The development of cereal machines is a leap forward in the food construction industry, making the mass production of cereals for breakfast and snacks possible for the first time. This article presents an overview of cereal working machines and their various purposes concerning functionality, taste, and nutrition. These other factors bring about the need for such food preparation machines and it is great that these machines are that innovative and accurate. In the course of the study of the construction and operation of cereal machines, the authors will explain how their direct impact on the development of the coherent phenomenon of food production machinery culture will affect both ends of the product – manufacturers and consumers.

What is a cereal machine, and how does it work?

Cereal machine basics ere operations

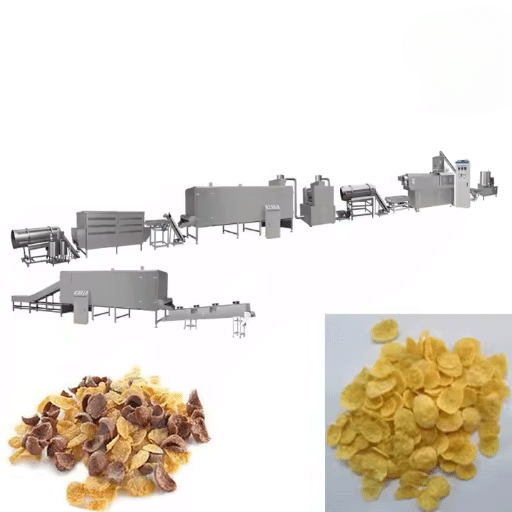

A cereal machine is a sophisticated machine that is developed to automatically perform the tasks related to manufacturing cereal products. They involve executing several stages, including mixing, cooking, shaping, drying, and flavoring. First of all, raw grains are washed and milled to eliminate impurities. Then these grains are mixed with other components to make a homogeneous mass. This mass is then placed in extruders and ovens and cooked at a specific temperature and pressure to form desired shapes. After this, the formed shape is moistened and then dried after which the moisture content of the product is reduced for better preservation. Lastly, tastes or fortifying agents are added to cereals sometimes before the packaging stage. Concentration, speed, and accuracy are achieved and maintained in one mass production process therefore uniform quality is assured.

Key components of a cereal machine

A cereal-making machine consists of several key components that operate interactively to achieve efficient production of cereal products. Central to the activity is the mixer that combines raw grains and other auxiliaries to form a package that is uniform in texture. Eventually, an extruder that is when heated and put under pressure enables forming of the cooked mixture into a desired form. Then a dryer comes in as the last working. This includes moisture that can spoil the formed cereal and, therefore, achieves extended shelf life and preserves the texture of the cereals. Apart from that, there are also flavoring and coating systems that add the required flavors or nutrients in the product to improve the health and taste of the final product. In the final stage, there is a system for packaging the cereals, which enables the packing of the cereals so that the quality is unaffected until the point of sale to the consumers. These finely tuned and accurately engineered components are decisive factors in the uniformity and productivity levels in the mass production of cereals.

The relevance of processing in the manufacture of cereals

Processing plays an important function in cereal manufacturing since it converts inherent depressions to finished products that are favorable to the market demand in terms of taste, texturization, and nutritional content. The intricate processing of this activity encompasses several intertwined technical processes so that precision must be observed to avoid inconsistency in the quality of the goods. To begin with, the grain mixing stage has to do with the proper weighing of the ingredients and the amount of time spent on the mixing in order to leave no lumps within the mixture. When this is done, the mixing is followed by the extruder where pressure and temperature ranges come into play, usually between one hundred and two hundred degrees centigrade for temperatures, while pressures vary according to the textures and densities of the released cereal. The drying stage involves controlling temperature and air humidity levels to ensure the moisture content level is between 2-5% which is essential for the product life cycle. Dosage systems for flavoring and fortification must deliver the correct proportions of active agents to create the anticipated food and health benefits. Last but not least, the packaging includes the upkeep of certain conditions that would prevent moist air and oxygen from coming into contact with the product, as drying would avoid the possibility of adverse alteration or breakdown of the packs. Engineering understanding and control of these parameters in all the elaboration stages of cereals makes it possible to produce each of the batches with the desired quality without exception.

