When talking about top-of-the-range embroidery machines, Barudan has to be one of the most recognized names due to its contribution to enhancing and improving the fashion and textile industry. This guide details the different types of Barudan embroidery machines available in the market, including their specifications, prices, and features that make them different from their competitors. Immerse yourself in the fascinating world of embroidery by mastering Barudan’s newest technological advances. Discover the machine that best suits your requirements, and discover the worth of each model in terms of multipurpose use and efficiency. This article objectively discerns between these options to facilitate decision-making; thus, it does not matter whether you are an expert or just getting started; this guide will benefit you.

What are the Key Features of a Barudan Embroidery Machine?

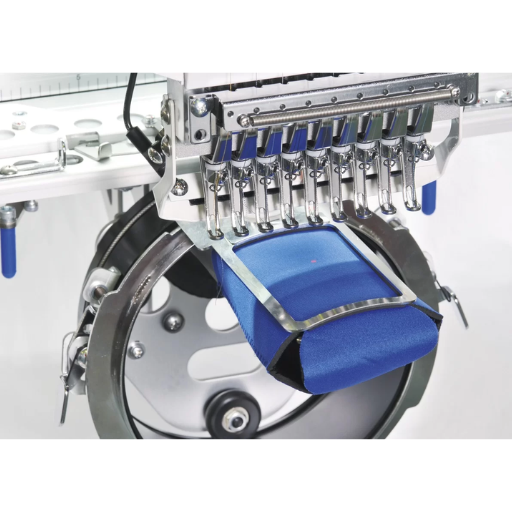

Using barudan embroidery machines sets them apart from others due to some notable features that are beneficial for the industry and small-scale ones. One of the foremost vi features is unprecedented power that allows them to maintain the quality of stitching consistently. These devices are also user-friendly, offering simple, effective controls and touchscreen operations. In addition, Barudan Machinery is known for its solid industrial construction, which allows it to withstand use for long durations. The ample area where the embroidery can take place gives way to more intricate and elaborate models, and with several needles in place, changing colors and designs would be easy. In addition, due to automatic threading and efficient thread tension systems, these machines are a must-have for any professional searching for reliable and all-purpose embroidery machines.

Understanding the Embroidery Technology

The cutting-edge features embedded in the embroidery technology enhance the efficiency and precision of the Barudan machines. Computerized systems that enable intricate stitching patterns feature prominently in this technology. These systems allow users to upload digital designs that the machine executes in detail. The advanced software has the potential to cover most fabric types and thicknesses, making it easy to alter tension and stitch density to produce quality output.

Moreover, Barudan’s patented head technology eliminates thread breakage by facilitating coordinated movements of the needle and hook devices, improving the stitching process. The sewing machines also have multidirectional sewing heads that can easily change design styles without moving the fabric. This accompanies high-speed performance, hastening the completion of even the most sophisticated designs while maintaining set quality.

The ability of Barudan embroidery machines to work with other digital tools for easy design adjustments and monitoring further emphasizes their versatility. Altogether, these features allow the Barudan machines to take the lead in the most econometric embroidery technologies, constructed especially for large-scale manufacturers and small-scale custom design industries.

Exploring Barudan Embroidery Machine Models

To remain competitively relevant, businesses must adapt to the newest trends and the regularly expanding market. Companies that deal in embroidery must adapt to the times, focusing on advancements that can enhance their productivity. One such company that manufactures high-quality machines is Barudan, which, being a leader in the market, produces a wide range of different machines from which Barudan embroidery machines have been popularized.

Let’s take a step back and explain this in the simplest of manners possible, allowing us to understand the various categories of machines produced by Barudan. For firms specializing in bulk embroidery, the Barudan Elite Pro Series is an outstanding investment because it boasts the fastest embroidery speeds and maintains a quality almost unmatched by others. This model is guaranteed to increase productivity rates, given that it efficiently streamlines the company’s production process.

Taking a broader view, the Barudan Multi-Head embroidery machine can also be beneficial for firms looking for a return on investment as it increases scalability as the machine focuses on multiple goods. This ensures a faster workflow, allowing the company to meet higher demand in less time. Another segment of the business to explore would be the single-head series, which offers extensive personalization options without compromising functionality. This series of machines not only possesses advanced networking capabilities but also has user controls that are simple and easy to use. However, due to the complexity and variety of Barudan’s machine models, it can be not easy to choose the right one. However, one thing is clear: all these models will help embroidery professionals around the globe.

