Inevitably, when starting or growing a banana chip production there comes a concern about the choice of banana chip machinery: about its model and price. The zealous effort to cut across a vast maze of sources available in the market for your ideal banana chip machine, within your production levels and financial suitability, is what this extensive guide to banana chip machine purchase intends to offer. Different factors will have an impact on the cost of the machines, such as capacity, technology, brand, and additional functions. This article is written to help both small and large-scale manufacturers by detailing what to consider when purchasing to increase efficiency and profits.

What is a banana chips-making machine, and how does it work?

banana chips machine price

A machine for making banana chips is a unique piece of equipment that endeavors to mechanicalize the conversion of original bananas into banana chips. Usually, this device has many units that cooperate to realize effectual output. At first, raw bananas are peeled and uniformly sliced to a thickness that will aid in even frying of the chips. The fried slices of bananas are further processed in a frying machine, which fries the pieces to the required crispness. The chips, after frying, are typically passed through an oil removal system or an oiling machine to reduce the fat covering of the chips’ ointment for healthier consumption. The chips are then cooled and sometimes passed to a seasoning section where flavors are added. These machines help in improving the consuming process by control of time, uniformity in performance, and product quality, and therefore, both small and factory requirements of production are satisfied.

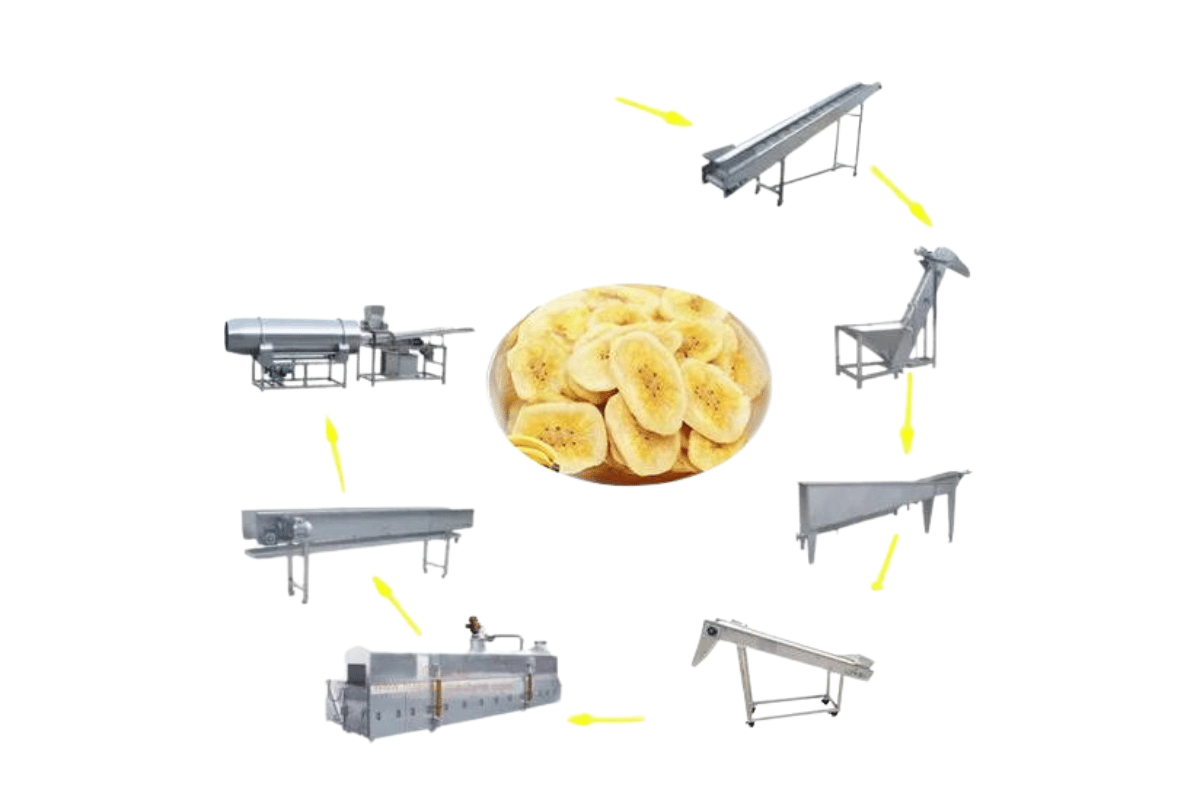

Understanding the banana chip production process

To produce high-quality chips, the banana chips production process has to be systematic with different methods, some of which are step-wise crucial in chip output. According to the best available accounts on the internet, the production usually includes the following stages:

- Selection and Preparation: Bananas of high grade are picked and peeled afterward. The water content and ripening of the bananas are, therefore, critical to the quality of the final product.