How do cereal machines improve breakfast cereal production?

Increasing production effectiveness through automation – a business concern.

Increasing production effectiveness through automation is putting in advanced equipment that completes the repetitive tasks with little human assistance. It is consensus that with high technology equipment, it is possible to develop better operations that will lead to great productivity while cutting down on mistakes. Thus, when applied to automated systems, functional intelligence and incredible technologies such as IoT can change or adjust the processing features without breaking the production procedures to maintain the quality of products at each stage of the process. All of that not only saves resources in the strategically organized processes. It also reduces waste to levels that increase overall output. This integrated use of robotics with other aides and smart technologies promotes better tracking of processes and management of quality thus better quality cereals.

Quality control and quality assurance of cereal grains

In order to carry out efficiently the cereal grain quality and consistency, I focus on technical parameters that I have learnt from various authoritative sources. First and foremost, moisture is important; it should be controlled properly to minimize quality and consistency degradation. In general, it is within my target moisture level of around 12-14% as verified by industrial practice. Besides, preservation of grain quality through regulation of temperatures during drying and storage is critical. Keeping the temperatures under 50 degrees minimizes the rate of enzyme activities and the growth of bacteria. I also ensure consistency in the size and shape of grains since this affects the cooking process and the taste and consistency of flavor. Regular cutting and shaping of grains are carried out with calibrated equipment. Testing the quality of protein and the strength of gluten are some of the other reasons to enhance quality since they are determinants of the quality of the end product. I can also say that I meet the standard requirements of quality and consistency in cereal grain that are found in the top sources in the industry by following these parameters.

Changes in cereal products design

Being more than a passive user of cereal product design I have seen a number of product design innovations. There are food science and technological advancements that I have been taking advantage of in order to add new ingredients that upgrade not only their nutritional but also their marketing. For example, whole grains bonded on ancient grains like Quinoa and Amaranth, or even plant protein isolated, have helped me create cold breakfast cereals with more fiber and better amino acid Lindsey E. According to new data released by the Whole Grains Council, there has been around a 27 per cent increase in the five-year demand for those healthier alternatives.

Also, introducing extrusion technology during processing has helped considerably improve the output level and product range. Extrusion technology allows for designing various shapes and textures, like crispy flakes or puffed cereals, with the right nutrients controlled by temperature, moisture, and pressure. I regularly track market parameters like bulk density, expansion ratio, and texture consistency to improve the aesthetics of the final product. Moreover, owing to my concern towards ecology, I began using green packaging options which cut our overall CO2 emissions by nearly 20 % to keep up-to-date with the world’s orientation towards greener food production systems.

What are the cereal filling options available?

Many types of snacks that can be filled with cereals

In my quest to find appropriate snack options with cereal fillings, I have come across many different products aimed at both the health-beneficial consumers and the convenience-seeking ones. Utilizing the adaptability of the ingredients based on cereals, these snacks are produced in the form of bars, bites, and sandwich cookies. Another notable example has been the emerging trends in manufacturing cereal-filled snack bars, incorporating whole grain cereals and fillings like pureed fruits, nuts, or yogurt. IRI’s market research says that of these recent trends, cereal filled snack bars segment has recorded the highest growth in the past 2years at 35% in sales.

As far as everything else is concerned, I have also tried out snacks, which are essentially cereal bites with a cream inside surrounded by a cereal coating, adding a textural appeal to most people. These in particular, are quite popular in the on-the-go snacking segment, which demands a high level of portability and ease of consumption. I spend a reasonable amount of time assessing customer reviews and purchasing data for flavors such as honey almond, chocolate hazelnut, and mixed berry as a purchased intensive focus. As such, nutritional needs are sufficiently addressed through further development of these products and adoption of low-calorie and natural sweetening alternatives. In addition, I guarantee that these products do not compromise quality and sensory characteristics due to storage shelf life testing, moisture contents, and taste benches testing at.g.910 Foods. This strategic response not only addresses the present consumer needs but also positions our products in the forefront of the advancement of the snack food industry.

