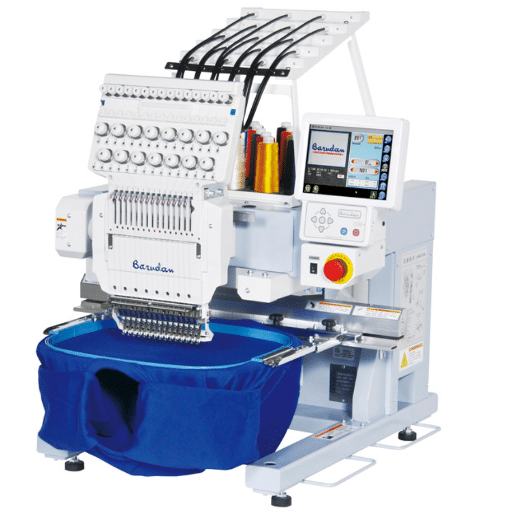

In the field of embroidery, there is always Barudan, which is well-known for excellence and innovation. This elaborate guide focuses on the features offered by Barudan embroidery machines and the benefits brought throughout the commercial world of embroidery. In case you are a professional or just entering the market wanting to make a purchase of such high-tech machines, this guide will help clear some aspects of the Barudan machines. Each feature provides a specific task that, together with the rest of the machine’s modules and components, improves the embroidery process’s overall efficiency and creative potential. We will also go through the recommended maintenance procedures and tips on how to utilize these robust machines best so that they last and perform well. This helps set a clear understanding as to why Barudan machines are respected in the industry. By the end of this article, readers will have an insight into the underlying reasons why Barudan machines are given high accolades.

What Makes Barudan Embroidery Machines Stand Out?

Different from other brands, Barudan embroidery machines incorporate advanced technology with high durability. They come with an easy-to-use interface and accurate stitching systems, which translate to fewer mistakes and high-quality embroidery. The machines are versatile in that they use all sorts of fabrics and threads, enhancing creativity and customization. Furthermore, Barudan machines are backed up by solid support and service networks, which make maintenance and upgrades easier. With the spirit of innovation and constant improvement, they remain competitive within the embroidery industry, which is why companies that meet their demands for constancy and quality choose this brand.

Understanding the Embroidery Machine Technology

A few notable details regarding the technology incorporated in Barudan embroidery machines stand out. First, the precise engineering, implemented in their stitching systems, ensures that the machine’s output is consistent in stitch density and length. About 1,200 stitches for each minute can be completed by a standard Barundan machine, which ensures that speed is coupled with perfection. The devices also allow for the use of multiple needles ranging between 6 and 15, allowing embroiderers to stitch many threads without needing to change the threads all the time.

Regarding Barundan’s technical parameters, Barundan machines usually provide a big sewing area of disecomp $ 450mm x 520mm, which is enough for more intricate embroidery patterns. Usually, the control panels are quite simplified with the use of LCD touch screens for better navigation, while designs are still uploaded easily through thumb drives and PCs. What Barudan makes different is its design software, which guarantees users success no matter which design structure they decide to use, such as .dst or .emb.

Barudan pays great attention to machine embroidery equipment, which is why their devices are equipped with automatic cutting and thread tensioning, which reduces the involvement of the operator and the downtime. In turn users are able to work at great productivity levels to further elaborate on intricate embroidery works, which makes these machines ideal for the industry where the two things: precision and efficiency are needed in abundance.

Exploring Barudan’s Multi-Head Capabilities

Barudan’s multi-head embroidery machines stand out in terms of the large-scale production of embroideries. With these machines, several heads are able to function at the same time, which increases output while still maintaining quality. Also, each head is independent and covered with different thread colors, creating different stitches. Finally, they are perfected for the mass production of complex designs. The head’s synchronization is crucial for consistency across units, and that is much required in mass-produced equipment. Furthermore, there are Barudan multi-heads that are very easy to customize for ease in scaling operations. These machines also have excellent support, ranging from lightweight fabrics to heavy materials, enabling different projects to be pursued. Barudan multi-head machines are thus the best fit for people in this industry when high-volume, high-quality embroidery is needed.