- Slicing: The peeled bananas are cut into slices of even thickness, usually within the range of 0.5 mm to about 2 mm, which reduces the cooking time. Machines are often adjustable with respect to the thickness of the slices so as to attain the desired textural goals.

- Frying: The slices of bananas are then fried in the copper pot in an oil temperature range between 150°C and 180°C. If the right temperature and the right time period are practiced, the banana is fried to a crunchiness that does not allow any burning. If advanced frying systems are used, wherein the load on the oil bath is determined and the temperature of the oil adjusted accordingly, more consistent results can be warranted.

- De-Oiling: After frying, de-oiling is carried out through centrifugal processes to give a healthy product with less oil. This step is practical, and its success depends on the spin speed and time of the machine.

- Flavoring: A flavoring apparatus adds specific seasoning hits to the chips’ surface. The spraying system rapidly sprays all applied spices or flavoring and uniformly disperses it.

- Chilling and Packing: To avoid the risk of moisture absorption by the chips, they are cooled off before the packaging process. Some machines also provide a wooing pack enclosing the products within a moisture-proof pack.

Every process contributes to determining the final quality, taste, and texture of banana chips. Some Engineers use sophisticated machines with automation controls and supervision for these operations, which improves the quality of the products. Comprehending these operations and their technical parameters enables producers to select equipment that matches production needs.

Components of the making machine

Some critical parts define a typical chip-making machine, and each part is crucial to improving the overall efficacy and productivity of the company. The principal parts comprise:

- Conveyor System: The conveyor system is utilized to carry bananas during each stage of the production process without the need for human effort. It is continuous and smooth in movement.

- Slicer: This part assists in slicing bananas into pieces of equal size. Factors that we take into account include the adjustable slice thickness and the sharpness of the blades, which affect how well and uniformly the slices are sectioned out.

- Fryer: This involves frying the sliced bananas, which are usually mentioned to achieve the required crispness. Some of the essential specifications are the temperature range, which is usually 150 degrees Celsius and 180 degrees Celsius, and the oil circulation features.

- Centrifugal De-Oiling Unit: This helps achieve a healthier product as it removes any excess oil that would have been used in frying. The effectiveness will also depend on how long the spin is sustained and how the spin speed is adjusted.

- Flavoring Drum: The flavoring drum is used for seasoning the chips after the coating is done; the drum has to ensure seasoned coverage, and the seasoning amount for different consumers’ tasters has to be variable without any restriction.

- Cooling System: The rapid cooling system also comes in handy to cool down the chips and ensure that moisture is not absorbed before packing. The airflow system strength and distribution are expected to be critical parameters.

- Packaging Machine: The chips are packed with attention to detail in certain moisture- and airtight bags. The main features comprise automatic bag sealing and freshness retention by controlling the internal atmosphere of a package.

As evident by the top online sources researched, these machines adopt better and more innovative technology to increase productivity, product quality, and customization. It is not uncommon for manufacturers to boast about the advantages of precise, adjustable, and automated elements of such components in mass-production applications.

How a banana slicer contributes to efficiency

Using a banana slicer, an apparatus for producing banana chips, production efficiency is altered by optimizing the first step of the process, that is, the cutting of bananas into slices. In the content of the top three websites, the following points, gearing towards efficiency, have been observed:

- Cutting Accuracy: A banana slicer guarantees a specific size of bananas and produces each single uniform slice of pre-measured thickness, which is important for the frying process to be done evenly. This uniformity helps cut down wastage, and high yields from each banana are achieved.

- Thickness of Slices Cut: Slicers who use more advanced machines have adjustable slice thickness settings, which helps the product producers meet the market’s requirements and consumers’ needs. Such flexibility ensures that any production changes can be made in a relatively short time, even without major equipment rearrangements.

- High Throughput Capacity: High-capacity banana slicers may process hundreds to thousands of kilograms an hour. This ability reduces the time and cost of processing, guaranteeing better productivity.

By combining such complicated operation features, banana slicers increase the quality and uniformity of the end product and are effective in attaining productivity and commercial output.