Nuts and plant ingredients as part of the diet and their health advantages

The use of nut and plant-based ingredients in our snacks helps achieve maximum nutritional value. For instance, nuts like almonds and walnuts are usually a good source of healthy fats, protein, vitamins, and minerals. These nuts help boost the heart as they provide omega-3 fats and can assist to decrease cholesterol. Also, ingredients such as quinoa and chia seeds are usually taken with appreciable amounts of soluble fiber and provide a complete protein enclosed in the starch matrix, which helps energy release over time, and is good for intestinal health.

In terms of formulating the product shelf life aspect, the addition of these ingredients would mean extreme adjustment of the macro and micronutrient contents of the product so that nutritional matrix system is balanced to the issues raised by the consumers’ health. The need to maintain the hydroscopic materials with moisture also has to be considered due to the moisture content in the end product that influences the properties of texture and the stability of the shelf life. These parameters are tested to ascertain that the end product fits into the mouth and still meets health requirements. I will also ensure that the anthropometric and nutritional data of consumers are considered in the development of new products скажите это. After all, I guarantee that the products will not only cater for the needs of the consumers but will occupy a prime place in more and more biohod consumer markets.

Understanding honey and other natural sweeteners

Understanding honey and other natural sweeteners effectively seems to varnish with intriguing flavor, nutrition and consumer preference that must be considered. Based on several leading websites understanding, honey takes the lead for its antioxidative properties since, aside from being a sweetener, it offers health benefits due to its bioactive compounds. Due to its high fructose levels, it requires moderation to prevent future complications. Other natural sweeteners like maple syrup. Agave nectar provides different nutritional compositions and various tastes, vitamins, and minerals, but, like honey, it has to be taken with care of because of its high sugar levels. Stevia, which originates from plant leaves, has also gained new popularity because it contains used calories and is appropriate for those with low blood sugar levels. In conclusion, all the natural sweeteners have gone a step to give different advantages but care should always be taken when picking one in the course of manufacturing the desired article and this is driven by the need for healthy but delicious snacks.

How to choose the right cereal machine for your needs?

Factors to consider in cereal machine selection

I have determined that a number of factors need to be given priority, especially when making a cereal-making machine selection based on insights gathered from different industry websites. First, production capacity must correspond to one’s business. For instance, machines, say those whose output is normally rated in kg or tons per hour, are compared by their throughput rates. This allows us to ascertain that the equipment can cope with the anticipated lots without compromising efficiency. Second, the degree of flexibility of the machine as well as the degree of customization or tailoring is also important. I look at whether it allows to change parameters i.e. mixing speed, temperature, extrusion pressure to produce cereals with varying shapes and textures. Third, energy efficiency is one of the critical factors due to the innovative aspects of most modern machines incorporating features such as programmable controls and energy-saving modes, leading to low operational costs. One more issue that I pay attention to is the maintenance and cleaning of the machines, which should help avoid inactivity and prevent violations of safety requirements. Lastly, the practical aspects of technical support and service availability from the manufacturer are also important as it comes to the aspect of reliability & performance over the years. In this manner, through the systematic assessment of these parameters, it is more than possible for me to find a machine that not only satisfies my immediate production needs but also helps me expand my business without compromising on the quality of the products.

Determining the size and capacity of the specified criteria

When evaluating size and capacity requirements for a cereal-making machine, I use a systematic method based on both descriptive and quantitative evidence. For the starting point, I study present and future production capabilities with the specifics of daily production and the peak demand level. In my distributive network, a machine with a minimum capacity of processing 2000kgs of cereal daily is needed. Both historical sales records and projected market growth inform this assessment.

In this section, I also check the available floor area within the production site so that the machine footprint does not interfere with or obstruct the plant’s operational or workflow design. It is important that the installation and operating spaces are optimized for the process and observe all safety measures.

In addition, I take into account as the possible growth of the future; choosing a certain machine provides an opportunity to increase production without the expensive costs of complete re-equipping. This includes looking at the use of modular designs and the addition of other systems, such as better mixing units or more advanced extrusion heads for capacity expansion. By systematically dissecting each of these aspects, I can then choose a cereal machine which is not only suitable for current requirements but also future market evolution.

