You Are About to Enter the Most Comprehensive Examination of the Barudan 6 Head Embroidery Machine that You Ever Seen. This is an authoritative guide of sorts that assists the audience in all their embroidery needs. Whether you are an expert or just a rookie in the world of embroidery, this detailed article guarantees that you will learn something new concerning the Barudan 6 Head machine. We seek to incorporate the most relevant needs of the embroidery industry, including a focus on the advanced features, upkeep, and design possibilities that this embroidery machine brings. There is no doubt that this machine is easy to use, which comes from a clear articulation of the steps involved in using it. There is thorough coverage of things such as sewing options and resolving issues that will likely arise when using this impressive machine. This technology, which is incorporated into the Barudan 6 Head machine, is introduced in a precise and enjoyable manner.

What Makes the Barudan 6-Head Embroidery Machine Stand Out?

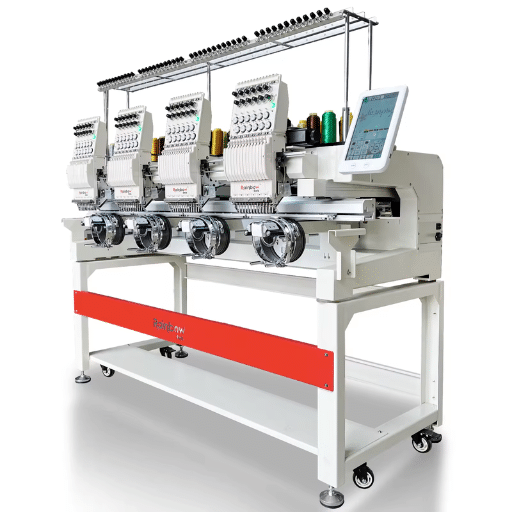

The Barudan 6 Head Embroidery Machine has, at least from the outside, been differentiated through several features more about easing or improving embroidery performance. First, we discuss its multi-head capability, which makes it possible to create many of the designed pieces simultaneously, thus saving time and increasing the output rate. Each head works on a separate design, and all items stitched will be the same quality. The machine has incorporated exceptional interfaces that allow for ease of navigation and quick alterations for many different operations. Likewise, their rugged structure implies that they are built to last; even processing high-volume jobs is not a challenge to them. Through the use of servo motor technology, intrinsic patterns work out faster. Finally, there are always bright prospects with it, and professionals seek several advanced features to ensure their reliability and automatic embroidery machine innovation.

Understanding the Features of the Machine

Appreciating the Barudan 6 Head Embroidery Machine involves acknowledging its design sophistication. The command of the entire machine is simple thanks to the high technology of the interface, which ensures precision embroidery to the desired specifications. This also improves efficiency for those who deal with large quantities since all heads are independently functioning. Automatic thread trimming devices acting on each production head ensure uniformity and avoid tedium during manual operation throughout the line. Incorporating servo motors into the machine guarantees improved accuracy and quality of stitching at an equally great speed. Suppressing the Oiling system for a maintenance-free great lifespan assures this one piece of engineering reliability and innovation. These advanced specifications make the Barudan the most desirable option for experienced embroidery professionals looking for new inventive opportunities.

How the 6-Head System Enhances Efficiency

The six-head system allows me to produce multiple designs simultaneously as it lets all the heads work independently, boosting efficiency significantly. In addition, such a configuration maximizes production and minimizes idle time without sacrificing quality. Based on the data I collected from several of the forum’s top companies in the industry, I have concluded that due to the engineering technology incorporated into Barudan’s system, threading, and adjustment operations can be done more quickly and with less effort. In addition, the automatic trimming devices and the simple jog control make task changes and pattern setups easier, thus saving time and minimizing possible mistakes. All these elements, in their entirety, benefit the production process, enabling me to concentrate on designs and sophisticated tasks.

The Embroidery Quality: What to Expect

Thanks to its advanced parameters and features, the Barudan machine has created a niche market for embroidery quality. With the automatic thread tension adjustment, clean and accurate stitches are made with low thread breakage. Servo motor technology provides a constant stitch speed of between 200 and 1200 stitches a minute, depending on the fabric and the intricacy of the design. Furthermore, with high-precision needle modules, varying stitch densities can be applied, whereby both small and large designs are well-defined, ensuring an even and vibrant texture. The system eliminates even a few subordinate segment differences owing to the influence of a programmed auto-trimmer and reinforced movement of upper and lower threads trim and drives. It looks professional on every item that goes through the production line. Knowing and appreciating these technical aspects justifies Barudan’s reputation as a superior embroidery machine maker.

