the effectiveness with which build quality, safety standards, packaging materials, and energy consumption are addressed is always a vital consideration.

Contemplating on Support and Maintenance Services

Support and maintenance services are crucial for properly functioning and operating any systems or products. These services often consist of updates, software patches maintenance, troubleshooting, and even technical support to tackle issues in advance, if they arise. A properly executed maintenance plan consists of proactive measures, including planned reviews and performance assessments, and reactive support, such as rectifying unplanned outages and failures. Improved maintenance and support services increase user satisfaction, reduce interruptions, and increase the system’s or product’s longevity.

Reference sources

Frequently Asked Questions (FAQs)

Q: What types of baked goods can industrial packaging machines handle?

A: Industrial packaging machines are versatile and can handle a wide variety of baked goods, including cookies, crackers, pretzels, granola bars, muffins, and even chocolate bars. These machines are designed to accommodate different shapes, sizes, and textures, making them suitable for various bakery products and frozen foods.

Q: How do automatic packaging machines improve cookie production efficiency?

A: Automatic packaging machines significantly enhance cookie production efficiency by streamlining the packaging process. They offer high-speed operations, reducing manual labor and increasing output. These machines can handle tasks such as weighing, filling, sealing, and labeling with precision and consistency, leading to improved productivity and reduced packaging errors.

Q: What are the benefits of using a flow wrapper for cookie packaging?

A: Flow wrappers offer several advantages for cookie packaging. They provide a sleek, professional appearance to the final product, protect cookies from moisture and contamination, and extend shelf life. Flow wrappers can handle various package sizes and styles, including single-serve and multi-pack options. They also offer high-speed wrapping capabilities, making them ideal for large-scale cookie production.

Q: Can industrial packaging machines handle delicate cookies without damaging them?

A: Yes, modern industrial packaging machines are designed to handle delicate cookies and other fragile baked goods with care. Many machines incorporate gentle handling mechanisms and adjustable settings to ensure that cookies are packaged without breakage or damage. Some systems even include specialized features like cushioned conveyors or soft-touch grippers to protect delicate products during the packaging process.

Q: Are there packaging machines specifically designed for weigh filling of cookies?

A: Absolutely! There are packaging machines specifically designed for weigh filling of cookies and other baked goods. These machines use precise weighing systems to ensure accurate portioning of cookies into packages. They can be integrated into complete packaging lines and are often used in conjunction with automatic flow wrapping machines or form fill and seal baggers for a comprehensive packaging solution.

Q: How can I choose the right packaging machine for my bakery’s needs?

A: To choose the right packaging machine for your bakery, consider factors such as production volume, types of products, desired packaging styles, and available space. Assess your current and future needs, and look for machines that offer flexibility and scalability. It’s also important to consider factors like ease of use, maintenance requirements, and compatibility with your existing systems. Many manufacturers offer customization options, so don’t hesitate to contact us to discuss your specific requirements.

Q: What are the advantages of using automatic flow wrapping machines for cookie packaging?

A: Automatic flow wrapping machines offer numerous benefits for cookie packaging. They provide high-speed packaging capabilities, allowing for increased production output. These machines can create hermetically sealed packages, ensuring product freshness and extending shelf life. They also offer versatility in packaging formats, including pillow packs and fin-sealed packages. Additionally, automatic flow wrappers can easily integrate with other systems in your packaging line for a seamless production process.

Q: Can industrial packaging machines handle both fresh and frozen cookies?

A: Yes, many industrial packaging machines are designed to handle both fresh and frozen cookies reliably. These versatile machines can be equipped with temperature control features to maintain product quality during packaging. Some systems also include specialized components for handling frozen products, such as frost-resistant materials and heated sealing jaws, ensuring efficient packaging regardless of the product’s temperature.

Q: What types of packaging materials can be used with industrial cookie packaging machines?

A: Industrial cookie packaging machines can work with a variety of packaging materials, including flexible films, laminates, and foils. They can handle materials suitable for creating stand-up pouches, pillow packs, and other popular packaging formats. Many machines are compatible with eco-friendly and recyclable materials as well. The choice of packaging material depends on factors such as product requirements, shelf life expectations, and marketing preferences.

Q: How can I ensure my packaging machine maintains consistent quality for different cookie types?

A: To maintain consistent quality across different cookie types, look for packaging machines with adjustable settings and easy changeovers. Many modern machines offer programmable recipes for different products, allowing you to switch between cookie types quickly and efficiently. Regular maintenance, operator training, and quality control checks are also essential. Some machines include built-in quality control features, such as weight checkers or vision systems, to ensure consistent packaging quality for various cookie types.