The Role of Positive Needle Drive Technology in Barudan Machines

The Innovative Needle Drive Technology, as integrated into Barudan machines, is significant in improving embroidery’s precision and efficiency. From my understanding, this technology allows the operator to control the needle’s movements better than relying on friction alone. With Positive Needle Drive, the needle is inextricably driven to the rotary shaft with suitable penetrative force, thereby being driven directly by the machine motor. A set of parameters are defined, which would include the stitch error rate, which is said to be less than 1%, along with which it becomes easy to operate at faster speeds – usually at 1,000 stitches for every minute. Ultimately, this would allow needles to achieve embroidery of more uniform quality – faster machines with less wear of equipment.

How Does Barudan’s Multi-Head Embroidery System Work?

It can be stated that Barudan’s Multi-Head Embroidery System is an efficient method of embroidering through the synchronization of different heads to work towards a certain design which in turn increases efficiency. Each head is devoted to stitching out the same design on different articles of clothing or fabric panels at once, thereby making this the ideal technology for heavy embroidery tasks. The system can only be controlled through a central computer system that allows me to check and change the alterations across all heads easily without risking any headpiece change, ensuring that each garment has the same standard. Not only does this configuration reduce the required labor, but it also reduces the chances of errors; in the case, there are any differences in any components, all units can be easily adjusted from one point. The modernized software further reduces the complexity of the process and time required, as multiple products and different designs can be used with ease, increasing the productivity of the system as a whole.

Advantages of Multi-Head Embroidery Machines

Multi-head embroidery machines have a number of distinctive features that improve the efficiency and quality of embroidery goods manufacture. One such advantage is the increased output through the use of several heads at the same time, making it possible to fulfill bulk orders in a very short time with the same degree of accuracy. Such a functionality decreases the processing time and mee, ts scheduled deliveries, who makes these machines popular with mass production companies. Furthermore, these machines can deliver equal outcomes because of their synchronized performance, ensuring that every item is produced to the exact specification and quality level. This accuracy reduces mistakes and squanders, leading to inexpensive mass production. Another advantage is the machines’ ability to quickly change between patterns and different fabrics. Such flexibility makes it possible to use the machines for various applications ranging from garments and trim items to detailed works on unusual surfaces. The central control unit helps facilitate both organization and supervision, reducing the complexity of the model, thus allowing effective organization and quick changes, making them more suitable for constantly changing production conditions.

Exploring Embroidery Design Capabilities

While examining the design aspects of embroidery, multi-head embroidery machines have great design and creative potential. These machines not only present the capability to create diverse and exquisite patterns but also can work with many thread types and color combinations. Such flexibility is important for the modification of the designs and for meeting the requirements of various clients. Also, the use of modern software ensures easy conversion of ordinary patterns into digital form, thus allowing the movement from the design stage to the actual production without any complications. This technology makes it difficult for embroidery designs to enter the embroidery industry, even for experienced professionals and even for starters.

What are the Key Features of Barudan’s Single-Head Machines?

Barudan single-head embroidery machines are considered the best on the market due to their advanced features and rugged construction range. One of the highlights of these machines is the relatively more extensive embroidery range, which allows for wider designs without the necessity of re-hooping. With time, these machines have evolved, and in today’s world, they can work with a speed of around 1,000 to 1,200 stitches per minute and great precision. On the side of the embroidery machine, there is a multifunctional control panel that is easy to operate and works with a variety of drawing formats, reducing the design importation time. Furthermore, Barudan’s machines feature a robust automatic thread-trimming mechanism that enhances efficiency by cutting down cycle times. The design of these machines helps them to last long, and the automatic tensioning system also ensures good fabric embroidery without losing quality. For embroidery services and small businesses, these are some of the core reasons why Barudan’s single-head machines are widely used these days.