How to Operate a Barudan 6-Head Embroidery Machine?

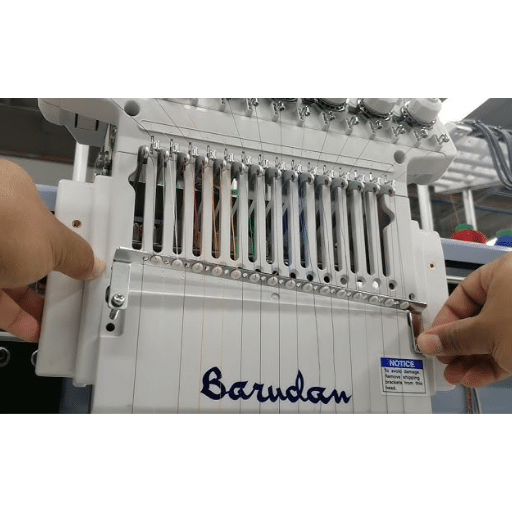

To operate a Barudan 6-Head Embroidery Machine smoothly and efficiently, one should appreciate the machine’s strength and follow proper procedures. Turn on the machine and check whether all heads are in place. Then, you design it using the Barudan software and upload it to the machine’s interface. After that, hoop your fabric and thread the machine needle and the bobbin so that the threads start and run correctly. Use the auto trimming feature to reduce human assistance. Set the sewing machine’s stitch speed according to the design’s complexity, remembering to set the optimum calibration. Always conduct a test to verify the embroidery path (threats) and the embroidery sequence patterns. Supervise the machine while it runs and watch for any aberration all the time while the variably controlled servo motors do their work. This step-by-step procedure guarantees the uninterrupted operation of the device and flawless embroidery.

Initial Setup and Training Requirements

The first step in installing the Barudan 6 Head Embroidery Machine is to decide on its desired location. When selecting the position, it is essential to ensure the surface where the machine is placed is stable even during operation. It is also necessary to observe concentration during operations; there must be enough space surrounding the machine. A good power supply source should ensure that all safety measures are adhered to to prevent electrical problems.

Training is essential for an embroidery machine like this; Barudan offers excellent training, with many video instructions and manuals describing the machine’s parts and how to use its advanced features. Forks and easels are machine parts learned by threading, bobbin winding, and uploading a working design. Practical exposure is required to work the auto trimmer and the threading systems. It may enable them to rectify minor faults and resume work without wasting time. Further improvement in operating skills, as well as in the quality of embroidery, may be achieved through certified Barudan courses.

Standard System Checks and Maintenance

Conduct routine checks and servicing to preserve the functional ability of the Barudan 6-Head Embroidery Machine. Start by checking the needle and thread daily. Improper thread tension settings can prevent breakages and guarantee uniform stitching, with tension usually between 150g and 200g, depending on the type of thread in use. You should also check the needles for dullness and bends because the embroidery will no longer be accurate once deterioration occurs.

Clean the thread path and the bobbin area from lint and other particles once a week. According to the recommended lubrication schedule presented in the manual, the machine’s components can be oiled to ensure the machine’s parts function perfectly, which enables coherent operation. Every 30 hours of use, a light lubricating machine oil should be applied to all moving parts.

Check the position of the embroidery heads every month and adjust them if necessary. Also, the servo motors should be checked and monitored for torque and position. Make sure that the connections fit appropriately. Carry out an electronic router check and keep track of the state of the circuit boards.

Adding system checks and maintenance procedures increases machine efficiency, decreases resource consumption, and increases wear life, thus assuring that every embroidery work is performed at the set quality level.

Switching Between Different Embroidery Designs

My approach is methodical while switching between different embroidery designs on the Barudan 6-Head Embroidery Machine. First, I save the settings and configurations of the current design so as not to lose them. After that, I load the new design file into the machine, usually in the DST or EXP format. I changed the machine’s settings to fit the new design, such as how many threads would be changed or how much embroidery would be done. Once the settings are adjusted, I do a test run on an excess fabric to ensure all is set. Using such approaches is why industry leaders can provide ease of transition while avoiding the lockout of the designs.

