In the current modern culinary scenario, possessing certain tools tends to make a lot of sense. These include cheese cutting machines. This blog post aims at informing its readers about the latest trends in these machines by concentrating on how the machines which have been designed recently can promote efficiency and accuracy in the cheese cutting process. We will look at the options, their scope and variety and how they are suitable for the layman and the professional. Regardless of whether you are preparing a cheese plate for a social dinner or using it to eat Gouda cheese at your home, these machines are going to enhance your cheese experience further. Let us tell you which cheese cutting machine would be the best for you and transform your kitchen into a center of excitement.

What Are the Main Features of a Cheese Cutter Machine?

Precision Cutting: These machines guarantee clean and uniform slices, enhancing presentation and portion control.

Adjustable Settings: Users can customize slice thickness to suit various cheese types and personal preferences.

Durable Construction: Made from high-quality materials, these machines withstand regular use and maintain sharpness.

Ease of Use: Intuitive designs ensure operation is simple and user-friendly, requiring minimal effort.

Safety Measures: Non-slip bases and finger guards protect users, reducing the risk of accidents during operation.

Understanding the Precision of Modern Cheese Cutting Equipment

Modern cheese cutting equipment excels in precision due to several key innovations. Advanced blade technology ensures accurate and consistent slices, crucial for presentation and portioning. The customizable settings allow users to adjust thickness based on cheese type, enhancing versatility. Sturdy materials like stainless steel increase longevity and maintain blade sharpness even with frequent use. Intuitive design features, such as ergonomic handles and non-slip bases, simplify operation and promote safety. These advancements make cheese cutting equipment not only efficient but also essential for both culinary professionals and home cooks seeking impeccable results.(Recommended: Processing and Packaging Machines)

Exploring the Benefits of Stainless Steel Blades

The use of stainless steel blades for cheese cutting tools has several advantages over their counterparts. They are resistant to rusting, thus enhancing their longevity and reducing the costs associated with replacing them. The angle of the cutting edge of stainless-steel blades improves accuracy and always provides cut meat evenly and neatly. These blades hold their own over time and do not get blunted fast despite being used regularly. They are however easy to maintain and do not encourage any cross contamination of taste between different types of cheese. To sum up, stainless steel blades improve effectiveness and reliability; hence, making them suitable and preferred for both normal kitchen and professional chef’s environment.

How to Choose the Best Cheese Slicer for Your Needs?

Choosing the best cheese slicer involves considering key factors. First, decide on the type—wire slicers are great for soft cheeses, while plane slicers work well for hard varieties. Look for durable materials like stainless steel for longevity. Consider adjustable thickness settings for versatility in slicing. Ergonomic handles enhance comfort during use. Lastly, ensure the slicer is easy to clean to maintain hygiene. By focusing on these elements, you can select a slicer that caters perfectly to your cheese preferences and cooking needs.

Factors to Consider for Different Types of Cheese

When choosing a cheese slicer, consider the cheese type. For soft cheeses like Brie, a wire slicer works best to create precise cuts without sticking. Hard cheeses such as Parmesan need a sturdy plane slicer with sharp edges to handle firm textures. Semi-soft cheeses benefit from an adjustable slicer to cut varying thicknesses. Moist cheeses require slicers with non-stick properties to prevent residue build-up. Additionally, select a slicer with a comfortable grip for ease of use, ensuring a smooth slicing experience across different cheese types.

The Importance of an Adjustable Blade

An adjustable blade lets me control slice thickness, accommodating different recipes and presentations. It helps me achieve precision whether I’m slicing thick chunks for cheese boards or thin slices for sandwiches. This flexibility reduces waste, as I can adapt the slicer to the specific cheese and dish, ensuring every slice is perfect. Overall, an adjustable blade enhances my efficiency and creativity in the kitchen.

Finding a Professional Cheese Cutter for Soft Cheese

For soft cheeses, selecting the right cheese cutter is crucial to ensure clean, precise slices. When browsing for a professional cheese cutter, prioritize those with wire or thin, sharp blades designed specifically for soft textures. These tools minimize sticking and tearing, providing smooth, consistent slices each time. Check for adjustable wire slicers that allow for thickness customization, enhancing versatility for different cheese types. Consider ergonomic designs that promise comfort during prolonged use. Additionally, look for durable construction and materials that resist corrosion, ensuring longevity and hygiene. With these considerations, you can find an ideal cheese cutter that handles soft cheeses effortlessly, enhancing your culinary presentations.

