Across the food industry, whether it is a small restaurant or a large food processing company, an automatic chicken cutting machine can be a huge workload reliever. This post aims to assist the reader in comprehending some of the major features and challenges involved while selecting the relevant automatic cutting machines. Broadly, we will be focusing on the various types of machines starting from the small machines found in restaurants to the large machines found in factories for efficient decision making among the target audience. Moreover, we will also examine how cutting the chicken into pieces without human hand involvement increases productivity and also the quality of the finished product. This entire write-up should be understood by everyone in the industry, experienced or newbie, who wants to know which among the various available machines is suitable for their operations.

How Does an Automatic Chicken Cutting Machine Work?

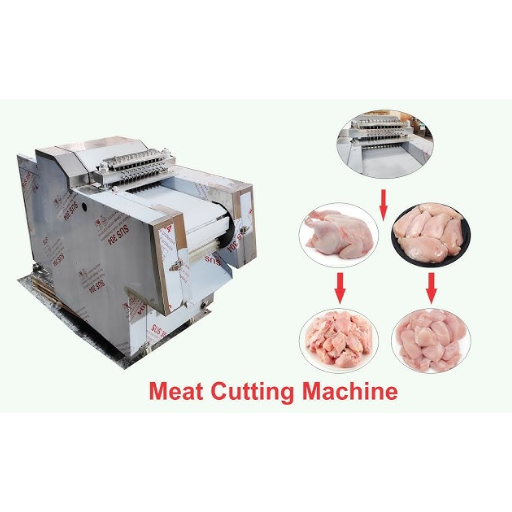

An automatic chicken cutting machine functions by using a series of blades and mechanisms specifically designed to process poultry efficiently. The machine draws in whole chickens or chicken parts and feeds them through a conveyor or processing line. As the poultry progresses through the system, it passes by strategically positioned blades that cut the meat based on pre-set specifications. These machines often allow for adjustments in cutting size and style to cater to diverse culinary needs. Some advanced models incorporate sensors or cameras to ensure precise cutting and consistency, while others may include options for deboning and portioning. By automating these tasks, the machine drastically reduces manual labor and increases output, providing consistent results with minimal human intervention.

Understanding the Mechanism Behind Chicken Cutting Machines

To grasp how chicken cutting machines operate and answer related questions, consider their components and operation. These machines efficiently handle poultry by using rotating blades and adjustable settings. Sensors detect the size and instruct blades to make accurate cuts. Machines pull chickens along conveyer paths toward customized blade placements. Advanced models use integrated scanners to boost precision by analyzing each piece before cutting. This automation speeds up production and ensures uniformity, reducing human involvement while maintaining high-quality outcomes.

The Role of Blades in Efficient Meat Processing

The significance of the blade in a meat processing activity is as it increases the efficiency and the accuracy of operations. Blades easily cut through the bird with little effort and give uniform sized and quality produce. The application of stainless steel is also good for this purpose as it enhances the life span of the blade. Basic maintenance such as sharpening and cleaning ensures the blades are safe and effective. Modern devices allow for easy use of blades since they self-adjust to different forms and sizes of meat. Blades also enhance the performance as they make the meat cutting efficiency better, help in reducing waste and hence more meat can be obtained. This would be very important in the meat supply chain as the blades aid in improving the outputs of the meat processing sector.

Ensuring Hygiene and Safety Standards

Meat processing involved several hygiene and safety concerns, which if neglected could adversely affect the processing of meat and even consumer trust. I often carry out cleaning of the entire machine to avoid contamination. Certain measures are taken to make sure every part, particularly blades, is washed daily. In order to avoid accidents and protect staff, personal protective equipment (PPE) is enforced. Regular inspections are necessary for timely identification of risks and problems with machinery. I make sure that professional standards are implemented in practice by properly instructing personnel and using operating instructions. Increasing hygiene and safety compliance, I keep the production environment clean and organized.

What Are the Benefits of Using a Chicken Cutting Machine?