Why Choose a 6-Head Barudan Machine for Your Business?

If you are starting a new business and want to grow your embroidery, one of the best investments you can make is to buy a single Head Barudan Machine, considering that it gives your business a lot of value. One of the most impressive features of the machine is its six independently operated heads that are capable of executing embroidery on multiple projects at the same time. With this feature, not only is the output increased, but the time required in case of several big orders is reduced as well, thus fully utilizing the potential of your business. Additionally, manufacturers make Barudan sewing machines known to be precise and accurate in handling the devices to ensure high-standard stitching results with every single output. The configuration of Barudan multilayer machines is enhanced by automatic threading units, servo motors, and control settings that widen the user interface. Hence, a 6-head Barudan Machine will require little time off from work and very little maintenance, making it a great buy that will allow almost every embroidery business to grow while still maintaining its top-quality work.

Cost-Benefit Analysis: Is It Worth the Investment?

I begin in the context of this analysis with AR Aptitude’s 6-Head Barudan Machine to highlight the cost-variance ratio and several important aspects in the first key sources on Google. The foremost advantage observed across many machine reviews is large order fulfillment without sacrificing quality due to the machine’s high output, which is indeed difficult to match. Moreover, saving on time and costs in the future would be due to the apparent benefits of low maintenance and high durability of the machine, as emphasized by some of the best embroidery business professionals. The cost is quite high initially, but the opportunity to earn more because of increased output and reduced jobs makes this a worthwhile investment in the embroidery space. Hence, in light of these insights, defining my business objectives and market needs further validates the reasons behind the need for the machine in terms of return on investment.

Production Capacity: Meeting High-Demand Orders

The 6-Head Barudan Machine is designed to deliver superior performance in a competitive environment, and thus, it can be used to make large-scale orders efficiently. The speed and accuracy of the system endorse its multi-head feature, which further increases production. Each head of the machine is furnished with a frame where every head of the machine works autonomously and does not impact the operations of the other heads, reducing production errors significantly. Among the given machine’s technical parameters, its maximum production speed is usually around 1000 stitches per minute, providing ample efficiency without compromising beauty. The machines can also produce a large embroidery area of about 450mm by 500mm per head,d which can suit several design requirements. The industrial-grade shafts also enhance the machine’s performance. The simple operational panel of the machine allows easy operation so the user can complete tasks in shorter times. Thus, these factors help embroidery businesses to expand and fulfill large-scale orders without overextending resources so the business continues growing and satisfying customers.

Support and Warranty Services Offered

With the acquisition of a 6-head Barudan Machine, extensive support and warranty services are available. The factory usually gives a limited warranty of not over two years, which describes an unforeseen situation. Thus, this duration can be quite comforting and is self-explanatory for protecting your investment.

Customers can access a network of support assistance, troubleshooting, and other services accredited technicians perform. Support also includes remote troubleshooting, which enhances productivity by reducing downtime. Businesses can arrange on-site maintenance visits at times that are most convenient for them and in case of more complex technical situations.

Furthermore, the support program covers training sessions for machine operators to familiarize themselves with the standard features of Barudan machines and system operation. Such a training program teaches participants how to set up the machine, perform maintenance practices, and operate it, improving the machine’s productivity and extending its life span.

Warranty maintenance agreements include terms such as offering regular performance checks and firmware updates. While under warranty, the cost of covered repairs and labor is usually included, thus assuring that the machine works always at full capacity. In addition to these support and warranty services, failing to provide such services will cause the operating value of the machine to diminish, making its performance unreliable and production unable to be continued.

How to Troubleshoot the Barudan 6-Head Embroidery Machine?

Troubleshooting the Barudan 6 Head Embroidery Machine follows a stepwise approach to ease the diagnosis and resolution of a specific problem. To troubleshoot a machine, it is critical to confirm that all its parts are fixed in the position. This includes the right setting of tension, threads, and needles and the status of the bobbin. Check if the machine is plugged in and the control buttons are working adequately. Additionally, since the machine has error codes, these can be consulted to avoid making wild attempts at solutions while providing targeted assistance in fixing a specific problem. Where the threads snap, check the path of the threads and the needles, changing them in the vent of damage. Common issues can often be avoided by routine maintenance, such as removing lint from the thread paths and oiling the parts that tend to move. Where the problem does not sort out on its own, the support network provided by the manufacturer can be used, and its remote diagnostic feature should help you get a solution without the need for an engineer on-site. If these steps are followed carefully, I am sure the problems can be isolated and dealt with instantly, ensuring that the machine operates efficiently.