Why is Stainless Steel Preferred in Cheese Cutting Machines?

Stainless steel is preferred in cheese cutting machines due to its durability and resistance to corrosion. Its strong, non-reactive surface stays sharp longer and retains its integrity through frequent use. Stainless steel also offers easy cleaning, maintaining high hygiene standards essential for food preparation. This material’s robustness ensures it can handle both hard and soft cheeses effectively, making it a practical choice for regular kitchen use.

Durability and Hygiene Benefits of Stainless Steel Cheese Equipment

Stainless steel cheese equipment stands out for its unmatched durability and superior hygiene qualities. The material’s resilience allows it to withstand daily use without losing strength or shape. Its corrosion-resistant nature ensures the equipment remains rust-free, safeguarding the food’s quality. Stainless steel’s non-porous and smooth surface simplifies cleaning, effectively reducing bacteria buildup and ensuring the highest hygiene standards. Furthermore, this material is non-reactive with acidic foods, maintaining taste integrity. These properties make stainless steel an essential component in cheese cutting environments, promising consistent performance and longevity.

Comparing Stainless Steel Cutting with Other Materials

When comparing stainless steel to other materials in cheese cutting, several factors are evident. Stainless steel excels in its durability and corrosion resistance, outperforming materials like plastic and aluminum that may warp or rust over time. It maintains a sharp edge longer than ceramic, which is brittle and can chip. Unlike wood, which is porous and prone to bacteria buildup, stainless steel’s non-porous surface ensures easy cleaning and superior hygiene. Additionally, it remains non-reactive, preserving the natural flavors of the cheese. These advantages highlight why stainless steel remains the top choice for cheese cutting equipment.

Can a Cheese Slicer Handle Other Food Products?

Yes, a cheese slicer can handle other food products. Its sharp blade can effectively slice fruits, vegetables, and deli meats. However, softer or more delicate foods may need a more specialized tool to avoid damage. Always ensure cleaning between uses to maintain hygiene and taste integrity.

Versatility in Cutting Meat and Cheese

A cheese slicer’s versatility extends to slicing various meats efficiently, owing to its sharp blade that glides through both hard and soft products. According to top sources online, stainless steel slicers significantly enhance performance due to their durability and non-porous nature, which ensures consistent hygiene and ease in cleaning. Unlike tools that require frequent sharpening, high-grade stainless steel maintains its cutting edge longer, saving time and effort. Additionally, its non-reactive quality guarantees that both meats and cheeses retain their natural flavors, providing a reliable and versatile slicing option in any kitchen environment.

Understanding the Shape and Portion Control

Understanding the shape and portion control of cheese is crucial for both aesthetics and taste experience. Cheese slicers enable precise portioning, allowing consistent slices that enhance the presentation and flavor balance. The tool’s design ensures even thickness, which is essential for recipes that depend on uniform cooking or melting. By utilizing a cheese slicer, you can easily manage portion sizes to reduce waste and maintain dietary control. This efficiency benefits both home cooks and professional chefs who emphasize consistency in their culinary creations.

What Are the Innovations in Industrial Cheese Cutting?

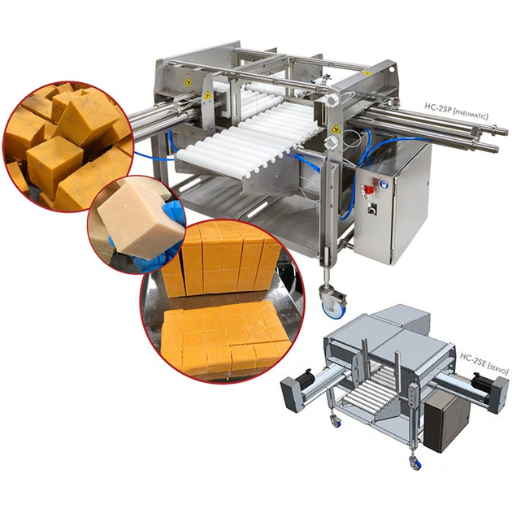

Industrial cheese cutting has seen significant innovations in recent years. Advanced machines now use laser technology for precision slicing, which minimizes waste and ensures uniformity. High-speed cutters with automated controls allow manufacturers to slice large batches efficiently. Furthermore, the integration of AI and IoT technologies enables real-time monitoring and adjustments, enhancing consistency and quality. These developments not only boost productivity but also maintain high standards in cheese texture and presentation.

