You’re in for a treat because we’re about to educate you in-depth on capsule-filling machines. Whether you operate in pharmaceuticals, nutraceuticals, or any industry that fills capsules in bulk, this one’s for you. We want you to use this article as a guide to learn all that there is to learn about capsule-filling machines and their usage, which includes benefits, maintenance, and various types of empty capsules as well. With all the information covered, we hope that you will be familiar with all about capsule-filling machines at the end of the article. Ultimately, this means that you can make informed withdrawals as per your and your organization’s production needs. So, let’s reel in and see what capsule-filling machines offer for you and your business.

What is a Capsule Filling Machine and How Does it Work?

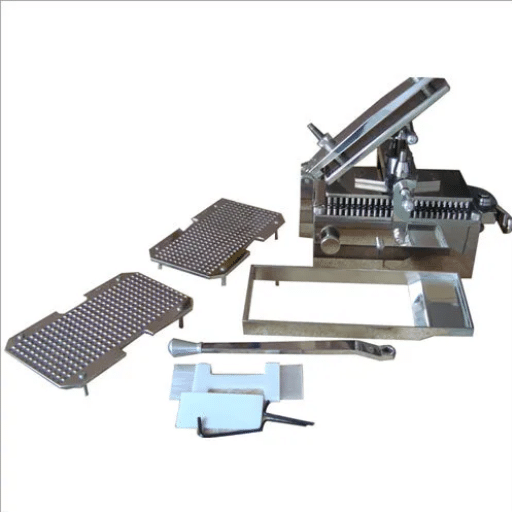

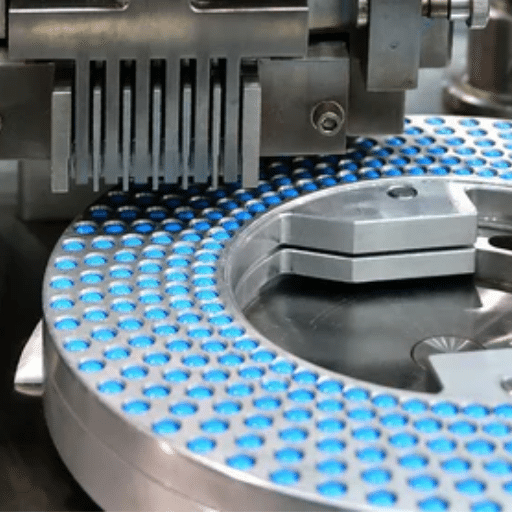

Now let’s talk briefly about the functions of a capsule filling machine. The main function of a capsule filler is to fill a prescribed drug form in a prescribed amount into a prescribed capsule to enhance capsule strength and improve safety. Automated capsule-filling machines have a plate holding a few hundred capsule shells on the upper part. The only requirement from the worker’s end is preparing the medicine powder in bulk enough for production for sustained durations.

Understanding the Basics of a Capsule Machine

The knowledge of its constituents and operation principles assists in deciding which machine is most suitable for particular production requirements, hence making sure the capsule-filling process is efficient and accurate. In this domain, having a basic understanding of the workings of the capsule-filling machine is paramount, especially if one intends to have the capsule-filling process carried out correctly. Such equipment includes elements such as a hopper, capsule tray, dosing system, and sealing device that serve the needs of the machine. A capsule filling machine is a device that cuts central the capsule filling operation and starts by evenly dispersing sealing materials. Understanding its components and working principles can help any production manager make an informed and correct choice regarding the capsule filler that suits the production requirements best.

Components of a Capsule Filler

A capsule-filling machine includes many crucial elements aggregated in the capsule-filling process. Features include a hopper, tray of capsules, dosing system, and sealing feature. The hopper is where the substance to be dosed in the capsules is kept. The capsule tray ensures that the free capsules are secured and clash with one another minimally while the filling is ongoing. The dosing system fills the amounts of a specified substance owing to each capsule. Lastly, the sealing feature encloses the filled capsules to prevent spilling. Getting knowledge about such components will be helpful when you are trying to decide which capsule printing machine will suit your requirements. You will make a more reasonable selection of a capsule printer by looking into different brands and models of capsule fillers and considering customer feedback, dependability, spare parts support, and technical assistance.