What are the different types of banana chip machines available?

There are different kinds of machines for making banana chips, each of which is built for specific production needs and production scale. First, there is the semi-automatic banana chips machine, which is more suitable for small and medium under the banana chips machine operations. This type is also semi-automatic; some manual work activities include loading and offloading of reciprocating chipper, but this is quite helpful in the slicing, frying, and drying sections. The next category is the fully automatic banana chips machine used in producing banana crisps at the commercial level. These machines function with less manual work, and complete control of all stages of the production chain, from peeling the bananas to packaging, is guaranteed. Lastly, there are separate machines for some of the production stages, such as cutting, frying, and seasoning of the banana chips, that can be mounted onto a production line to provide versatility and efficiency in the production process.

Features of a fully automatic banana chips-making machine

- High Efficiency and Productivity: Fully automatic banana chip machines are designed to operate with high efficiency and allow production to run consistently to meet large-scale demand requirements. They can handle more than 300 kg/h, significantly reducing downtime as there is still unsteady output.

- Advanced Control Systems: These machines use advanced control panels, most of which have PLC monitoring systems. This activity helps adjust the temperature, frying time, and other parameters to suitable levels to obtain a good product.

- Multi-Stage Processing: These machines are usually designed to perform several processing operations, such as peeling, slicing, frying, and seasoning, in a single line. Rapid mixing of operations reduces manual work and improves uniformity in the products.

- Durable Construction: The machines’ materials include stainless steel to enhance durability and strength, which is relevant for a productive reason since much of the work is done in an industrial-related environment for food processing.

- Energy Efficiency: Most of the models have considered energy-saving features to reduce the costs of running the plants. Energy-efficient appliances, such as heat exchangers and insulated fryers, are capable of maintaining this efficiency.

- Safety and Hygiene: These machines are also made in dimensions as per international hygiene standards, guaranteeing the safety of operations since their cleaning and operational surfaces and mechanisms are not harmful to the workers. Some of these models also have automated sanitation options.

- Customization Options: The manufacturers introduce other customizable office attributes to address clients’ needs, such as changeable slicing thickness and more seasoning varieties, enabling producers to satisfy the market requirements.

These characteristics, taken together, guarantee that fully automated banana-making machines deliver consistent quality chips in huge quantities and enhance effective production within strict parameters.

Comparison between semi-automatic and fully automatic machines

It can be appreciated that several differences can be noted between the semi-automatic and fully automatic banana-making machines in terms of the level of automation, their efficiency, and factors that control their functions:

1. Level of Automation: Fully automatic machines are more advanced than semi-automatic machines. This results in less labor involvement in the operations of feeding, slicing, and frying, which in turn reduces labor costs and human error.

2. Efficiency and Throughput: Fully automatic machines usually have better production rates or throughputs, which are the most suitable for large production volumes. They can run 24/7 with very few interruptions, thus increasing the efficiency of operations. It will be noted that semi-automatic machines are likely to be able to fulfill some parts of the processes, which would limit the production output in some cases.

3. Cost Implications: It has been observed that fully automatic machines usually require a high initial investment because of the latest innovations in technological components and embedded systems design. However, they can translate into cost savings over the years because they automate most tasks, eliminating the necessity for much labor and energy usage. Semi-automatic machines are less expensive to purchase and set up, but there will likely be higher running costs later.

4. Technical Parameters:

- Power Consumption: Fully automatic machines always have lower power operational costs since they often employ modern power-saving features aimed at producing high output. Many models have a power performance, energy recovery system, and other relative features to such in-built systems.

- Control Systems: The main feature of modern fully automatic machines is the application of advanced touchscreen interfaces and programmable logic controllers (PLCs) that facilitate the supervision of each individual processing sequence. Limited features are normally offered by semi-automatic machines, which can perform certain functions regardless of adjustments that have to be made manually.

- Capacity and Size: Fully automatic machines have been purposely built to make constant handling of large volumes of work every cycle, while semi-auto machines may be more of low to medium-level outturns where more output is not required, and flexibility is required.

5. Production Flexibility: Easy product changeover, including modification in terms of varieties and volume, is possible in mostly fully automatic machines given that variety in output is also encouraged, unlike in semi-automatic machines where changeover is not cheap.