The Role of Cutting Wires in Hard Cheese Processing

Cutting wires play a vital role in hard cheese processing, offering precision and efficiency. These wires slice through dense cheese blocks with minimal waste and ensure uniformity in each cut. Their sharpness and strength maintain cheese integrity, while their flexibility accommodates various shapes and sizes. This tool significantly boosts production speed, reduces manual effort, and enhances the consistency of cheese products, meeting both consumer and industrial standards.

Exploring the Cheese Cutter Divide-O-Matic

The Cheese Cutter Divide-O-Matic revolutionizes cheese processing with its efficient and precise slicing capabilities. Its advanced blade technology ensures uniform cuts and reduces product waste, optimizing the output for both small-scale and large operations. The device’s user-friendly interface allows operators to adjust slicing parameters easily, accommodating different cheese types and sizes. Built with durability in mind, the Divide-O-Matic requires minimal maintenance, increasing uptime and productivity. By integrating cutting-edge features, it meets the demands of modern cheese production, enhancing both efficiency and quality.

References

-

Precision Cheese Cutting Equipment – HART Design – Offers a range of equipment for precise cheese cutting, including conveyors and trimming tools.

-

Intelligent Cheese Cutting Systems – Marchant Schmidt – Features systems using 3D camera technology for precise cheese cutting.

-

Cheese Cutting Tools – Wasserstrom – A selection of cheese cutting tools from various brands.

Frequently Asked Questions (FAQ)

Q: What makes the latest cheese cutting machines easy to use?

A: The latest cheese cutting machines are designed with user-friendly features such as interchangeable cutting blades and ergonomic handles, which make them easy to use. Many models also have intuitive controls and compact designs that fit well in any kitchen setup.

Q: Can these machines handle different types of cheese like mozzarella and cheddar?

A: Yes, the machines are versatile and can handle various types of cheese, including mozzarella and cheddar. They are equipped to cut through different textures, whether soft or hard, providing consistent and precise results.

Q: Are cheese cutting machines suitable for cutting cheese blocks and loaves?

A: Absolutely, these machines are specially designed to efficiently handle large cheese blocks and loaves. They provide even and accurate cuts, allowing you to slice, dice, or cube cheese portions as needed.

Q: What is the benefit of having interchangeable cutting blades?

A: Interchangeable cutting blades offer flexibility and customization for different cutting needs. You can easily switch blades to achieve various types of cuts, such as slicing, dicing, or shredding, ensuring you have the perfect cut for every cheese and other food products.

Q: How do these machines ensure precise cut quality and exact weight for cheese portions?

A: The machines are equipped with advanced technology and robustly designed cutting lines that allow for precise cut quality and consistent weights of cheese portions. This feature is particularly beneficial for deli and commercial settings where exact measurements are crucial.

Q: Are the machines easy to clean and maintain?

A: Yes, most cheese cutting machines feature easy-to-clean designs, often with removable parts and sanitary materials like stainless steel 304, making maintenance straightforward and hassle-free.

Q: Can these machines be used for cutting other food products besides cheese?

A: Many cheese cutting machines are versatile and can be used for cutting other food products, such as sausage and ham. Their robust construction and adaptable design make them suitable for a variety of slicing tasks in the kitchen.

Q: How does the design of these machines contribute to an economical and efficient operation?

A: The compact footprint and efficient use of raw materials in the design of these machines contribute to economical operation. They are built for years of trouble-free service, ensuring long-term reliability and efficiency in cutting cheese and other food products.

Q: What makes the Boska cheese cutter stand out in terms of design and functionality?

A: The Boska cheese cutter is renowned for its hart design and the use of high-quality materials. It features a robust construction ensuring years of trouble-free service, making it a top choice for both home and professional kitchens.

Q: Is it possible to achieve custom cuts, such as angular portions or euroblocks?

A: Yes, many modern cheese cutting machines offer the ability to customize cuts, including angular portions and euroblocks, thanks to their adjustable settings and precision cutting capabilities.