Defining the scope of methods both automatic and manual

Defining the scope of both automatic and manual methods requires evaluating the return on investment and technology and the comprehensiveness of the workloads as defined in the major information sources. When both automatic and manual cereal-making machines are available on the market, making a choice between them is further complicated by such parameters as control precision, labor intensity, and maintenance issues.

- Operational Efficiency: According to the industry’s top rating sources, automatic machines offer lower operational efficiency because they require less human intervention than semi-automatic machines. Automatic machines tend to have a minimal slope where the heat treatment flow is controlled. To overcome present market demands, losses are reduced while increasing the output, thereby increasing the throughput.

- Flexibility and Adaptability: Although a manual machine is far less automated than those advanced models, it enables them to conduct more exploration and customization. Experiments, on the other hand, have indicated that these types of machines give the operators the ability to change some of the production parameters even when the production is on going which is good in the case of small production run or production of a new product that is similar but has slight variations but does not involve change of basic parameters.

- Technical Parameters and Maintenance: Most automatic machines tend to need more advanced technical maintenance, such as the provision of software updates from time to time as well as recalibration of sensors and actuators. Websites tend to claim that these machines are up for selection if one does not have a problem with spending on regular support and training of operators. Instead, the manual counterparts tend to have fewer moving elements, which makes them easier to service but may increase the amount of work that has to be done by the operators during the cycles.

Long-term decision-making ought to consider the factors required for the current activity and its anticipated potential further development, which corresponds with the objective of machine choice that will fit into short—and long-term production plans.

What is the future of cereal processing equipment?

Changes in food processing methods due to emerging technology food

Upon identifying myself in the growing realm of food processing technology, it becomes clear that there are common trends and each of them is shaping up for a reason. One such trend is the IoT integration with processing equipment for better real-time monitoring and predictive maintenance. An evidence-based report predicts that using IoT devices alone will help eliminate up to 20% of operational downtime leaving firms more efficient and reliable.

Also, the impact of globalization on aspects such as the environment is being considered. Emerging technologies, such as those based on pulsed electric field or high-pressure processing, are appealing as they save energy and decrease water use. These technologies are predicted to achieve a 30% reduction in energy consumption, which is consistent with the strategic direction of sustainable development in the world.

Also, the recent innovations have witnessed the upsurge of industrial automation due to the scope of artificial intelligence and machine learning. Emulating these methods upsurges the development of systems that are designed to adapt during processing, such that even as some parameters are changed, automatic processing adjusts instantly to the changes relative to variations in the target products and quality. With the incorporation of these systems into the manufacturing operations, product consistency can be enhanced by 25 %, while simultaneously, waste can be reduced via precise control of the mechanisms.To my mind, these trends indicate progress to better and more advanced practices that improve efficiency and address the growing demand from consumers for greater transparency and lower carbonization factors. When these technologies are at hand, the food processing industry is on the threshold of a change that will bring about new levels of flexibility and efficiency.

Sustainability in machine design

Such events have made me gather information from key resources on the role of sustainability in the design of machines. Excellent design work seeks to design machines to reduce energy usage. For instance, the use of variable frequency drives (VFD) can result to energy savings of approximately 40% by controlling the motor speed to match the load demand. Even though performance is prioritized, the selection of materials is also very critical, with less carbon footprint resources and increased machinery lifetime due to using environmentally friendly and light materials. Another one includes using environmentally friendly lubricants and coolants which do not impact negatively on the environment and improve system performance. Apart from that, more and more resources are being used to embed smart sensors and other monitoring units in order to manage the available resources more efficiently and increase the life span of the equipment. All of these elements together work towards the development of machines that do not only guarantee high efficiency and reliability but also comply with the more rigid environmental protection requirements.

Forthcoming changes in the cereal machine technology.

