While the sewing industry has changed a lot over the years, having the most appropriate machine helps to both improve functions and unleash creativity. Thus, this guide will help clarify some curious issues concerning the choice of equipment: what features make the Brother sewing machine the best option for quilting and embroidery? First, we will outline the essential parameters that allow these sewing machines to stand out in terms of accuracy and versatility. A good amount of their mechanics and technology will be reviews in detail, especially the variety of stitches, ease of use, and other electronic features. Далее, , today’s popular models will be compared, and their performance characteristics will be highlighted through customer feedback and expectations. Lastly, in order to help the reader choose the equipment suitable for him/her, practical advise and recommendations from professionals will be offered, customized to suit a quilter or an embroiderer. This detailed study is supposed to be interesting and useful to the audience of inductees and advanced sewers searching for the appropriate standards in this work.

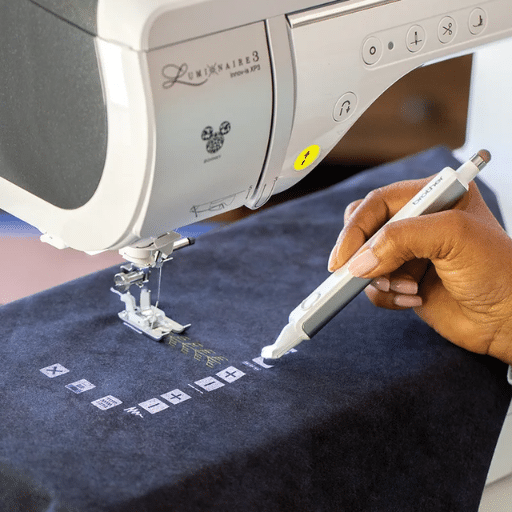

What Makes the Brother Luminaire 3 Stand Out in the Sewing and Embroidery World?

Brother Luminaire 3 is a sewing and embroidery machine that incorporates the latest technological advancements and facilitates user reception. The most important is the one-of-a-kind technology – StitchVision, which projects stitches in the fabric to ensure their precise location and accuracy. This model features a working area of 13.1″ and a 10.1″ LCD touchscreen to provide ease of movements and improve user experience. In addition to the above, a wide range of built in stitch and embroidery variations allows users to push their creativity to the extremes. Moreover, users can draw and alter designs on the machine itself and thus, the user’s need to create is provided for in a very simple way. In short, an effective combination of technology, rich functionality and good quality is what makes the Brother Luminaire 3 one of the best sewing and embroidery machines available in the market today.

Exploring the Luminaire 3 Innov-ís XP3 Features

The Luminaire 3 Innov-ís XP3 is a revolutionary device that encompasses many different features that focus specifically on precision, simplicity, and creativity. One of the important features is Enhanced InnovEye Plus Technology, a combination of a high-resolution camera and positioning that assists with double the scanning speeds, enabling accurate design positioning. In addition, the design is equipped with a large 10.6” by 16” embroidery area, creating more room for larger embroidery without the need for constant frame registration. The XP3, however, comes with an optional My Design Snap mobile app to conveniently upload designs for any added text without having to recreate the entire image again. On top of that, there is a QuiltBrite LED Lighting system that provides proper brightness for the size of any given viewing angle. The machine stands as a moments creation sewing and embroidery device because it combines a huge embroidery design base with about 1500 patterns and the availability of USB ports to upload new ones.

How Built-in Designs Enhance the Embroidery Experience

In the case of embroidery machines of the kind found in the Luminaire 3 Innov-ís XP3, various built-in patterns considerably improve the owner’s experience by offering a huge number of ready designs that improve how quick the creative process and the end result looks. These patterns are perfected to ensure that artisans produce quality stitches and are an outcome of the marriage of art and precision engineering. As a case in point, the XP3 contains more than 1,500 in-built designs, including outdated motifs and new ornamental patterns, all made with a specific purpose behind them: to achieve the best results possible. Some of the technical parameters that would fall under this category include sophisticated stitch algorithms that control even spacing between stitches and the definition of the outline edges. Furthermore, the large variety provides opportunities for users to practice different looks without too much time in actual design, hence broadening the limits of creativity. Smart technology has made the process of choosing, placing, and changing these built-in designs hassle-free with an easy-to-understand interface, which makes it easy even for beginners. Therefore, given the wide range of designs and their advanced features, it is clear that built-in designs are one of the key features of each embroidery machine which improves the user’s experience.