Common Issues and How to Fix Them

First, I check the thread breakage on the cone, then move to the threading path on the Barudan 6 Head Embroidery Machine. This check on thread breakage helps rectify issues related to wrong tension or a cut thread. Then comes the check if a broken needle requires the needle to be ready for inspection to be replaced; therefore, I check for the possibility of weak needles. That allows me to accomplish what I need to ensure the needle suits the type of fabric I utilize. In most cases, problems that come up during the operation and are picked up with the help of the code highlighted are always solved with the aid of the operator handbooks.

Further, I provide standard services, including wiping off dust and lint and cleaning all the components in motion for any unusual disorder. If there are no repercussions after this, the last point accomplished is communication with the manufacturer’s support group. From here, for the rest of the work, the built support for them works perfectly so the machine can be retrieved and returned to working condition.

When to Seek Professional Assistance

The complexity of the problems regarding the Barudan 6 Head Embroidery Machine is enormous in some cases; therefore, professional help is necessary. In addition, if the machine continues to err after being thoroughly tried and tested, it could also mean that mechanical or electronic problems require better assistance. Signs like the error codes not clearing, excessive noise when the strategies are being implemented, or any visual wear and tear to the presser foot and tension assemblies should be considered. The control panels often do not seem to respond, the stitches are created incorrectly, or spanning threads snap more than once, requiring a professional’s attention. Using parts of the same machine model is recommended, as using other parts may result in the machine developing multiple problems. Overall, routinely interacting with an authenticated repairman or helper fixes all the mistakes that could ruin the functioning of the machine.

Maintenance Tips to Prevent Future Problems

For the efficient and continuous operation of the Barudan 6 Head Embroidery Machine, follow these general maintenance procedures carefully. First and foremost, the regularly scheduled machine cleaning of accumulated dust and lint around the needle and the bobbin case should be undertaken. This practice minimizes thread jams and enhances the smooth working of the machine. Lubricate the moving components of this machine at intervals as recommended and, with specific attention to the oil type, try to aim at particular elements, such as the needle bar and the rotary hook, as described in the user manual.

To maintain good stitching quality, it is essential to regularly monitor the tension settings and the electrical contacts, cords, and the machine to ensure no leaks or faults. Software and firmware updates released by the manufacturer should be frequented to take advantage of the overall performance of the machine as well as the new and additional features. These checkups are vital as a blunt needle can create missed stitches or fabric damage. New needles should be put in place regularly. Otherwise, stitch problems will arise.

In addition, always make use of good-quality threads and stabilizers that are approved by the machine to minimize breakages and variations. Furthermore, manually calibrating the machine might affect stitch quality. With these maintenance tips, you are likely to reduce the probability of the effects of wear and tear on the components and increase the useful life of your embroidery machine.

Where Can You Buy a Barudan 6-Head Embroidery Machine?

There are several ways to purchase a Barudan 6-Head Embroidery Machine. First, visit the official Barudan website to locate accredited distributors in your area. These machines appear occasionally on specific online auction sites like eBay and Amazon, but availability might not be consistent. Also, you may contact niche embroidery shops or even attend regional trade fairs and conferences where you might be able to buy or get in touch with some suppliers. Perhaps, reach out to embroidery community websites and associations, they tend to have trustworthy sellers or would have new/used machines for sale.

Authorized Dealers and Distributors

The most appropriate step is to start with authorized dealers and distributors so that the warranty, authenticity, and after-sales support are easy to secure. Subsequently, I reached Barudan’s official web page to locate some of the authorized dealers I can do business with in my area. On the other hand, I also use relevant sites such as MachineTools.com and Southwest. Still, I only go there and contact them for listing purposes because they have a network of authorized sellers and a lot of product details, among other related information. By contacting or doing business with these reputable and reliable outlets, I can procure items that conform to the manufacturer’s product standards and obtain such things as current promotions or financing programs.