The Role of Computerized Embroidery Machine Systems

The world of textiles has been profoundly impacted by the development of computerized sewing and embroidery machines that have made it possible to increase productivity while allowing for more excellent imaginative designs. These systems combine advanced automation and accurate sewing operations, allowing users to understand intricate designs effortlessly and precisely. Some key aspects that must be evaluated in these machines include embroidery speed, number of needles, and hoop size, as they directly impact the capacity and the variations of the designs that can be produced.

- Embroidery Speed: In commercial machines, a moderate compromise between speed and stitch quality is achieved with speeds ranging between 500 and 1,200 stitches a minute, commonly referred to as SPM (stitches per minute).

- Number of Needles: These range between 6 and 15 needles, eliminating the need for manual swapping of different colors of thread. This increases efficiency while broadening the scope of the designs.

- Hoop Size: Broadly speaking, the larger the embroidered area, the more complex and large designs can be sewn on a piece. There are a variety of hoop sizes, of which larger-sized machines have up to 500mm x 500mm feitas para projetos maiores.

Also, elements like automatic thread trimming, color change cycles, and touch screens improve operations and workflows. The networking ability allows quick design modification and data management, important in maintaining a competitive edge in a fast-paced production setting. With those aspects, computerized systems stay active in many sectors, servicing small craft producers and large industrial plants that require precision and flexibility.

How Much Does a Barudan Embroidery Machine Cost?

The price of a Barudan embroidery machine depends mainly on the configurations required and the machine’s features. Basic models suitable for small business operations or artisans start in the region between $10,000-$15,000 and have basic features, average speeds, and needle count. On the other side, multi-head versions which are more robust can multifunction more swiftly, require more needles and possess larger hoop dimensions, these can range from $20,000 up to &50,000 or even higher. Furthermore, other considerations that may incur additional expenses are customization options such as a software update. A consideration that will help buyers is their production expectations and financial threshold amid such machines.

Factors Influencing the Price of Embroidery Machines

Many aspects contribute to the overall cost during the purchase process; one is the price of the embroidery machines. A recognition of the brand and its reliability is significant. Simply stated, if the brand is known for quality and service, it uses that to charge a higher price. Secondly, the specifications and features of the machine are crucial. Automatic thread cutters, large LCD touchscreens, and large embroidery machines capable of high-speed operation will raise the cost of the machine. Multi-needle and multi-head models also result in higher costs, accommodating more complex and diverse projects. Software compatibility and its updates affect the machine’s price due to the availability of machines that work with many design software or even have their software, which increases its price. Last but not least, sales support and warranty services are an added advantage; they serve the purpose of long-term use along with satisfaction, which can alter the price. Buyers must consciously decide their production needs and how much they can invest.

Comparing Single-Head vs. Multi-Head Models

It’s important to understand that your requirements dictate whether you choose a single-headed or multi-headed embroidery machine. Single-headed machines are generally operated by small businesses or custom projects where there is neat portability. Such models perform simple tasks and are best suited for low production volume and custom-made products. Ensuing technical parameters commonly include one needle set and a hoop that ranges from 4 x 4’ upto 14 x 14’.

In contrast, multi-headed machines are made for large-scale production, targeting big businesses aiming to improve their efficiency. Since they allow for several designs to be stitched at once on numerous garments, they tremendously minimize the time used in production. For multihot models, typical technical parameters feature 2 to 6 heads, and each head has several needle sets, which are necessary for color and variety of design without excessive need for employees. These machines typically have wider embroidery fields per head, so some may have 16” x 20” or more and can stitch between 800 and 1,200 stitches each minute while the design constantly changes.

Be sure to examine your design scale and the intricacy embedded within the design to determine the best model for your franchise.

Where to Find Embroidery Machine with Price Details

If you wish to obtain further detailed information on the pricing of embroidery machines, I suggest you first use the largest online markets, such as Amazon, which often provides a range of models, customer feedback, and price comparisons. For more detailed specifications and prices, Brother and Janome’s websites contain a wide range of models for all business needs. Also, sites specializing in embroidery, such as Embroidery.com, offer useful readings that allow one to compare and feature prices, which will come in handy in deciding on the purchase about the specific purpose, whether personal or business. Through these readings, I can gain a comprehensive understanding of both the technical requirements and the financial implications of buying an embroidery machine.

What Makes Barudan a Top Choice for Embroidery?