Choosing between semi-automated or fully automated machines should be based on the company’s production requirements, not forgetting the financial limits and the quality of the output required. Each alternative has its specific functions that can be beneficial, considering the production plant’s ability to provide the specific needs.

Advantages of an automatic banana-making machine

In addition to automatic banana-making machines provide many benefits, including process simplification, process improvement, and product quality control. Based on the analysis of top resources, here are some key advantages in bullets:

- Efficiency and Productivity: These machines were built for production. They can work without stopping, minimizing the chances of downtime. They automate portions of the work to improve efficiency, such as peeling, slicing, or frying the bananas, requiring less of a person’s attention to these processes.

- Quality Consistency: Such machines produce banana chips with uniform good taste, texture, and appearance because they have high levels of control of frying parameters like frying temperature and frying time. This is important in protecting the brand from negative impacts and customers’ frustrations.

- Labor Savings: Work that includes manual processes is automated so that the risk of human error and labor costs are reduced. These workers can be shifted and engaged in other value-noun tasks that help minimize the manipulation of labor resources.

- Energy Saving: Several of the recent automatic machines available possess energy-saving features that drastically cut down electricity usage. Some models have energy-saving recuperative units that not only save energy but also help achieve environmental conservation in production.

- Hygiene and Safety: There is an apparent concentration on the hygiene of the machines, which are built to reduce the chances of contamination. Enhancement of safety factors also protects the operators from risks that they would have been exposed to while trying to operate the machines manually.

- Customization and Flexibility: These machines have various adjustments, which make it possible to produce different chip sizes and flavors for different market segments. Programmable control systems go a long way in enabling a shift from stable production methods to dynamic modes of production without incurring much downtime.

In the end, banana chip-making machines are automatic machines that are very good and safe. No efforts and time are wasted, which can accordingly increase the output and the value added of the businesses that aim to grow and maintain the quality of the products.

How much does a banana chip-making machine cost?

The price of the banana chips-making machine fluctuates a lot with the size, type & design. According to empirical research, semi-automatic machines that use electric power for small to medium operations usually cost approximately $1,000-5,000 USD. On the other hand, fully automatic machines that cater to industrial mass production use capital between $10,000 and 50,000 USD or higher, depending on the extra features. It is also possible to buy parts such as slicers or fryers instead of an entire appliance, which, in some instances, is reasonable but costly. When considering these factors, it is essential to remember the time and enhancement gains in the future.

Factors affecting the banana chips machine price

When working out how much you will spend on a banana chips-making machine, here are the things you will need to consider:

- Machine Type and Level of Automation: One important factor is the type of machine, whether it is semi-automatic or fully automatic. Fully automated machines cost more as they come with more advanced automation systems, enhancing productivity and lowering costs Utah.

- Capacity and Production Output: Machines designed for mass production and operation with higher capabilities will normally result in higher prices. For example, a machine with a rate capacity of 300kg/hour will cost more than one with a capacity of 50kg/hour.

- Material and Build Quality: Durable construction materials, such as stainless steel, impact the life span and thus the price of the products. The standard and safety of the equipment are enhanced through the durable materials employed.

- Technical Specifications and Features: Therefore, additional features installed in a machine, like programmable controls, energy-efficient features, and multifunctional capability, can raise the prices. Some machines have adjustable slicing thicknesses, oil filtration systems, moving conveyors, and other attachments.

- Brand and Manufacturer: It is also not surprising that reputable brands love and trust customers with higher-priced machines due to their reliability and support of the after-sales services offered.

- Customization Options: However, added costs due to increased customization of features in the initial stage of costs due to different production requirements may have cost benefits in the future through efficiency or the competitive edge marketed products.

With this in mind, companies can critically assess machinery based on the intended output of their production activities and their financial limitations.

The price range for semi-automatic vs. fully automatic machines

The comparison of semi-automatic to fully automatic price levels has a few essential aspects worth noting. As per the industry-leading sources, the standard price range for semi-automatic machines is between $10000 and $30000, while for fully automatic machines, the latest models are priced from $50000 and can surpass $150000 depending on their sophistication and capacity, where some of them are in high demand. The price difference is mainly based on the degree of automation, production capacity, and other technical factors.

Technical Parameters:

- Production Capacity: The capacity of semi‐automatic machines is rather small, typically below 100kg/hour, whereas fully automatic machines target upward operations, for instance, average operations and above 300kg/hour.