The Process: How to Fill Capsules Effectively

In order to fill capsules properly, it is important to follow best practices from reliable sources. The materials, including empty capsules and encapsulation materials, are also prepared in advance. The correct positioning of the capsules is important for capsule integrity throughout the capsule filling cycle machine process and avoids sealing faults. Depending on the production scale, filling can be done by hand or machine. In addition, leveling and tamping are essential operations that ensure the compression and dosage accuracy of the filled capsules. Finally, sealing the filled capsules ensures their content does not leak or get contaminated. Following these steps and using information from reputable sources, it is possible to fill the capsules and thus ensure the final product’s quality and integrity. This systematic view protects against erroneous capsule filling and conforms to the production parameters.

How to Choose the Right Capsule Filler for Your Needs?

When determining how to fill a certain capsule, several features need to be considered, including the size and filling capacity, the speed of the filling process, and the level of automation required to meet the production volume. Manual fillers are appropriate for side operations but automatic fillers are suitable for more effective and efficient outputs. It is important to check the brand and models, check the customer feedback, check the reliability of the product, and check the availability of the spare parts and the technical support. These aspects have to be measured in order to enable you to purchase a capsule-filling machine that is capable of meeting your specific requirements while at the same time streamlining operations, maximizing productivity, and enhancing quality and cost-saving measures in your capsule production operations.

Factors to Consider: Size, Capacity, and Speed

In my opinion, it is crucial to understand what the market has to offer in terms of volume, size, and speed when looking for a capsule-filling machine. Space availability should be checked in conjunction with the dimensions of the filling machine. In other words, where would the machine go? Based on your production volume expectations, a larger capacity machine suits larger operations. On the other hand, smaller capacity machines can be used for smaller-scale or start-up businesses. The production speed determines the production rate, which means that the quicker the machines, the greater the output. At the same time, these machines will likely always be more expensive. When all these factors are considered alongside the business’s needs and how much the budget is, a suitable capsule-filling machine will be chosen. This would improve the efficiency and productivity of the capsule filling in the capsule production process. In this way, all performance requirements are met because your chosen machine will suit you.

Comparing Manual vs. Automatic Capsule Fillers

The choice between manual and automatic capsule fillers is imperative as it helps assess the most appropriate option for capsule filling. The Step manual fillers are cheaper in cost; however, they consume considerable time and labor, which is not optimal. On the other hand, automatic fillers allow for productivity augmentation through less manual intervention, faster speed, and higher efficiency. They also automatically fill out the capsules with the same amount of product, making the end product consistently of good quality and considering, fitting, or balancing production targets or constraints, budgetary constraints, or the degree of automation desired permits to make reasonable decisions regarding the choice of capsule fillers.

Top Brands and Models Available in the USA

In the USA, several top brands and models of capsule-filling machines are highly regarded. The Bosch GKF Series stands out for its precision, reliability, and high-speed capabilities, making it ideal for large-scale operations. Capsugel’s Ultra™ Series is known for its versatility, efficiency, and advanced control systems, suitable for flexible production. IMA Zanasi offers innovative solutions with precise dosing and durable performance, favored by pharmaceutical and nutraceutical manufacturers. Choosing the right brand and model depends on specific requirements such as production goals, budget, and desired automation level. Evaluating these factors alongside expert advice and customer reviews will help you find the most suitable capsule-filling machine. This ensures that you select a machine that meets your production standards and enhances overall efficiency.

What are the Benefits of Using a Capsule Filling Machine?

Capsule-filling machines make it possible to speed up operations and make them more efficient. They take over the filling procedure, thus, minimizing the workload while increasing productivity. With these machines, production is more accurate and consistent because every capsule is filled to the same level. These machines work at a very high speed and can work with many capsules, making it cheap irrespective of whether the need is for small-scale or mass production. Manufacturers who use these machines can improve their use of time, producing capsules of good quality while also avoiding boredom.

Efficiency and Productivity in Production

With the ever-growing demand for capsules, encompassing productivity and efficiency in their production has never been more important. As a capsule machine operator, I can make everything run well and stop at its best. I follow many innovations and best practices, which help me achieve as much production as possible with the best quality.

Ensuring Consistency and Quality in Each Capsule

Q’s and A’s on the importance of strategy incorporating and genesis to new capsules may arise. Considerable research conducted provides a certain amount of revelation to the methods which ought to be used and enhanced in the art of capsule formulation while taking the input of the greatest standards into consideration. This, in turn, has led us to be dynamic in our expansion, hence offering capsules that can suit our customers and ensuring that they remain satisfied.