Barudan distinguishes itself as the go-to solution for embroidery equipment due to several important considerations: precision, quality, and exceptional technology. Generally regarded as robust, the construction of Barudan machines suggests that they last long and remain functional over time, thus making them suitable for high production volumes. With the assistance of advanced servo drive technology, stitching accuracy and speed are significantly improved, enabling the easy execution of intricate designs. Furthermore, Barudan’s efficiently designed interface and embedded software aids even novice embroidery practitioners through design creation and resource utilization, making the work much easier. Finally, dedication to its customers and constant improvement are key factors that put Barudan at the top of the competition in the embroidery machine and equipment market, thus making it a good option for companies that target high-quality services.

High-Quality Embroidery Machines and Their Benefits

Some well-known brands like Brother, Janome, and Barudan manufacture knitting machines that boast exceptional quality and come with many benefits that would fit different avenues of embroidery work. One such advantage would be the accuracy of these machines, which is high enough to permit detailed, intricate, and somewhat sophisticated designs to be produced at a high rate. These machines are also equipped with advanced technology, such as automatic threading and tension control, which enhance efficiency and minimize manual errors, thus improving the workflow. Another major advantage would be the concentration on durability and reliability; for instance, Barudan is widely known for its strong structure, which withstands vigorous use in a busy environment. Furthermore, the company has provided engineering software and an easy-to-use interface, making it easier for beginners and advanced manufacturers to alter the designs according to fit. Lastly, the company also has a high reputation for its customer service as it provides plenty of assistance, classes, and upgrades to ensure that the machines and the business keep in touch with changing industry needs.

The Industrial Advantage of Barudan

While contemplating the competitive edge of Barudan embroidery machines, I realized their technology significantly distinguishes them. Their machines are built for high production but with great precision, which is ideal for bulk production. Barudan is well known for its reliability, and this is not by chance because it has strong, easy-to-maintain equipment that allows for heavy usage. Also, their interfaces shorten training periods and allow the integration of the products into the existing system quicker. All these factors enable Barudan to be the preferred option for companies that wish to adhere to high-quality standards and enhance efficiency and productivity at an industrial level.

Comparing Barudan with Like Tajima Barudan

Several technical parameters come into play in the case of Barudan and Tajima embroidery machines, focusing on each brand’s strengths and potential differences. Both Barudan and Tajima are treated with respect and are considered brands catering to differing industrial embroidery needs; however, they’re crafts of precision and reliability.

- Stitch Speed: The speed of Barudan machines is generally close to one thousand two hundred stitches per minute, which would enhance quick production. From a stitch speed perspective, the Tajima embroidery machines are on par or slightly beyond this, varying from one thousand two hundred to one thousand five hundred stitches per minute, which is ideal from a mass production point of view.

- Durability and Maintenance: Machines produced by both brands get a pass mark as they have strong body construction. One of the best features associated with Barudan machines is their low-maintenance design. In contrast, Tajima machines can be used longer but will need some maintenance now and then to function optimally.

- User Interface: Barudan, for instance, allows its users to alter the designs and, therefore, creates templates with easy-to-learn controls, making them less of a specialized item. Solutions of Tajima, on the other hand, creates embroidery designs for specific purposes. Still, their interface is a bit more sophisticated, with most dealing with more over-the-top designs.

- Depth in Embroidery: Both machines have a substantial degree of tolerance. Barudan has pointed out that it can produce constant stitch quality during mass production, a major focus for big corporations. Tajima can boast embroidery precision well-adjusted to more ornately designed and complicated tasks.

- Fielding and Updates: Barudan is best known for, relatively speaking, unsophisticated and easy machinery maintenance among sewing niches because its geographical location provides algebraic solutions and regular software updates. Support and training also exist at Tajima-identified dealers; however, such support may depend on location and distributorship.

The final remark may signify that both companies have advantages in different attributes. Barring’s fabrication is an overall easy-to-implement and sturdy option, while Tajima is highly sought after for its speed and detailed design. The choice of working with either usually depends on the actual work processes and expected results in the embroidery business.

How to Choose the Right Single-Head Embroidery Machine?

In selecting the idiosyncratic single-head embroidery machines that suffice your needs, consider the factors you focus on to suit your operational output. First, understand how many volumes of embroidery work you will be dealing with. In such high production areas, understand which machines are of greater strength and efficiency, such as Barudan for being strong and Tajima for speed. Next, ask yourself how complex the designs you want to produce are supposed to be. For instance, does it rely on intricate patterns and details? If so, perhaps it is best to recommend Tajima over Barudan since it has better design capabilities. Also, assess your current understanding and what else you are willing to learn since, for example, Barudan has a relatively user-friendly interface, which means it is best for beginners. At the same time, Tajima might be better suited to more experienced people who want more details in software. Also, looking into the technical support and maintenance services the manufacturers offer for such factors will undoubtedly add value to long-term efficiency and satisfaction. In closing it all up, the choice has to be based on your production planning focus, economic and financial limitations, and the design features you have in mind.