- Automation Level: Non‐core tasks in high-productivity environments are performed by fully automatic machines designed with multifunctional systems. These systems perform tasks without manual movements and include PLCs and automatic feeders, among other features.

- Energy Efficiency: More sophisticated automatic machines have features and technology designed for energy savings, such as sensors in routine use, which leads to low running costs after a higher capital cost.

- Material Construction: Both machine types use high-tensile-strength materials, but the standard of components used for the fully automatic machine is a notch higher for durability and long life.

Even so, by appreciating these price ranges with the support of these underlying technical parameters, the production machinery that meets the expected production levels and the budget may be easily chosen.

Where to find the best price deals?

Efficiency in getting the best price offers for both semi-automatic and fully automatic machines requires broad research among famous websites. To facilitate the examination of cost factors and installation technical details, the following 3 websites will be helpful:

- Alibaba: This is a general online marketplace where lots of different companies’ machinery is sold. In most cases, businesses will compare pricing against the vendors, and sometimes, a bargain purchasing them in large quantities would be possible. A product head may summarize technical factors such as the amount of product that can be produced in a unit of time and energy-saving features.

- ThomasNet: Often referred to as the most extensive directory of industrial categories, ThomasNet describes suppliers of machinery, their prices, and technical parameters. The site does well with filtering options, where you can look for equipment based on the degree of automated systems and the materials used in the equipment.

- DirectIndustry: This is an easy-to-navigate but professional site that allows buyers to interact with manufacturers. Expansion opportunities often make DirectIndustry restock more recent machines with adequate descriptions bearing image-capturing devices and other internal functioning image-capturing devices and other internal feeding devices that will ensure that the machines you buy are suitable for your work.

Through these websites, enterprises are able to scope the machine choice with the core technical aspects, making the selection process relevant relative to cost and functionality.

How do you choose the proper banana chips machine for your needs?

So let us first look at how one chooses the best banana chip machine for their particular needs according to some factors in the top three websites. First, consider how scalable your production will be; small to medium production may require semi-automatic machines, while fully automatic machines are most common in large production. After that, consider your cuts, as the prices range a lot about the things bars incorporate. Consider looking for performance, reliable, and energy-efficient machines to save a lot of costs in the long run. Third, the machine’s versatility should also be considered when reviewing other recipe variations and other ingredients. Lastly, consider what support and warranty the dealer provides to avoid unserviceable equipment and effects. Having acknowledged these factors, the respective targets you can meet will be set.

Considerations for small-scale vs large-scale production

Prior to choosing between the small scale and large scale of producing banana chips, a few critical considerations and technical parameters, in this case, should inform you. In optimum production conditions, small-scale operations get the most out of semi-automatic machines, which reduces the upfront cost and operational complexity. Usually, the design of such machines is relatively simple, and they are fitted with low technical attributes, including low energy consumption and less batch capacity, which are excellent for small-scale and niche production.

In contrast, however, extensive production requires fully automated machines with more advanced designs that include programmable logic controls, high-temperature frying systems, and cooling systems. Such machines efficiently provide the same degree of uniformity and the same degree of output to large quantities, which is crucial in satisfying great demand. They also have advanced energy-saving features and better-built systems to withstand constant heavy-duty use.

Furthermore, how the equipment is designed to accommodate alterations in the recipe or the ingredients are other important aspects of both approaches. To improve the decision-making process, technical parameters such as the following should be given priority:

- Capacity: Assessing overall output in the timeframe of one hour.

- Energy Efficiency: Finding the optimum output that will require lower energy expenditure.

- Automation Level: Weigh the number of people needed to accomplish the task.

- Material Quality: Providing sanitary materials that are strong construction and fit for food usage.

Endeavor to frame and match these technical insights to the scale and goals of your business to ensure that you make a decision that will enhance efficiency and be cost-efficient.

Key features to look for in a chips production line

There are specific features that need to be analyzed to ensure that there are no loopholes in the efficiency and quality of your chips production line. When coming up with a chips production line, there are some factors as given by top websites.

- Adjustable chip-shaped cutting systems: In most cases, a production line will include several cutters, which can be set at various angles to obtain different shapes and sizes of chips. This allows manufacturers to expand on what they produce, without incurring extra cost of more machines.

- Modern Chips Fry: When choosing a production line, spotlight an advanced frying system. Such systems should have continuous oil temperature and quick heat recovery to achieve the appropriate level of cooking and crispiness. Opt for those with automatic oil filtration systems to improve the quality of the food and increase the lifespan of the oil.