Wireless Connectivity and Its Benefits

The convenience of wireless connectivity when using sewing and embroidery machines such as the Brother Luminaire line improves the customer’s experience as it allows for integration with different devices and software programs. This feature makes it possible to send designs and make updates without cables’ intervention, enhancing efficiency and user-friendliness. One of the major advantages is that it can be used with software programs such as My Design Snap which permits the sending of design data from the user’s mobile phone. Such integration allows users to make alterations on the design in real time thus creating an environment that promotes creativity for the receiving personnel.

Wireless connectivity harnesses existing Wi-Fi and Bluetooth technologies, which these machines have built-in. It guarantees the reliable transmission of information over long distances at high speed, allowing for the transmission of heavy design files and sophisticated systems software updates. For instance, wireless connectivity enhances the mobile’s potential by allowing its user to access cloud design repositories, enhancing the machine’s creativity without the need for bulky storage devices. Software compatibility can include popular design lay-outing programs supporting file formats such as PES, DST, and PEN.

In general, the integration of wireless capabilities not only improves the speed of the embroidery process but also makes the operation of the machine more user-friendly and broadens the scope of imagination, thus making these machines very effective in both professional and nonprofessional sewing.

How Do Scanncut DX Machines Complement a Quilting Setup?

In recognition of the importance of improving usability and opening additional features to the user, the Scanncut DX technology has introduced a plotter of unprecedented capabilities. Welding new technology to an already existing process is what the Scanncut DX finally achieves. The addition of scan and cut capability accentuates an important aspect of quilting projects: the problem of making intricate cuts. Adjusting the blade depth and pressure according to the specific fabric seems industrious but the Scanncut makes it automatic. Irrespective of the fabric type, the Scan and Cut automatically adjusts the settings, streamlining the cutting procedure. Because of the automatic adjustment of all the cutting parameters, the need for manual cutting, which is both time-consuming and inaccurate, is eliminated. Another noticeable implementation is that of wireless connection that helps update patterns and transfer them seamlessly. Thus, the application of the machine on a quilting frame makes the process more efficient, substantially increasing the quality of the resulting quilts as well as the enjoyment of making them. Such an improvement ensures that a more productive quilting environment is created.

Integrating Scanncut DX with Your Sewing Projects

Integrating the Scanncut DX machine into your sewing projects can greatly elevate accuracy and creativity as it perfectly complements the rest of your sewing machine components. Automatic blade adjustment is one of the notable features that is very helpful in fabric that’s of almost all thicknesses ensuring sound cuts. The result is ideal regardless of the TO-DO, be it quilting blocks or the pieces of clothing itself. The scanning system aids in digitizing physical templates and their insertion into the projects above, mitigating mistakes and enhancing the entire creative flow.

From a technical perspective, this machine possesses attributes such as a cutting area of not more than 12″ by 24″, cutting thicknesses of many different types of fabric, and supporting FCM and SVG file types, which greatly enhance the design integration. Moreover, these files can also be sent wirelessly and used with cloud resources, which expands on large and complex undertakings without spatial alterations.

Integration embodies the comprehension of other technical measures, such as the force applied by the machine while cutting, which allows thin silk to be sliced through or thicker denim to be initialized through automatic adjustment. With the resolution reaching about 300 DPI whilst scanning, intricate designs get good detailing, which means that when transferred, the results are such that the designs retain their original quality.

The interoperability between Scanncut DX features and sewing projects greatly enhances your capacity for creative development while adding substantially to your sewing space for higher efficiency and better quality craft work.