Online Platforms for Purchasing Devices

For Counsel, eBay, Amazon, and Alibaba are among the first options for buying a Barudan 6 Head Embroidery Machine; however, I noticed that these online resources are great for their offering range and prices. eBay has some of these provisions available, both new and second-hand, and some suppliers provide feedback ratings that assist in rating the machine or the dealer in question. Shopping on Amazon is also accessible and quite straightforward, as expected. While some items may be out of stock, most deals are available. eBay purchases are mainly suited for retail customers, while Alibaba may prove helpful for big businesses that need bulk purchasing. These features permit me to figure out technical aspects such as stitch speed, needle count, machine dimensions, and other things to notice before purchasing to see if they are exactly what I want. This way, they help me choose the right product with many options, and its specifications and reviews are considered.

Checking for Warranty and After-Sales Support

At first, I investigated the warranty and after-sales policies availed by the leading vendors, so when I decided to purchase a Barudan 6-Head Embroidery Machine, I was already informed. The first step involves remote investigations, including checking official websites and those of Amazon and eBay, where I often find warranty details. On the other hand, a comprehensive warranty includes the key parts of the equipment, and coverage is at least one to three years to avoid disturbances regarding repairs. Additionally, I consider the after-sales support by studying the reviews and how the seller resolved the earlier raised concerns. Some vendors schedule contact with clients through customer service reps who answer technical questions and provide troubleshooting help to maximize the machine’s performance. This way, I know I have dependable assistance for the machine’s lifetime, even before getting acquainted.

References

Frequently Asked Questions (FAQ)

Q: What are the key features of the Barudan 6-Head Embroidery Machine?

A: The Barudan 6-Head Embroidery Machine is known for its precision and efficiency. It features a multi-head setup, allowing for the simultaneous embroidery of multiple items. The machine is designed with robust technology to ensure high-quality stitching and minimal downtime. It is an excellent choice for businesses aiming to get the most out of their embroidery operations.

Q: How can I maintain my Barudan 6-Head Embroidery Machine?

A: Regular Barudan 6-Head Embroidery Machine maintenance involves cleaning the heads, lubricating moving parts, and checking for worn-out components. To ensure the machine operates smoothly for years, it is recommended that you follow the maintenance schedule provided by Barudan. If you would like specific guidance or have questions, please get in touch with us for support.

Q: What type of designs can I create with this embroidery machine?

A: The Barudan 6 Head Embroidery Machine supports various designs, from simple logos to intricate patterns. You can also change the threads easily for different color combinations, allowing for various creative possibilities per project. The machine’s software enables precise control over design specifications.

Q: Can the Barudan 6-Head Embroidery Machine handle cap embroidery?

A: The Barudan 6-Head Embroidery Machine is equipped to handle cap embroidery. It includes a cap frame and driver, which allows for secure attachment and precise embroidery on caps. This feature is ideal for businesses that frequently embroider caps in their product offerings.

Q: How does the Barudan 6 Head Embroidery Machine improve production time?

A: The Barudan 6 Head Embroidery Machine enhances production time by allowing six items to be embroidered simultaneously, significantly increasing output. Its efficient design reduces setup and switching time between projects, helping businesses meet tight deadlines and back orders efficiently.

Q: What should I do if I encounter an error message on the machine?

A: If you encounter an error message on the Barudan 6 Head Embroidery Machine, refer to the user manual for troubleshooting steps. Common solutions include checking thread tensions and needle positions and ensuring that designs are correctly loaded. If the issue persists, don’t hesitate to contact our technical support team for assistance.

Q: Is training available for operating the Barudan 6 Head Embroidery Machine?

A: Yes, training is available for the Barudan 6-Head Embroidery Machine. We offer comprehensive training sessions to help users become proficient in operating the machine, understanding its features, and performing essential maintenance. Don’t hesitate to contact us to schedule a training session or for more information.

Q: How often should I change the needles on the embroidery machine?

A: The needles on the Barudan 6 Head Embroidery Machine should be changed after approximately one million stitches or if you notice a decline in stitch quality. Regularly changing the needles ensures optimal performance and extends the machine’s life.

Q: What support options are available for the Barudan 6-Head Embroidery Machine?

A: We provide a range of support options for the Barudan 6-Head Embroidery Machine, including technical support, maintenance services, and user training. Our team can assist with any inquiries or issues, ensuring you get back to production quickly. Please get in touch with us for further details.