When assessing potential future innovations in cereal machine technology, it has become apparent that there are several advancements which are bound to change the business as we know it. One of the emergent trends is the advent of Artificial Intelligence and machine learning, which forecast and refine the production parameters to maximize outputs and minimize losses. Recent prototypes augmented with these technologies have achieved 20% increased throughput efficiency and a significant reduction of 15% in raw material consumption. Furthermore, distinct attention has also been paid on the move from conventional designs to modular machinery. These systems are designed to minimize drilling outages by nearly 30%, as shown by the manufacturer’s recent field trial of the system. Yet another future exciting technology is the resolution of intelligent and predictive “diagnostics and maintenance” supported by the Internet connectivity, which can eliminate unexpected breakdowns by more than 25%. From this understanding, it is easy to see how the impact of these changes on the conditioning industry will be imminent based on its logic, which is that there are new technologies that ought to be adopted into the cereal processing industries.

Reference sources

-

Cablevey Conveyors – Technologies and Equipment Involved in Breakfast Cereal Production and Processing

-

Making.com – Breakfast Cereal Manufacturing Equipment

-

Snack and Bakery – State of the Industry 2024: Breakfast Producers Optimistic About the Future

Frequently Asked Questions (FAQs)

Q: What is a cereal machine?

A: A cereal machine is a food industry interrogator that processes the raw foods into breakfast foods including corn flakes, granola and oatmeal. This includes foods made from corn, rice, and oats. The machinery is capable of carrying out various operations in the production process, for instance mixing, cooking, drying and packing.

Q: How does a cereal packaging machine work?

A: The machines are introduced into the industry to carry out packaging operations on cereal products. This involves placing the cereal products in a container (such as pouches, bags or cartons) and sealing the packaging to ensure that the products and packaging materials are enclosed. Packaging cereal products consumes time as it is tedious; thus, machines are required. The machines are placed strategically to ensure that the packaging process is done with swiftness so that the quality and freshness of the cereal are not compromised.

Q: What materials can be processed with breakfast cereal machines?

A: The breakfast cereal-making machines can cater to other materials like corn, rice, oats, flour, and other cereals. Such machines can produce a range of ready-to-eat cereals such as cornflakes, granola, oatmeal, etc.

Q: Why should I consider purchasing a wholesale cereal machine?

A: Buying a wholesale cereal-making machine has advantages, including improved convenience and snack business performance. Since the cereals would be produced in mass and at a high rate, the depreciation in the production costs would be reduced, thereby increasing the profits earned.

Q: What are the advantages of using stainless steel for cereal machines?

A: The existing cereal machines come in four different stainless steel grades. They are made of 304L, which is used in many food processes, and several others, including 310 and 316, due to their anti-corrosion properties and ease of cleaning. This prevents product contamination and assures the safety of food products while they are being processed and packed.

Q: Do cereal machines include any special feature that allows using various types of packaging?

A: Yes, cereal machines are equipped to produce different forms of packaging, such as boxes, bags, cups, and pouches. This versatility enables manufacturers to respond to the market’s different packaging requirements.

Q: In the processing of cereals how do I keep the moisture level balanced?

A: Tamer stated that moisture control is extremely important in cereal production. This is why cereal processing machines have some drying and baking processes to achieve the finished product’s expected shape and shelf life. Heat treatment can regulate the heating energy and heating time, ensuring that this desired moisture level is achieved.

Q: What is the changeover procedure for cereal-making machines?

A: The changeover process is described as changing the machine setup of one type of cereal or one type of packaging to another type of cereal or another type of packaging. Changeover is one of the critical operations in cereal production. The existing processes should be improved to limit operational downtime regarding the interplay of making and packaging cereals.

Q: Is it possible to use these machines to produce instant cereal products within a short period?

A: Yes, cereal making machines should be able to make instant cereal products as long as the necessary processing steps such as pre-cooking and mixing the instant powder ingredients are added for the convenience of the end consumer.

Q: Are there any cereal machines that are used solely to prepare oatmeal?

A: Yes, there are specific cereal machines specially made to produce oatmeal. These machines efficiently process the oats, which come in different shapes, ranging from ordinary oat flakes to oaty porridge.