We’re delighted to have you aboard and provide you with this comprehensive guide on capsule-filling machines. All that you require to know so as to make an informed decision is provided here. Suppose you’re a pharmaceutical manufacturer, a supplement producer, or a person starting a DIY project. In that case, you can rest assured that there is a capsule-filling machine out there for you that is accurate and easily gets the job done. This blog will expand your knowledge of capsule-filling machines by explaining their function, components, and proper use. Then, we will focus on the distinction between manual and automatic capsule-filling machines so that you can decide which is appropriate for you. We will also cover the capsule size that you need to use, advice on how to fill capsules faster, maintenance, and troubleshooting tips. Thus, by the end, you’ll have a detailed understanding of capsule-filling machines, enabling you to make an accurate selection according to your needs. So please allow us to show you around the capsule filling machine’s space.

What is a Capsule Filling Machine and How Does it Work?

Capsule-filling machines assist you in dosing your powders. They are particular in that they have been made to fill capsules with precision and do the work with accuracy.

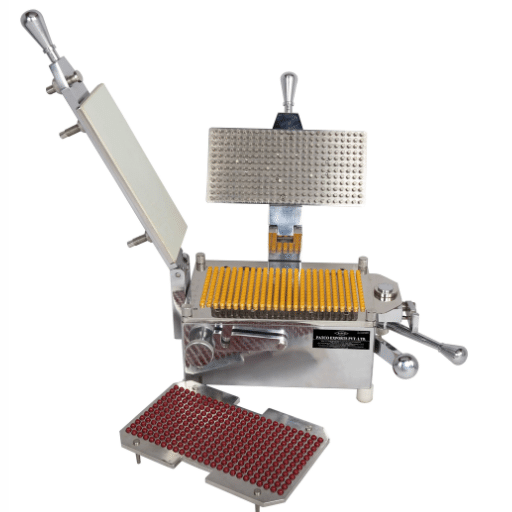

It has several components, including a fill material container, a dosing device, and capsule housing devices. The machine functions by mechanizing the process of capsule filling in an accurate and consistent dosage manner. The fill is transferred from the dosing system into the capsule shells before the capsules are completed after the capsules are filled. There are manual and automatic capsule-filling machines, and they all have pros and cons. Such a basic understanding is required to increase the productivity and quality of output in the process of capsule production. Let’s discuss the unique aspects of capsule-filling machines further!

Understanding Capsule Filling and its Importance

A capsule filling is an activity that many within the pharmaceutical manufacturing industry should comprehend and appreciate. In general, capsule filling is the process that involves filling emptied capsules with the required medications or supplements in the case of a capsule of a product. This allows for proper dosage, easy administration of treatment, and the systematic delivery of active ingredients. Its significance level rises to the most critical stage in manufacturing oral dosage forms as it facilitates easy mass production, control, monitoring, and adherence to set compliance levels. Understanding the processes and technologies associated with capsule filling should allow manufacturers to improve their production practices, improve production volume, and increase the availability of healthy and effective treatments for patients.

Components of a Capsule Filler Machine

A capsule-filling Machine consists of different parts that perform different functions while ensuring the efficient and accurate filling of empty capsules. A capsule hopper collects and loads the empty capsules into the machine. A powder-filling system dispenses a definite quantity of mass or granules in each empty capsule. Tamping pins compress the mass inside the capsules so that there is a uniform filling in each of the capsules. Once the capsules are filled, a capsule closing mechanism locks the filled capsules so that the medication is properly contained. The control panel allows the operators to monitor and alter some parameters, such as filling speed and capsule diameter. These components refine the processes within capsule filling, ensuring that pharmaceuticals of high standards are produced. Understanding the effects of each component concerning the machine’s operations enables the operator of the system to be sure of the performance and reliability of the products.

How to Operate a Capsule Filling Machine Safely

The correct operation of a capsule-filling machine involves focusing on every little detail and following instructions correctly. Various aspects include reviewing the manufacturer’s manual to know the machine’s capabilities, how to control it, and how to maintain it. The site of operation should be tidy, properly ventilated, and devoid of any risks. Operators should wear protective clothing, and a check should be carried out on the machine to determine whether it has any damage or tear before utilization. Adjusting the machine according to the medication’s specs is a very important task. Loading empty capsules and medication should also be done with caution as overloading them may result in negative impacts. During filling, the various steps in the filling process, such as placement, the amount given, and the end filling, must be kept in check. Regular maintenance, such as cleaning and lubricating, should also be done to enable the equipment to perform optimally. Detailed instructions regarding this aspect can also be found in the manufacturer’s manual or one may seek advice from qualified people. It is always beneficial to follow these procedures to ensure that a capsule-filling machine is operated safely and effectively.