Advantages of Using Brother Scanncut for Embroidery

To start off, I would like to include my personal experience while working with Brother Scanncut in embroidery. In my opinion, this device is of remarkable significance due to the efficiency and creativity it provides in embroidery. Firstly, Cutting of intricate patterns enables the embroidered pieces to have clean and precise edges and minimizes the fabric fraying. This is especially advantageous for applique designs where accurate pieces of fabric have a great effect on the aesthetics of the work. Also, the scanning technology that is built into this device makes it possible for me to sketch and, through that, prepare the patterns, which makes it suitable for use without wasting time. Moreover, the device is equipped with a range of compatible file formats, including FCM and SVG, which allows easy upload and modification of designs. In addition, there’s no need to change formats. Wireless capabilities also allow for changing designs anywhere at any time. Finally, due to its versatility, Brother Scanncut increases the level of precision and quality of my embroidery projects.

Why Choose a Computerized Sewing Machine for Your Projects?

Buying a computerized sewing machine allows you to greatly improve the efficiency and accuracy of any sewing project you undertake. Such machines come with very useful features like auto threading of the needle, adjustable stitches and their length/width, and more, making even intricate stitching pretty simple. This allows the sewing operations with a standard computer interface, which is much easier to use as a variety of stitches are stored with just a press of a button. Furthermore, computerized sewing machines are usually also set with embroidery functions, making switching between sewing and embroidery tasks easier. Thus, if you have such a machine, there is no doubt, that you would get the desired results. A computerized sewing machine is ideal for anyone who craves versatility and creativity in one’s sewing as it has all the technological benefits that one would need to advance in one’s sewing.

Understanding Built-in Stitches and Their Versatility

In attempting to study modern sewing techniques, I discovered the possibilities built-in stitches had greatly extended my first exploration work and sewing projects. Additionally, basic straight stitches to more complex decorative pattern stitches can be used for extensive experimentation without additional stitch accessories. Based on the information from argumentatively the best sources, I have understood that built-in stitches allow seams to be made in garments and the decorative finish on home furnishing products and craft works. By having the stitch type as the only criteria transformers in the machine, I see that the adjustment of the transformer units enhances design creativity as there will be more options for the final design. Furthermore, preset stitches are already set to the required tension and length to save quality uniformity and time for large-scale projects. Such a feature must help a person to avoid being frustrated when shifting from task to task, such as in quilting and embroidery and other sewing jobs, since this only requires me to move stitches or stitch back and reassured of the accuracy needed in both techniques. On these notes, it is not exaggerating to say that built in stitches are a very good feature for they have both functional and creative aspects.

The Role of LCD Display in Modern Sewing Machines

Modern sewing machines all have varied purposes, but one thing they have in common is the importance of the LCD display. My prior exploration has convinced me of its importance by increasing the usability of sewing and its accuracy. One can readily access a wide range of options on the screen regarding the types of stitches, including decorative and utility stitches. Depending on the kind of fabric and the kind of design being used, stitches can be lengthened or made wider with ease. Also, due to the LCD, working with nearing features and complicated sewing tasks, such as stitch permutation and selection of embroidery patterns, becomes easy. Moreover, issues regarding stitch quality greatly stand to benefit as optimum integration provides real-time feedback and error messages. Lastly, many of the latest designs and their models have stepwise attachments guidance right on the display so that one does not have to refer to bulky attachments and the sewing process becomes fast and fun.

How Does the Brother Luminaire 3 Facilitate Embroidery Lettering?

The Brother Luminaire 3 enjoys embroidery lettering due to its advanced technology and ample possibilities. The device encompasses a large ‘LCD Touchscreen’ of 10.1 inches, which allows greater control over letters and adjustment in terms of size so users can design and modify it before stitching it. The Luminaire 3 has built-in fonts that abound in combinations and sizes to satisfy the requirements of different projects. My Design Center is an addon that expands the ability to create lettering by easily merging them with a variety of designs and motifs. Also, the precision in stitching, along with automatic thread tensioning and cutting gasping systems, helps in achieving neat and quality lettering with little effort. With such a degree of control and customization, the user has the necessary means to create professionally looking embroidery lettering without much effort.