Cost-Effectiveness and Bulk Production

Such an approach not only enables me to forever keep tabs with the latest trends within the industry, it also helps me in the optimization of the company’s working processes while getting the most out of the raw materials put into the production. Given such an agile predisposition on the part of the company, the capsules’ quality is, however, still guaranteed to meet the minimal customer expectations as well as the firm’s cost provision constraints.

How to Maintain and Clean Your Capsule Machine?

Finally, I firmly believe in a proactive strategy of avoiding costly business interruptions, such as breakdowns due to wear and tear, replacing it with a planned maintenance and cleaning protocol. After each use, start by disassembling the unit and cleaning it using warm, soapy water. Pay particular attention while cleaning intricate parts of the machine that are hard to reach. Afterward, check for tears on the equipment and remember to lubricate moving parts according to the set guidelines. Most manufacturers will offer speaking points of contact for any issues that may emerge. Engaging with an outside agency that understands the fundamentals of capsule machines may be valuable. These maintenance activities will not only extend the lifespan of your capsule machine but will also ensure quality in your capsules.

Cleaning Procedures for Longevity

Owning a capsule vending machine is not a walk in the park as one would imagine; it entails a rigorous cleaning regimen that guarantees the machine functions optimally and that its lifespan is never compromised. The daily cleaning of the machine includes taking apart the machine and cleaning the detachable parts such as the capsule holder and tamper with tepid soapy water and a soft brush, this is then proceeded with rinsing and letting it air dry. Weekly, it is recommended that more extensive cleaning is conducted using the manufacturer’s recommended detergent. If no such cleaning agent is available, water and vinegar would do the job effectively. What is considered a light practice of cleaning by many people is periodic descaling, which comes in as an imperative cleaning routine when it comes to the people who own a capsule vending machine as it gets rid of any mineral deposits that can potentially lead to issues with the functioning of the Mechanism. All of these practices ensure the highest quality of the capsules created, the aroma and flavor are retained, and, last but definitely not least, the durability of the machine is increased. It is the best practice to always follow the instructions that are given out by the manufacturer when it comes to cleaning the specific capsule vending machine.

Regular Maintenance Tips to Avoid Downtime

We highly recommend performing regular maintenance so your capsule-filling machine works flawlessly. Also, downtime should be avoided, and conditions should be optimized for your specific machine model by adhering to the manufacturers’ guidelines. Protection from operational issues caused by residue and mineral deposits on capsules can be achieved by incorporating clean-outs of removable parts like the capsule holder, filling mechanisms into the usual processes, and occasional descales with specialized agents. Importantly, examine a machine and its equipment for damages and natural wear out, and any worn-out parts should be replaced instantly to retain usability. With such steps taken, the machine’s life expectancy will be increased, along with smell and taste of the capsules, the outcome will also be successful catered to the specified machine model. You are advised to read the instructions given by the manufacturer to perform the maintenance without any inconvenience.

Common Troubleshooting and Solutions

Like all machinery, capsule fillers might have problems. Here, a high level of risk can be eliminated: For capsule jamming or sticking, clear obstructions and ensure proper alignment. Ensure the machine’s adjustments are right, and the filling mechanism is consistent with filling, check and adjust as necessary. Ensure that jam is not the case and poor sealing becomes an adjust depending on the contamination of the sealing mechanism. Always keep in mind that there are other problems depending on the make and model of the machine that may vary. There is no substitute for the manufacturer’s instructions if one needs better and clear information applicable to a particular machine.

Exploring the Different Types of Empty Capsules for Filling

There are cheap bovine gelatin and veggies, which you might want to consider when selecting capsules for your supplements. Since they are made from gelatin, which is protein and provides strength while making them easy to swallow, these capsules are food-derived and fairly in common use. Veggie and other nasty incompatibles for meat are scent-free. Most weed capsules, softgel capsules, come in sizes 00, 0, and 000, 000 being the largest size. Select the appropriate type of capsule based on the target market, product, and diet requirement. Gelatin weed capsules are good for many things; veggie pill capsules are best suited for vegans and vegetarians. For effective filling, use the capsule size that meets the dosing requirements.

Gelatin Capsules vs. Veggie Pill Capsules

Gelatin and veggie pill capsules are the two most widely used forms for encapsulating dietary supplements. In the industry, gelatin capsules are the most utilized form obtained from animals. It has a decent shelf-life, it is also easy to use while being free from specific requirements. However, the major downside is that it appeals to a limited market. Using the alternatives available, veggie pill capsules are a good option to use as they are compliant with the vegan and vegetarian diets, unlike gelatin, which is produced from animals.