Manual vs. Automatic Capsule Filling: Which is Better?

The optimal choice of capsule filler machine will depend on various factors. Manual machines are cheap, adaptable, and user-friendly; thus, they are ideal for small-scale and cheap operations, while automatic machines offer speed, efficiency, accuracy, and more since they cut back on the amount of hand-work needed and thus improve productivity. Everyone’s preferences will determine the ideal one for them in terms of cost, output capacity or level of automation they want. Considering these factors will help increase both productivity and the quality of manufactured capsules.

Advantages of Manual Capsule Filling

As a capsule manufacturing professional, I have also researched top online resources on the advantages of manual capsule filling. Manual capsule filling machines have greater flexibility are more cost-effective, and are therefore ideal for low and budgetary operations. Compared to automatic fillers, they are often cheap and, therefore, enable start-ups and businesses that do not have high production volumes to blossom. With manual machines, operators can supervise the filling process and make alterations such as adding other formulations, varying the dosage, and using pre-defined capsule sizes and materials. Due to the nature of manual filling, it is easier to deal with specialized cases such as manual filling of research and development capsules or even capsules that have a unique formulation and are made in small volumes. Other factors that businesses want to determine the ideal capsule-filling method include production needs, finances, and strategic automation. Considering these limiting factors of the businesses will increase productivity and the precision required in capsule manufacture.

Benefits of Automatic Capsule Fillers

I have highlighted the arguments for businesses in the pharmaceutical and nutraceutical sectors for using automatic capsule fillers. Automatic filler of capsules makes the working processes more efficient; hence, the production manager gets high production speed and saves on labor costs. They guarantee increased accuracy and dosing precision that are necessary to preserve the quality of the product and compliance with standards. The advanced control system, which automatically rejects faulty capsules, guarantees the safety of the finished product. The user interface of the machines is very delicate and uncomplicated, cutting down the need for more training and including self-cleaning. Also, automatic fillers may be adjusted for the capsules’ size, fill volumes, and needed formulation, whether it is powder, granule, pellet or liquid. They are suitable for all businesses and can be scaled to address growing need without compromising on quality or efficiency. Automatic capsule fillers or automatic encapsulators are thus appropriate for any business wanting to improve their capsule manufacturing nhu cans operations.

Choosing the Right Capsule Filler for Your Needs

The shape, size, and composition of capsules, including the filler and drug characteristics, require some attention and consideration.

The first parameter to consider when designing capsules is the dose. This would be the most desired dosage of the intended drug and the amount of the active ingredient that would be used in each capsule. Additional properties may include product characteristics such as density, flowability, and moisture content of the dry powder. These facts must be considered in determining the requirements for both the filled and the performance and stability of the capsules.

The viewing angle is also of significance when considering some product capsules. Who would want to swallow such a capsule easily. Some may not like the branding need or such a capsule with a large space for branding. Some may prefer softgel capsules with smaller size for easy swallowing.

It has to be noted that the consumers’ viewpoints in that region will also be important. The thickness of the capsule filling will help to achieve the marketing goals regarding the areas of the intended marketing drive. Slanting research on regional or demographic preference to fit your capsule size, not forgetting the area target, will be of the utmost importance in selling the capsule filled with active ingredients.

In picking the right size of capsule holders for your team members and other allied vitamins across the bigger clinics with the best-ranked websites, an examination of these factors will help. The hope of every joining the market is that the selected thickness of capsule holders will boost AoI, market dominance, and product attractiveness and help exceed cutomers’ needs.

How to Select the Right Capsule Size for Your Product

The selection of the right capsule size is paramount. This is critical in terms of both their functionality and the satisfaction of the end consumer. These requirements can be associated with the dosage and the product, such as density, flowability, moisture content, and the desired dosage form format, such as ease of swallowing or the size of the branding space. Moreover, consider regional or demographic requirements. Considering these factors helps one determine the appropriate capsule size that satisfies the product and the intended market requirements. This is to achieve efficacy of filling, containment, and marketing appeal.

Common Capsule Sizes Explained

Capsules come in various sizes, and choosing the right size is crucial for product efficacy, customer satisfaction, and manufacturing efficiency. The most commonly used capsule sizes include:

- Size 000: This is the largest capsule size, suitable for products with high dosage requirements or bulky formulations.