Creating Custom Embroidery Designs with Ease

There’s no doubt that the creation of custom embroidery designs has been made much easier, primarily through the improvement of the embroidery machine alongside the software attached to it. As the leading sources regarding the customization of embroidery suggest, one of the key advantages of the modern-day web. O- is the intuitive digitizing (editing, whatever) software incorporated in these machines. Furthermore, many of these platforms include simple user interfaces that facilitate the entire process of reproducing art or sketches into digitalized embroidery files. Now, many machines also incorporate vasts design libraries as well as cloud services where users can retrieve various existing designs, which can then be enhanced or mixed with other designs made by the user easily. Popular sites clearly mention the effectiveness of such features as automatic color sorting and thread-cutting functions, which are said to minimize human errors in embroidering because the settings are made once, and that’s it. Last but not least, there are automatic digitizing and image scanning features which almost all the latest models of the microchips possess, which enable the user to convert images into stitches with very high accuracy. All of them combined make it possible for users to create complex yet accurate and neat custom embroidery designs efficiently and easily.

The Impact of 258 Built-in Embroidery Designs on Creativity

The amusing factor of Brother Luminaire 3 and other modern machines is the presence of as many as 258 built-in embroidery designs stretching the creative possibilities exponentially by allowing floral and geometric designs, among others, according to a report by leading sources which states that these embedded designs give the user the chance to experiment with various forms of artistry even without other supporting software. Moreover, this set is perfect for amateurs who wish to allocate their work to ready-made templates and provide stimuli for professional embroiderers to recombine them with individual features. The compatibility of devices with high-definition LCDs seems to be one of the most alluring technical specifications, as it enables thorough viewing of the interface and meticulous modification of touch essentials. About cloth material types and cloth composing objectives, every design is likely adjustable for least three elements comprising size, density, and orientation which provides varied applications for the different kinds of fabrics. Also, the machine is noted to allow for other file formats such as PES and DST, which further increase the likelihood of using external designing software to expand on customization capabilities. These attributes allow for a smooth, comprehensive artistic journey for the user as their embroidered ambitions come to life through extreme detail and excellence.

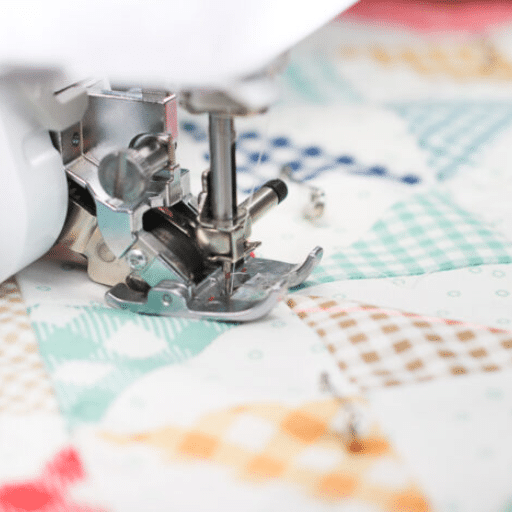

What Are the Benefits of Using a Dual Feed Foot in Quilting?

The walking foot, or dual feed foot, greatly assists in quilting as it ensures that the fabric feeds evenly. This feature is very important in keeping the quilt top, batting, and backing in place so that no shifting or puckering occurs while stitching. With the dual feed foot, stitch quality and the pattern or seam match can remain constant because the feed dogs are activated at the top and the bottom of the fabric layer. It’s ideal for several amounts of layers of fabric or fabric with texture as it is a great tool for precision quilting jobs. In addition, the use of a dual feed foot can be of startling advantage, for example, it can drastically lower the amount of fabric distortion and stretching, which in turn helps to create neat looking quilted pieces of work. So, there is an improvement in control and consistency, which, in the end, aids efficiency and enjoyment in the quilting process.