When to Choose Single-Head Machines

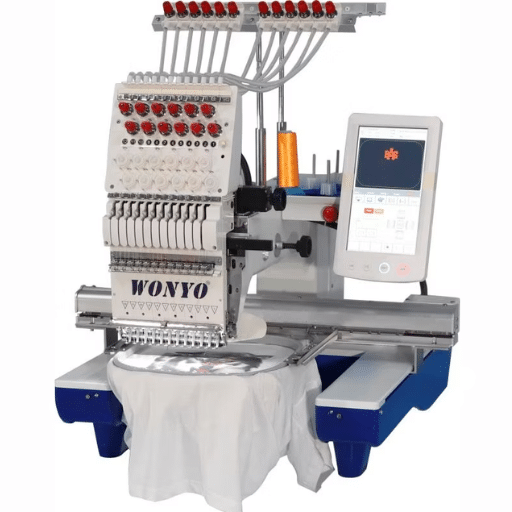

Selecting a single-head embroidery machine is ideal when your production needs require flexibility and customization without the demand for high-volume output. These machines offer individual attention to each project, making them perfect for small businesses, start-ups, or design-focused enterprises that prioritize bespoke items over mass production.

Technical Parameters to Consider:

- Embroidery Area: Up to 500x400mm for spacious design opportunities.

- Stitch Speed: High-speed operations ranging from 1,000 to 1,200 stitches per minute for efficiency.

- Design Format Compatibility: Supports popular formats like DST, PES, and more for easy file integrations.

- Thread Trimming System: Automatic thread trimming to minimize manual intervention and increase uptime.

- Tension Control: Advanced and adjustable tension controls to maintain stitch quality across different fabric types.

- Control Panel: Intuitive interface for easy navigation and design selection.

These features and specifications ensure that single-head machines are a versatile solution for individualized, high-quality embroidery projects.

Loading Designs with USB Connectivity

To load the designs through USB ports, I take my USB drive and put it in the slot of the embroidery machine. With its user-friendly interface, the control panel proves easy to work with when sorting through the various files that have been saved for recall. The machine supports DST and PES formats, so I chose the appropriate file format for design. These fast transfers help me make easy and swift switches between different embroidery projects, saving much of my time and allowing me to focus fully on the intricate details of the work.

How to Maintain and Troubleshoot Your Barudan Embroidery Machine?

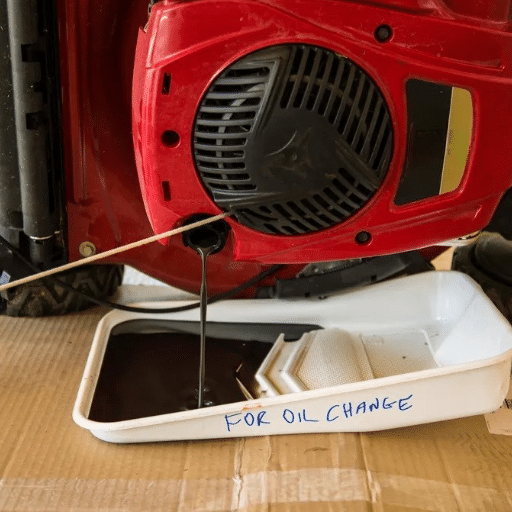

Barudan embroidery machine is also a delicate equipment, hence I employ measures that conform to the standard set of practices for the efficient maintenance and troubleshooting of mine. Some of the maintenance tasks include brushing off any dust, lint, and debris from around the needle and bobbin spaces. For stitch quality, changing fabric snagging needles every 8-10 hours is advisable. When it comes to oiling the machine, it is ideal to follow the manufacturer’s guidelines and recommendations of what part of the machine should be oiled and how often to avoid any wear and tear from friction.