- Size 00: A popular size for dietary supplements, allowing a substantial amount of powder to be encapsulated.

- Size 0: A versatile size suitable for various products, including herbal supplements and medications.

It is also worth mentioning that these sizes are not the complete sets, and other sizes solve other requirements. For example, factors such as dosage requirements, the product’s characteristics, and the customer’s preferences should all be incorporated into the choice of the size of the capsule. When the available capsules are grouped in sizes and their applications to deliver a product, the offered information helps the manufacturers meet the customer’s expectations of the product being delivered.

Factors to Consider When Choosing Capsule Size

While picking the optimal size of capsules, it is best to consider a range of aspects. These aspects are the dosage requirements, the character of the product, and even the product that will be used. These are critical in ascertaining the right size of the capsule to ensure the product works well and is pleasing to the customer. Such details included the capsule size and potential utilizations, which I found to be well explained in the sources. This gave me a clear perception of the drivers that would influence the choice of capsule size, including studying the details from these websites.

Understanding Gelatin and Vegetarian Capsules

It is also critical to be knowledgeable about gelatin and vegetarian capsules when determining the appropriate capsule size. I also obtained information about the capsules’ sizes and uses in my research. Such sources provided insights into the core considerations when deciding the capsule size, including the solubility and release time while using various active ingredients and the aim of the capsules. After going through content from these sources, I have changed my outlook on what capsules are used in different industries and their sizes.

Tips for Filling Capsules Quickly and Efficiently

In order to minimize filling errors and maximize speed during encapsulation, bear in mind the following suggestions: Equip yourself with all required tools and ensure that the environment is clean and orderly. Utilize a capsule filling tray or funnel so as not to spill the powder and ensure accuracy. Ensure that capsules are properly set in place during the filling machine operation to prevent jamming due to misalignment. The whole process in such cases would involve erratically low levels of trouble as all that would be needed to fill up the coconut oil or vegetable oil would be dipping the tray and the funnel and lightly banging them. For specifications, use the lot method to ensure filling integrity if dealing with many capsules. Always disinfect the machine and the working area in between the preparations to avoid cross-contamination andils. By following these suggestions, you can work more efficiently and provide better quality while also taking care of time factors.

Using a Filling Kit for DIY Projects

I have done my share of custom projects; hence, I have an idea as to why there is a need for a filling kit to pursue uniformity and accuracy. I think having the capsule aligned well on the filling machine is a way to assist in minimizing capsule breakage. Moreover, I also practice coarse movement; for instance, I bang the tray or funnel to ensure an even distribution of granules or powders in the capsules when filling. When I have larger amounts to fill, working in portions of small amounts assists me in maintaining the filling process accurately. It is also part of the cleaning routine to clean the apparatus and the working area which helps reduce contamination removal and preserve the quality of the overfilled capsules. Due to such practices, I have optimized the filling stage in terms of efficiency and final quality.

How to Avoid the Breakage of Capsule

To prevent the breaking of capsules, I will start by outlining strategies that emphasize the care of the caps. To begin with, I make certain that the caps get kept in a cool and dry place to protect their condition. When filling the capsules, I gently tap the tray or funnel to help spread the powder or granules evenly, thereby minimizing any chances of breakage. Furthermore, I also batch larger amounts to make sure I am accurate throughout the entire operation. Regular cleaning of the machine and the whole area is also important to avoid contamination and to sustain the quality of the capsules that are being filled. By following these steps, I have made the filling process more efficient and consistent, saving time and yielding satisfactory results.

Maintenance and Troubleshooting Your Capsule Filling Machine

Filling and sealing capsules is a recurrent process involving proper filling capsule filling machines to ensure that okay interventions are done. Cleaning of the machines is organized to ensure that residue materials are avoided, along with machining shifting of parts within the capsule filling machines. They also need near supervision to ensure the moving parts are oiled; checking for damages or wear is important. Lastly, proper calibration ensures that filling is done properly and that the machine is cleansed after storing. Most problems like obstruction, capsule breakage, and even inconsistent filling, amongst other problems that capsules may face, may be sorted up. This entails inspecting the capsules’ quality, making certain equipment modifications, clearing blockage, and evenly distributing the filling components. You should refer to the user manual or speak to the manufacturing company if the problems persist. Following this procedure guarantees the longevity and efficiency of the filling and sealing of the capsules machine.