Evaluating Product Quality and Cost

When comparing the quality of a product or its price for a single-head embroidery machine, it is always better to concentrate on several critical technical parameters to make the right choice. Let’s start by considering stitch quality, which is an important determinant of the overall look—machines with thread breakage in the stitching are of little use, so look for those with consistent tension control. Another important criterion is the machine’s strength or sturdiness; the materials used and the brand image in terms of reliability must be evaluated.

Then, we evaluate speed and efficiency; the more stitches in a minute, the greater the chances of being cost-effective due to the production volume that can be achieved. Software and usability are also essential; purchasing embroidery machines that are easy to operate and can add various editing features saves time and resources for training. Finally, and most importantly, consider the cost of the machine against what it is capable of doing; the features of the machine purchased must be accompanied by the support package, such as warranty and maintenance, so that the long-term expenses are minimized. Satisfying these criteria will go a long way in establishing the most cost-effective machine that matches your operational and budgetary needs.

Assessing Warranties and Service Options

The manufacturing industry is highly competitive, and with increasing competition, it has become increasingly important to focus on centralizing all services under one service. Be it warranty information or, in this case, an embroidery machine, it is critical that everything is contained. In doing so, it is also suggested that significant patterns for practical conclusions and reliable highlights be looked for. This further allows a focus on safeguards against deficiencies alongside substantiating malfunction or central defect. In such cases, potential guarantees should suffice, and as a general rule, protocols in a guarantee cover significant parts and labor – from one year up to five. Cited wood and other measurable resources are sometimes meant selectively and add value to remaining warranties, especially the onsite repair services. Some claimed that it is beneficial to default to seeking servicing companies offering a package to ensure comprehensive, including web-based assistance, technical support line, and user manual. A satisfactory measure that extends the operational gross of an embroidery machine can also include employing companies that provide preventative maintenance planning to maximize machine downtimes.

Moreover, corroborate if the solution set maintains item replacements as primary issue areas within breach of contract or the supplier’s restoration timeframe. Finally, do not forget to check the terms and conditions of the warranty or other service mechanisms to be aware of possible coverage restrictions or exclusions from service. Consequently, these basic but thorough steps will cover the underlying dimensions pertinent to an embroidery machine’s cost-efficiency and productivity in the foreseeable future.

Exploring Automatic and Manual Features

While looking at the automatic and manual features of the single-head embroidery machine, I focused on the versatility and ease of use as depicted in front-line industry websites. Undoubtedly, automatic embroidery machines are effective as they come equipped with features such as automatic threading and color changes, saving time swapping out threads during the setup. They also include various designs that have been pre-programmed, which makes them perfect for people new to embroidering or companies that do not want to waste a lot of time. However, manual features provide more enhanced control over the finer details and designs that are more complex or have to be custom-made; this gives a scope to adjust details while sewing. This approach is mainly advantageous to seasoned users who seek absolute precision. These functionalities allow me to take advantage of both modes as an asset, enabling me to achieve an enhanced production ratio without compromising on the quality and uniqueness of the finished project.

What is the Future of Barudan Embroidery Machine Technology?

Looking ahead, it is apparent that Barudan embroidery machine technology is becoming increasingly integrated with automation and digital linking. With the development of the industry, we foresee an improvement in machine effectiveness and accuracy as IoT and other smart technologies are embedded to provide easy monitoring and maintenance of machines. New generations of these machines will likely include better user interfaces and advanced software systems, allowing an operator to control the machine most simply and providing a greater variety of custom designs from which to choose. In addition, the integration of eco-friendly technologies and approaches to the manufacturing and operating processes of the machines is also expected to conform to the requirements of the world environment. By taking these technologies together, Barudan will be able to acquire the position of the market leader by providing products that are in sync with market fluctuations and end-user ambitions and ensuring Barudan embroidery machines appeal to revolutionary innovations.