In cases where the machine misses stitches or the thread breaks while embroidering both, I check the tension for the tension settings and make the appropriate changes, making sure they correspond with the fabric being sewed as well as the thickness. On top of this, I still check if the thread path has any material blockage of any means and also go step-by-step to ensure the design format I am working with is DST or PES. When utilizing the control panel, I familiarize myself with it and thus can easily work around the error messages and the user manual in my possession with regard to the error codes. These sets of activities are exercised to ensure that the extent of service of the embroidery machine is comprehensive and the productivity of the apparatus is sufficient for my sewing purposes. If the problems persist, I will write to the support service of the manufacturer, Barudan.

Common Embroidery Issues and Solutions

Embroidery problems that clients usually raise to me include a couple of recurring issues.

Let’s assume I notice some inconsistency in stitch formation. In that case, the first thing that I do is deduce whether or not the needle has been bent away from its normal position or is blunt as this would affect the quality of the stitches formed.

Another common problem is breaking threads; to avoid this, I confirm that the tension of the machines is not too tight, and I have the best thread to match the kind of fabric in use. Bird nesting occurs when there is an excess amount of thread gathered up beneath the fabric, and this has resulted from poor tension settings or the thread not being fed in the right manner; for this, I rethread the machine and change the tension settings.

Most of the time, a simple recalibration of the tension of the embroidery hoop works; sometimes, the embroidery design doesn’t align as it should, and then this combination of steps works just fine. These measures help me handle the majority of the embroidery problems in a fast and effective manner.

Contact Us for Barudan Support and Services

In the event that you need Barudan products support or any service, I recommend visiting the official website, as there is a contact form and contact number to get in touch with customer service. In addition, there’s also an online portal that includes basic guides, questions and answers, and videos to address more common concerns easily and quickly. For more personalized assistance, I’m always there to help you with your queries and make sure that you make the best out of the Barudan products. As for technical help or questions about the upgrades and maintenance, I am only a phone call or an email away.

Why Choose Barudan for Your Embroidery Needs?

Barudan is arguably one of the best choices in embroidery machinery as it maintains a competitive edge in the market regarding quality and reliability. I know that Barudan machines are designed to be robust, accurate, and effective, making it easy for me to create complex and beautiful patterns. Their equipment is fully featured and can include such advances as multi-needle arrangements and sophisticated but simple commands to ensure total usage of the machines and a minimal amount of downtime. Additionally, their backing is of the highest quality, essential in not interrupting one’s productivity. In terms of technical specifications, Barudan machines are equipped with as many as 15 needles per head, embroidery area measuring not more than 550mm by 600mm, and a speed of stitching reaching an astonishing 1000 stitches per minute, which means they can easily handle both detailed and large scale works. From these features, it is evident that not only does the quality of my work improve but the turnover volume as well, thereby guaranteeing the required return on investment.

The Reliability of Barudan Machines

Barudan machines are of the highest quality in the entire embroidery field as it has been claimed by numerous customers and reviews of the machine. To my knowledge, Barudan’s machines are built in a manner that allows them to endure your rigorous demands and still continue functioning effectively on a daily basis without breaking down regularly. There is always a stock of spare parts with them, and they are simple to install, thus reducing downtime. In addition, their technology focuses on the job and guarantees great results every time, which is something vital for my business. I’ve realized their great design plus engineer support means my investment is safe, and nothing interferes with production timelines. This same reliability point is why I continuously seek out Barudan for my embroidery machines and equipment.

Innovations in Embroidery Equipment

I stumbled upon specific changes in this business when I was looking for some new changes in the embroidery machines. For starters, quite a number of these new models contain some sophisticated software that facilitates design and accommodates peripherals, which essentially makes it relatively easy for me to craft design as I can incorporate more than one device. Furthermore, wireless communication is fast becoming a prerequisite, which facilitates the movement of design files stored in my computer or mobile phone and therefore cuts on the time taken, enabling the workflow to be more efficient.

Further, new machines are incorporating energy efficiency. This improvement encourages me to not only save in expenses on utilization of resources, but also support good environmental practices. Provision of LED lighting also enhances visibility hence enabling one to perform detailed work without necessarily increasing the use of electricity(Recommended products:Sewing Machines)

Last but not least, I like the fact that there’s more focus on customization and flexibility on embroidery machines. There are, for example, various modular options available for many of the machines, which allows me to configure it as I want or grow it later when my company will demand it. These developments in the area of technology, communication, and environmental care means that I will be relevant and proactive towards the markets.