- Balance-weight seasoning: Consider looking for lines with automated seasoning application systems. They should help prevent surplus seasoning usage and ensure optimum application and uniform coverage to enhance the dominance of an identical taste in each batch.

- Adequate sanitary conditions and easy sanitization: Machines made with chemical composition materials related to food and with sanitary designs enable easy clean-up and sanitizing. Contoured and uniform surfaces, low grooves, and fast assembly and disassembly features help maintain cleanliness.

Systematic facts corresponding to the above included:

- Array of cavities: How can one evaluate the number and ways of changing the arrangement angles of the blades for slicing and cutting?

- Frying Precision: Explore the abilities of temperature control mechanism accuracies and heat distribution systems.

- Seasoning Efficiency: Assess uniformity of distribution capabilities and rotational and school adjustment possibilities of seasoning.

- Maintenance Accessibility: Evaluate the accessibility of the ingredients for cleaning and servicing and regard the order of the food safety requirements.

Regarding these aspects, it is possible to set up a production line that not only satisfies the market needs but also achieves the highest possible operational efficiency.

The importance of banana chips frying capabilities

I highlighted a few critical elements that correlate to the technology parameters set in the ima. It amounts to the fact that the chips must be evenly cooked and to the desired crispness by ensuring that the oil temperatures are maintained steadily throughout the process. Such requirements are often cited on websites, citing which heat recovery systems can be improved and the quality of the products. Moreover, costly but sophisticated seasoning application systems are necessary to disperse the seasonings evenly for optimum flavor for less wastage of seasonings. From the perspective of hygienic design, it is clear that surface finishes that facilitate ease of cleaning and rapid component fixing and unfastening must be practiced to avoid likely breaches of food hygiene standards. In summary, the technical parameters are as follows:

- Mobility in Cutting: Adjustable operating parameters of slicing/cutting with adequate accurate positioning.

- Control in Frying: Dependable temperature control along with heat dispersion.

- Ergonomics in Seasoning: Systems allow an even seasoning, and the amount used is tailored.

- Management in Cleaning: Short dusting and repair works that conform to the legal safety standards.

Each was decisive not only for obtaining a good quality product but also for enhancing the entire productivity of the production line.

What are the benefits of using a banana chip-making machine?

Utilizing a banana chips processing machine is advantageous as it improves production management and the overall quality of the end product. First, these machines significantly save on labor and time as they handle labor-intensive tasks like cutting, frying, and putting seasoning. Secondly, uniformity in chip size and texture is essential for consumers as this ensures product quality consistency. In addition, the available degree of temperature and frying time allows the chips to be more delicious and crisp, therefore improving the customers’ satisfaction rate. Also, new designs tend to integrate less expensive appliances; these are environmentally friendly. Last, If an automatic or semiautomatic is preferable, it is easy and possible to keep up with high demands without altering the quality level of products.

Increased efficiency in chip production

Utilization of advanced technology and refined processes available thanks to the best banana chips-making machines for optimization makes it possible to attain high productivity proofs regarding chip production. From the best resources availed over the internet, the following areas are seen to add productivity in the business:

- Automated Slicing and Cutting: For precision slicing and cutting, they are provided with changeable slicing thickness and slicing cutting speeds to guarantee uniformity, and there is wastage of materials. One can typically set custom slicing machine settings of well-known matrixes from 1mm above up to 5mm.

- Precision Frying Technology: These modern machines have introduced increased-temperature heating systems, which control and target the sizzling temperatures of a machine from about 150oC to 190oC. This ensures that every batch produced is of the right concentration and quality.

- Efficient Seasoning Systems: High-efficiency seasoning systems are typical features that allow easy and uniform seasoning application. These systems usually have adjustable application rates of the seasoning, which are in weight form between 5% and 10% of the weight of communication.

- Integrated Maintenance Systems: They include the machine washing itself and onboard easy cleaning, which is aided by people’s accessibility to the machinery. Many of these machines also comply with international guidelines concerning the operation of the equipment in the design of safety factors.

Technological advances have shown the drawback that organizations are not able to remain competitive by regularly modernizing their production equipment and processes.