Using a chicken cutting machine offers numerous benefits that significantly enhance the meat processing operation. Firstly, it increases efficiency by drastically reducing the time required to cut poultry compared to manual methods. This leads to a higher production capacity and allows for better management of labor resources. Secondly, the machine delivers consistent cuts, ensuring uniformity in size and portion, which is crucial for packaging and presentation. Additionally, chicken cutting machines improve safety by minimizing direct contact with blades, thereby reducing the risk of workplace accidents. These machines also help in maintaining hygiene standards, as they are designed for easy cleaning and sanitation. Overall, the use of a chicken cutting machine enhances productivity, consistency, safety, and hygiene within the meat processing industry.

Enhancing Efficiency in Meat Processing

To enhance efficiency in meat processing, chicken cutting machines streamline operations by performing fast and accurate cuts. These machines increase production speed, allowing facilities to meet high demand while managing labor costs effectively. Uniform cuts improve packaging consistency and product appearance, making them ideal for commercial sales. Additionally, these machines incorporate safety features to minimize direct blade contact, reducing workplace accidents. Their design prioritizes ease of cleaning, helping maintain stringent hygiene standards essential in food processing. Overall, adopting automated cutting technology boosts productivity, maximizes cost-effectiveness, and ensures high-quality, safe products.

Reducing Manual Labor in the Kitchen

Reducing manual labor in the kitchen involves technological innovations like food processors, blenders, and automated cutters. These devices simplify meal preparation by quickly chopping, blending, and slicing ingredients. Such appliances save time and reduce physical strain, making cooking more efficient and less exhausting. Automation eliminates repetitive tasks like kneading dough or whisking batter, allowing chefs to focus on creativity. Moreover, smart kitchen gadgets equipped with IoT technology enhance precision by offering programmed cooking times and temperatures. Thus, integrating these tools into daily activities streamlines operations and boosts productivity.

What Types of Chicken Cutting Machines Are Available?

Chicken cutting machines come in various types, each designed to fulfill specific processing needs. Some popular options include manual chicken cutters, which are simple and cost-effective for smaller operations. For larger production lines, semi-automatic machines offer a balance between manual operation and automation, providing decent throughput and ease of use. Fully automatic chicken cutting machines, on the other hand, deliver the highest levels of efficiency and precision, often incorporating advanced features like programmable settings for different cuts. Additionally, specialized machines such as breast deboners or wing segmenters focus on processing specific parts of the chicken, enhancing versatility in food production environments.

Exploring Automatic and Manual Options

Automatic chicken cutters offer high speed and precision, ideal for large-scale operations. These machines reduce labor costs by enhancing productivity through programmable settings. Conversely, manual chicken cutters are budget-friendly and suitable for smaller scale needs, providing control and flexibility without significant upfront investment. Semi-automatic machines bridge the gap, offering a mix of efficiency and hands-on operation, suitable for businesses aiming for balance between cost and output. Each type includes various features, such as adjustable blades and safety mechanisms, to cater to diverse processing requirements.

Comparing Bone Saw and Cutter Models

Bone saws and chicken cutters each serve distinct roles in poultry processing. A bone saw excels in cutting through hard bones, making it ideal for larger cuts like whole chickens or turkeys. It operates with a rotating blade, ensuring precise and smooth cuts, highly valued in butchery for its efficiency. Chicken cutters, however, focus on separating meat from bones, offering precision in slicing and dicing. These machines use sharp blades to target specific sections, perfect for preparing boneless products. By choosing the right model, businesses can enhance productivity, maintain quality, and meet their unique processing demands efficiently.

Choosing the Right Machine for Poultry and Beef

When choosing the right machine for poultry and beef, I first consider the scale of my operations. For large-scale processing, automatic machines are my go-to for their speed and precision. If budget constraints arise, I prefer manual cutters for smaller tasks, as they are affordable and easy to control. The need for a balance leads me to semi-automatic models, offering a good mix of efficiency and manual input. To handle different processing needs, I look at features like adjustable blades and safety mechanisms. Ultimately, I pick a machine based on whether I need to cut through bones or focus on meat separation, always aiming to boost productivity and quality.