Barudan’s K Series: A New Era of Embroidery

“Barudan K Series opens up new horizons in embroidery practice and technology due to its sophisticated engineering designs with various special features incorporated to address the distinct business requirements.” There is enough evidence on K Series’s superiority in several key areas by visiting and drawing out lessons from Embroidery Machines Australia, BarudanAmerica, Apart from Stitch It International.

To start with, the K Series is known for its high-speed capabilities, which enhance productivity and attempt not to compromise on stitch quality. However, with speed comes solid build quality, which increases durability, lessens maintenance rounds, and, therefore, reduces downtime. These attributes directly address the persistent questions of efficiency and reliability.

Next, friendly interfaces make the operation understandable at a basic level so that even inexperienced people in the embroidery field can catch up fast enough and make the most of the machine. Many times, a touchscreen interface with embedded PICS software makes design adjustments and changes easier than ever.

Moreover, the K series also considers eco-friendly features, which fit the current environmental protection trend. Many design efficiencies make energy saving and waste reduction possible without sacrificing performance.

The Barudan K Series is suitable equipment for embroidery firms seeking to enhance their quality and competitiveness in such a dynamic environment owing to its combination of speed, simplicity, and environmental conservation.

References

Frequently Asked Questions (FAQ)

Q: What makes Barudan embroidery machines stand out compared to others?

A: Barudan embroidery machines are renowned for their reliability and innovative features. Since 1959, Barudan has been a leader in the industry, offering machines that keep thread taut and eliminate false thread breaks. Barudan machines are designed to handle a wide range of embroidery tasks efficiently.

Q: What is the Barudan 5-3-2 warranty?

A: The Barudan 5-3-2 warranty offers 5 years on the sewing head, 3 years on other parts, and 2 years on electronics, excluding consumables. This comprehensive warranty ensures long-term reliability and peace of mind for users.

Q: How does Barudan America support customers with embroidery machines?

A: Barudan America provides excellent customer support and service, ensuring that users can access the best deals on Barudan machines, accessories, and reliable embroidery solutions. They also offer extensive training and resources to help users maximize their machine’s potential.

Q: What are the advantages of using a Barudan single-head machine?

A: Barudan single-head machines are ideal for businesses looking to produce high-quality embroidery without the need for multiple machines. They are versatile, allowing for cap embroidery and other specialized tasks, and they come equipped with Barudan’s newest technology to enhance sewing progress and efficiency.

Q: Can designs be easily loaded onto Barudan embroidery machines?

A: Yes, designs can be loaded onto Barudan embroidery machines with ease. Most machines are equipped with the latest technology to support a variety of design formats, ensuring seamless integration and flexibility in your embroidery projects.

Q: What types of embroidery tasks can Barudan machines handle?

A: Barudan machines are capable of handling a wide range of embroidery tasks, including cap embroidery, multihead projects, and more. With 100 memory locations, they allow for extensive design storage and execution, making them suitable for both small and large-scale production.

Q: Are there any special features on the newest Barudan machines?

A: The newest Barudan machines incorporate advanced features such as enhanced tensioners to keep the thread taut and eliminate false thread breaks. These machines are designed to improve sewing progress and ensure consistent, high-quality results.

Q: How does the network capabilities of Barudan machines benefit users?

A: Barudan machines with network capabilities allow users to connect multiple machines for streamlined workflow and increased efficiency. This is particularly beneficial for businesses looking to scale up their production while maintaining control over each machine’s performance.

Q: What should I consider when purchasing a new Barudan machine?

A: When purchasing a new Barudan machine, consider factors such as the type of embroidery tasks you plan to undertake, the number of heads you need (single head vs. multihead), and the warranty options available. It’s also important to evaluate the machine’s features, network capabilities, and support services offered by Barudan America.