Improving Quilting Designs with Enhanced Control

The mentioned content enhanced the quilting process through improved control techniques by emphasizing the technological advancements in quilting machines and tools. Most scholars discussed the advancement of feed systems such as dual feed foot or integrated walking foot technology that facilitates fabric of any quality, beam or thickness to be fed at an appropriate rate and even level. In addition, stitch regulation, which is extensively supported by computerized stitching methods, makes it workable for quilters to ensure every stitch made is of a predetermined length. Quilting enthusiasts who do not hold commercial notions of quilting but rather a love for the craft tend to make their pieces more and more creative, as not too far from basic sewing machines, custom-made quilting stitches and motifs became available in the quilting machines’ programming. This enables the quilters to adjust the density, size, and orientation of their motives to better fit their ideal designs. In addition, user-friendly touch screens support interactivity and enable live modifying, aggravating the required visual clear precision and meeting of set designs. Each of these features works together to reduce distortion, rectify details, and widen creative opportunities, which accelerates all stages of the quilting experience.

Seamless Integration with Embroidery Projects

There’s high technical compatibility to consider when integrating quilting and embroidery projects with newer technology sewing and embroidery machines. As some of the leading portals reported, the major steps in this process are software compatibility and machine capabilities. An average contemporary embroidery machine expects the use of many file types, including PES, DST, and EXP, ensuring that even custom or pre-existing design files can be connected with the embroidery part of the quilting project. Many upscale models allow the user to position editing of the designs inside of the embroidery machine itself, which lets them alter the size and color and even change the placement of embroidery designs on the machine.

Automated functions like color sorting and thread trimming also become a part of this process in order to streamline the operation, as such minimizes manual interventions in a way that increases efficiency. Brother Luminaire 3 and Baby Lock Solaris Vision are high-end machines that possess advanced features such as needle threaders and multiple needle configurations, which saves time for the embroidery segment. Apart from all these features, automatic foot pressure, and adaptive tension ameliorate the synergistic attachment of the layers of the quilting fabric and its embroidered complement with the least distortion or precision loss. Overall, these elements help improve how quilting and embroidery techniques are integrated into a single operation.

References

Frequently Asked Questions (FAQ)

Q: What features do Brother quilting and embroidery machines offer?

A: Brother quilting and embroidery machines provide various features, including a wide table, free arm, and large LCD for easy navigation. They often come with built-in Disney embroidery designs and wireless LAN connectivity, allowing users to transfer embroidery designs directly from platforms like ibroidery.com.

Q: How can I personalize projects using a Brother machine?

A: You can personalize projects using Brother machines by accessing a wide range of embroidery designs through the ibroidery.com platform. The PE-Design 11 software also enables you to customize designs to let your imagination run wild.

Q: Can Brother sewing and embroidery machines be connected to a wireless network?

A: Yes, many Brother sewing and embroidery machines are equipped with wireless LAN functionality, which allows you to transfer designs between your machine and the Internet.

Q: What is the advantage of the Brother single needle embroidery machine?

A: The Brother single-needle embroidery machine is ideal for beginners. It is easy to learn and offers precision with each stitch, making it perfect for personalizing home décor and monogramming projects.

Q: How does the Brother serger enhance the sewing experience?

A: The Brother serger enhances the sewing experience by providing professional finishing on seams and edges, ensuring that your sewing and quilting projects have a polished look.

Q: What creative options does the Brother ScanNCut DX SDX325 provide?

A: The Brother ScanNCut DX SDX325 expands creativity by allowing you to cut fabric and paper designs with precision. It can be paired with the PrintModa Studio Fabric Printer to create unique designs and patterns.

Q: How can the Brother flat brim cap frame be utilized?

A: The Brother flat brim cap frame is designed to make embroidering on caps easy and efficient. It holds the cap securely in place, allowing you to add personalized embroidery designs directly onto the brim.

Q: What is the role of PE-Design 11 software?

A: PE-Design 11 software creates, edits, and personalizes embroidery designs. It allows users to explore their creativity with the Brother machine and offers a comprehensive set of tools for design customization.

Q: How does the Brother machine support creativity?

A: Brother machines support creativity by offering features like wireless LAN connectivity, a wide selection of embroidery and sewing stitches, and access to a world of sewing designs. The large LCD and ease of use encourage users to explore new projects and techniques.

Q: What is the benefit of using Brother genuine accessories?

A: Using genuine Brother accessories ensures compatibility and optimal machine performance. These accessories enhance your embroidery journey and ensure your projects look professional and polished.