How to Choose the Best Beef Pork Chicken Cutting Machine?

To choose the best beef, pork, or chicken cutting machine, start by assessing your specific processing requirements. Identify whether your operations involve handling large cuts with bones or focusing on precise meat separation. For tasks requiring repetitive bone cutting, a bone saw might be ideal due to its efficiency and strength. Conversely, if your goal is to produce boneless cuts with fine slices, a chicken or meat cutter with sharp, precision blades will be more suitable. Consider the scale of your operations; large-scale processing may benefit from automatic machines for their speed, while smaller setups might work well with manual or semi-automatic models. Pay attention to features such as blade adjustability, safety mechanisms, and ease of maintenance, as these factors will contribute to enhanced productivity and quality. Balancing these aspects based on your unique processing goals will guide you to the most effective machine for your needs.

Factors to Consider: Blade Quality and Thickness Adjustment

Blade quality is crucial. High-quality, stainless steel blades last longer and resist corrosion. For thickness adjustment, machines with adjustable settings allow for versatile cutting, catering to different customer demands. A good system should be easy to operate, ensuring consistent slice sizes every time. Reliable thickness control boosts efficiency and reduces waste. Always favor models that offer quick and safe blade swaps to minimize downtime and enhance workflow. These features collectively improve productivity and meet diverse processing needs effectively.

Understanding Warranty and Service Options

In regard to the construction and design of the meat processing machine, warranty and service options should be given due consideration. Pay attention to the manufacturers who are willing to provide you a one year reliable parts and labor warranty. Such warranty allows great ways of protecting the machine against any defects. Moreover, high-profile features such as troubleshooting that involve consumer service representatives should be looked at as well. Manufacturers that provide maintenance services also help extend the reliability of the machine. Make sure replacement parts are on hand so that the amount of downtime is reduced. Anytime any of these factors are concentrated on, there is any efficient operation and it ensures that the device in question is well maintained.

Evaluating Cost-Effectiveness and Long-Term Value

When evaluating cost-effectiveness, I prioritize upfront costs and expected savings over time. I look for machines with energy-efficient ratings which can significantly reduce operating costs. Additionally, I consider the potential for increased revenue through enhanced productivity. For long-term value, I assess the machine’s durability and maintenance needs. Choosing a model with a strong warranty and easy access to spare parts contributes to its longevity. I also look at user reviews to gauge real-world performance and reliability. By focusing on these factors, I ensure my investment effectively meets my processing needs while remaining a financially sound decision.

What Are the Maintenance Tips for a Frozen Chicken Cutting Machine?

Regularly conducting maintenance on your frozen chicken cutting machine will provide it with a long lifespan and excellent efficiency. Here are some tips provided by manufacturers for maintenance of the machine:

Cleaning The Machine: Use appropriate detergents for cleaning. After every use or the end of every shift, the machine should be cleaned dried and assembled again.

Maintaining Lubrication: Depending on the manufacturer’s guidelines some moving parts of the machines may require lubrication infrequently to prevent friction.

Maintaining Blades: Blades of the machine need to be checked for their sharpness and any signs of wear. If the blade appears to be blunt or damaged, it should be sharpened or replaced as necessary.

Holding Inspections: Make sure to check the machine regularly to see if there is any possible wear that can occur over time. If there are any such issues, they should be dealt with immediately to avoid going for larger repairs.

Checking Wiring: All electrical connections should be firm and connections connected to the cords should be undamaged; frayed wires and malfunctioning parts should be replaced.

Regular Cleaning and Sanitization Processes

To maintain a frozen chicken cutting machine, begin by consistently cleaning it after each use. Quickly remove any leftover debris using mild cleaners, ensuring every part is dry before putting it back together. Keep all moving parts in top shape by lubricating them regularly; this prevents excessive wear. Pay special attention to blades—check often for sharpness and replace them if damaged. Regularly inspecting the machine helps spot any issues early—fix them before they worsen. Lastly, ensure all electrical components are intact and functioning, replacing any damaged connections promptly. These steps will keep your machine running efficiently and extend its lifespan.