Routine Maintenance Tips for Longevity

Maintenance of capsule filling needs to be done in a commendable manner, and that greatly ensures the longevity of the machine. Avoiding oil and grime from contaminating the capsule filling machine needs periodic cleaning supervised with agents stated by the manufacturer. Also, parts that tend to move within the machine need proper ventilation and need to be moved with care so that wear and tear on them is not created. Minor or major damage to such machines needs to be addressed or realigned before it gets out of hand, there is a need for regular disassemblies and engagements to flush such issues. To ensure the filling is precise calibration should be administered occasionally. Lastly, the capsule filling machine needs to be stored at a cool temperature along with low humidity when the machine is not in use; with this advice and mod the user manuals, you will prolong the working life of the capsule filling and sealing machine. Otherwise, inform the manufacturer instead of trying to solve problems outside your understanding.

Common Issues and How to Resolve Them

Several difficulties may be encountered when utilizing capsule-filling machines, such as capsule breakage, inaccurate fill amounts, or trouble with the equipment. Regarding capsule breakage, switch off the machine, clear off all leftover capsules and waste, inspect the aligning of parts in the machine, and clean and oil the machine before returning to operation again. If the dosage adjustment mechanism, refill or pour capsule modification operating load frequently, adjust the mechanism and read the manual. For regular breakdowns, check the manual for solutions, assess the machine for wear, and conduct preventive measures. This can be done without panic as the machine completes the entire assignment. If these risks are dangerous or mean a financial risk, consult an expert engineer or the distributor immediately. Dealing with these nightmares and following proper maintenance strategies would ensure maximum yield and the longevity of capsule-filling machines. Seeking help to deal with such complicated issues is the best way to do it.

References

Frequently Asked Questions (FAQ)

Q: What is the best capsule-filling machine for empty gelatin capsules?

A: The best capsule-filling machine for empty gelatin capsules depends on your specific needs, such as production capacity and ease of use. For small businesses, a manual capsule filling system with a filling tray and capsule holder can be effective. At the same time, larger operations might benefit from a semi-automatic or fully automatic machine.

Q: How can I fill size 00 capsules quickly and easily?

A: To fill size 00 capsules quickly and easily, consider using a capsule filling system with a filler tray, filling tool, and capsule holder. These tools allow for efficient filling, reducing downtime and increasing productivity.

Q: Are there filling machines suitable for vegan or HPMC capsules?

A: Yes, filling machines are designed to handle vegan and HPMC capsules. These machines are typically adjustable to accommodate different capsule types and sizes, including vegetarian and HPMC capsules, ensuring a smooth filling process.

Q: What should I consider when choosing a pill filler for clinical trials?

A: When selecting a pill filler for clinical trials, consider factors such as the machine’s precision, ease of cleaning, and ability to handle different capsule sizes. A fully automatic capsule filling system may be preferable to minimize human error and maximize efficiency.

Q: Can I fill a single capsule using a capsule-filling machine?

A: While most capsule-filling machines are designed for batch processing, you can still fill a single capsule manually using the tools provided, such as a lab spoon or spatula, for precise dosing.

Q: How does a capsule-filling machine improve productivity for a small business?

A: A capsule filling machine enhances productivity for a small business by allowing faster and more consistent capsule production, reducing manual labor, and minimizing errors. This efficiency leads to increased output and better resource utilization.

Q: What are the benefits of using a capsule-filling tray with 100 holes?

A: A capsule filling tray with 100 holes allows for the simultaneous filling of multiple capsules, greatly increasing production speed and efficiency. This setup is ideal for small to medium-scale operations that require quick turnaround times.

Q: Is it possible to fill capsules of different sizes with the same machine?

A: Many capsule filling machines are adjustable and come with interchangeable parts to accommodate different capsule sizes, such as size 0, 00, and 000. Check the machine’s specifications to ensure compatibility with the sizes you need.

Q: What should I look for in a capsule-filling machine for R&D purposes?

A: For R&D purposes, look for a capsule filling machine that offers flexibility, precision, and ease of operation. Features such as adjustable settings for different capsule sizes and types, along with easy cleaning and maintenance, are crucial for research environments.

Q: Are there capsule-filling machines that are halal-certified?

A: Some capsule filling machines are designed to work with halal-certified capsules. It is important to verify the machine’s compatibility with halal gelatin capsules and ensure all materials and processes meet halal standards.