In this detailed guide on cereal bar production lines. This article is intended to provide reasonably detailed answers to questions related to the entire production processes, starting from the choice of the raw materials which are the ingredients used in the final product and ending with its packaging. If you are potentially looking for smarter ways to establish yourself within the snack market as a new business owner or, are on the other end of the spectrum and are ready to take your existing production to the next level, this guide contains a wealth of information and tips. To achieve this, we will examine the most important equipment and technologies used in cereal bar production, examine the scope of measures that should be taken to provide the necessary quality of the end product, and outline the basic principles of preserving economic efficiency and sustainable development in the production of cereal bars.

What is a Cereal Bar Production Line?

Gaining Insight on the Cereal Bars Industrial Manufacturing Process

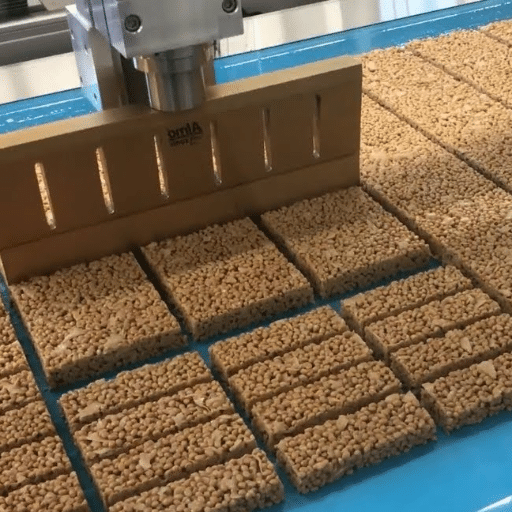

A process line of cereal bar filling machine can be described as a set of integrated machines and tools that incorporate high technology efficiency in the making of a cereal filling bar. It usually involves combining various food materials such as grains, or sweeteners, nuts and shaping them into bars, then baking or chilling them to harden and finally wrapping them for sale. Such production lines are made to improve effectiveness, accuracy and uniformity in the production of high quality cereal bars with minimal manual effort.

Key Components of a Cereal Bar Production Line

A cereal bar production line consists of various units that are integrated to give a smooth production flow. These units usually comprise of mixers where the ingredients are blended; Elioting devices that cut the journal into bars;stoves or cooling wigwams for solidifying the bars: and packing machines that wrap and-ready the bars for the market. Each unit is important in thye facilitation of smooth operation and quality of the production line.

The function of Cereal Bar Equipment

Cereal bar making equipment is quite essential in the production line as it reduces human effort in some stages by performing a particular function automatically. They Mix the ingredients, form the bars, bake or cool them and wrap them with accuracy. As a result of mechanization of these operations, the production of cereal bar machinery is more rapid, superior quality products are obtained, and a lot of manual work is saved; hence it is a very important aspect of cereal bar making.

How Does a Bar Manufacturing Machine Work?

Cereal Bar Making Machines – How it Works

As a rule, cereal bar making machines carry out each operation required to produce bars in a systematic stepwise manner. All these processes begin by mixing the necessary ingredients using a mixer, thereafter the blended ingredients are transferred to the forming machine which shapes the mixture into bars. The bars are then baked or subjected to cooling in an oven or cooling tunnel to help retain the shape and texture of the bars that were formed. The bars are subsequently taken to the relevant packaging machines where the bars are encased to be shipped for sale, meeting quality checks for each bar before being placed in the market.

Functions of a Bar Forming Machine.

The bar forming machine provides quite a number of functions such as forming the mixture into uniform bars, forming bar types and shapes accurately among others. It also compacts the materials into desired sizes and shapes which is important in ensuring all bars are similar since this is key in upholding quality and the requirements of the industry.

Significance of the Cooling Tunnel

The cooling tunnel is an important unit operation in the manufacturing of cereal bars since it helps in shaping the final structure as well as the texture of the bars upon formation. This controlled cooling process lowers the temperature in a step-wise fashion to ensure that the bars can harden evenly, eliminating the risk of distortion. The purpose of this is to improve quality characteristics of the final product as to its visual and structural uniformity.

What to Consider When Choosing Bar Manufacturing Equipment?

Cereal Bar Machinery: Principal Characteristics

Always think about the machine’s capacity while selecting the bar foaming equipment as it should satisfy the output requirements. Think carefully about simplicity as well in terms of operation and servicing as a way of ensuring effectiveness as well as durability. All such machines should have a capability of producing different size and varied composition bars. In addition, examine the machine’s efficiency and its ability to integrate with other devices within the production. Mind also the company’s reputation and customer support and services.