Another point to consider is the target population. If targeting vegans or vegetarians, then it is better to use veggie pill capsules which are more situational specific, however, for other dietary preferences gelatin capsules work as the best option. There are many factors to consider such as dietary preference, compatibility to the product, and the target market. Ultimately, it comes down to your needs and the preferred ones in the target market.

Understanding Capsule Sizes: 00, 0, and 000

This leads us to understand the capsules’ sizes and how they can be effective when filling supplements. The most popular ones are 00, 0, and 000 in terms of this use, so this is most likely the combined factor. These sizes determine the capacity of the capsules and vary in terms of the content they can hold. To put it adequately:

- According to Healthline, capsule sizes are standardized and designated by numbers. The larger the number, the smaller the capsule size and capacity.

- CapsuleConnection.com mentions that size 00 capsules are the largest and can hold approximately 735-1000 mg of content, size 0 capsules can hold around 500-700 mg, and size 000 capsules can hold up to 1000-1600 mg.

- Capsuline.com adds that selecting the right capsule size depends on desired dosage, product compatibility, and target audience preferences. It’s crucial to consider the intended use and the amount of supplement or medication to be filled.

By understanding capsule sizes and considering your specific requirements, you can choose the appropriate capsule type that best suits your supplements and caters to the needs of your target market.

Choosing the Right Capsule Type for Your Supplements

When choosing the right capsule type for the supplements, some factors should be considered. According to articles on some of the best-rated websites, ‘the capsule sizes have been regulated and are given numbers, where the smaller the number, the greater the size and capacity. However, there is some confusion, as one site claims to have 00 as the biggest size and 000 as the smallest, which is not the rule.’ Although all these seem unrelated, choosing the right size of the capsule does depend on the dosage amount required, compatibility with other products, and what the population that would be consuming them prefers. The point is in one’s awareness of the standard measure and their pointers to choose the best capsule type for your supplements to fill the gaps in your target market.

References

Frequently Asked Questions (FAQ)

Q: How can I use a semi-automatic capsule filling machine to fill 00 capsules easily?

A: A semi-automatic capsule filling machine can fill 00 capsules by placing empty pill capsules into the machine, adding your powdered ingredient into the hopper, and operating the machine to separate, fill, and cap the capsules efficiently. This process allows you to fill large quantities with minimal effort quickly.

Q: What types of capsules can be used with the machine available on Etsy?

A: The machine can be used with various capsule types, such as empty gel capsules, veggie pill capsules, and empty vegan capsules. To ensure the machine operates smoothly, it’s essential to select the correct capsule size, like 00.

Q: What is the capacity of the semi-automatic capsule-filling machine?

A: The capacity can vary, but many machines are designed to handle large batches, such as 1000- or 500-count trays, allowing for efficient production in a single session.

Q: Can I fill capsules with different types of powder, such as herbs or vitamins?

A: Yes, you can fill capsules with various powdered substances, including herbs, vitamins, and other supplements. Ensure that the powder is finely ground for the best results.

Q: What materials are the machines typically made from?

A: Many semi-automatic capsule filling machines are made from stainless steel, which is durable, easy to clean, and suitable for lab or industrial use.

Q: Do I need additional equipment for the capsule-filling machine?

A: While most machines come ready, you may need additional accessories, such as a spoon for measuring powder or a tray for organizing empty caps. Some kits may include these items.

Q: How does the machine handle the separation and capping of capsules?

A: The machine uses a mechanism to separate the capsule halves, fill them with the desired powder, and then cap them securely. This automated process ensures consistent results and reduces manual labor.

Q: What should I consider regarding shipping when purchasing a machine on Etsy?

A: When purchasing on Etsy, check the shipping policies for details on delivery times, costs, and any potential customs fees if ordering internationally. Some sellers may offer free shipping or expedited options.

Q: Is the machine suitable for DIY projects and small-scale production?

A: Yes, the semi-automatic capsule-filling machine is ideal for DIY enthusiasts and small businesses looking to produce capsules on a smaller scale without investing in a fully automatic unit.

Q: Who should I contact if I need help with my capsule-filling machine?

A: If you need help, contact the seller through the Etsy platform for support or guidance. They can assist with troubleshooting or provide additional information about the machine’s operation.