Routine Inspection and Blade Sharpening

Regular inspections are crucial to catch any early signs of wear and tear. Examine the machine weekly, looking for loose bolts and any unusual noises. For blades, aim to sharpen them after every 10 hours of use. Use a proper sharpening tool to maintain their edge. Sharp blades ensure precise cuts and reduce stress on the motor. If you notice blades are chipped or damaged, replace them immediately to avoid further issues. Consistent care like this keeps the machine reliable and extends its operational life.

Prolonging the Lifespan of Your Processing Equipment

First, establish a cleaning routine that includes removing debris and drying all components thoroughly. Use mild cleaners and lubricate moving parts to avoid wear. Inspect blades frequently for sharpness and replace them if damaged. Check the machine weekly for loose bolts and odd noises. Replace worn or damaged blades immediately to ensure precision and preserve the motor. Ensure all electrical connections are intact and replace malfunctioning parts without delay. These preventative steps keep your processing equipment efficient and extend its service life.

References

-

Semantic Scholar – Development of Automatic Chicken Cutting Machine: Discusses the development and benefits of automating chicken cutting processes.

-

Reddit – Tools for Auto Dicing Chicken: A community discussion on tools available for dicing chicken.

-

Featherman Equipment: Offers a variety of poultry processing equipment, including chicken pluckers and other tools.

Frequently Asked Questions (FAQ)

Q: What is a full automatic chicken cutting machine?

A: A full automatic chicken cutting machine is a device designed to efficiently cut chicken into various sizes and shapes, such as cubes or slices, with minimal human intervention. It is often used in commercial kitchens and poultry processing facilities for its high efficiency and ease of operation.

Q: Can the chicken cutting machine cut other types of meat like beef or pork?

A: Yes, many chicken cutting machines, including the Chickenninja, are versatile and can handle beef, pork, and other meats. They are equipped to cut both fresh and frozen meats, making them suitable for a variety of meat processing tasks.

Q: What types of cuts can a chicken cube cutting machine make?

A: A chicken cube cutting machine can make precise cuts into cubes, slices, or strips, depending on the settings and blade configuration. It is designed to handle both fresh and frozen chicken meat efficiently.

Q: How does a meat cutting machine ensure hygiene?

A: A meat cutting machine ensures hygiene through its design and materials. They are typically made from stainless steel, which is easy to clean and resistant to corrosion. Regular maintenance and proper cleaning protocols further ensure that the equipment remains hygienic during operation.

Q: What is the advantage of using a chicken cutting machine from Coimbatore?

A: Chicken cutting machines from Coimbatore are known for their durability, high efficiency, and advanced technology. They are often customizable and supported by local manufacturers, providing excellent after-sales service and technical support.

Q: Are there specific models suitable for small kitchens?

A: Yes, there are various models, including compact versions, suitable for small kitchens. These machines, while smaller in size, still offer high efficiency and can handle commercial chicken processing needs.

Q: What should I consider when choosing a chicken cutting machine manufacturer?

A: When choosing a chicken cutting machine manufacturer, consider factors such as the quality of materials used, the machine’s efficiency, ease of use, maintenance requirements, and the availability of customer support. It’s also important to evaluate the manufacturer’s reputation and experience in the industry.

Q: Can a chicken ninja floor model handle frozen chicken meat?

A: Yes, many chicken ninja floor models are designed to handle both fresh and frozen chicken meat effectively. They are equipped with robust motors and blades that can cut through tougher textures like frozen meats.

Q: Is it possible to adjust the cutting thickness on a meat slicer?

A: Yes, most meat slicers, including those used for chicken and other meats, offer adjustable cutting thickness. This allows users to customize the size of the slices according to their specific needs.

Q: What are the benefits of using a bone cutting machine in poultry processing?

A: A bone cutting machine is essential in poultry processing as it provides precise cuts, reduces wastage, and improves efficiency. It is designed to handle bones without damaging the meat, ensuring a clean and professional cut every time.