Benefits of Buying Used Cereal Bar Equipment

Purchasing used cereal bar equipment may prove beneficial in many aspects. To begin with, one of the most common advantages is its lower costs as compared to buying new equipment which is important especially when the finances are restricted. Secondly, older machines have quicker lead times which makes them more useful because they can be immediately incorporated into production. Access to these machines helps in assessing how reliable the production systems are from the perspective of maintenance and performance over time. Finally, buying used equipment made by well known manufacturers helps in future productivity as spare parts and further service will be available.

Suggestions for Maintenance of Equipment in Bar Production Line

It is important to carry out regular maintenance on equipment used in a production line for bars to ensure they are long lasting and operate effectively. Begin by setting up periodic evaluations so that any problems including damaged components or incorrect alignment can be addressed before they worsen. Maintain the cleanliness of the machines by eliminating debris and other remnants of products which may hamper the machine’s performance. Moving parts should be lubricated in accordance with the manufacturer’s specifications. It’s also crucial to periodically refresh the software and application firmware. Finally, suitably encourage your personnel to follow appropriate operation practices so that the equipment is not exposed to mistreatment that may cause damage.

How to Optimize Your Cereal Bar Production Line?

Increasing the Productivity in Bar Manufacturing

For increased productivity in bar manufacturing, it is advisable to introduce automated processes or machines so as to minimize the number of workers employed on the manufacturing sites. Make sure the production line is designed in such a way that the transport operations do not create bottlenecks and that there is a good flow of work processes. Invest in good components and dependable suppliers so that the quality of the final products will never fluctuate. Analyze production data regularly to determine unproductive factors and redistribute the existing capacities in the most efficient way possible. Also improving the sustainability in the production of cereal bars can take the form of employee training on efficient practices and the adoption of new methods.

Incorporating a Cereal Bar Machine into Your System

To start integrating the cereal bar machine into your production system, first consider your personal needs and your goals of production. Pick out a machine that meets your expectations in terms of desired production scale, capacity and types of case production. Make sure it is compatible with the equipment you already have in order to limit massive disturbances or extensive changes to be implemented. Place the machine in the most appropriate area of the production line in relation to workflow and the time taken to move between operations. Educating the personnel about the new machine and its working methods is indispensable in order to maximize performance while improving safety levels. Moreover, perform this maintenance on a regular basis in order to preserve optimal working conditions for the machine and thus the quality of production and its volume.

Reducing Latex Downtime in Granola Bars Production

In order to minimize the downtime of production of granola bars, great emphasis should be placed on mechanism repair and damage through planning for routine checking and repair of the machinery. Also, ensure that there are enough spare parts in the stores so that equipment failures do not create too much interruption time. There is a need to have a comprehensive training program for the employees so that they are able to diagnose some of the common problems and resolve them without delays. The method of enhancing communication between operative staff and those charged with the upkeep of the facility helps reduce the duration of scope for downtime. Last but not the least, every operational management strategy that is used in the system should be evaluated and modified regularly to avoid inefficiencies.

Reference sources

-

Making.com – Cereal Bar Making Equipment

-

Loyal Machine – Unlock the Secrets of Cereal Bar Production

-

Loyal Intelligent – Cereal Bar Production Line

Frequently Asked Questions (FAQs)

Q: What is a cereal bar production line?

A: Cereal bar production line exists of machines and equipment needed in the making of cereal bars such as granola bars, protein bars, nut bars among other snacks. It usually has forming, cutting and packaging systems for the cereal bars.

Q: How does the bar-cutting process work in a cereal bar line?

A: The bar-cutting process in a cereal bar line comprises the actions of a cut bar machine including guillotine cutter, slitter which cut the formed bars into cut shapes and sizes. This guarantees that each bar produced has distinct size and shape.

Q: Which particular function does a conveyor in a cereal bar production line serve?

A: A conveyor is vital in a cereal bar production line because, it moves the bars from one machine section to another in order to enhance non stop production activity. Therefore from forming and cutting to packaging, the process is made more efficient.

Q: Is it possible for the cereal bar production line to produce different types of bars?

A: Yes, a complete cereal bar production line is designed to make all kinds of bars such as muesli bars, nougat, sesame bars, peanut candy bars, and energy bars. The versatility of the line permits the making of a wide range of products.

Q: Describe the role of a coating chocolate machine in a production line?

A: A bar coating or enrobing machine is a type of machine that coats bars with a layer of chocolate or some other coating. This procedure is called enrobing, and it improves the taste and presentation of the final product.

Q: What is the role of the control system part in cereal bars production line?

A: Cereal bar production line control system coordinate control or supervision of the whole processing to make sure end operation is accurate, quality control shall be met and operations remain efficient through interlinking sections of machines.

Q: Why is a hopper important in granola bar production?

A: For granular bar rending, the ingredients that are fed into the line are supplied through the hopper and its contribution to the line is automatic and it is steady. It distributes materials to be bar shaped evenly and it minimizes the occurrence of the stoppages of the line.