Innovations in High-Speed Embroidery

It would be best to gain further understanding of the context by explicitly stating what this article focuses on. As we delve into the advancements of speedy embroidery, one can tell that the state-of-the-art progression drives forward the analysis. The rotary screen process is often considered a standard in the embroidery world, but there is arcane moves of ideas towards improvement. Improvements such as Last-range stitching machines allow companies to use servo motors and precision engineering advances. Such a boost elevates productivity and dependably superior final product quality since the effects of stitching at high operational rates are unfavorable in wide terms, and this will be lighter in specific. Also many forms of stitching designs operational processes become automated due to the addition of smart technology, and indexing systems through the use of IoT technology and innovation, this reduces time and focuses the market shift towards kitting out. This repeats market improvements accordingly so that our embroidery solutions keep up with technology development.

Adapting to New Design Trends

Change is the only constant, especially in the embroidery industry, characterized by a rapidly changing world. Perusing emerging design trends that catch the eye of consumer interests is instrumental in gaining an edge in the market. Some of the top insights obtained from the leading voices of the sector_detail_ declare that, however, the general outline remains the same_ the core customizable and personalized aspects are still very much present. Seeking pertinent minutes, consumers are more than ever looking for locally stitched designs that fit their style or brand identity, thus making it a necessity for embroidery designs to be flexible. Among multiple options available today, specific key technical parameters such as DPI (dots per inch) for design sharpness, fabric-appropriate stitch density, and color matching are crucial to ensure an exact and rich embroidery result.

Moreover, the global pursuits of pushing for sustainable ideals and green designs are being seen and felt. Most of the time, manufacturers struggle to meet this demand by sourcing recycled components and utilizing environmentally friendly impact dyes. We can further observe a trend of using 3D embroidery with various foams and threads more frequently as they add a new dynamic _ dimension_ to the designs. It will encourage companies to adjust and incorporate more design variations in this respect. Therefore, we meet the customer’s ever-changing demands by incorporating advanced embroidery techniques.

The Impact of Technology on Embroidery Machines

According to my understanding, technology influenced everything regarding embroidery machines. I have seen how everything changed with the growth of digital and automation technologies. Today’s embroidery machines are better than at any other time in history. Most modern machines are embedded with CAD (computer-aided design) software, allowing for easy design replication and more efficient production processes. The interaction enables intricate patterns to be completed faster than before, making the time and cost of production cheaper. Furthermore, cloud technology development continually reinforces the current need for easily available designs worldwide. Apart from lifting productivity, these technological changes also mean we can provide an opportunity for customization that meets our customers’ different styles and needs.

References

Frequently Asked Questions (FAQ)

Q: What are the main features of Barudan embroidery machines?

A: Barudan embroidery machines are known for their high-quality performance, reliability, and variety. They offer features like digital controls, multi-function capabilities, and options for different embroidery needs, including flat and cap embroidery.

Q: How does a computer embroidery machine by Barudan work?

A: A computer embroidery machine by Barudan uses digital technology to sew designs onto garments precisely. It has a computer interface allowing users to input designs, which the machine replicates with high accuracy.

Q: What is the price range for Barudan embroidery machines?

A: The price for Barudan embroidery machines varies depending on the model and features. Entry-level machines like single-head computer embroidery machines are generally more affordable, while multi-head or 15-needle machines can be more expensive due to their advanced capabilities.

Q: Are Barudan embroidery machines suitable for home use?

A: Yes, Barudan offers models well-suited for home use, particularly single-head machines that provide high-quality embroidery without requiring professional-level investment or space.

Q: What types of embroidery can be done with Barudan machines?

A: Barudan machines can handle various embroidery types, including flat embroidery, cap embroidery, and t-shirt embroidery. They are versatile enough to be used for both small-scale and large-scale production.

Q: Do Barudan embroidery machines come with a warranty?

A: Yes, many Barudan embroidery machines come with a warranty, often up to 5 years, which ensures long-term support and reliability for the user.

Q: How can I ensure fast delivery of a Barudan embroidery machine?

A: To ensure fast delivery, it is recommended that you purchase from authorized Barudan suppliers or dealers who offer reliable shipping options and have a good stock of machines ready for quick dispatch.

Q: Can Barudan machines handle multi-head embroidery?

A: Yes, Barudan offers multi-head embroidery machines designed for high-volume production, which makes them ideal for businesses looking to increase their output efficiently.

Q: What makes Barudan embroidery machines different from other brands?

A: Barudan machines stand out due to their Japanese engineering, high-quality manufacturing, and innovative features such as digital interfaces and robust performance, which ensure precise and reliable embroidery results.

Q: Where are Barudan embroidery machines manufactured?

A: Barudan embroidery machines are manufactured in Japan and are known for their precision and high engineering and production standards.