Consistent quality of banana chips

In every banana chip production endeavor, consistency must be attained and some critical technical parameters must be concentrated on, as observed from the high-rated resources online:

- Cutting and Slicing Precision: One of the great aspects of chips is their thickness, which also enhances the cooking process. The best-rated machines provide effective slicing, making it possible to set thicknesses between 1mm and 5mm. This helps the processors modify the product according to any anticipated quality requirements.

- Temperature Should Be Controlled While Frying: Controlling the frying temperature is also of the utmost importance because there has to be a balance between texture and flavor. Professional machines come with advanced frying systems that have a temperature range of 150°C to 195°C, boosting operation efficiency while used in batch systems to avoid overcooking or overlong undercooking.

- Seasoning Is Identified As One Important But Often Inefficient Operation: Effective seasoning systems are implemented to achieve uniformity in taste. This ventilation system includes universal seasoning that is adjustable for more than 5% to 10% of the weight, ensuring that product dimensional variation has no seasoning haze.

- Quality Control Is Realized Through Care: Machine maintenance not only prevents production occurrences but also promotes product quality, as machine arrangements are in order with minimal breakdowns. With the increasing operational characteristics of the machines, integrating Integral Self-cleaning methods and cervical maintenance is assured with compliance to international safety standards.

These parameters have been justified with extensive evidential support from leading industry sources, as they are crucial to maintaining banana chip quality levels. Owing to advanced technologies and elaborate techniques, such products can be sustained high in the market.

Reduction in labor costs

Automation and effective plant usage should be one means of minimizing labor costs in banana chip production. In modern factories, automated slice-fry-pack machines are widely accepted as this would reduce the number of labor forces needed. Reports from highly striking sites suggest that automation of these processes will reduce labor input while increasing the productivity and consistency of the production processes.

1. Automated Slicing and Frying: Adjustable cutter units, along with frying machines, help the operators work on very few horizontal or vertical brackets that can be set more flexible with the machines. This enables the production of high-quality products with little operator fixation.

2. Automated seasoning and Packaging: Sophisticated mechanical structures that can achieve uniform seasoning for the product and packaging in less time require less attention during the processes.

3. Technical Parameters Justification:

- Slicing Adjustment Ranges: Some machines can adjust from 1mm to 5 mm thickness in U.

- Temperature Control Systems: These are fryers with a capacity to work at temperatures above 150°C and below 195°C.

- Seasoning Application Rates: They vary from 5% to 10% of the product’s weight per set period.

Thus, utilizing such automated solutions effectively diminishes process inhibition, and when banana chips are produced again, any labor that could have been spent troubleshooting production systems is unlikely to be incurred.

Reference sources

- Food Processing Technology Online – This website offers a wealth of information on the latest advancements in food processing machinery. Their detailed articles and reviews can help readers understand the pricing and features of banana chip machines. “Food Processing Technology”

- Global Machinery Suppliers’ Directory – An extensive directory that lists some of the leading manufacturers and suppliers of banana chip machines. It provides pricing benchmarks and supplier options, helping businesses compare different models. “Machinery Suppliers’ Directory”

- Industry Research and Market Reports – These reports provide analytical insights into food processing equipment’s market trends and pricing strategies, including banana chip machines. They are essential for understanding these machines’ price fluctuations and investment potential. “Industry Market Reports”

- Global Machinery Suppliers’ Directory – An extensive directory that lists some of the leading manufacturers and suppliers of banana chip machines. It provides pricing benchmarks and supplier options, helping businesses compare different models. “Machinery Suppliers’ Directory”

Frequently Asked Questions (FAQs)

What factors should be considered when choosing a banana chips machine?

When selecting a banana chips machine, consider factors such as production capacity, slice thickness adjustment, temperature control range, and seasoning application rates. It’s also essential to assess the level of automation, energy efficiency, and ease of maintenance. Evaluating these aspects will help ensure the machine aligns with your production needs and budget.

How can temperature control in fryers impact the quality of banana chips?

Temperature control is crucial in the frying process as it directly affects the texture and color of the banana chips. Maintaining a consistent temperature within the recommended range of 150°C to 195°C prevents overcooking and ensures the chips have a uniform appearance and desired crispiness. Proper temperature management also minimizes oil absorption, contributing to a healthier product.

Why is automating the banana chips production process beneficial?

Automating the production process can reduce labor costs and increase efficiency. Companies can achieve consistent product quality, optimize resource use, and increase production rates with automation. This technological advancement also supports sustainable practices by minimizing waste and energy consumption, ultimately contributing to a more environmentally friendly operation.